Ultrasonic spray nozzle integrated with spray width control device

A control device, ultrasonic technology, applied in the direction of spraying device, spraying device, liquid spraying device, etc., can solve the problem that the directionality of micronized particles cannot be controlled, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

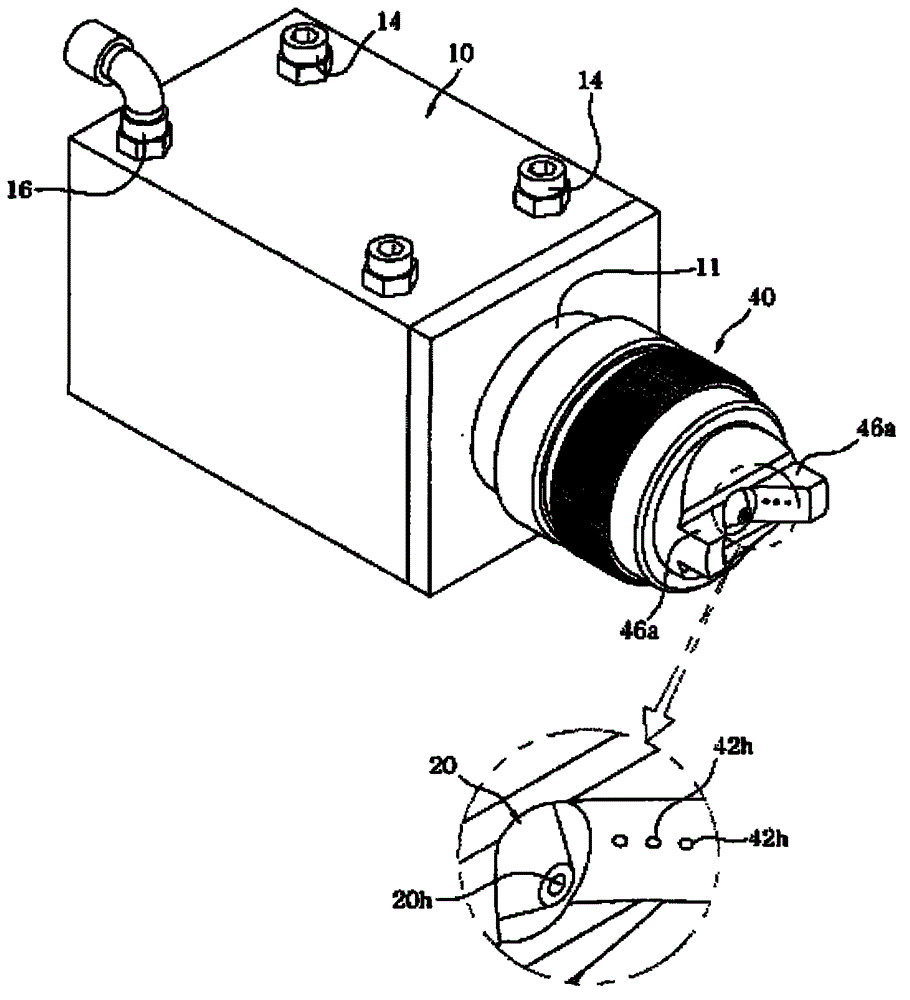

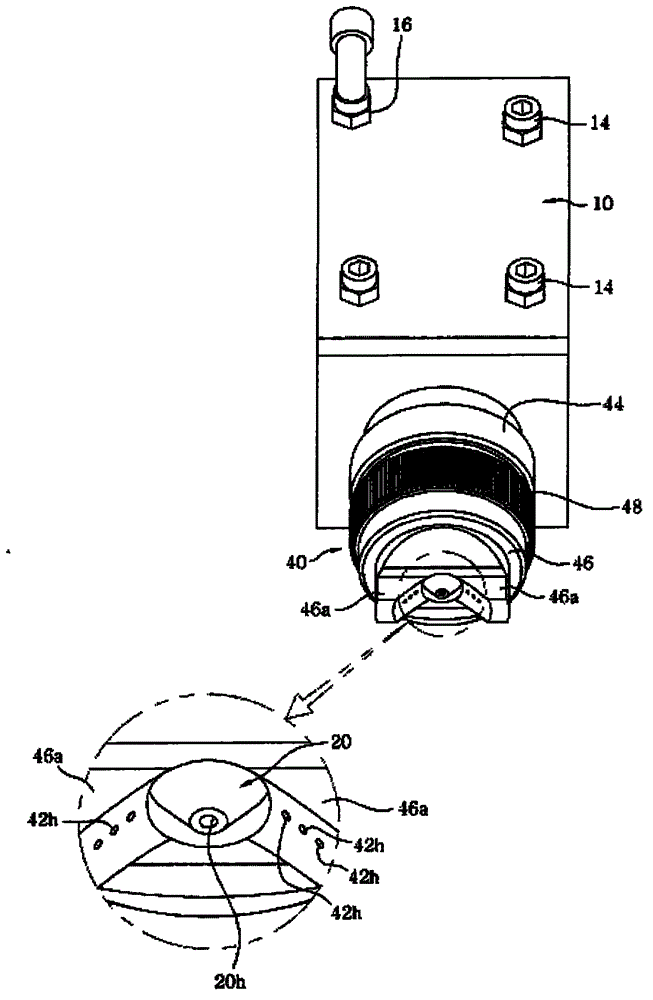

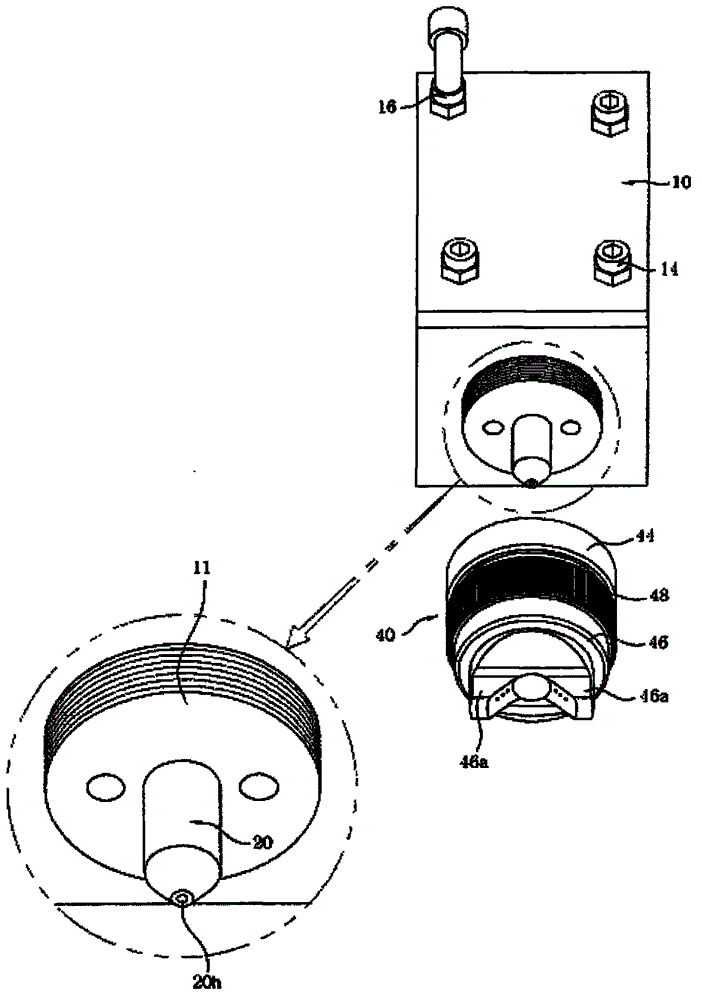

[0031] The present invention is an ultrasonic nozzle integrated with a spray range control device, which is characterized in that it comprises: a nozzle body 10 with an inflow chamber 12 inside; a nozzle sleeve 20 built into the nozzle body 10 and facing to the nozzle sleeve The inside of the cylinder 20 is supplied with the spray liquid 6; the ultrasonic vibrator 30 is built into the above-mentioned inflow chamber 12 of the above-mentioned nozzle body part 10, and is used to cause the above-mentioned nozzle sleeve 20 to generate ultrasonic vibrations so as to pass through the inside of the above-mentioned nozzle sleeve 20. The spray liquid 6 is atomized; the compressed air guide part 40 is arranged on the front of the above-mentioned nozzle body part 10, and the front end part of the above-mentioned nozzle sleeve 20 is exposed to the front end part of the above-mentioned compressed air guide part 40, and is inside the compressed air guide part 40 There are at least two compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com