Controllable preparation method for single-walled carbon nanotube without sulfur impurities by growth promoter

A technology of single-walled carbon nanotubes and growth promoters, applied in the directions of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of reduced catalyst stability, difficult removal, high material requirements, etc., and is conducive to treatment. and recycling, beneficial to treatment and recycling, and the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

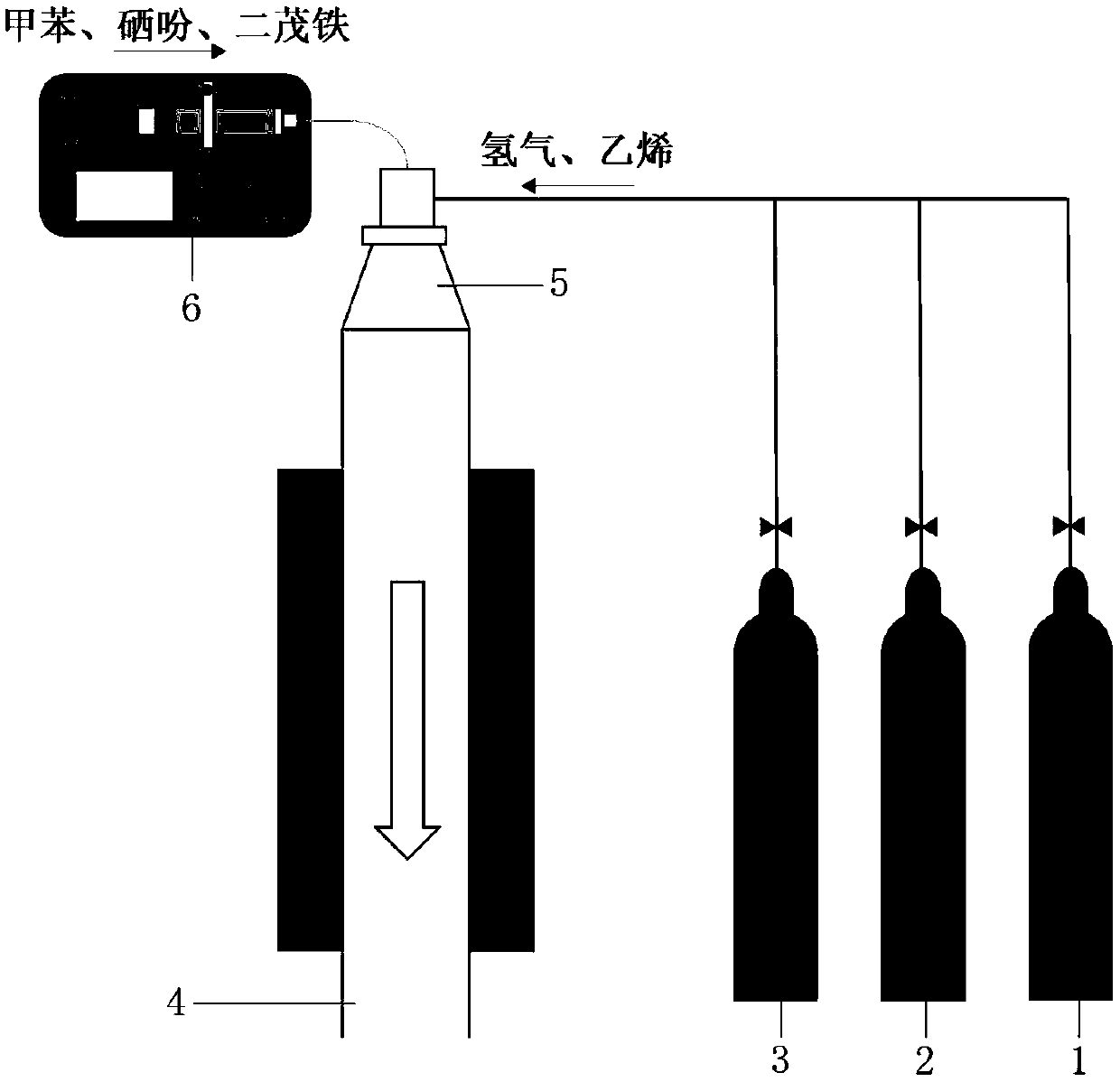

[0041] In this example, under the protection of 200 ml / min of argon gas, the temperature of the chemical vapor deposition furnace was first raised to 1100 ° C, and then 5000 ml / min of hydrogen and 5 ml / min of ethylene were introduced, containing the catalyst precursor two The toluene solution of ferrocene and growth promoter precursor selenophene is injected into the ultrasonic nozzle at a speed of 0.2 ml / hour, and the grown carbon nanotubes flow to the end of the tube with the airflow, and finally form carbon nanotubes on the porous filter membrane placed at the end. tube film.

[0042] Raman spectroscopy, scanning electron microscopy, transmission electron microscopy, and thermogravimetric analysis were performed on the single-walled carbon nanotube thin film sample (denoted as 1#) prepared above.

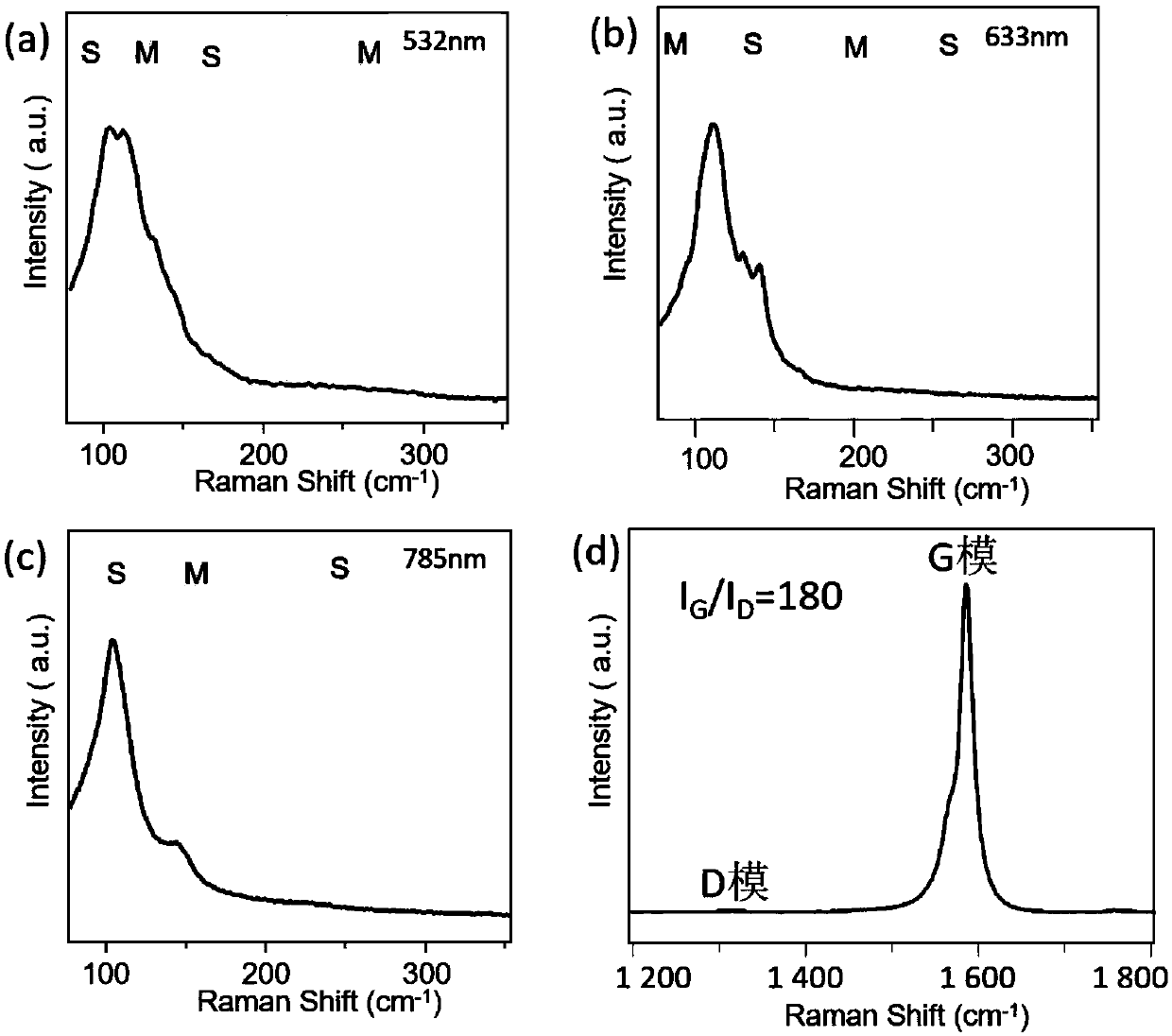

[0043] Such as figure 2 As shown in (a, b, c), the peaks of the Raman spectral breathing mode of SWNT films are concentrated, indicating that the diameter distribution of SWNTs...

Embodiment 2

[0045] In this example, under the protection of 200 ml / min of argon, the temperature of the chemical vapor deposition furnace was first raised to 900°C, and then 2000 ml / min of hydrogen and 15 ml / min of ethylene were introduced, containing the catalyst precursor two The toluene solution of ferrocene and growth promoter precursor selenophene is injected into the ultrasonic nozzle at a speed of 0.5 ml / hour, and the grown carbon nanotubes flow to the end of the tube with the airflow, and finally form carbon nanotubes on the porous filter membrane placed at the end. tube film.

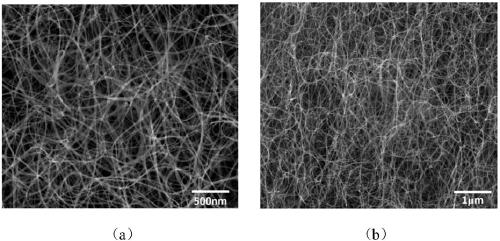

[0046] The sharp peak shape of the breathing mode of the Raman spectrum of the single-walled carbon nanotube film indicates that the diameter distribution of the single-walled carbon nanotube is narrow, I G / I D is 170, indicating that the crystallinity of single-walled carbon nanotubes in the film is very high; scanning electron microscope observation shows that the surface of carbon nanotubes is very cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com