Hydrogen peroxide sterilization device and method

A technology of hydrogen peroxide and sterilization device, applied in the direction of chemistry, vaporized substances, etc., can solve the problems of limited injection rate, energy waste, condensation of vaporized hydrogen peroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background technology, the existing hydrogen peroxide gas sterilizer consumes a lot of energy, and condensation phenomenon is prone to occur during the transmission of hydrogen peroxide.

[0034] Next, the specific technical solution of the present invention will be introduced in detail.

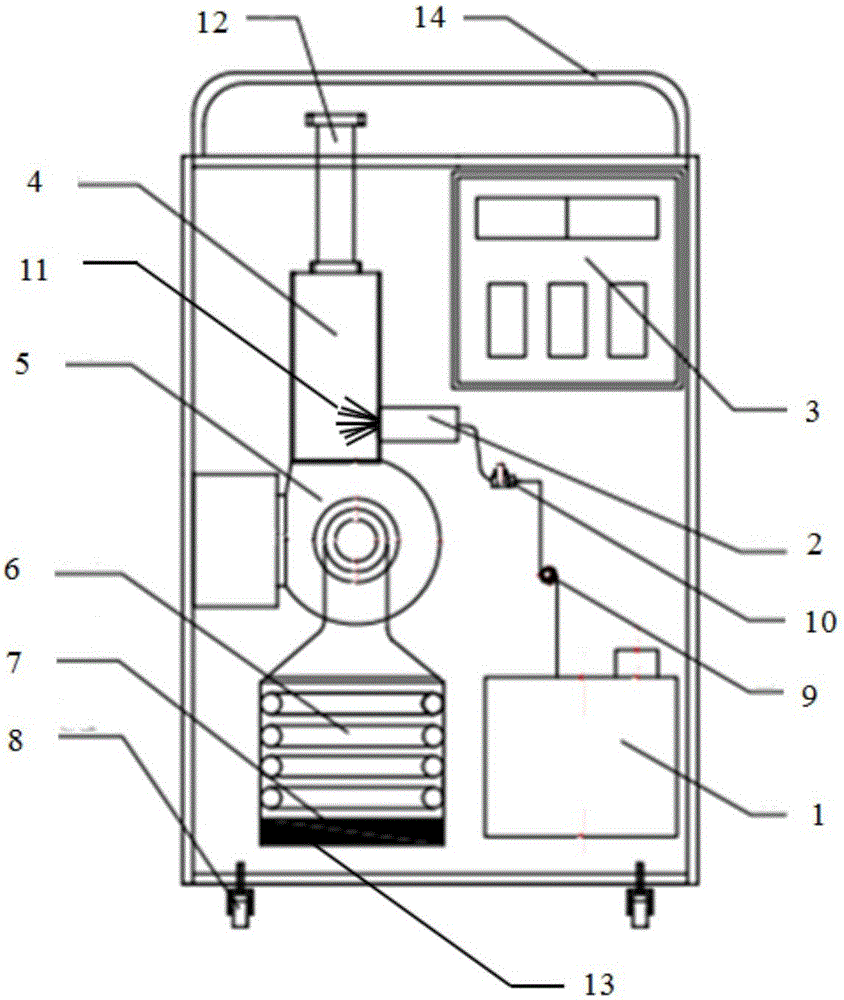

[0035] See figure 1 , the hydrogen peroxide sterilizing device of the present invention is placed in a sterilization chamber, and the hydrogen peroxide sterilizing device includes a hydrogen peroxide liquid storage tank 1, an ultrasonic atomizer 2, an electrical control unit 3, a vaporization chamber 4, and a blower 5 , heater 6, filtering device 7 and moving device 8. The hydrogen peroxide storage tank 1 stores a hydrogen peroxide solution with a concentration of 35%. The hydrogen peroxide storage tank 1 is connected to the vaporization chamber 4 through a pipeline, and the ultrasonic atomizer 2 is installed on the middle and lower side walls of the vaporization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com