Patents

Literature

73 results about "Hydrogen Peroxide Sterilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sterilization process that uses radicals that form from hydrogen peroxide to kill microorganisms.

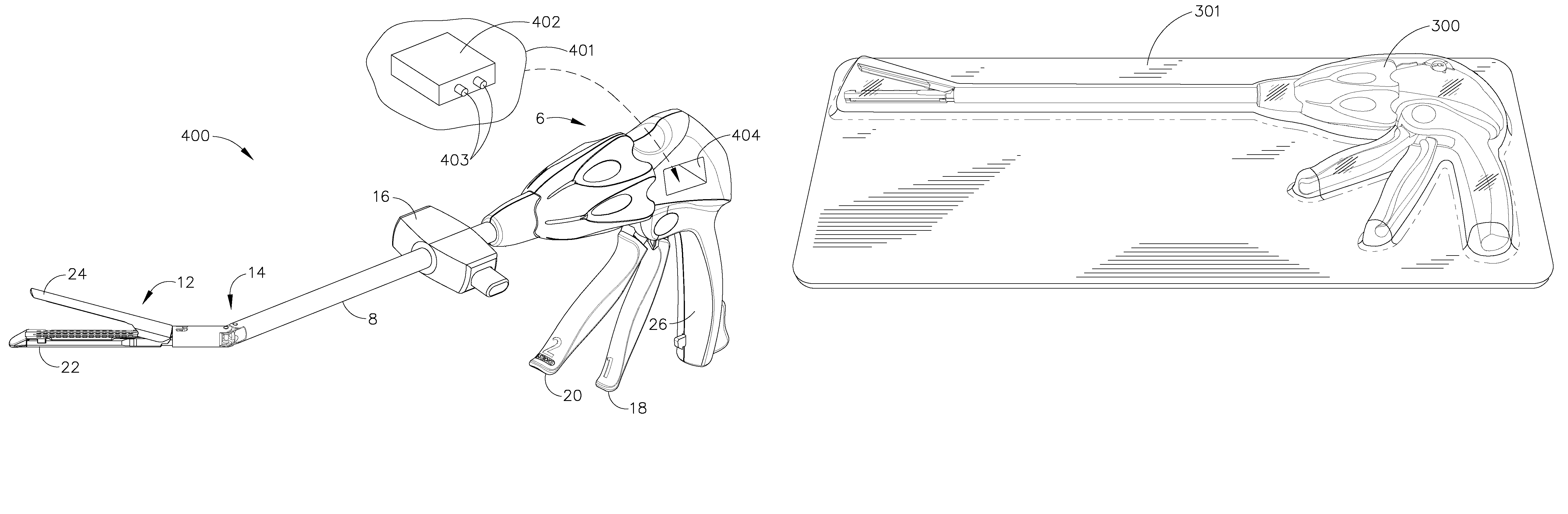

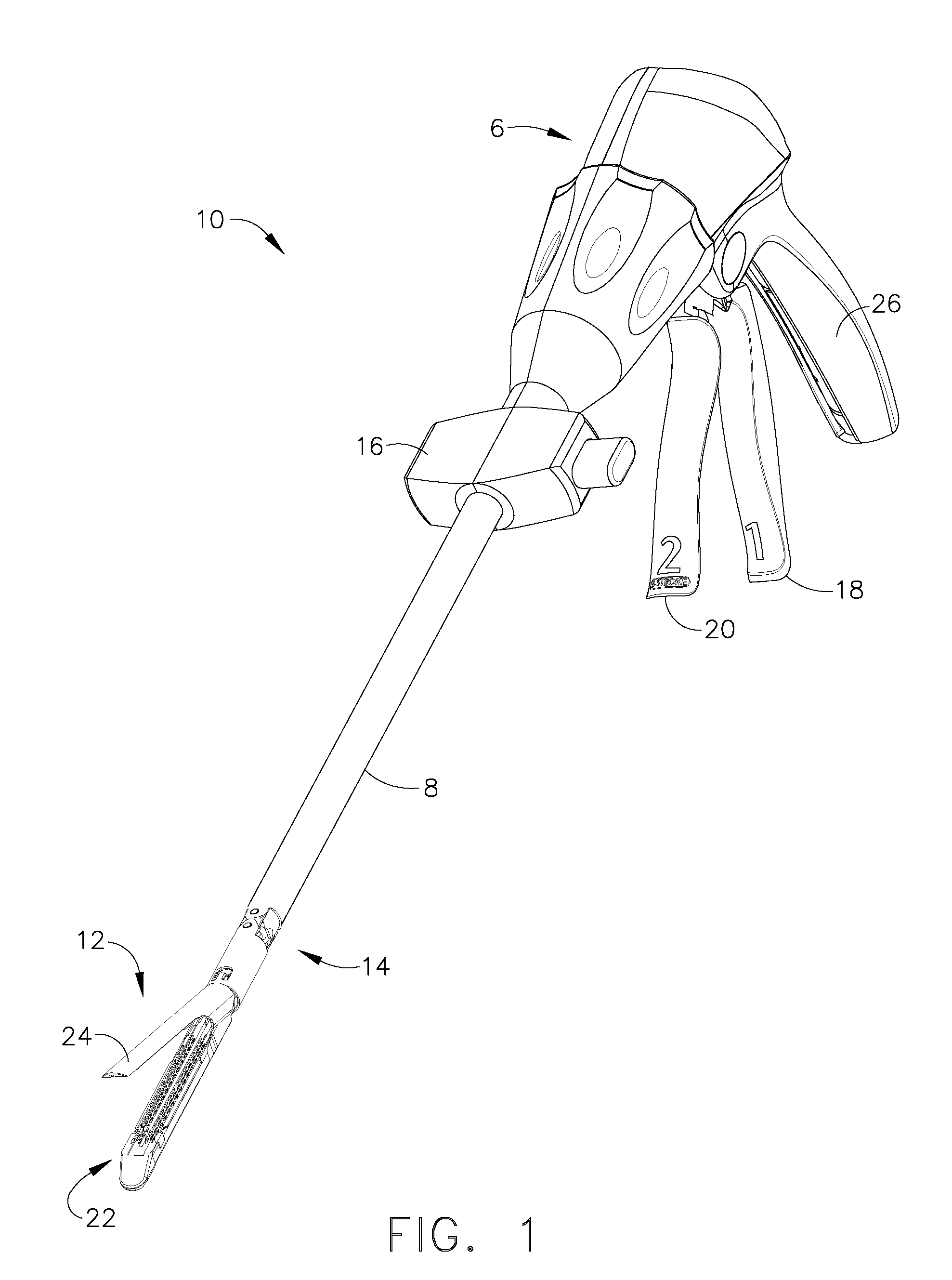

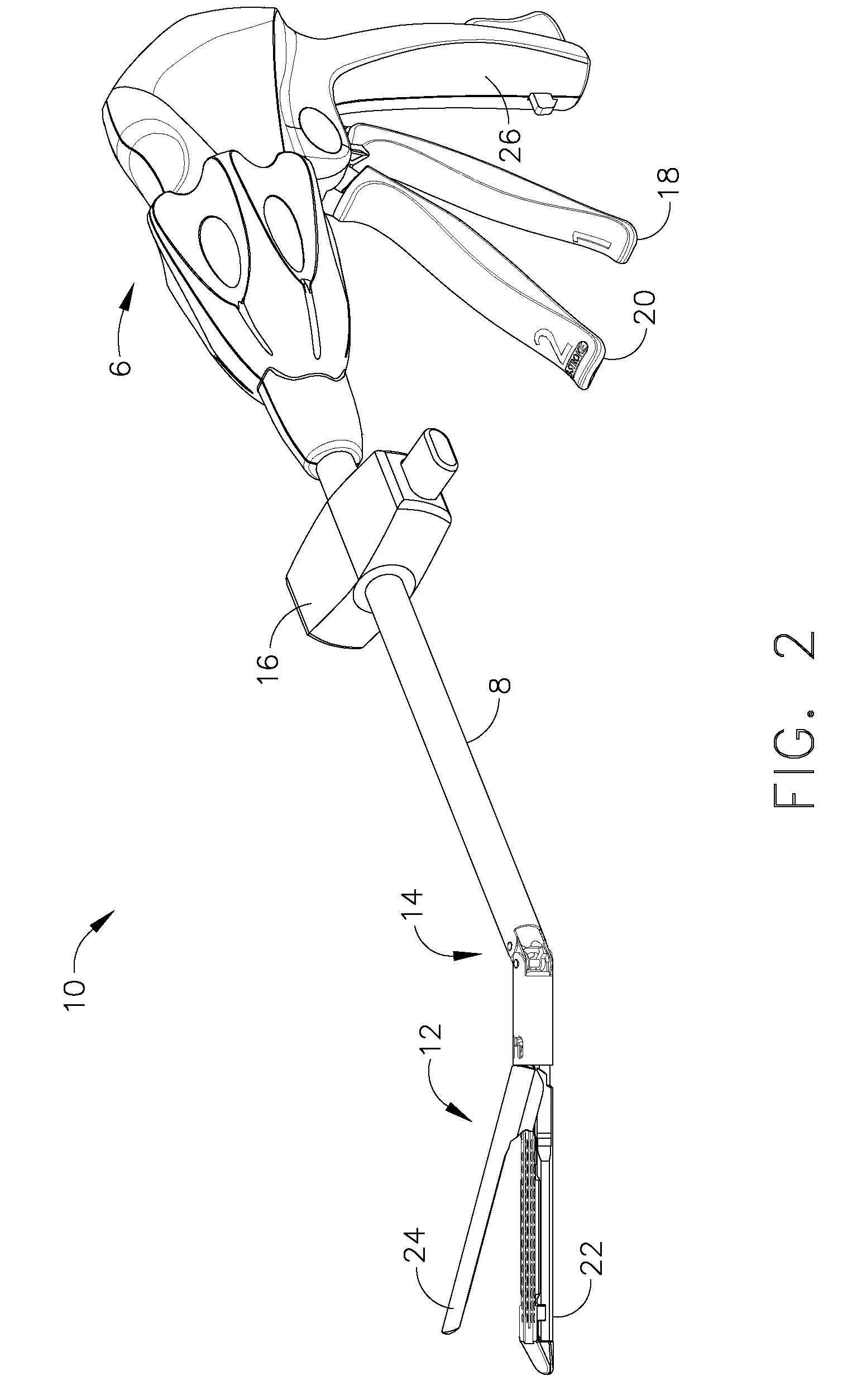

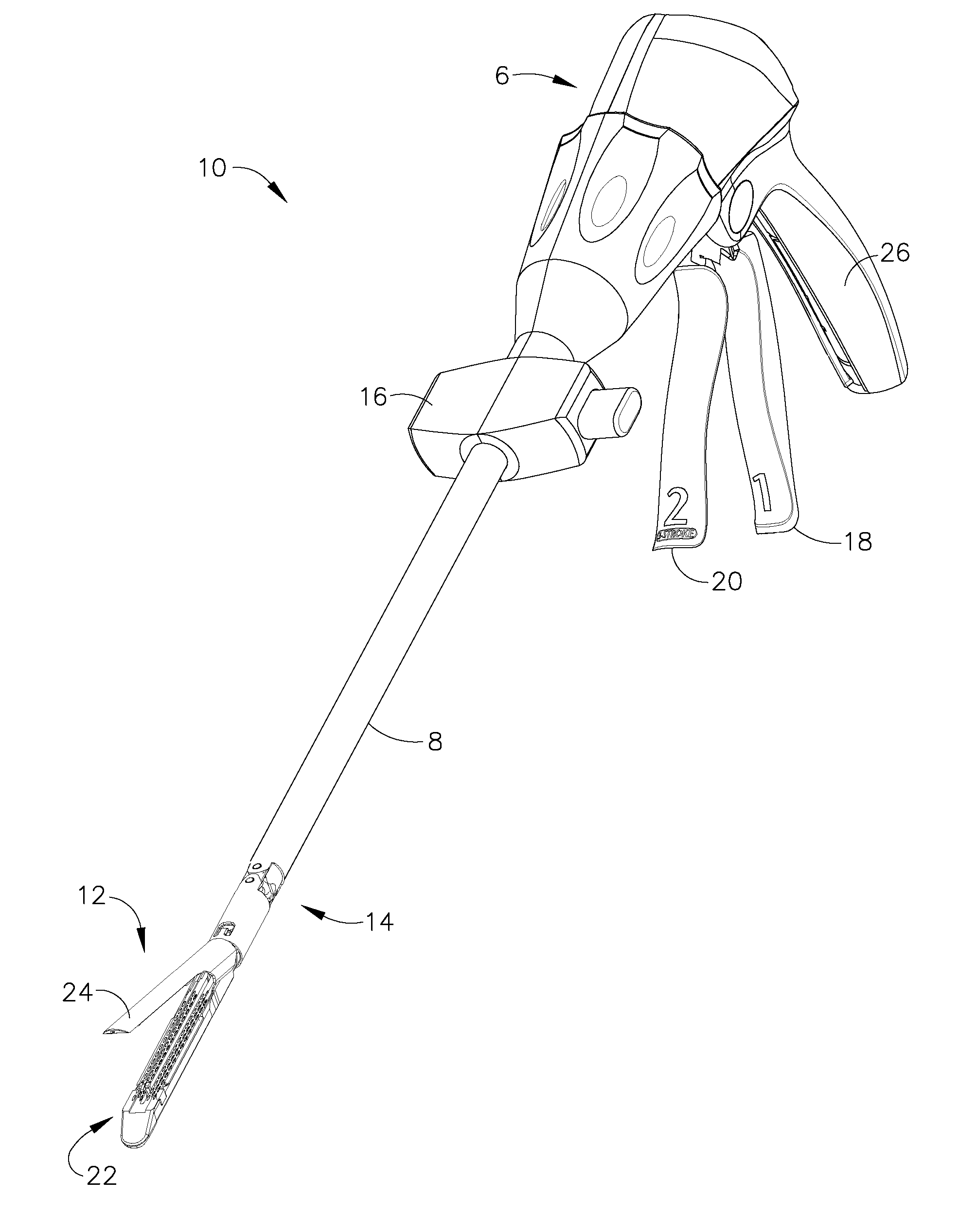

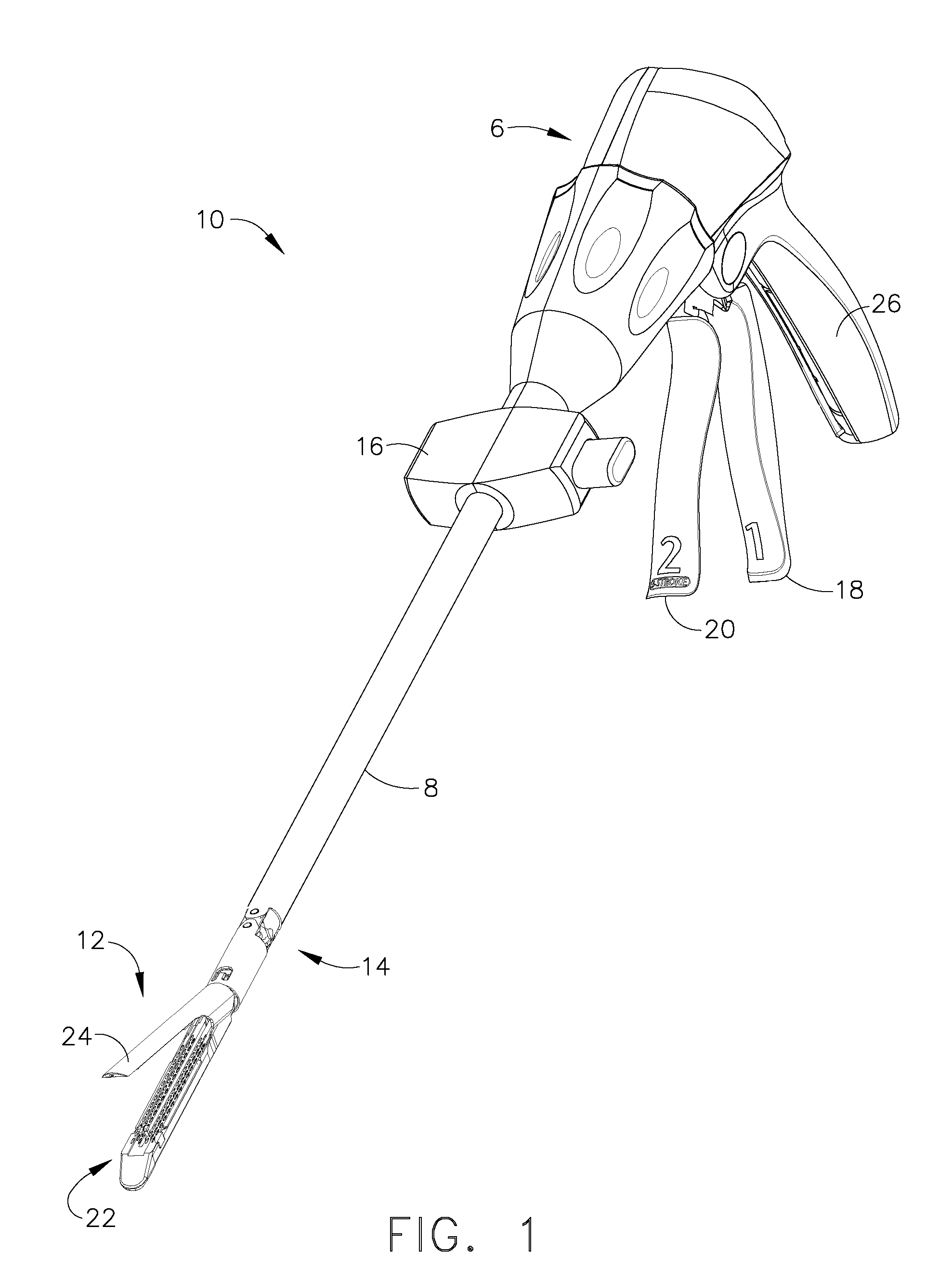

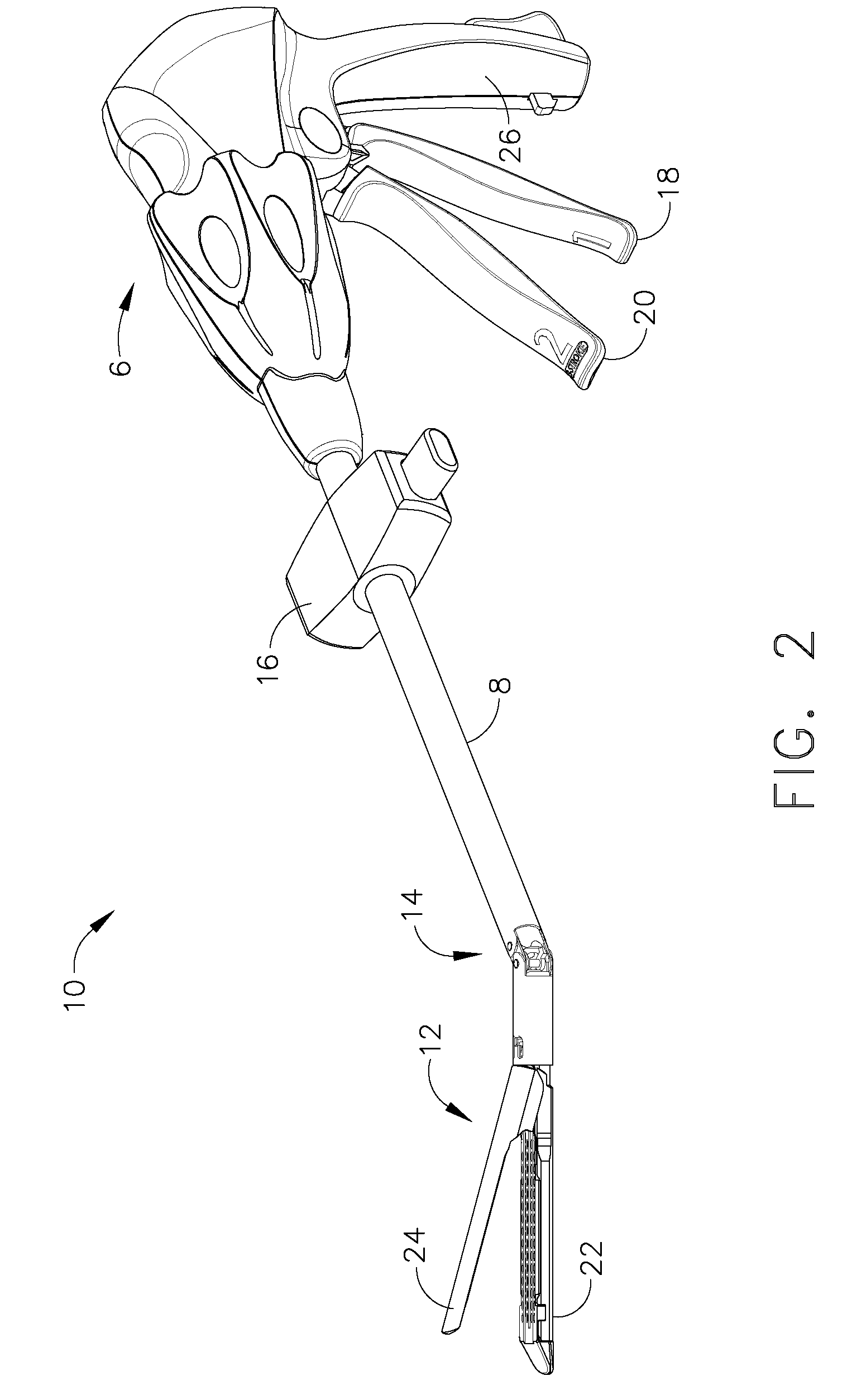

Sterilizable surgical instrument

A surgical instrument including a first portion and a second portion, wherein the second portion can be sterilized separately from the first portion. The first portion can comprise an anvil, a staple cartridge channel and / or staple cartridge, and a movable cutting member. The second portion can comprise electronic components configured to control the surgical instrument and / or record data collected during the use of the surgical instrument. The first portion can be sterilized using a gamma radiation sterilization process while the second portion can be sterilized using a different sterilization process, such as steam, ethylene oxide, ozone, and / or hydrogen peroxide sterilization processes, for example. As a result, the first and second portions can be sterilized separately and delivered in two separate containers. The second portion can be stored within a sealed bag and can include an electrical terminal which can penetrate the bag and communicate with the first portion.

Owner:CILAG GMBH INT

Sterilizable surgical instrument

ActiveUS20100193569A1Avoid damageReduce the possibilitySuture equipmentsStapling toolsElectronic componentHydrogen Peroxide Sterilization

A surgical instrument including a first portion and a second portion, wherein the second portion can be sterilized separately from the first portion. The first portion can comprise an anvil, a staple cartridge channel and / or staple cartridge, and a movable cutting member. The second portion can comprise electronic components configured to control the surgical instrument and / or record data collected during the use of the surgical instrument. The first portion can be sterilized using a gamma radiation sterilization process while the second portion can be sterilized using a different sterilization process, such as steam, ethylene oxide, ozone, and / or hydrogen peroxide sterilization processes, for example. As a result, the first and second portions can be sterilized separately and delivered in two separate containers. The second portion can be stored within a sealed bag and can include an electrical terminal which can penetrate the bag and communicate with the first portion.

Owner:CILAG GMBH INT

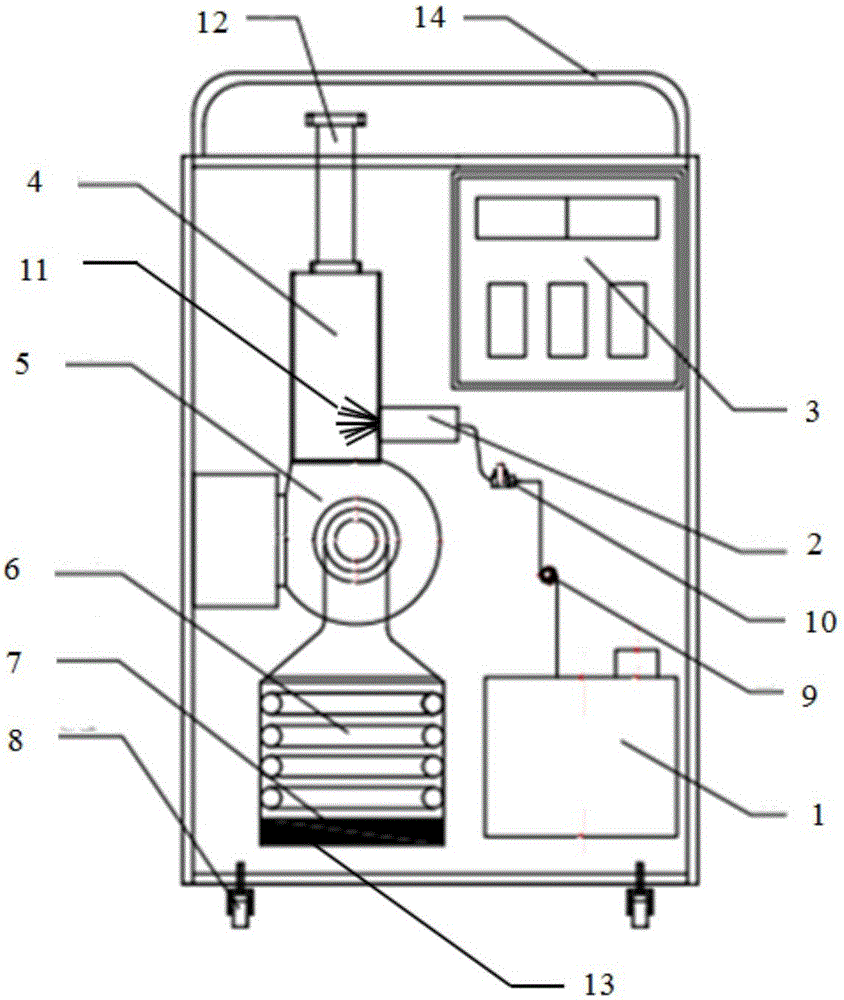

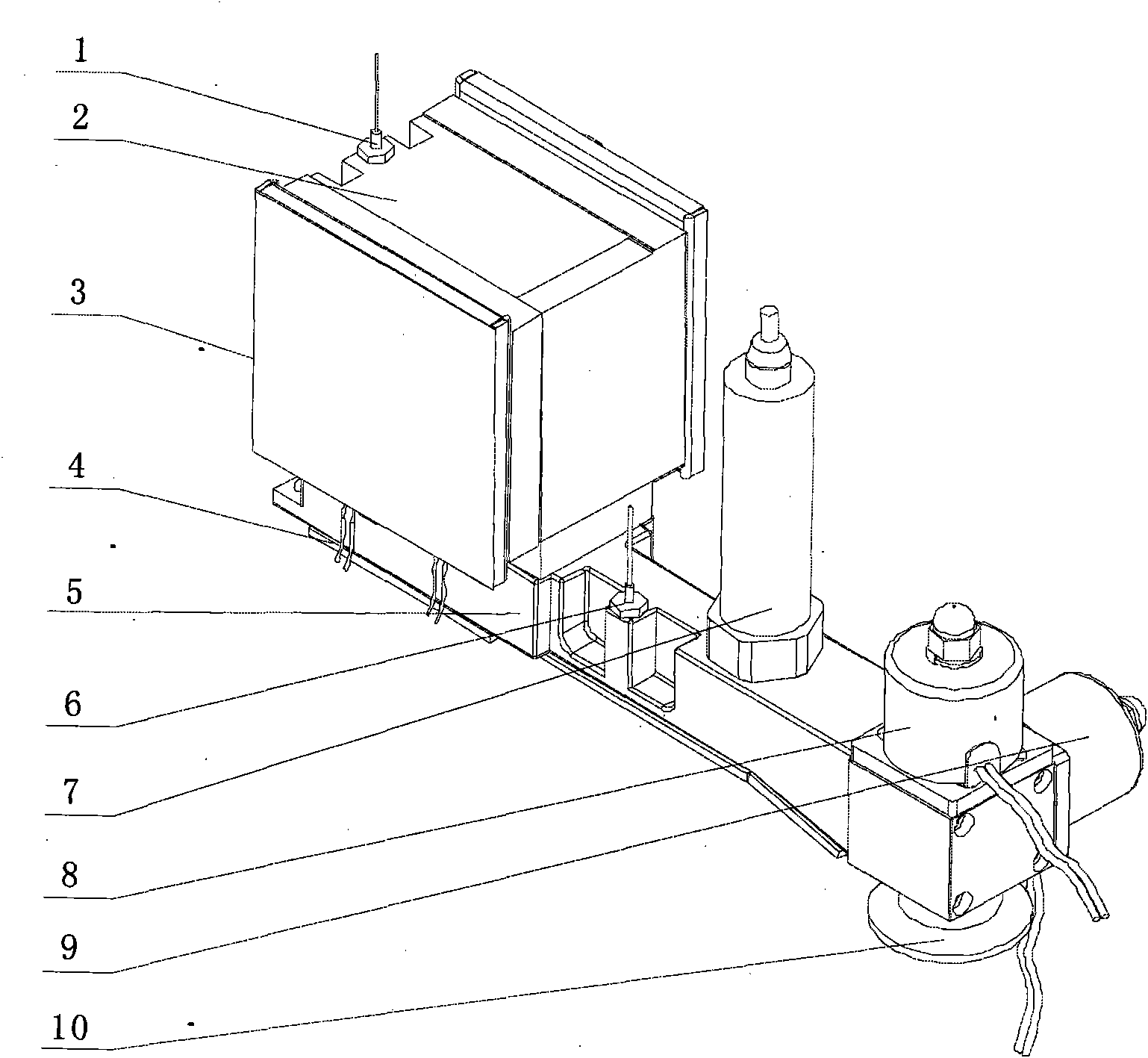

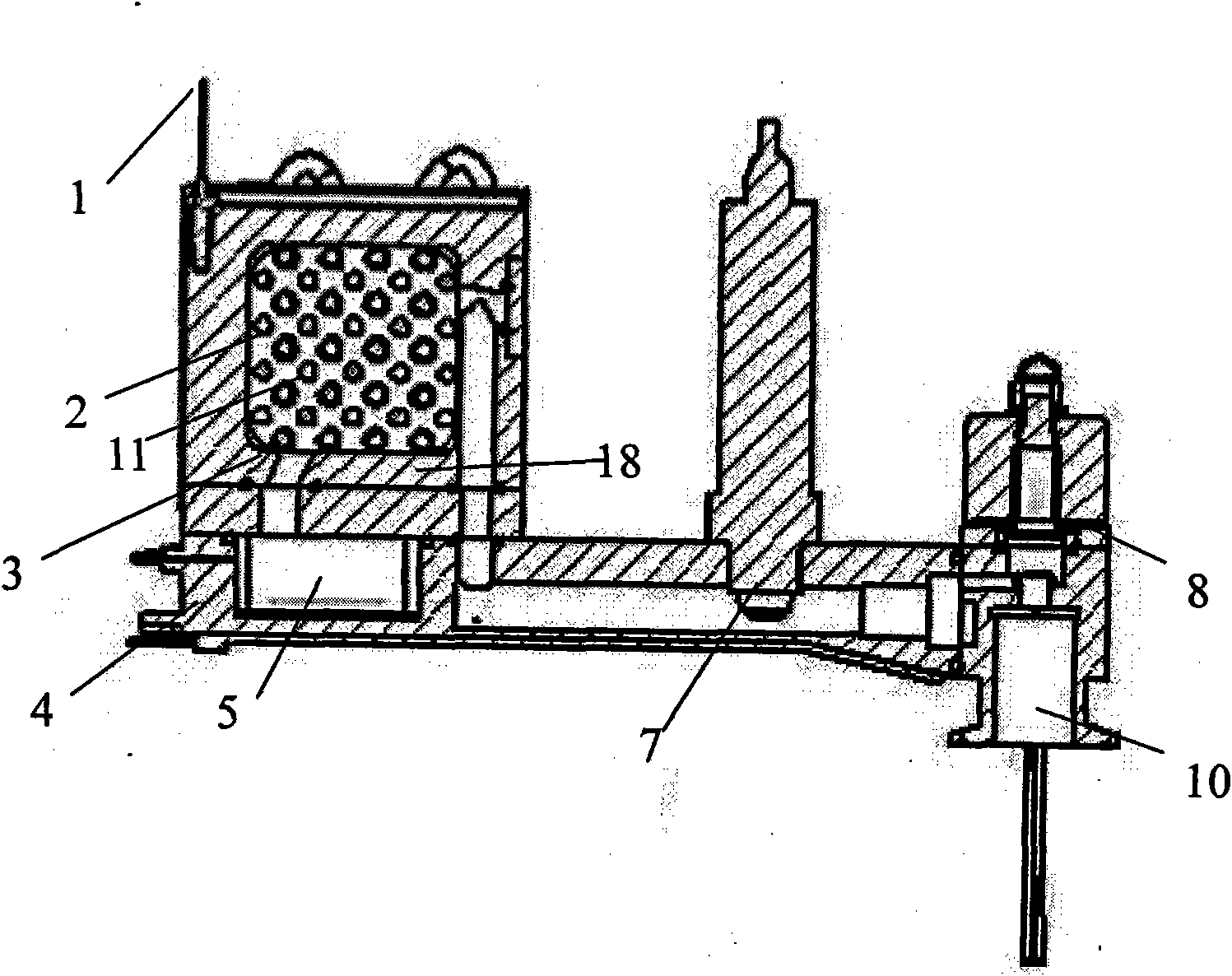

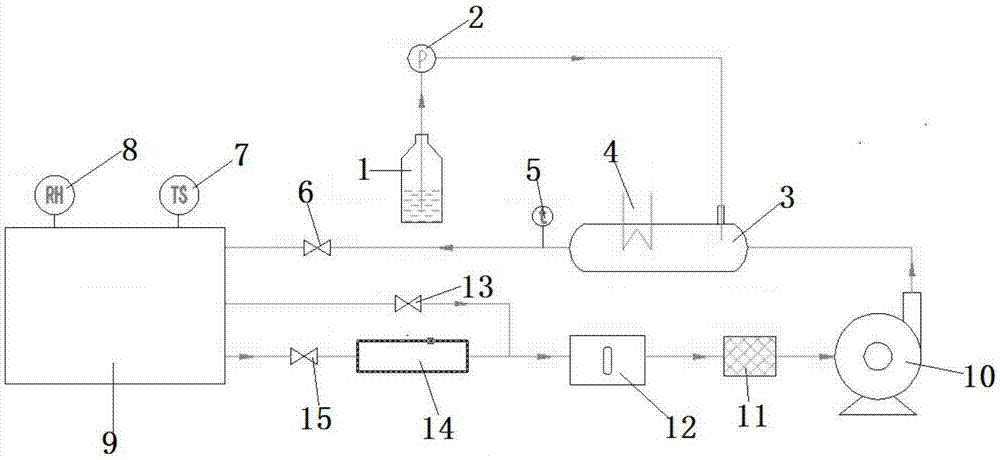

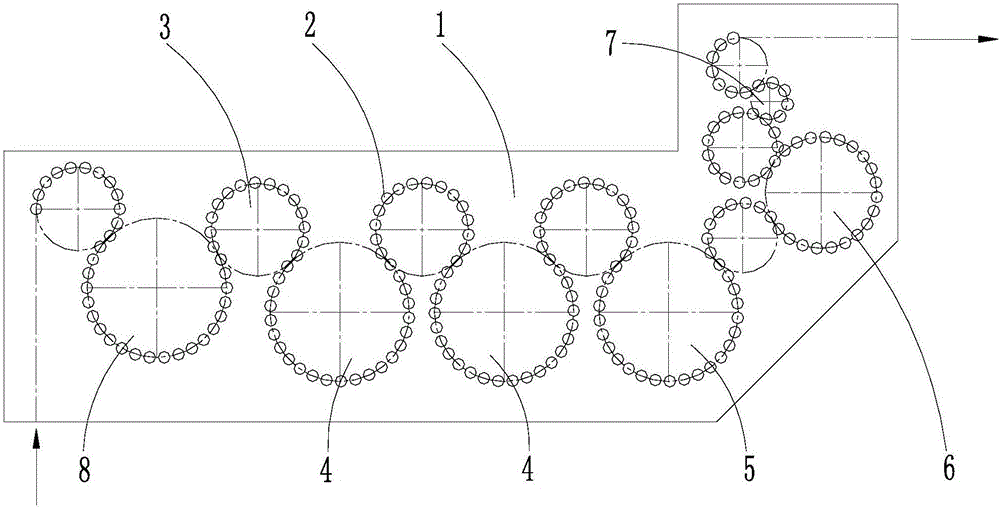

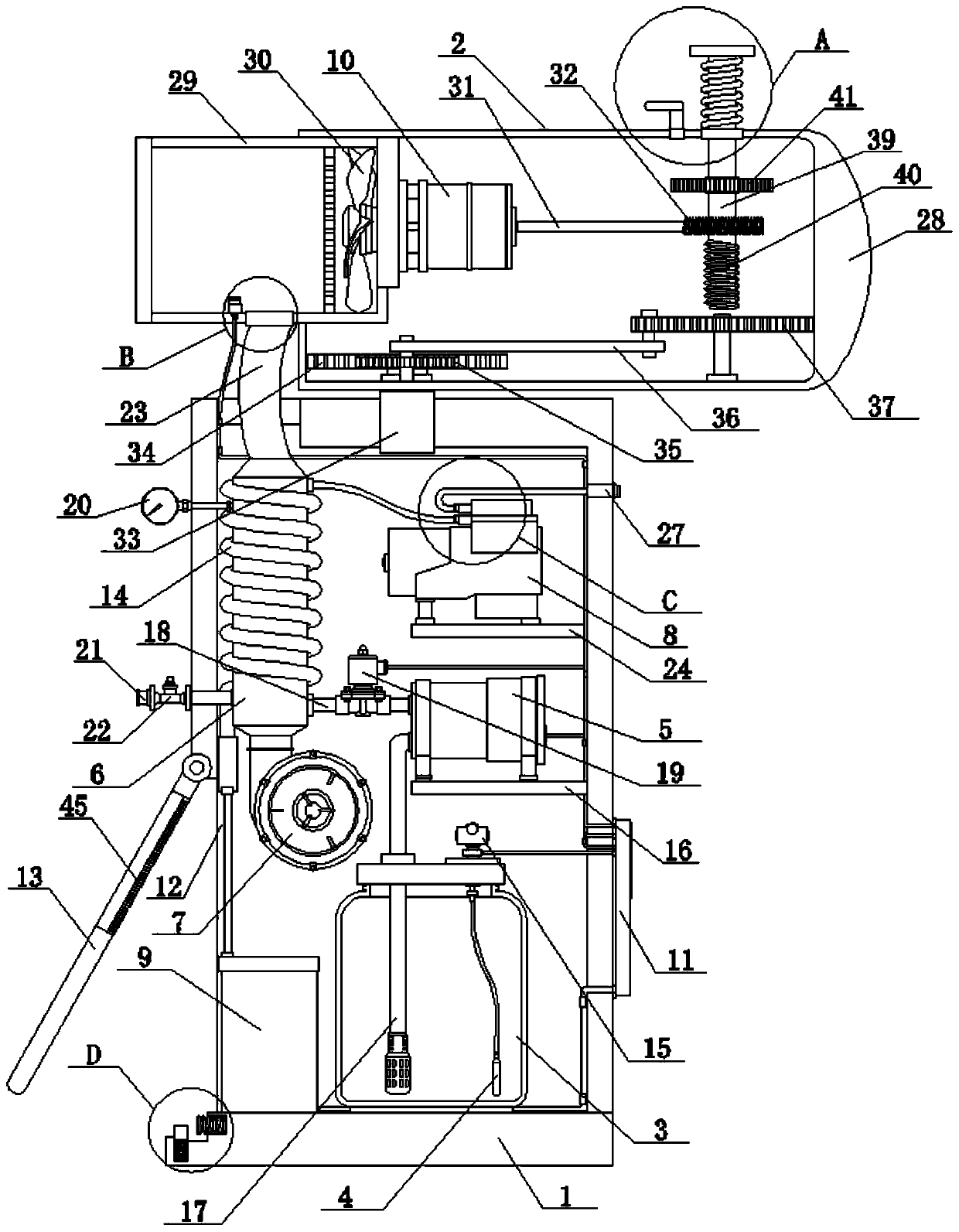

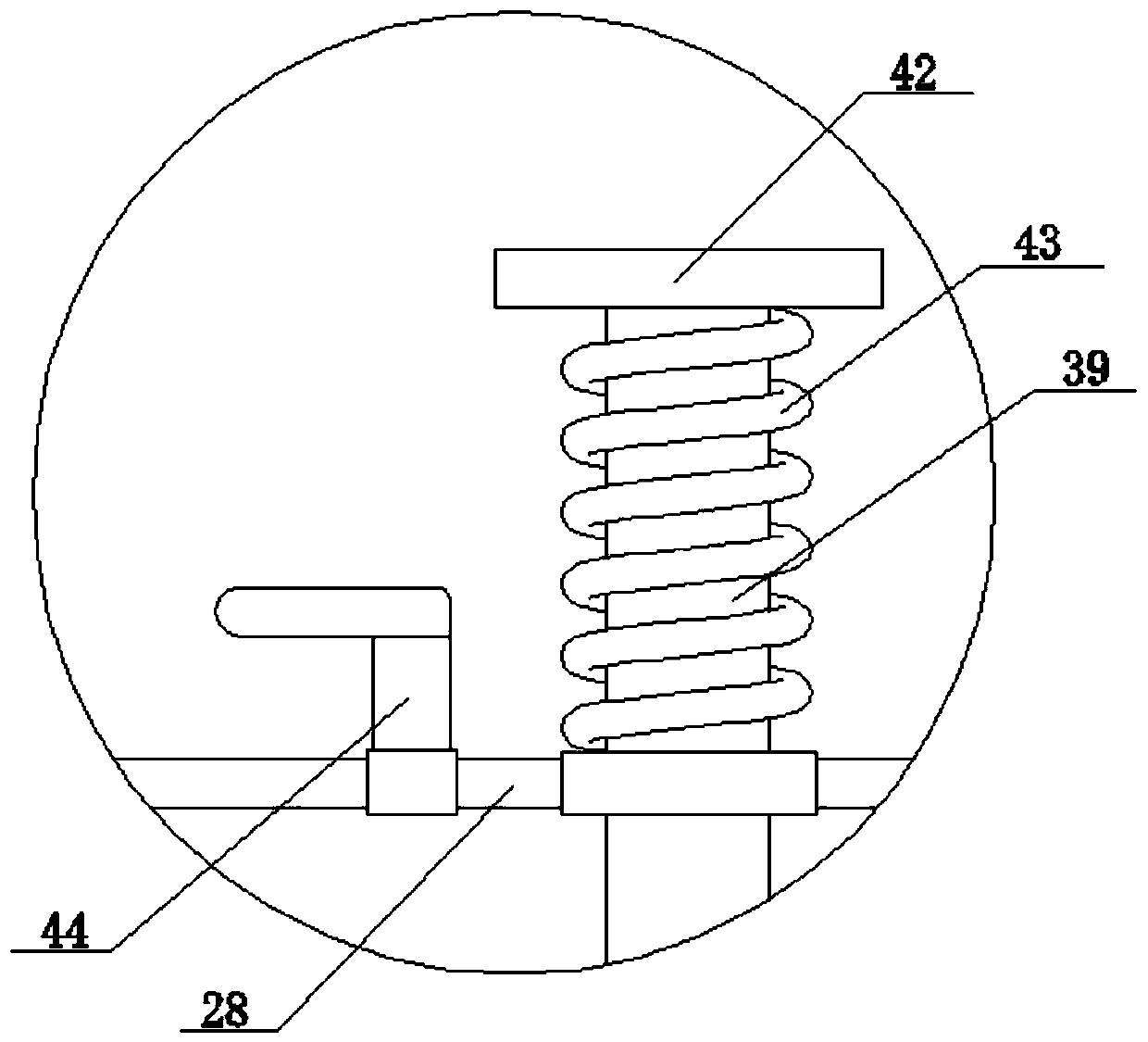

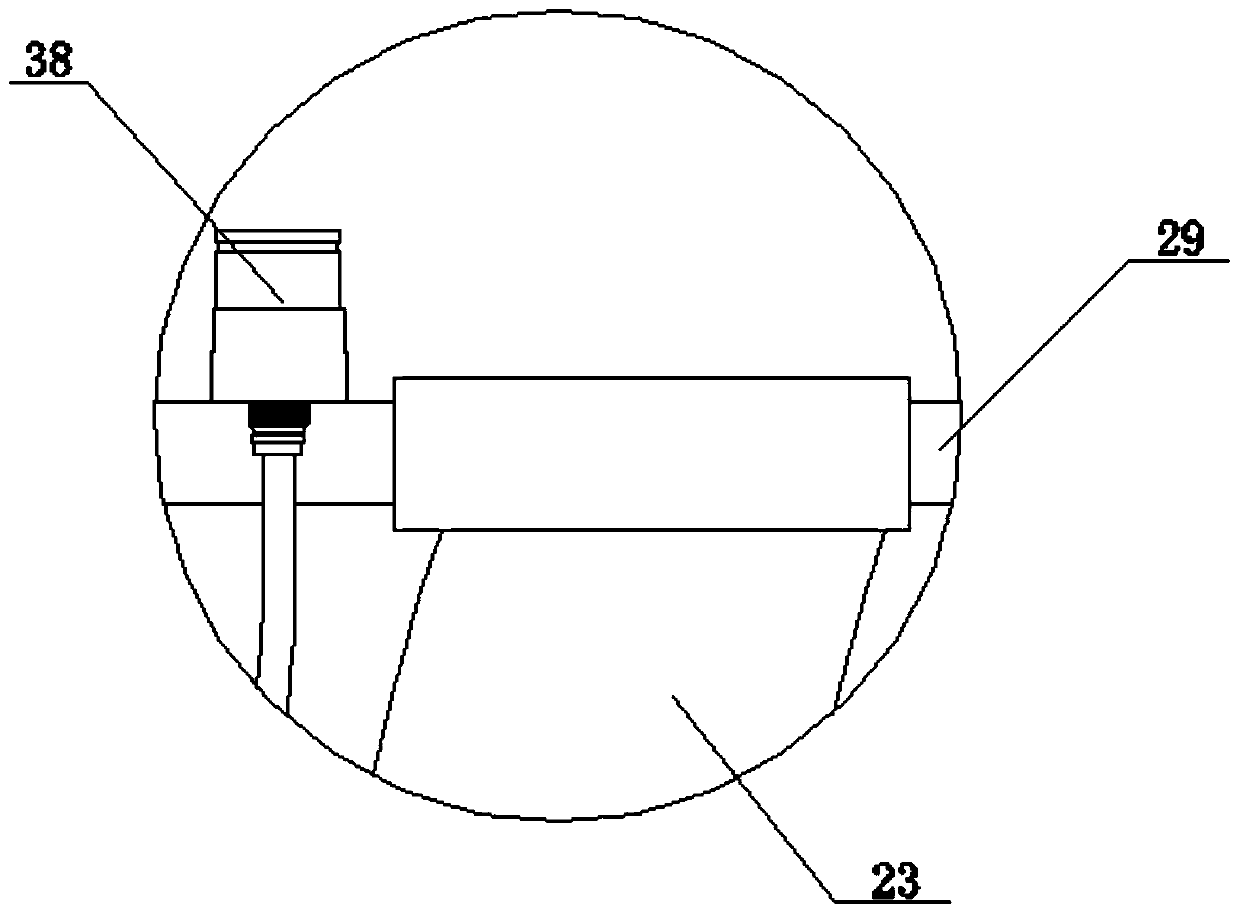

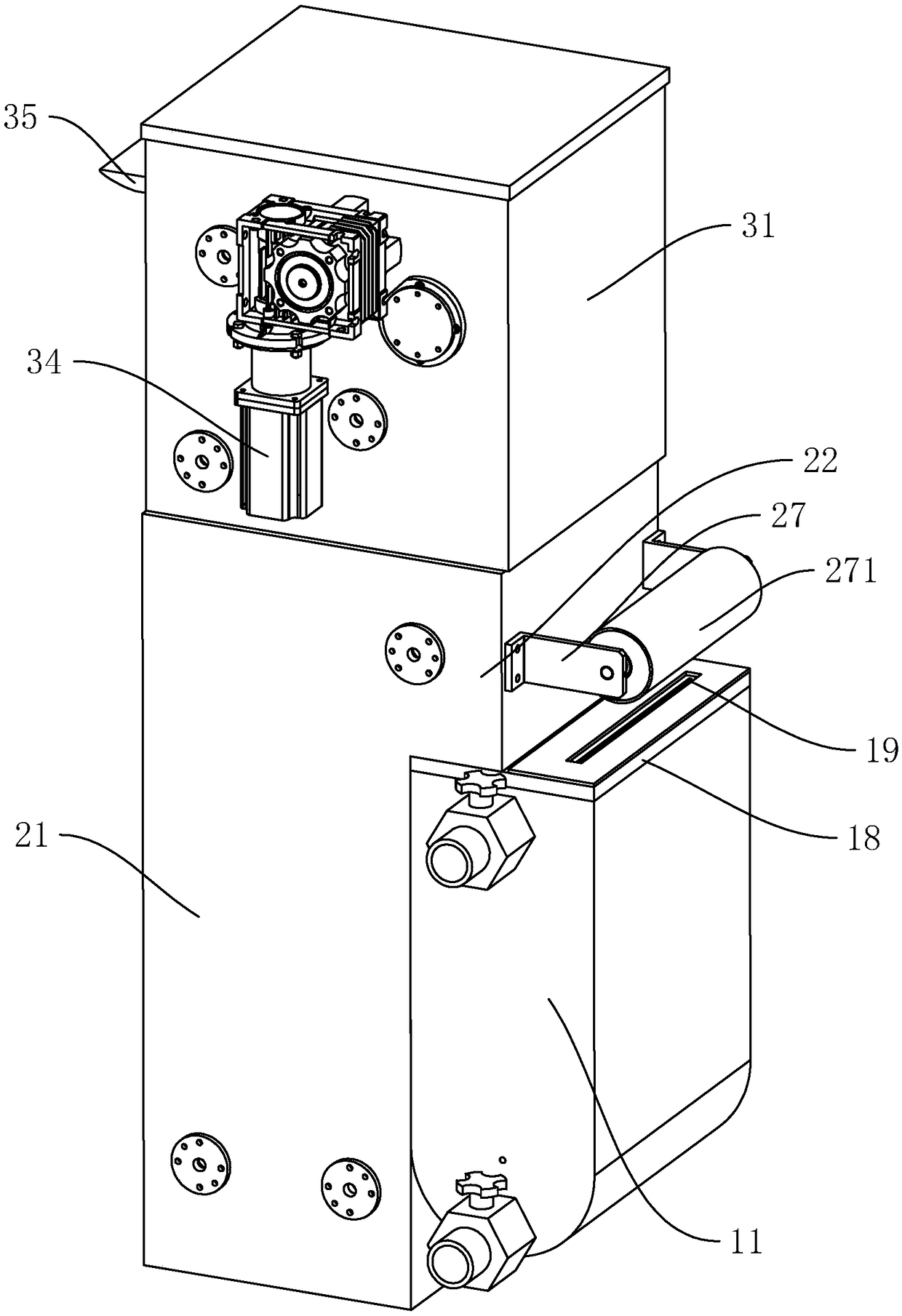

Hydrogen peroxide sterilization device and method

InactiveCN104984378AReduce the temperatureSuitable for sterilizationGaseous substancesChemicalsUltrasonic nozzleAir blower

A hydrogen peroxide sterilization device comprises a hydrogen peroxide liquid storage barrel, an ultrasonic atomizer, an electrical control unit, a vaporizing chamber, a metering pump, an solenoid-controlled valve, an air blower, a heater, a filter device, an air inlet and a steam outlet pipe; the ultrasonic atomizer is further provided with an ultrasonic nozzle provided with an air flue to evenly diffuse atomized hydrogen peroxide microdroplets in the vaporizing chamber, the vaporization efficiency is improved, the atomized hydrogen peroxide microdirplets can be vaporized rapidly at a lower temperature, and the energy is saved. Indoor air serves as carrier gas, outside air is not introduced, and secondary pollution is avoided. Hydrogen peroxide big droplets which are not vaporized in the vaporizing chamber can drop back on the heater under the action of gravity to be vaporized again. By controlling various related parameters, a dew point temperature of output vaporized hydrogen peroxide is made to be lower than the indoor temperature all the time, a steady flow is guaranteed for the vaporized hydrogen peroxide, and the water mist condensation phenomenon which occurs in the transport process are avoided.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV

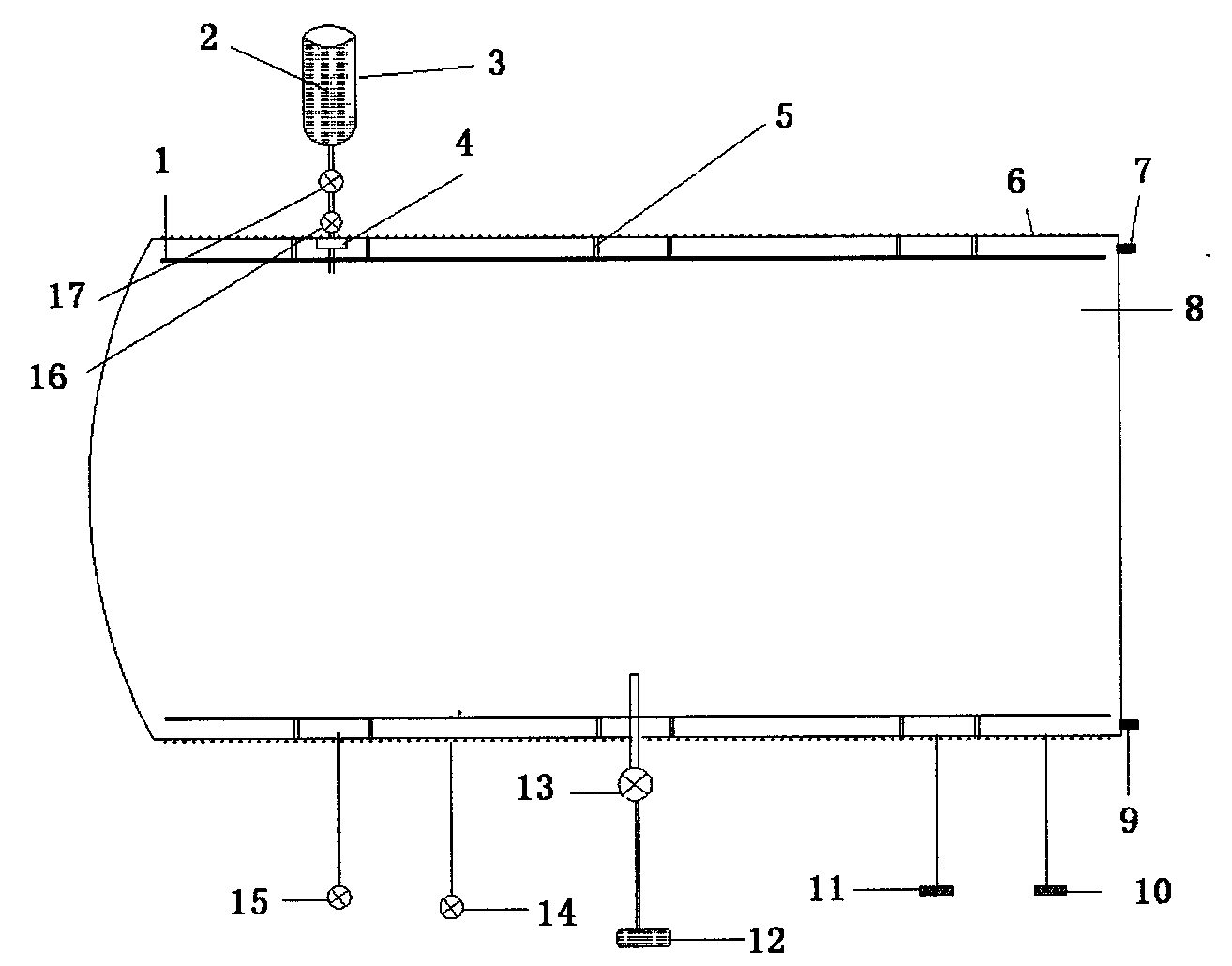

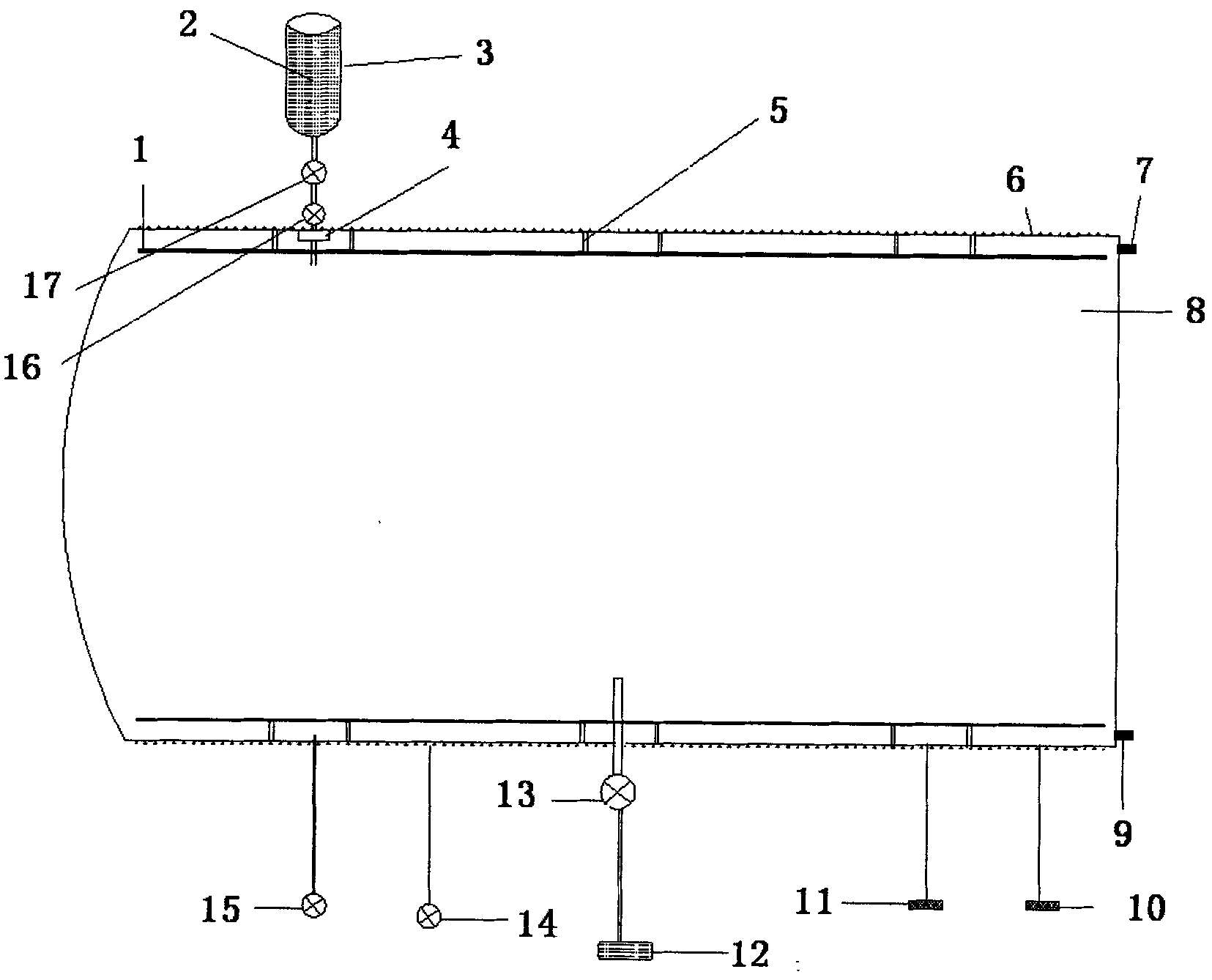

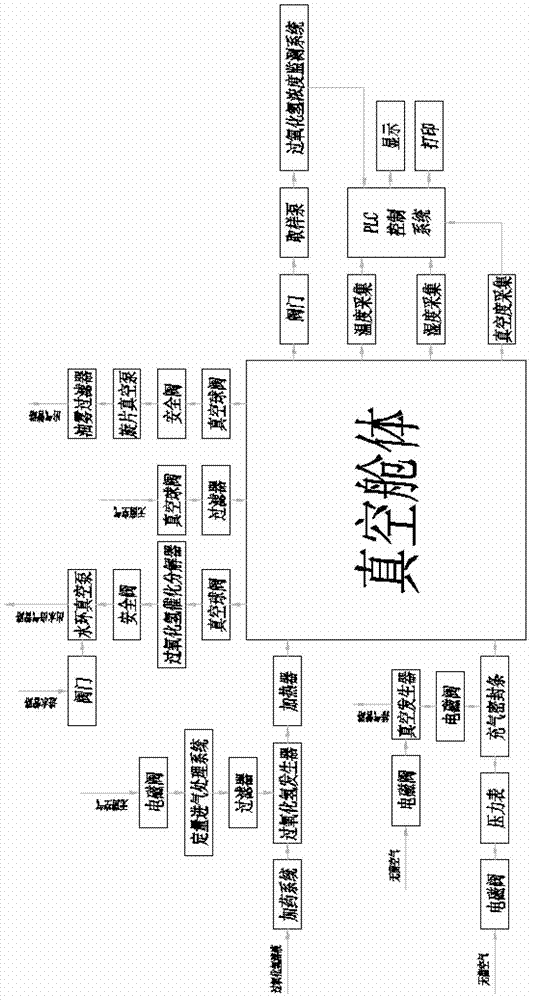

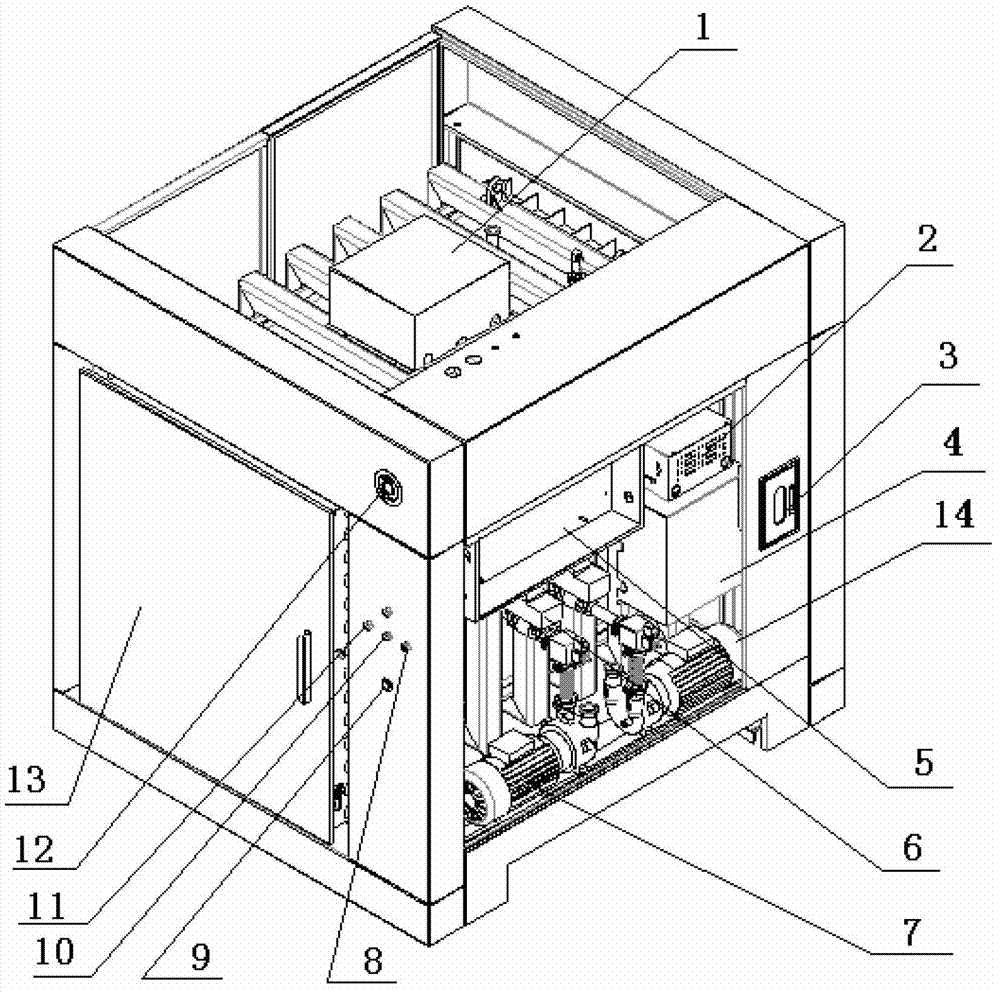

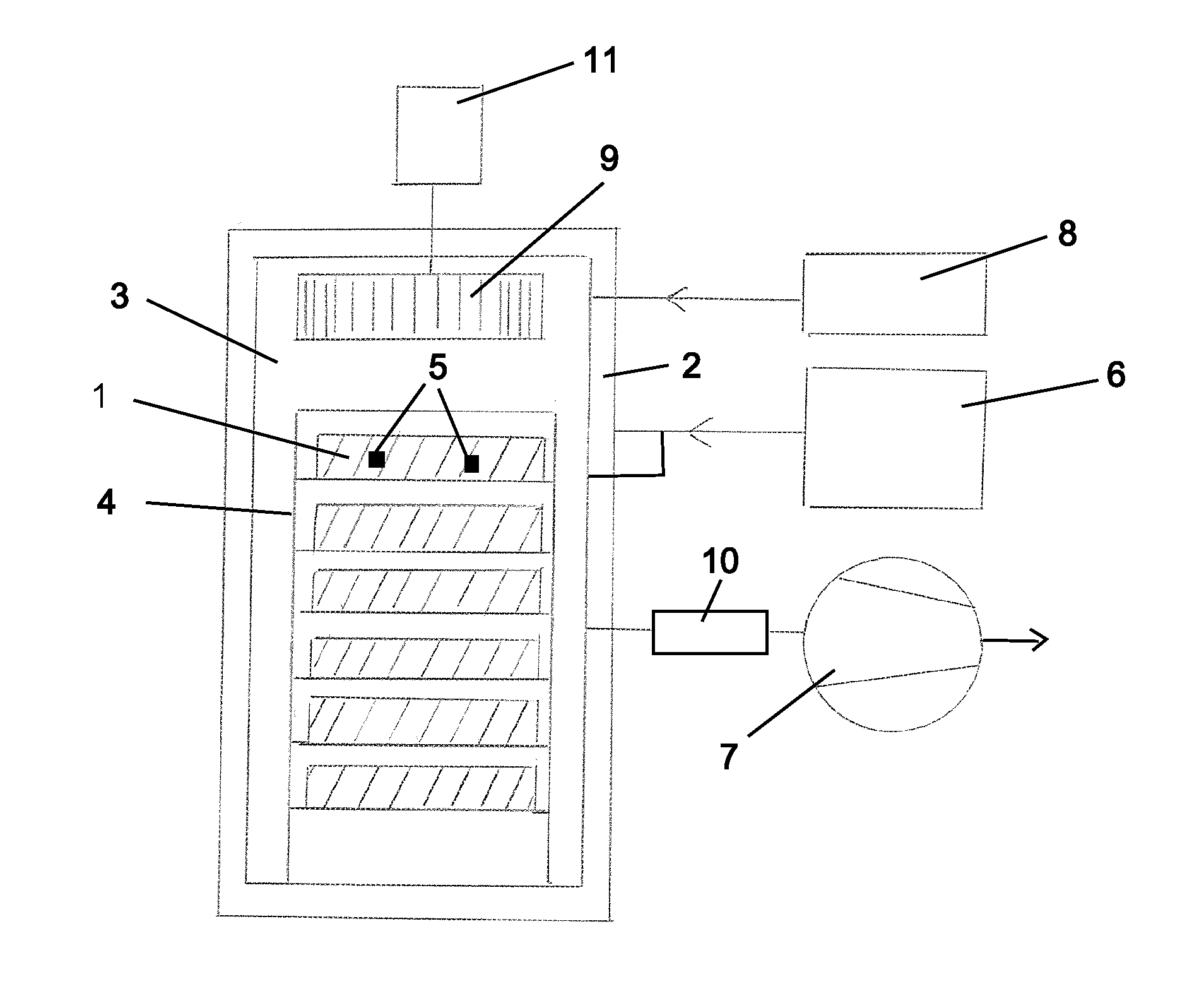

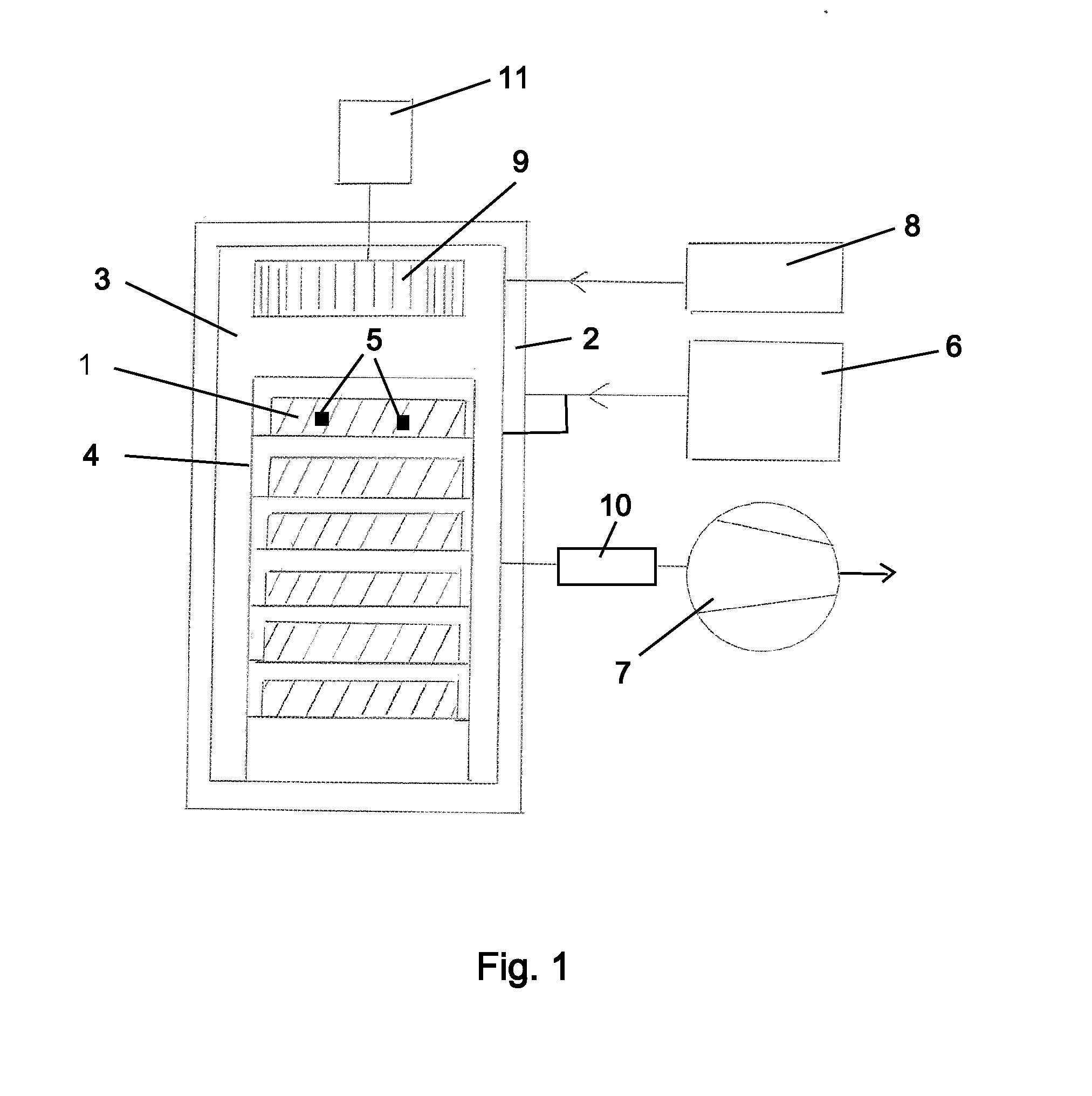

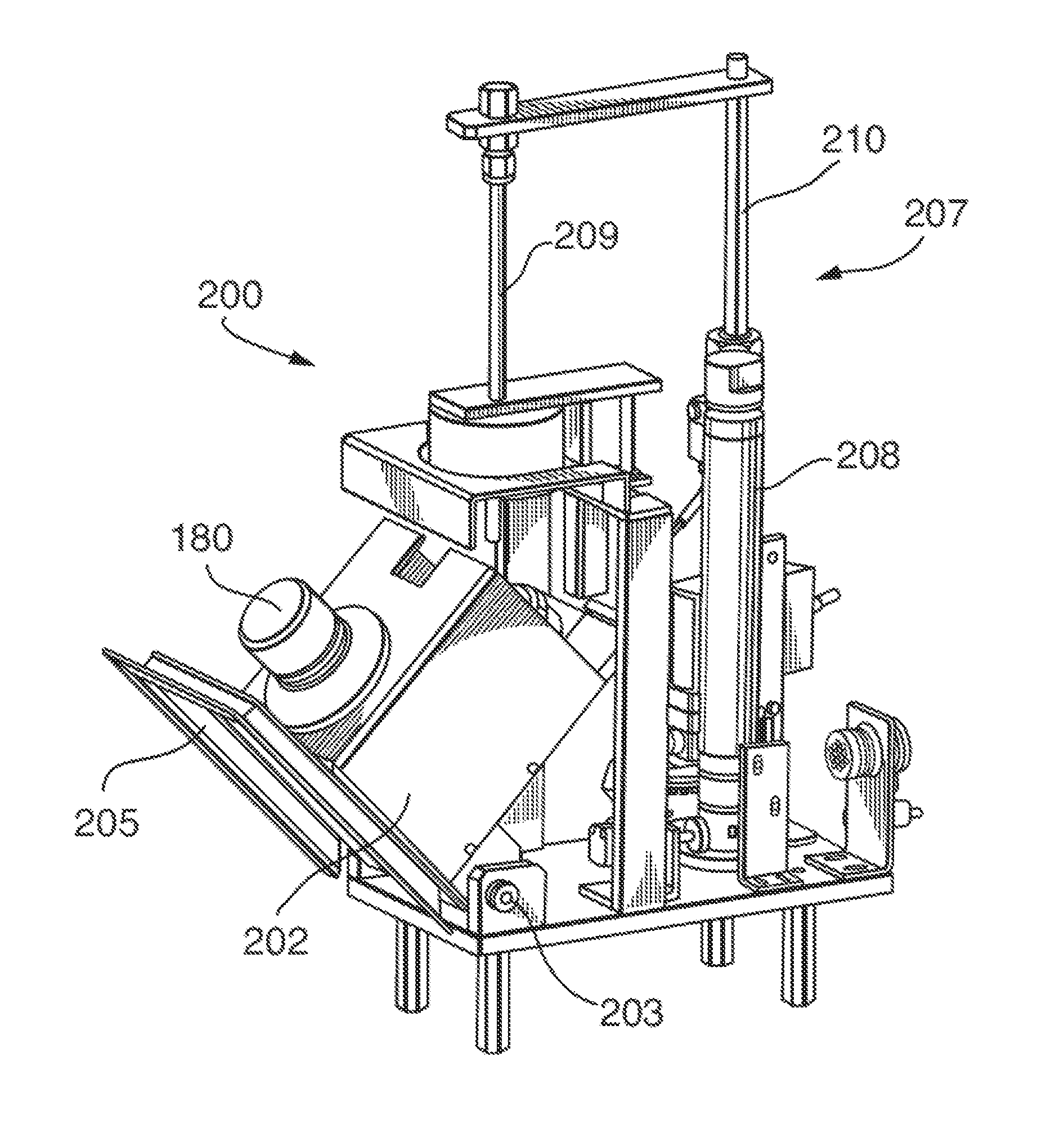

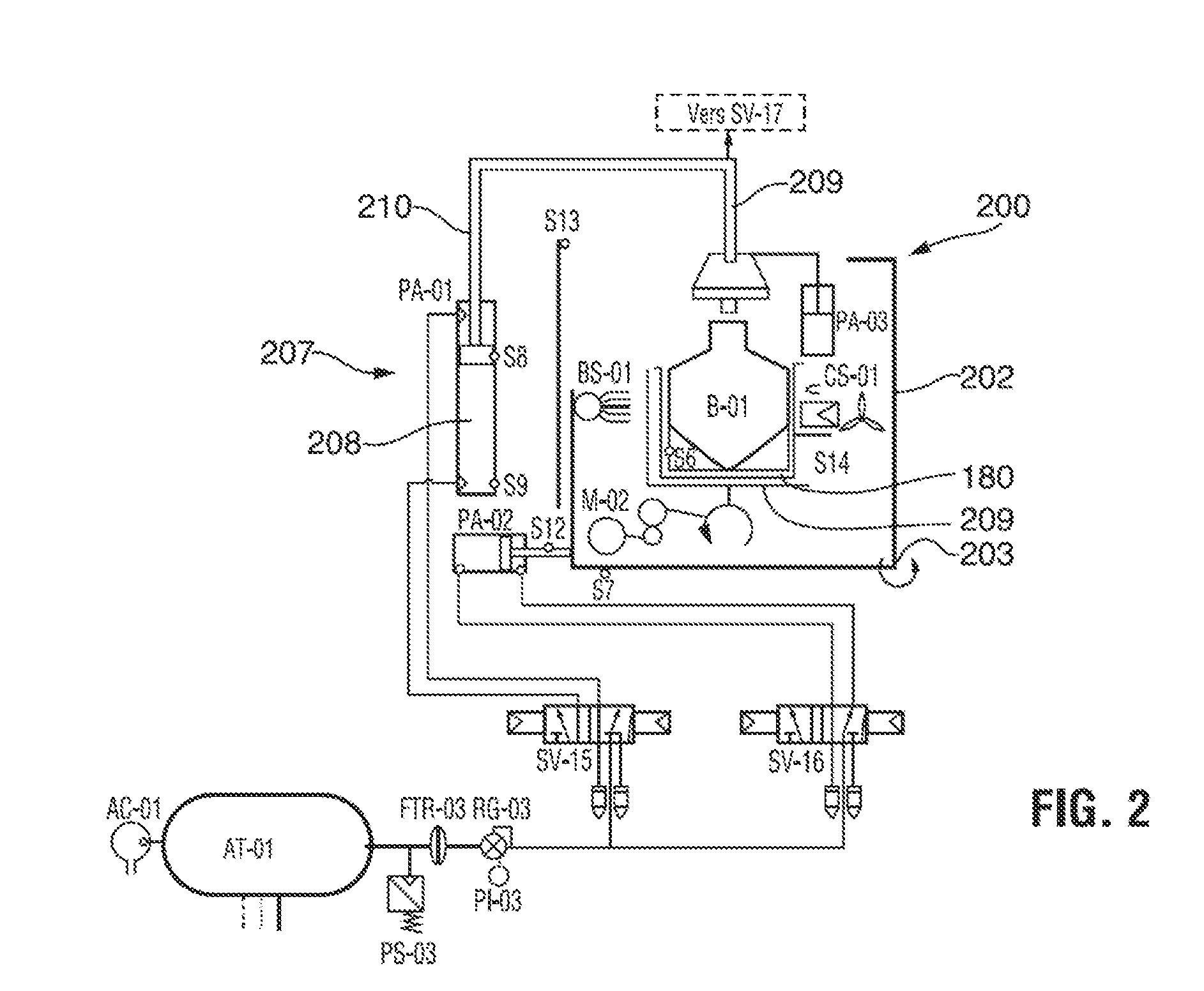

Hydrogen peroxide plasma sterilizer and sterilizing method thereof

ActiveCN101618226AEasy to storeEasy to transportLavatory sanitoryChemicalsHigh concentrationControl system

The invention relates to a hydrogen peroxide plasma sterilizer which comprises a sterilizing cabin, a vacuum system, a liquid feed system, a plasma generator, an air inlet system and a control system, wherein the sterilizing cabin is used for accommodating a sterilizing object; the vacuum system is used for emptying gas in the sterilizing cabin; the liquid feed system is used for filling a hydrogen peroxide sterilizing agent containing water into the sterilizing cabin; the plasma generator is used for exciting a content of the sterilizing cabin to be in a plasma state within a period of a sterilizing circle; the air inlet system allows abacterial air to enter the sterilizing cabin to break the vacuum of the sterilizing cabin; and the control system is used for controlling components of the sterilizer, so that the sterilizer can carry out sterilizing works as a set program. The hydrogen peroxide plasma sterilizer is characterized by also comprising an evaporator used for purifying the hydrogen peroxide sterilizing agent containing water, vaporizing the purified hydrogen peroxide sterilizing agent and conveying the hydrogen peroxide sterilizing agent to the sterilizing cabin for sterilizing. The evaporator can purify the lower-concentration hydrogen peroxide sterilizing agent containing water which is convenient for storage and transport into a high-concentration hydrogen peroxide sterilizing agent, and water is basically removed from the system, thus the sterilizer can sterilize more quickly, sufficiently and effectively.

Owner:LAOKEN MEDICAL TECH

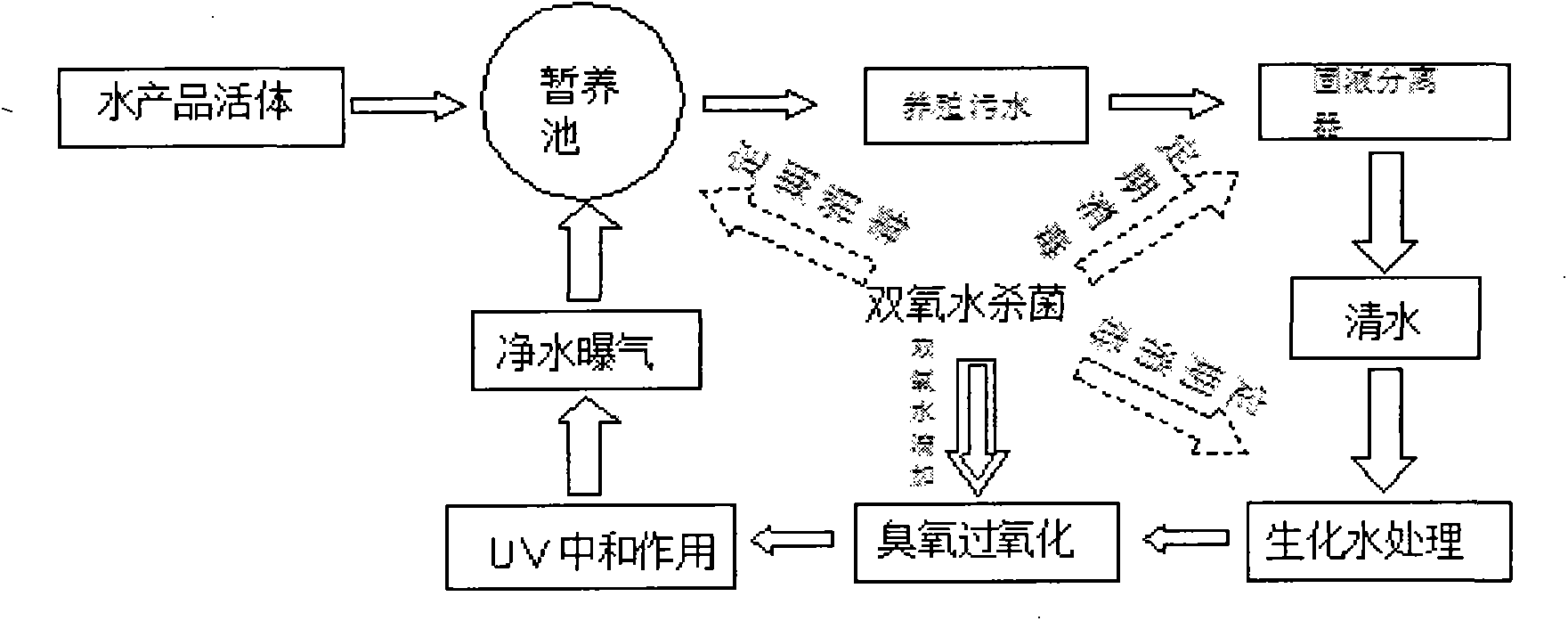

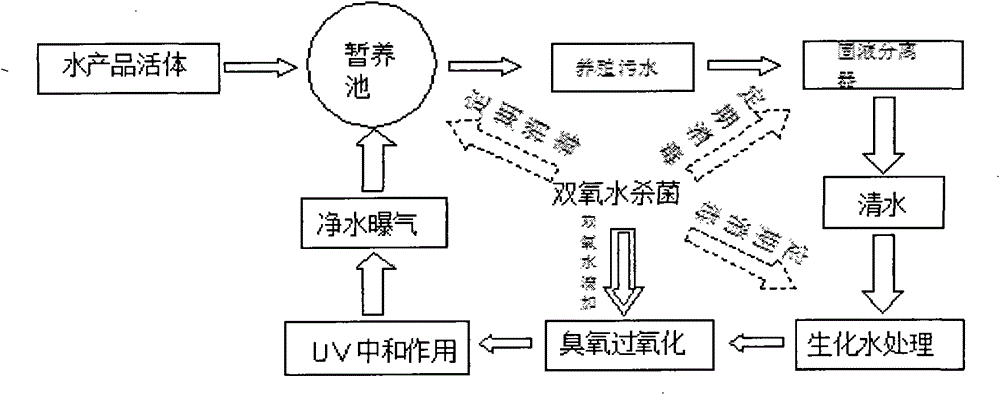

Method for improving quality of aquaculture products

ActiveCN103651194AResidue reductionMeet the health standards for consumptionClimate change adaptationPisciculture and aquariaWater dischargeHazardous substance

The invention discloses a method for improving the quality of aquaculture products, and relates to the technical field of aquaculture. The method particularly includes the steps of placing aquatic product living bodies in a circulating water aquaculture system for aquaculture; filtering water discharged form an aquaculture pond with a solid-liquid separator, wherein the hole diameter of a filtering net ranges from 20 micrometers to 100 micrometers; enabling filtered clean water to enter a microorganism biochemical water processing system; conducting peroxidation processing on clean water after biochemical water processing in a hydrogen peroxide-ozone oxidation pond; conducting ultraviolet sterilization processing in an ultraviolet sterilizer on clean water after the hydrogen peroxide-ozone oxidation processing , enabling the clean water to return to the aquaculture pond, and achieving cyclic utilization of aquaculture water. The method is easy and convenient to operate, 2-methylisoborneol, dimethyl naphthalene alcohol and generated microorganism sources of the 2-methylisoborneol and the dimethyl naphthalene alcohol which cause peculiar smells such as the earthy smell are directly or indirectly eliminated under the synergistic effect of ozone, the ultraviolet technology and the hydrogen peroxide sterilization technology, residues of hazardous substances such as a plurality of kinds of heavy metal and pesticides are remarkably reduced, ad the quality and the value of the products are improved.

Owner:SUZHOU FISHSEEDS BIOLOGICAL TECH CO LTD

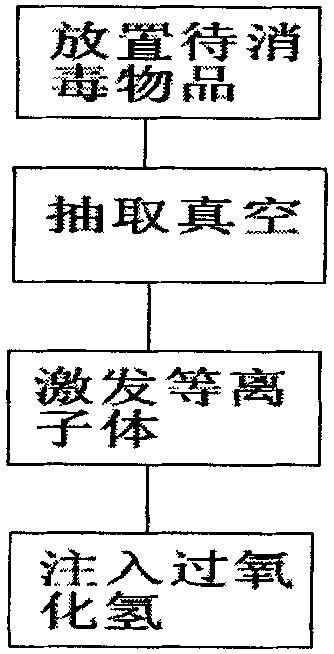

Method and device for controlling precise measurement of hydrogen sulfide pulsation injecting liquid through pressure degenerative feedbacks

The invention relates to a method for controlling precise measurement of hydrogen sulfide pulsation injecting liquid through pressure degenerative feedbacks. The method comprises the steps of placing articles to be disinfected in a sterile chamber for disinfection; using a vacuum system to extract vacuum or inflate for the sterile chamber in which the articles to be disinfected are placed; using a plasma generating device to excite the generation of plasmas; using pressure variation signals obtained by a testing control system in the sterile chamber to control a hydrogen peroxide injecting system and determine the dosage of an injected hydrogen peroxide disinfectant, and the injected hydrogen peroxide is excited by the plasmas. Thus, the hydrogen peroxide medium in the plasmas is fully excited, too much or too little injection of the hydrogen peroxide is prevented and precise control of the dosage of the hydrogen sulfide is achieved.

Owner:BEI JING BAI XIANG NEW TECH

Hydrogen peroxide sterilization apparatus and hydrogen peroxide sterilization method

InactiveCN106963962ASafe and controllable processSterilization is safe and efficientLavatory sanitoryGaseous substancesPeristaltic pumpInlet valve

The present invention belongs to the field of sterilization apparatuses and sterilization methods, and particularly relates to a hydrogen peroxide sterilization apparatus and a hydrogen peroxide sterilization method. With the hydrogen peroxide sterilization apparatus and the hydrogen peroxide sterilization method, vaporized hydrogen peroxide can be produced so as to effectively sterilize the space and the object requiring sterilization, and the hydrogen peroxide residue can be rapidly cleared after the sterilization is completed. The hydrogen peroxide sterilization apparatus of the present invention comprises a liquid storage container, a peristaltic pump, a vaporizer, a heating device, a temperature sensor, a sterilization gas inlet valve, a sterilization space, and a related control system.

Owner:HANZHOU YINGTIAN SCI INSTR

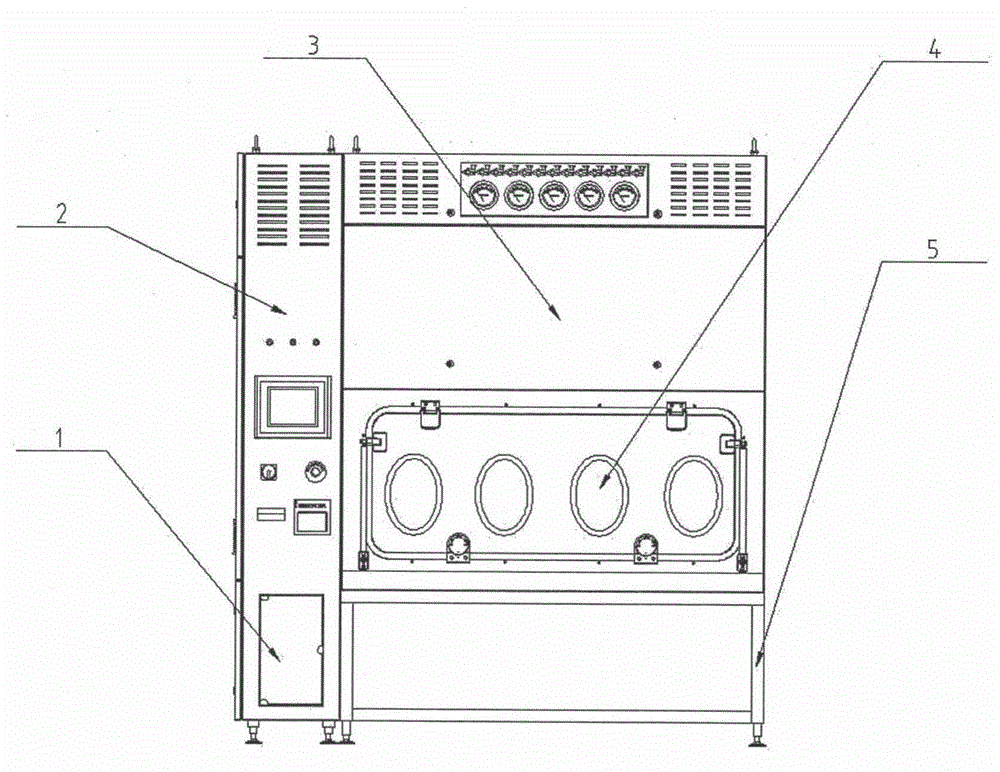

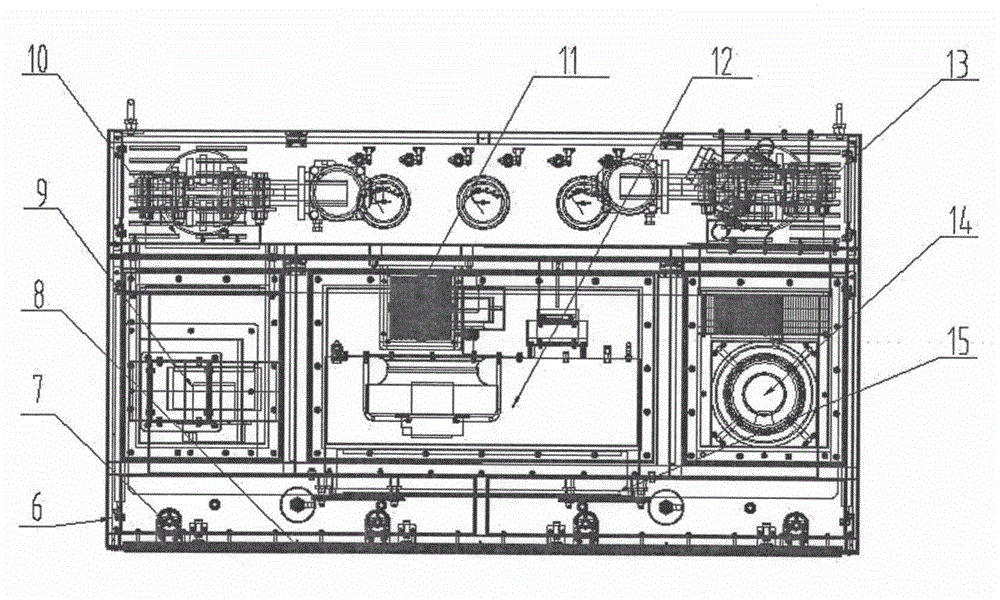

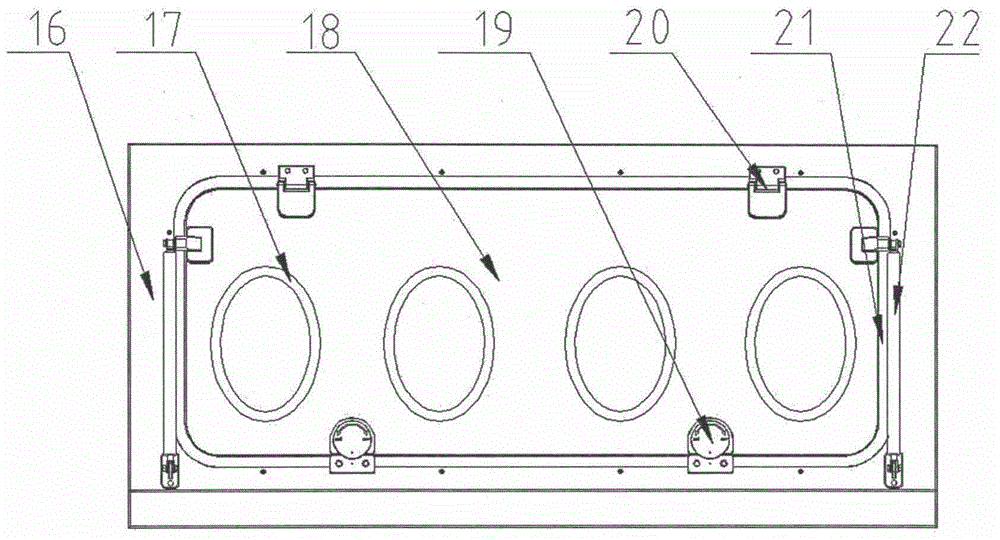

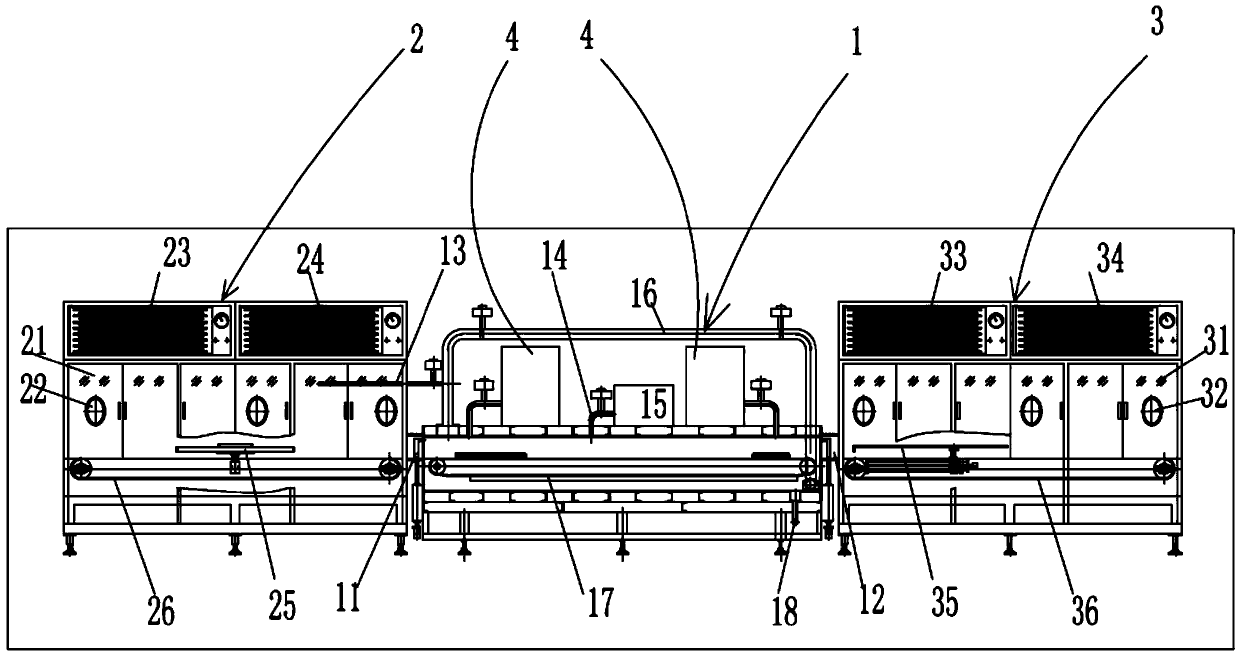

Sterility test process isolator

InactiveCN104353095AGuaranteed tightnessConvenience guaranteedManipulatorChemicalsOperating pointEngineering

The invention discloses a sterility test process isolator which is characterized by comprising a frame component at the bottom, a glove operation box component arranged on the frame component, an air handling system at the top and an electric system, wherein a hydrogen peroxide steam sterilization system is integrated on one side of the electric system. The isolator completely isolates internal production environment from operators and external environment, reduces the risk of artificial pollution and meanwhile reduces pollution to the operators and the external environment; the isolator reduces a production cleaning area, greatly increases the controllability of a production area and further lowers the operating cost and the maintenance cost; besides, the integrated hydrogen peroxide steam sterilization system is arranged, so that the on-line SIP is realized and the sterility of operating environment is guaranteed.

Owner:上海东富龙爱瑞思科技有限公司 +1

Compound hydrogen peroxide sterilization powder

InactiveCN106342883AShort sterilization timeThorough sterilization timeBiocideDisinfectantsCopperCarbon steel

The invention discloses compound hydrogen peroxide sterilization powder. The compound hydrogen peroxide sterilization powder comprises the following components in percentage by mass: 50-86% of an antioxidant, 10-25% of a synergist, 3-12% of a pH regulator, 1.5-9% of a penetrant, 3-15% of an anti-corrosive agent and 3.0-5.0% of a stabilizer. According to the compound hydrogen peroxide sterilization powder, the synergist is particularly added for enhancing the sterilization function of the hydrogen peroxide sterilization powder and is capable of ensuring that the sterilization time is shorter and more thorough when hydrogen peroxide is in low concentration; the anti-corrosive agent is particularly added, so that the hydrogen peroxide sterilization powder has the advantage of no corrosion and can be safely applied to disinfection and sterilization of instruments such as plastic instruments, rubber instruments, stainless steel instruments, copper instruments, aluminum instruments, carbon steel instruments and iron instruments.

Owner:山东消博士消毒科技股份有限公司

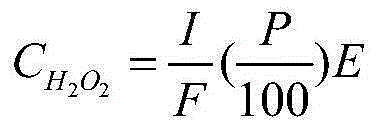

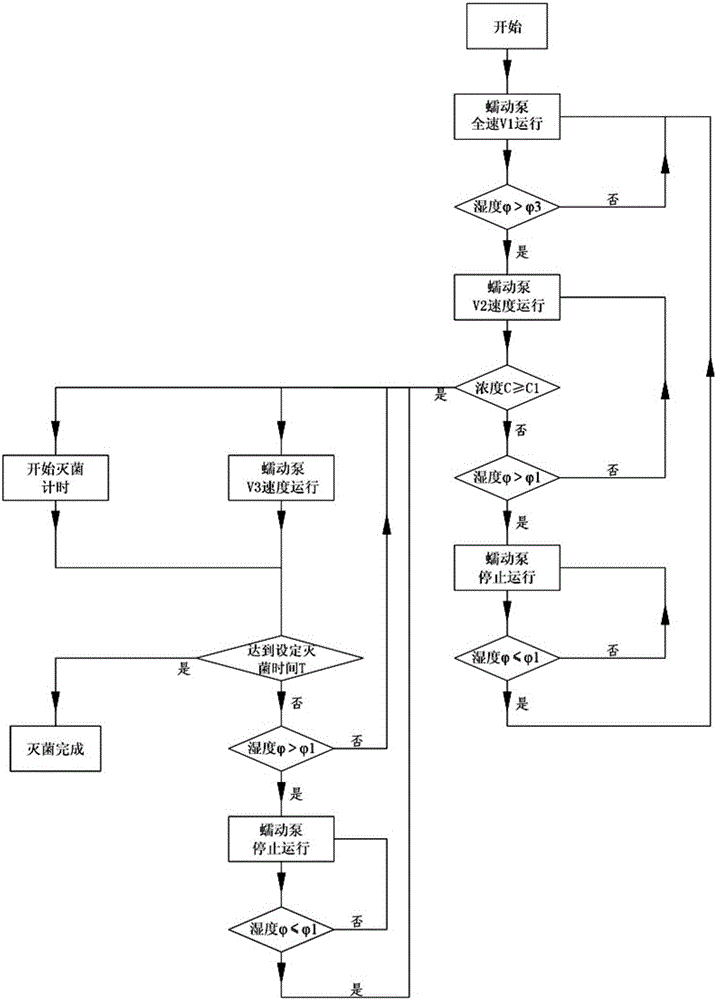

Hydrogen peroxide sterilization method

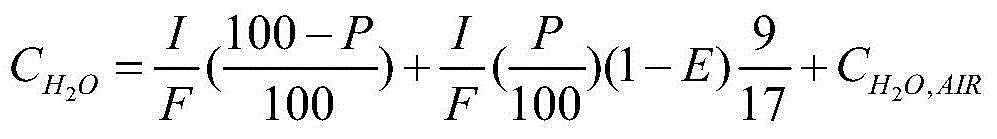

ActiveCN105999333AHumidity homeostasisAvoid condensationLavatory sanitoryChemicalsEvaporationHydrogen Peroxide Sterilization

The invention discloses a hydrogen peroxide sterilization method which comprises the following steps: S1, detecting the humidity Phi inside an isolator, and the concentration C of hydrogen peroxide; S2, filling a hydrogen peroxide solution into a heated evaporation disc, and introducing a gas evaporated from the hydrogen peroxide solution into the isolator; S3, setting a humidity value as Phi 1, if Phi is greater than Phi 1, turning to step S4; if Phi is less than or equal to Phi 1, turning back to step S2; S4, stopping filling the hydrogen peroxide solution into the evaporation disc; S5, setting the sterilization concentration of hydrogen peroxide in a sterilization state as C1, if C is greater than C1, turning to step S6, if C is less than C1, turning back to step S2; S6, keeping the sterilization state till a set sterilization time T; S7, stopping detecting the humidity Phi inside the isolator and the concentration C of hydrogen peroxide, stopping heating the evaporation disc, stopping filling the hydrogen peroxide solution into the evaporation disc, and the like. The hydrogen peroxide sterilization method has the advantages that no coagulation can be caused and instruments and meters of sterilization equipment can work stably for a long time.

Owner:TRUKING TECH LTD

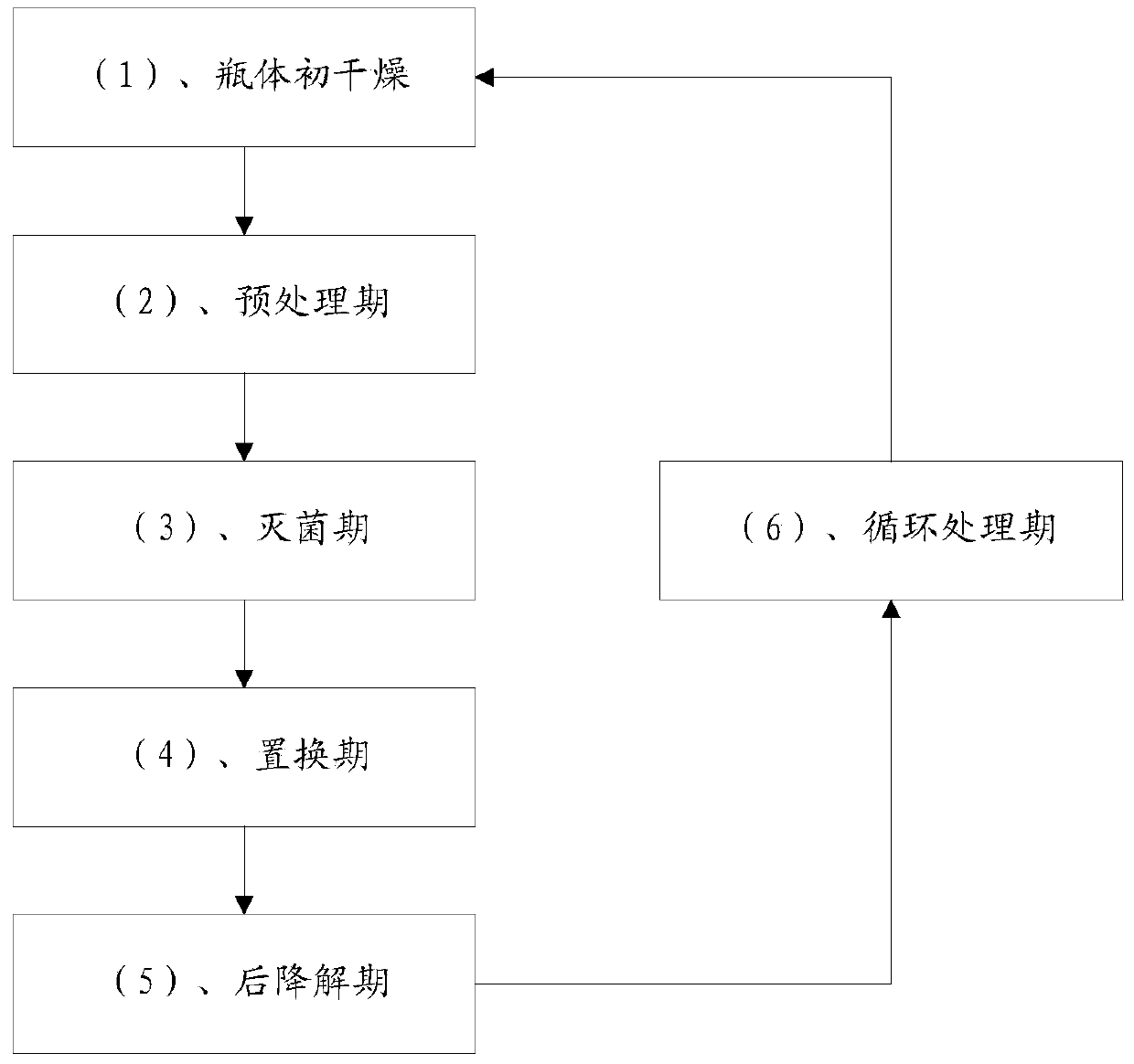

Tunnel-type hydrogen peroxide sterilization method and tunnel-type hydrogen peroxide sterilization device

InactiveCN103418002AEnsure sterility indexCompliance with regulatory requirementsChemicalsHydrogen Peroxide SterilizationVaporized hydrogen peroxide

The invention discloses a tunnel-type hydrogen peroxide sterilization method. The method includes the following steps of preliminary drying of a bottle, pretreating, sterilizing, replacing and later degrading. By vacuumizing the interior of a box and a box pressure-restoring pipeline for replenishing fresh air, most of vaporized hydrogen peroxide is degraded; residual hydrogen peroxide is further degraded in a front / rear buffering portion through laminar flow air, so that concentration 1ppm of hydrogen peroxide outgoing from the plastic bottle of equipment and left by operating personnel of the equipment meets requirements of laws and regulations, production speed is increased, and sterility indicators of the plastic bottle are guaranteed by the clean laminar flow air of the front / rear buffering portion.

Owner:叶明 +1

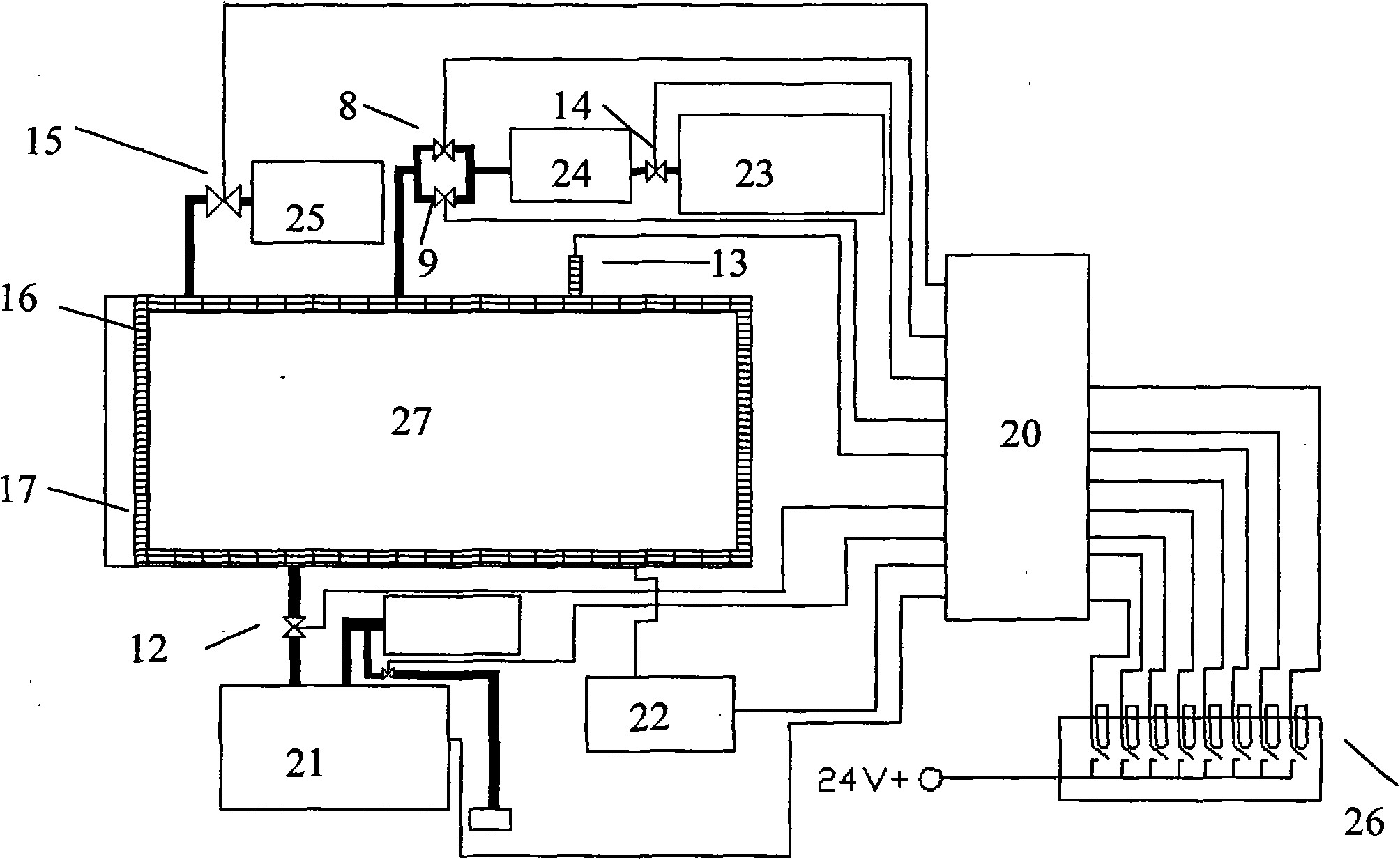

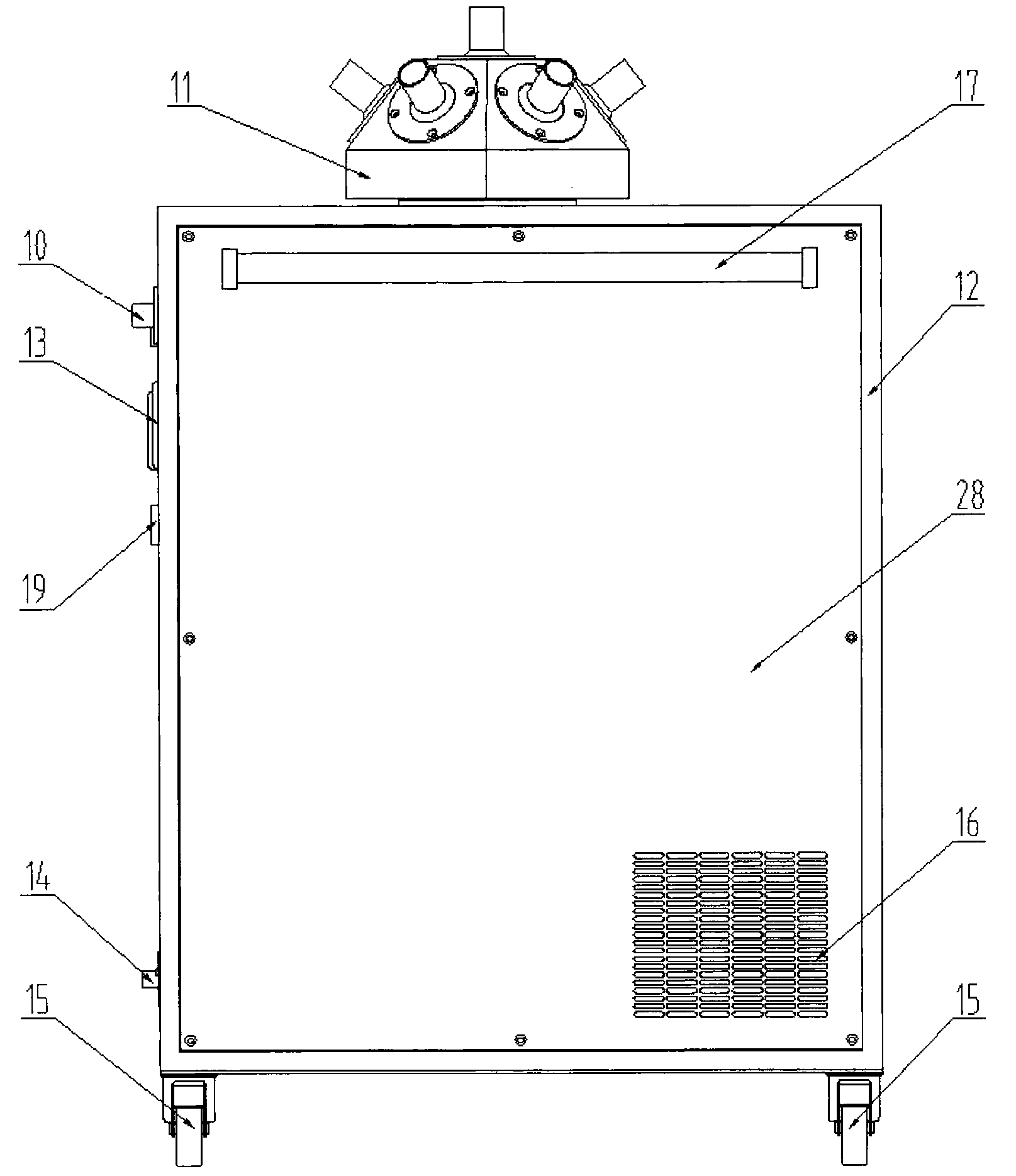

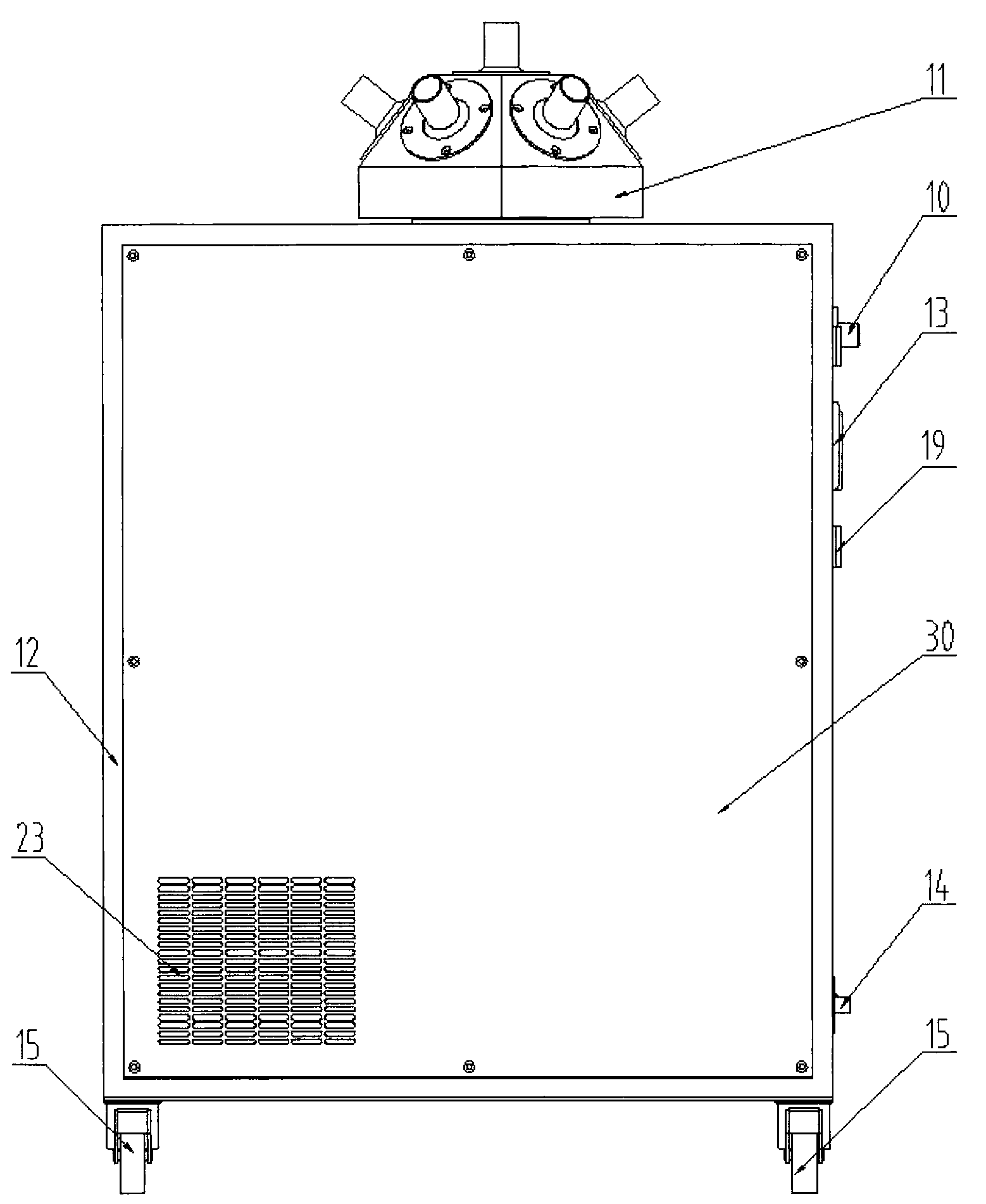

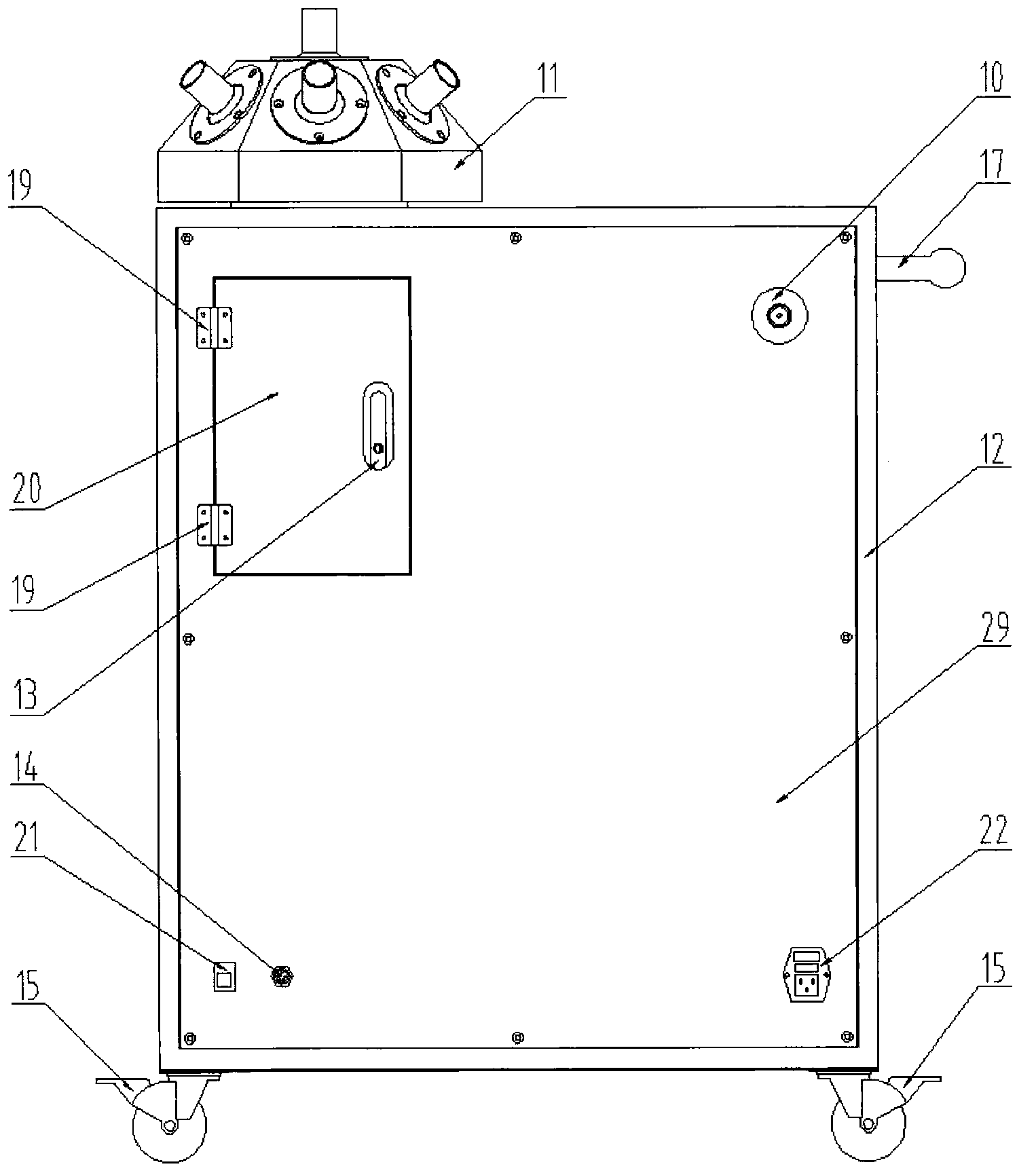

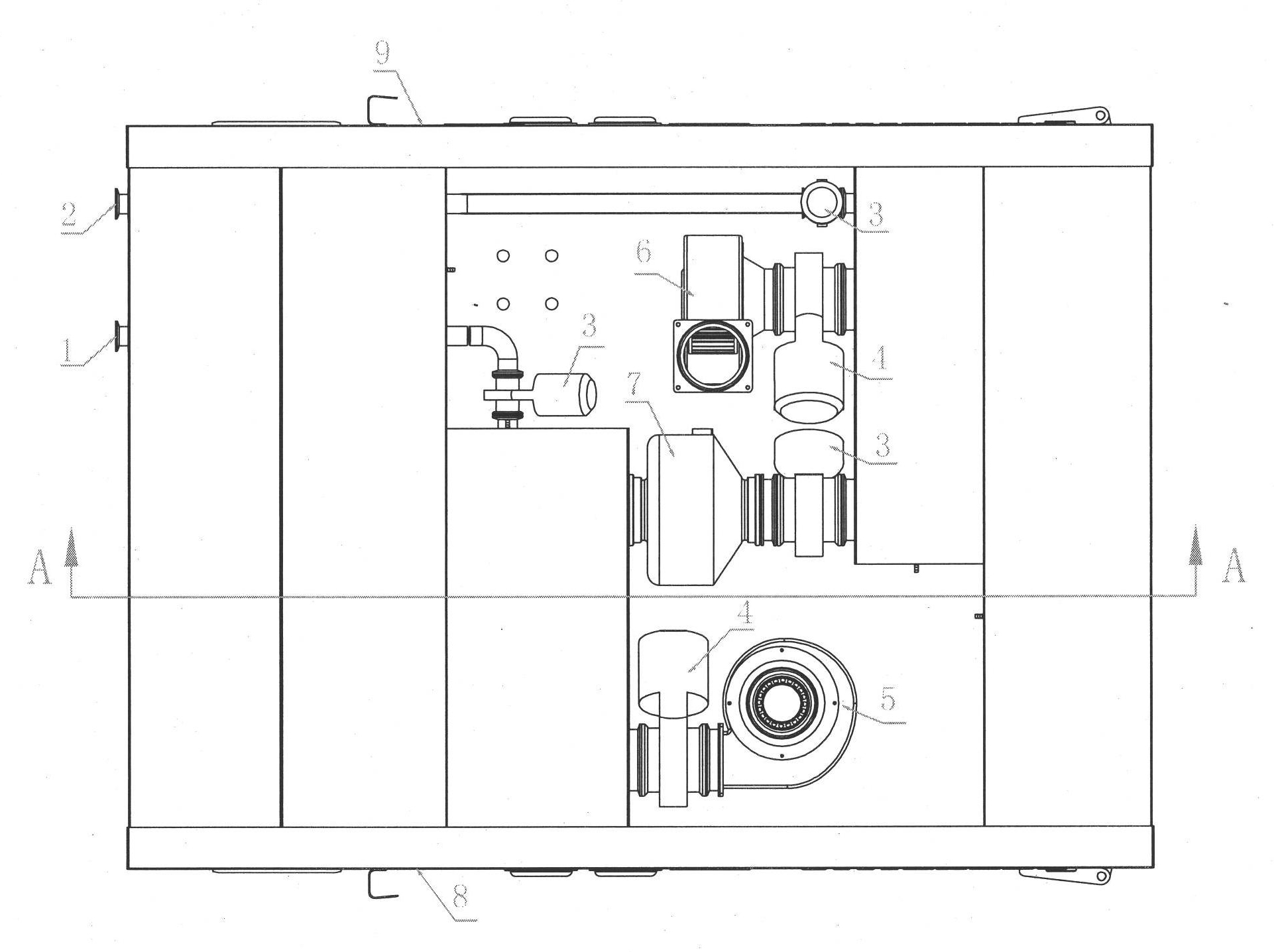

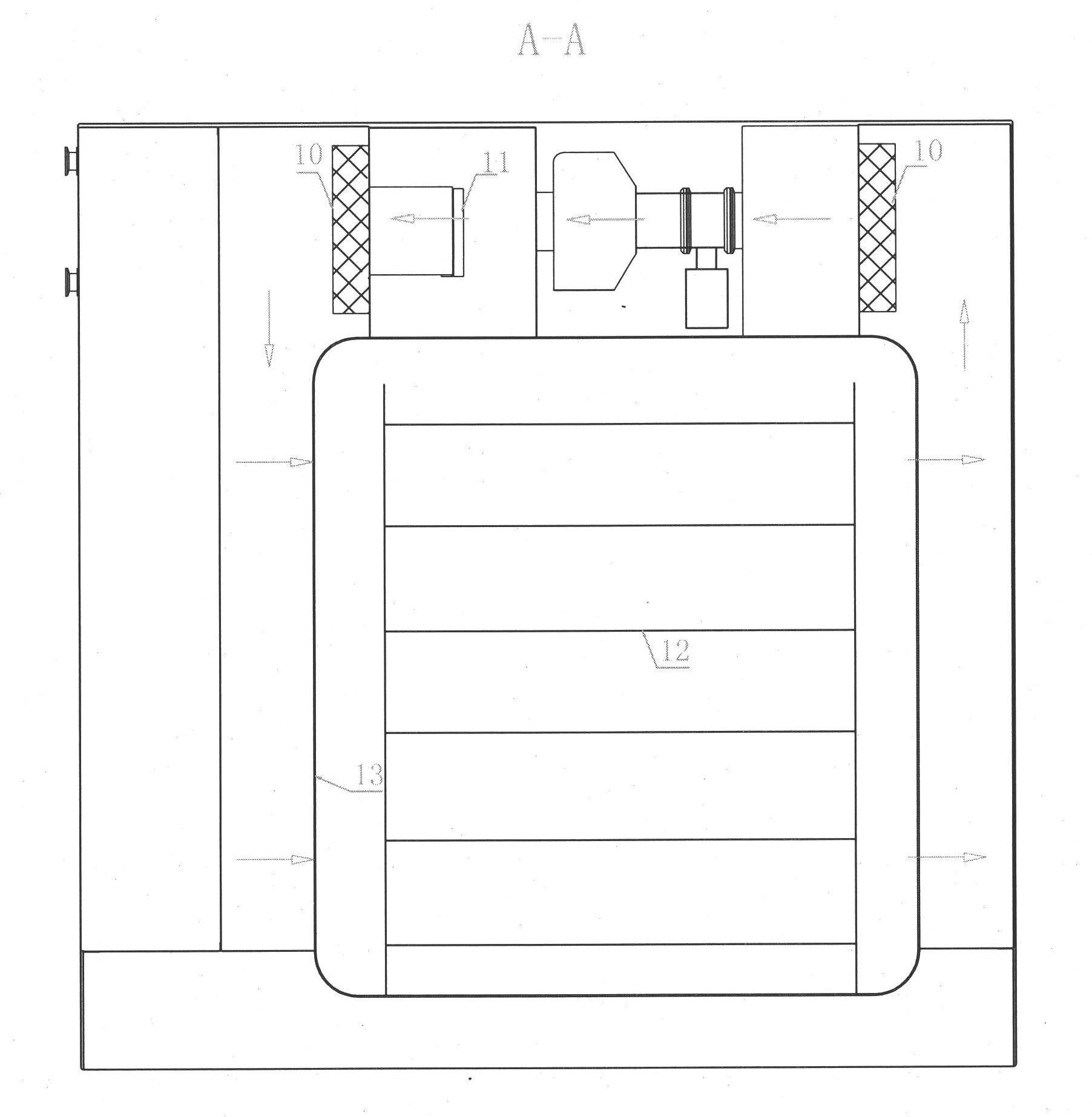

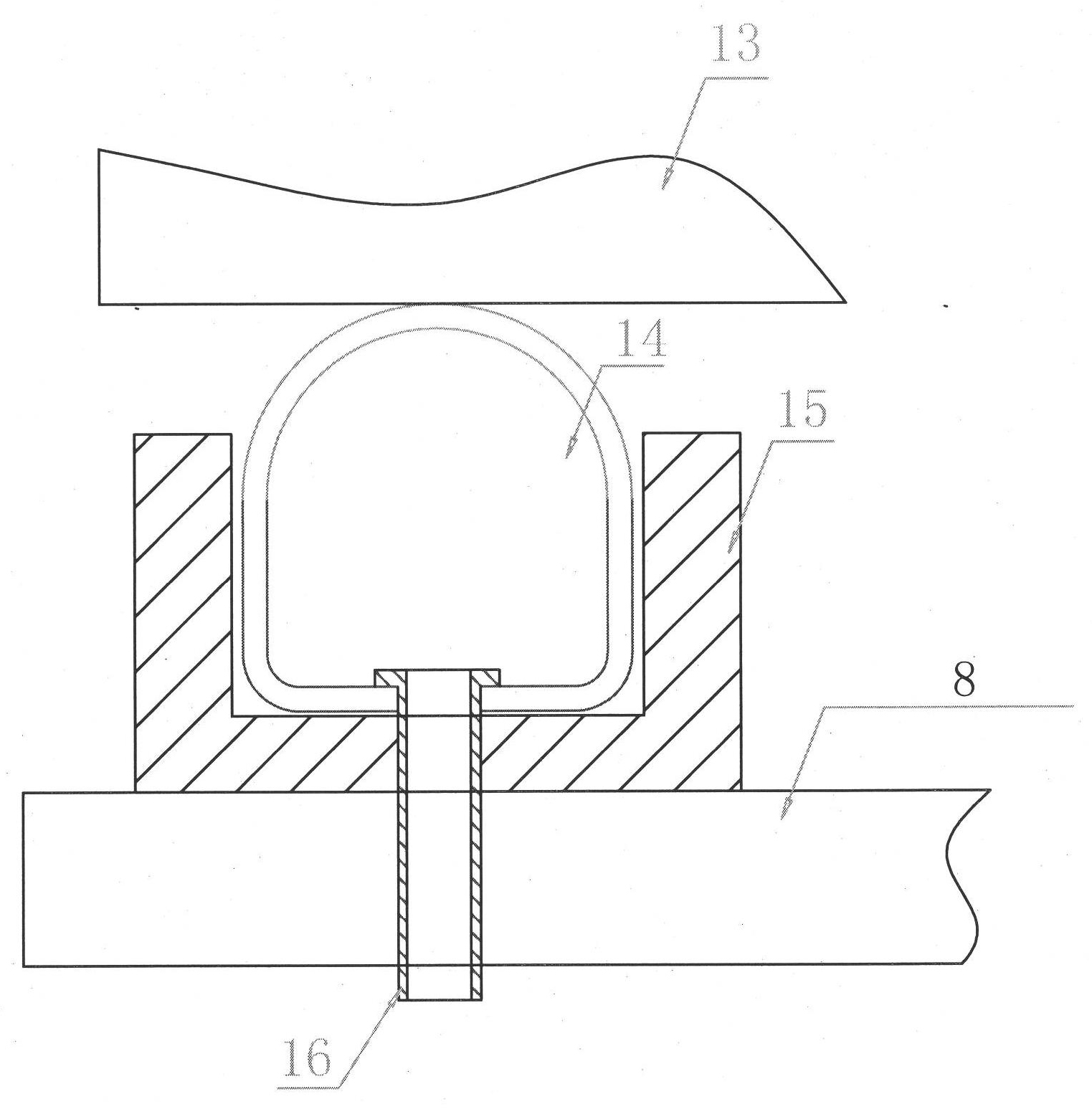

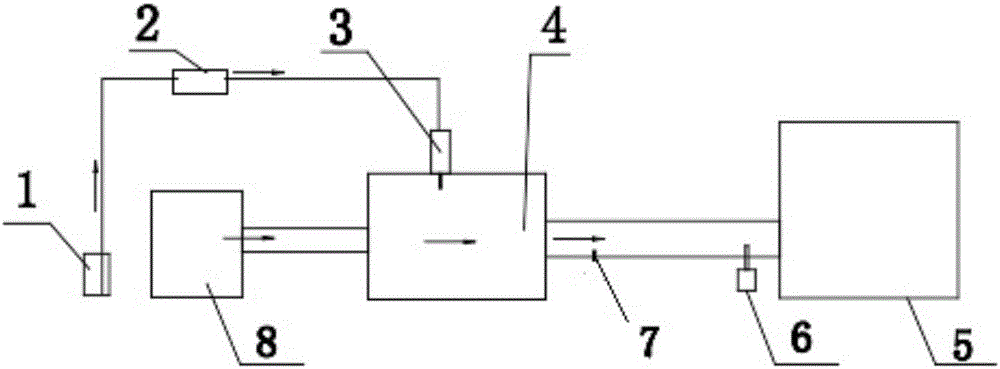

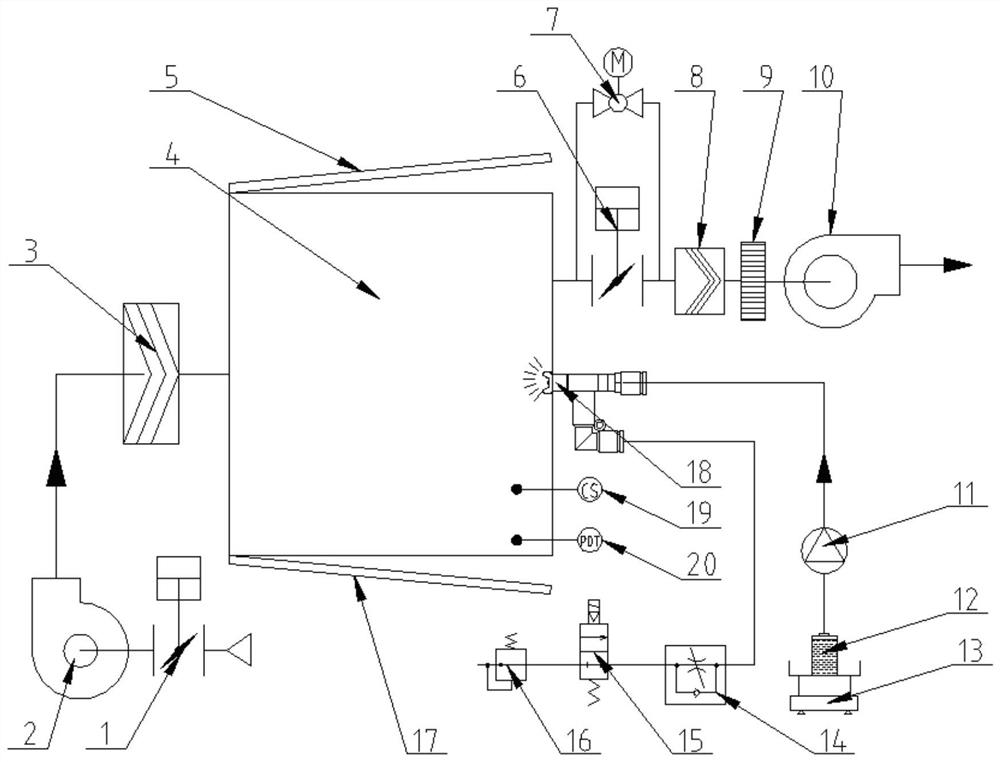

Movable type room vaporization hydrogen peroxide sterilization system

ActiveCN103263682AProtectFlexible moving processGaseous substancesChemicalsDecompositionControl manner

The invention provides a movable type room vaporization hydrogen peroxide sterilization system. The movable type room vaporization hydrogen peroxide sterilization system is characterized by comprising a generator, wherein the generator comprises an outer housing; the outer housing is provided with an air outlet and an air inlet; the inner part of the outer housing is partitioned into two parts through an partition board; the first part is communicated with the air outlet; the second part is communicated with the air inlet; the first part is internally provided with a high-efficiency filter; the second part is internally provided with a catakytic decomposition filter, an evaporator and a circulating fan; the circulating fan is connected with a fan discharge pipe; an outlet of the fan discharge pipe is connected with the high-efficiency filter; the evaporator is connected with one end of a hydrogen peroxide suction pipe; and the other end of the hydrogen peroxide suction pipe is arranged inside a hydrogen peroxide placing barrel. By using a dual-cycle control manner, the whole sterilization process can be monitored, the movement is flexible, the operation is reasonable and simple, the running is reliable and low in cost, the sterilization speed is high, and broad-spectrum sterilization can be realized, so that the sterilization ability and efficiency are greatly improved, and people and the environment are protected.

Owner:上海东富龙爱瑞思科技有限公司 +1

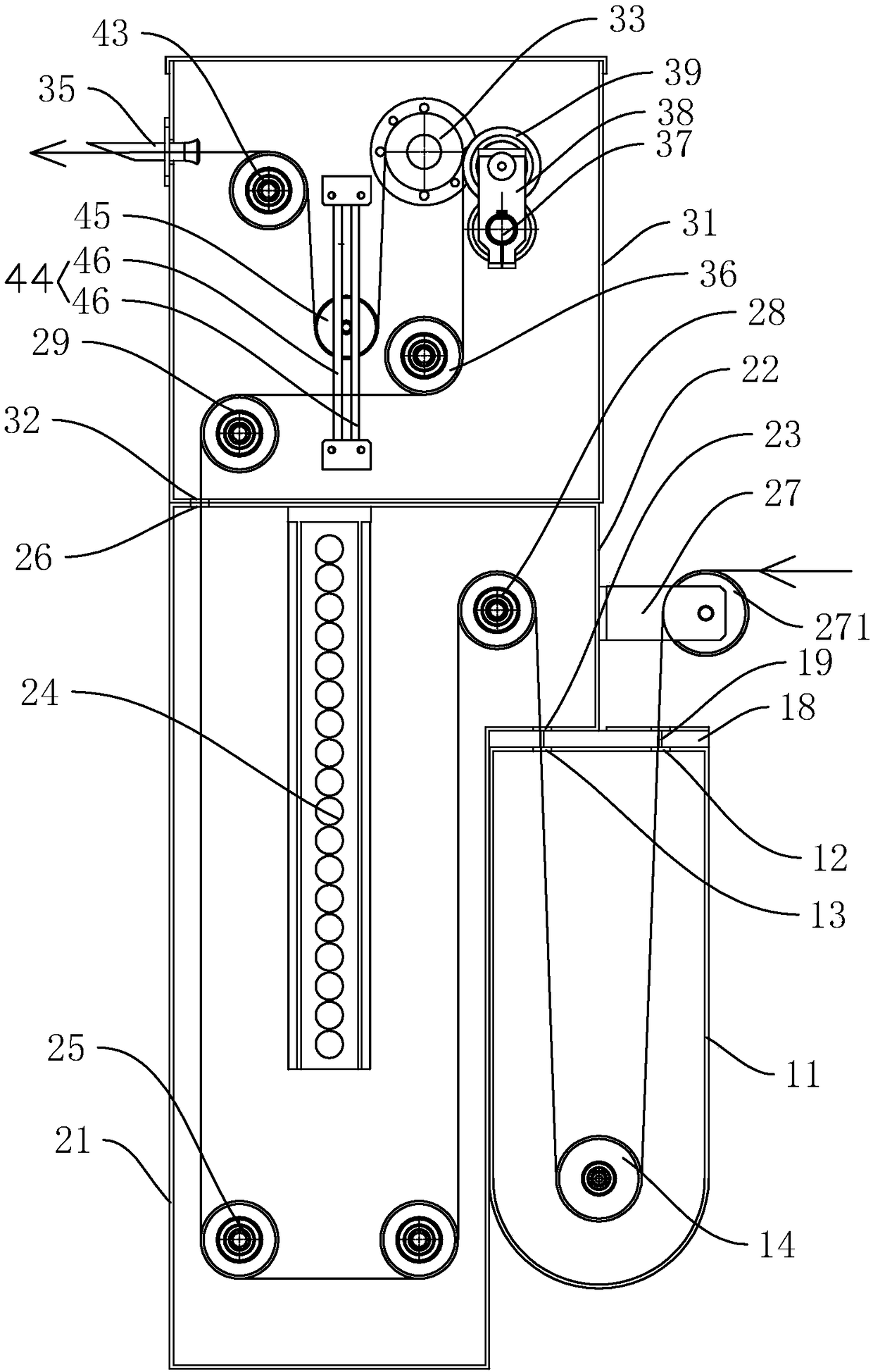

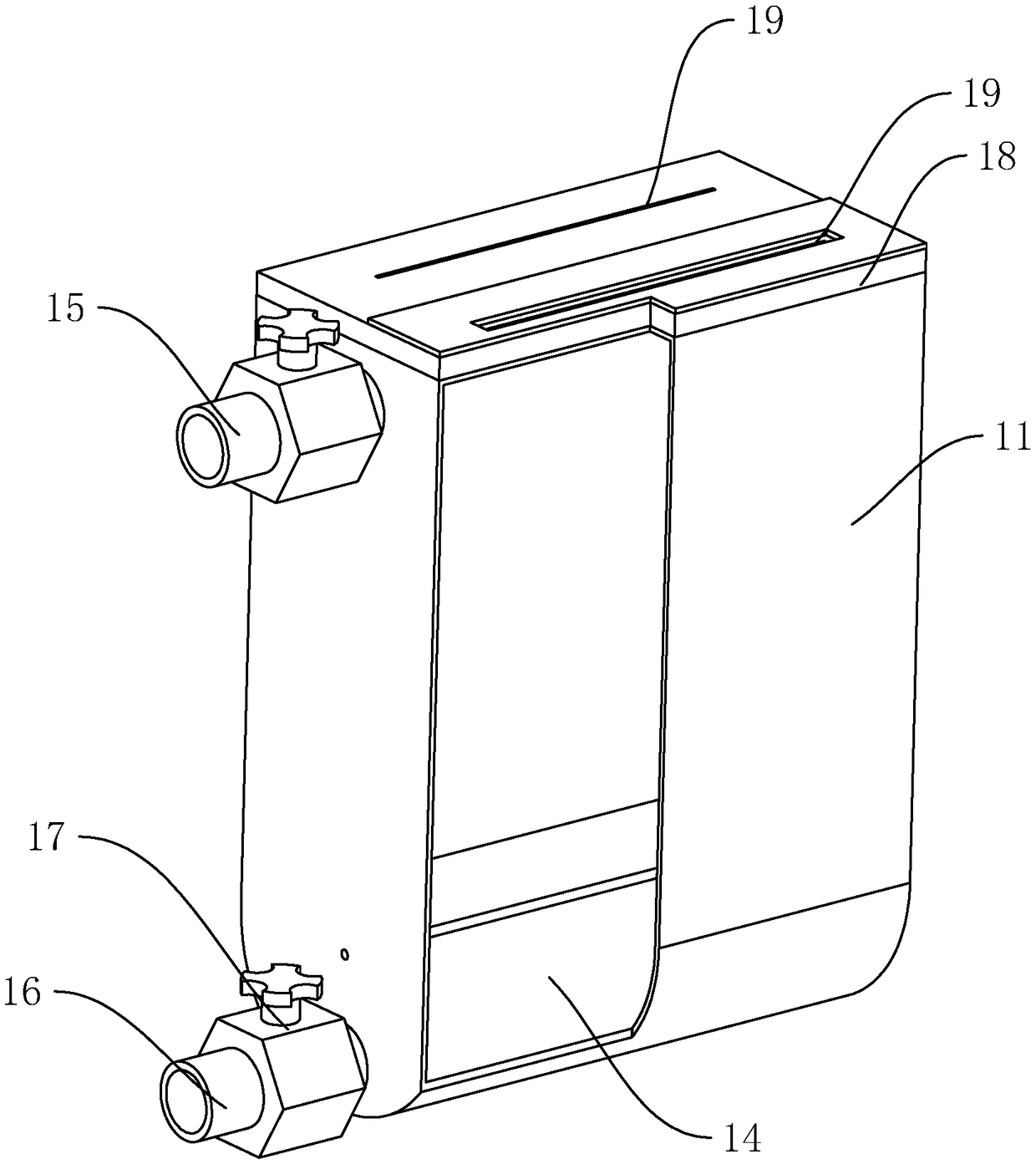

Vacuum type transmission device for vaporization hydrogen peroxide sterilization

ActiveCN103110970ANo dead angle for sterilizationImprove distributionChemicalsVaporizationVacuum chamber

The invention discloses a vacuum type transmission device for vaporization hydrogen peroxide sterilization. The output end of a vaporization hydrogen peroxide device is communicated with a vacuum cavity body; a sealing device is used for sealing a cabin door in the vacuum bin body; a first high vacuum generator and a second high vacuum generator respectively ensure that the vacuum bin body is positioned at two vacuum degree states; the first high vacuum generator also has a function of exhausting vaporization hydrogen peroxide in the vacuum bin body; the output end of an evacuation device is communicated with the vacuum bin body; and a parameter monitoring device is used for monitoring vaporization hydrogen peroxide concentration, temperature, humidity and vacuum degree in the vacuum bin body. The transmission device is short in sterilization period and high in security, and the toxicity, the pollution and the damage to equipment are avoided.

Owner:ZHEJIANG TAILIN BIOENG

A transfer chamber with hydrogen peroxide biodecontamination function

The invention discloses a transferring cabin with a peroxide biological decontamination function, which consists of a transferring cabin body, a ventilation system, a sterilization circular air returning system, a positive temperature coefficient (PTC) auxiliary heating system, a filtering system, a pneumatic control system, an electric appliance control system, a peroxide generator, and the like, wherein the adequate sterilization of materials to be transferred in different clean areas can be guaranteed, and the problems of the bacteria cross infection caused by the halfway sterilization of materials during the transferring process among different clean areas can be fundamentally solved. In real application, the transferring cabin is particularly suitable for the product with the surface requiring low-temperature and high-temperature sterilization, and has the beneficial effects of no residue after the sterilization and no pollution.

Owner:ZHEJIANG TAILIN BIOENG

Filling equipment

The invention discloses filling equipment which comprises a rack and a conveying mechanism that is arranged on the rack and is used for conveying filling bottles. The filling equipment further comprises a hot air mechanism, a sterilization mechanism, a drying mechanism, a filling mechanism and a cap sealing mechanism that are arranged on the rack along the conveying direction of the conveying mechanism sequentially; the hot air mechanism is used for supplying hot air into the filling bottles; the sterilization mechanism is used for supplying atomization hydrogen peroxide into the filling bottles; the drying mechanism is used for carrying out hot air drying on the filling bottles; the filling mechanism is used for filling the filling bottles; and the cap sealing mechanism is used for carry out cap sealing on the filling bottles. Through an ionic air blowing mechanism, dust in the filling bottles is removed through blowing during electrostatic eliminating; through the combination of the atomization hydrogen peroxide sterilization mechanism and the drying mechanism, hydrogen peroxide after sterilization can be decomposed into water and oxygen more quickly, the residue of hydrogen peroxide in the filling bottles is reduced, and the quality of filling liquid is prevented from being affected; atomization hydrogen peroxide has fast bactericidal effect and consumes short time, so that the profile of the filling equipment is smaller than the traditional machine type during equipment manufacture, and the maintenance of the filling equipment is facilitated better.

Owner:JIANGSU NEWAMSTAR LIQUID PACKAGING ENG TECH RES CENT CO LTD

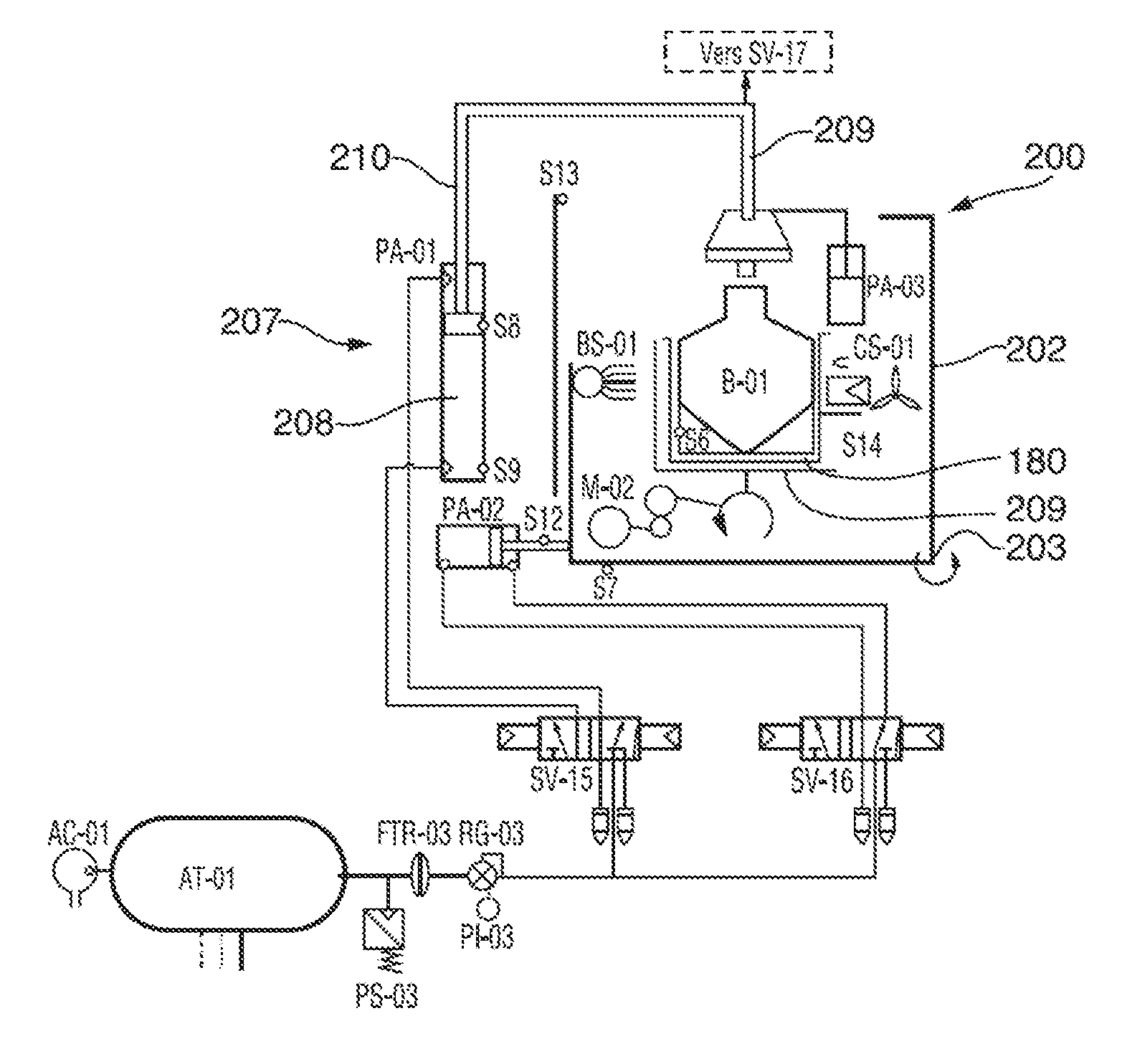

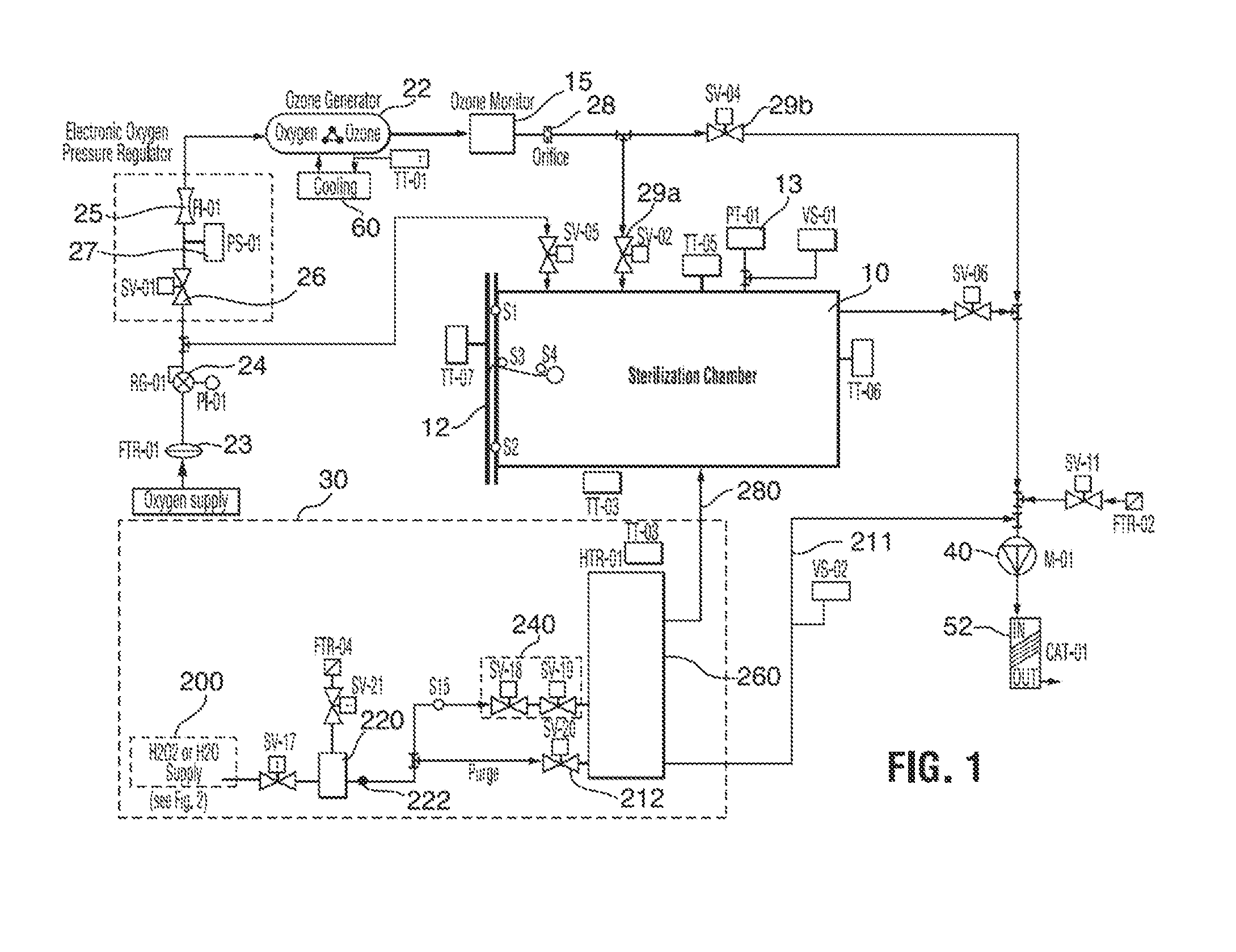

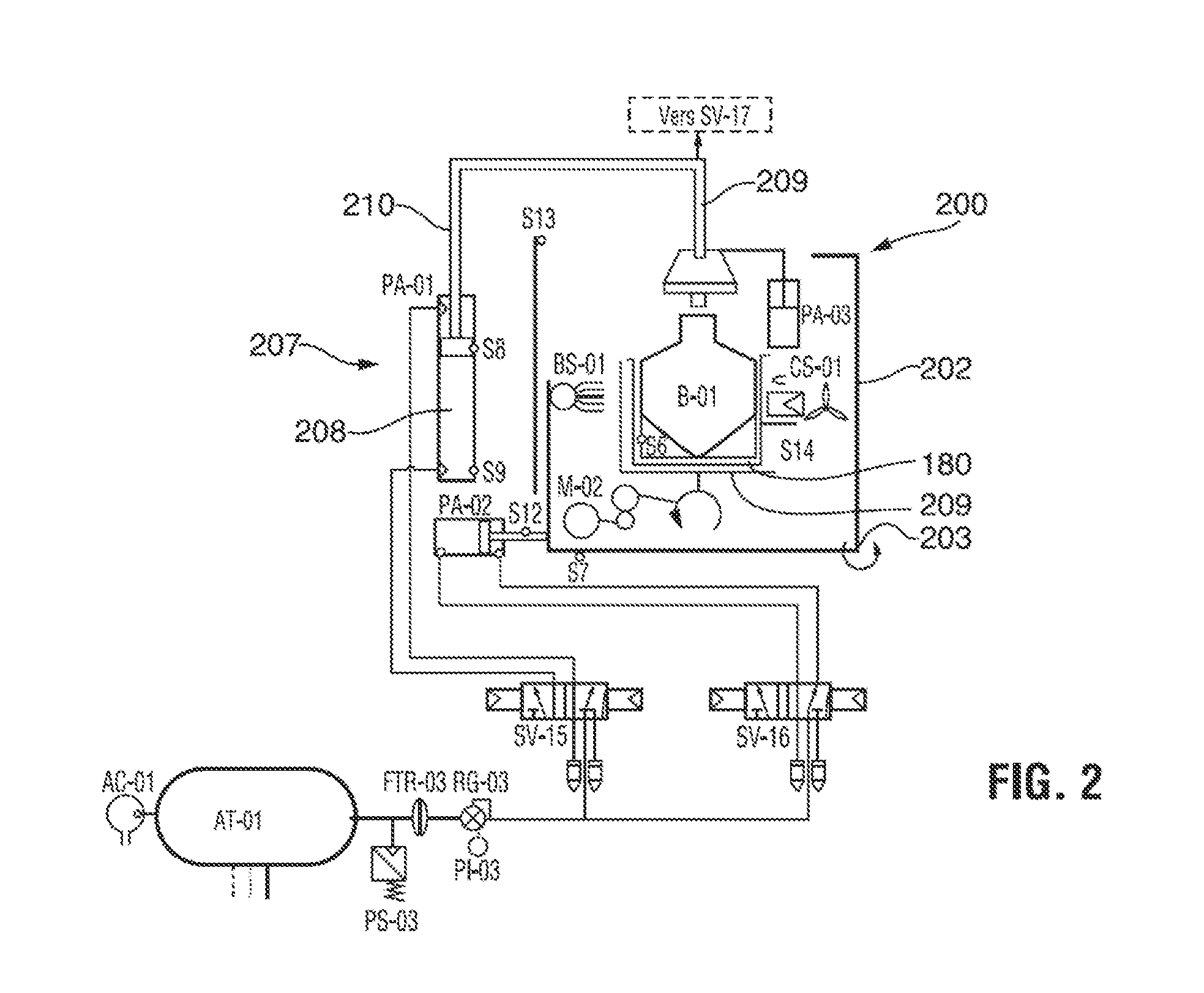

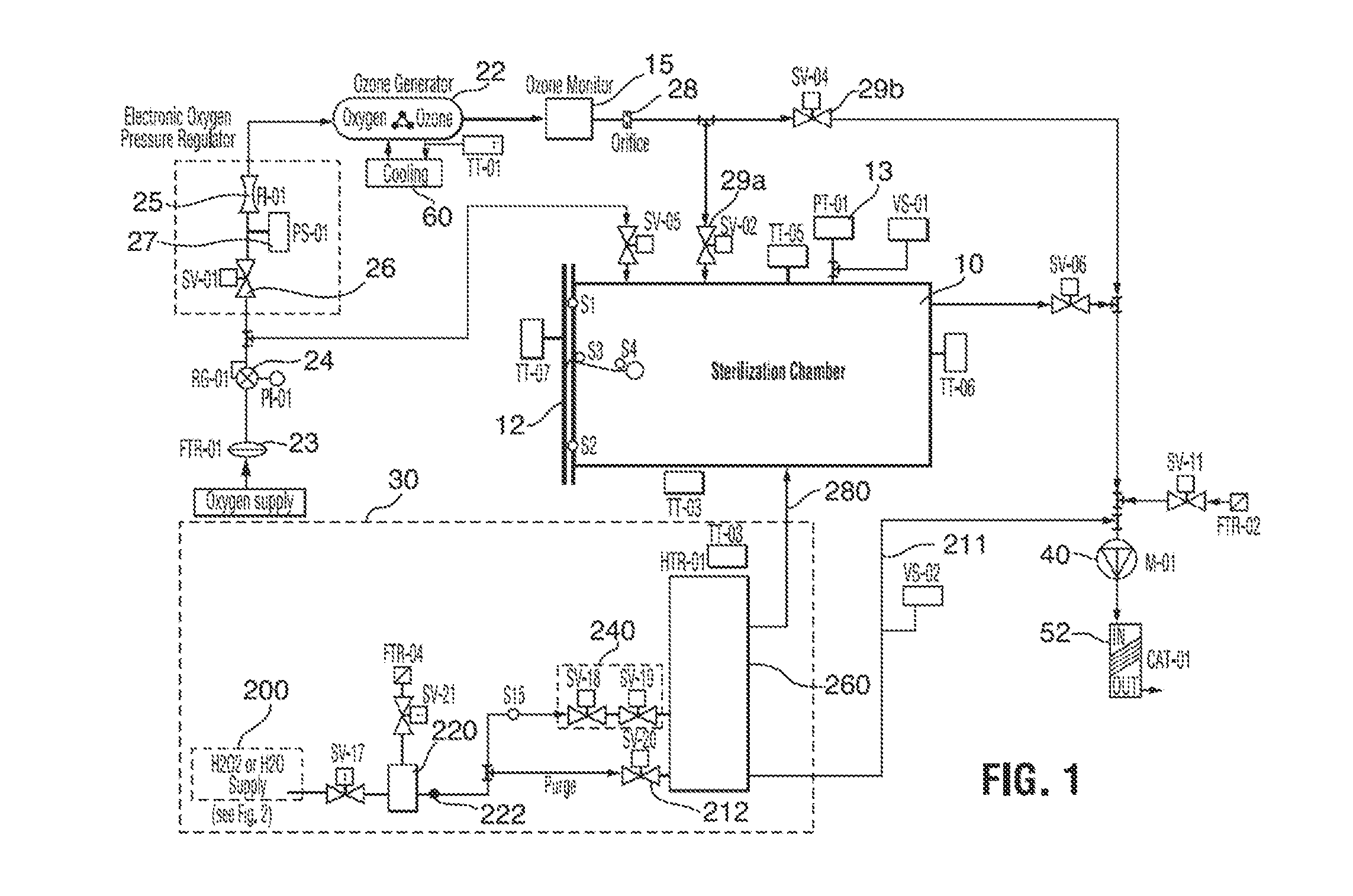

Method and device for hydrogen peroxide sterilization

ActiveUS20160235877A1Accelerate the circulation of gasReduce usageChemicalsProcess engineeringEngineering

The invention relates to the sterilization of a load of goods with hydrogen peroxide vapor in a closed space. The method involves a sequence of creating a sub-atmospheric pressure in a sterilization chamber, introduction of vaporized hydrogen peroxide and the use of a gas circulation device within the sterilization chamber, whereby the output of the gas circulation device is controlled according to the pressure in the sterilization chamber. A uniform and consistent distribution of hydrogen peroxide throughout the load is achieved.

Owner:STERIS EURO INC SUOMEN SIVULIIKE

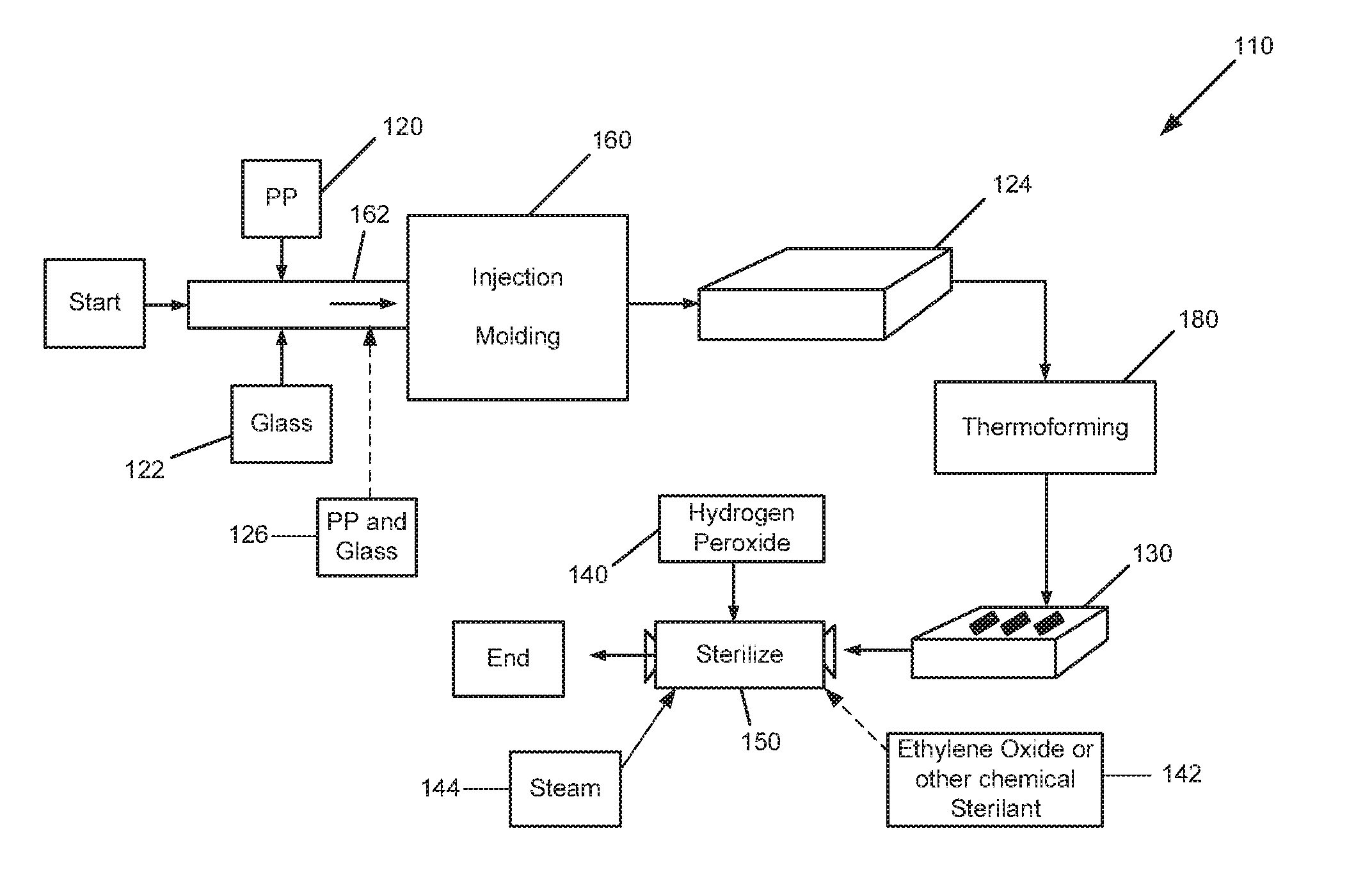

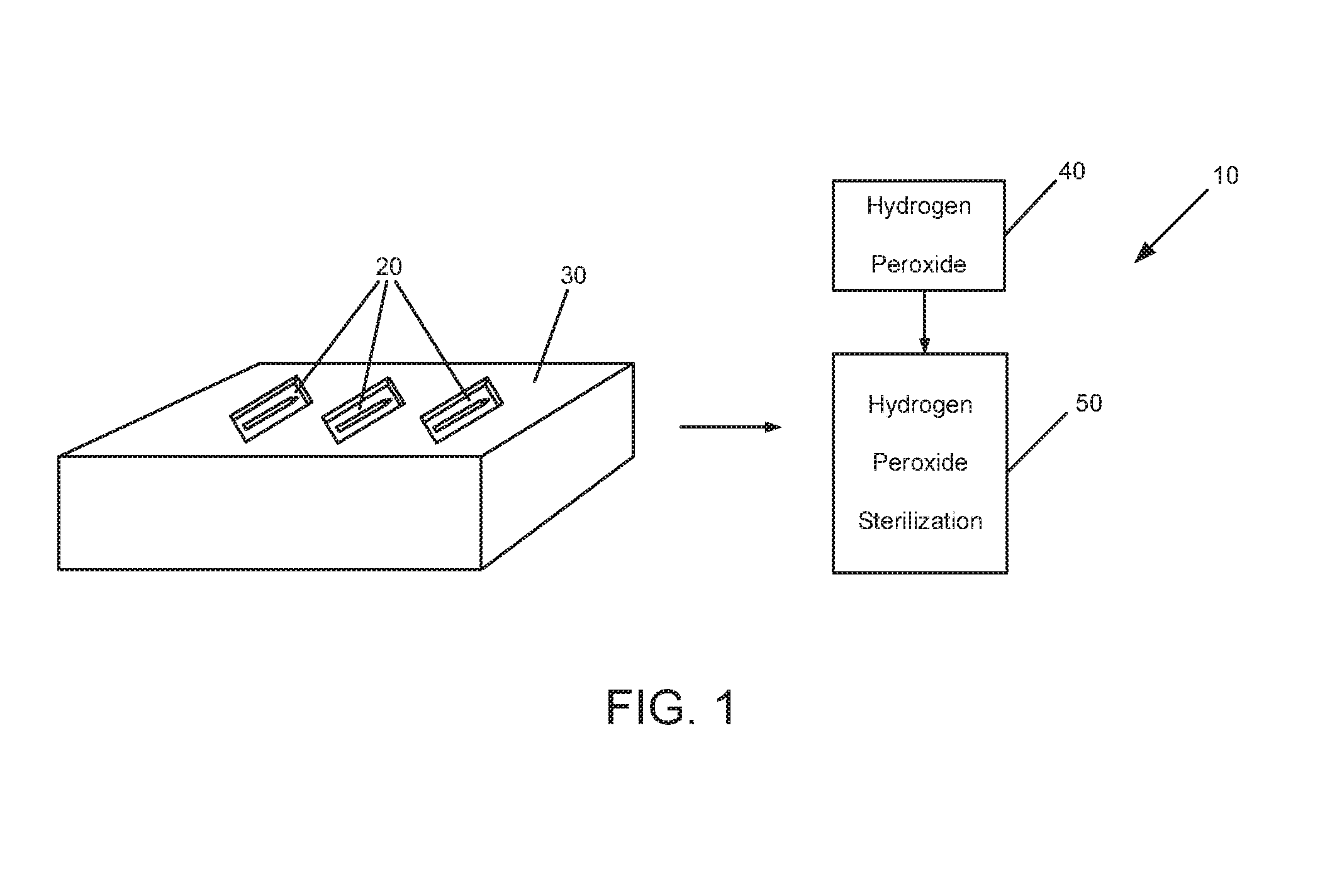

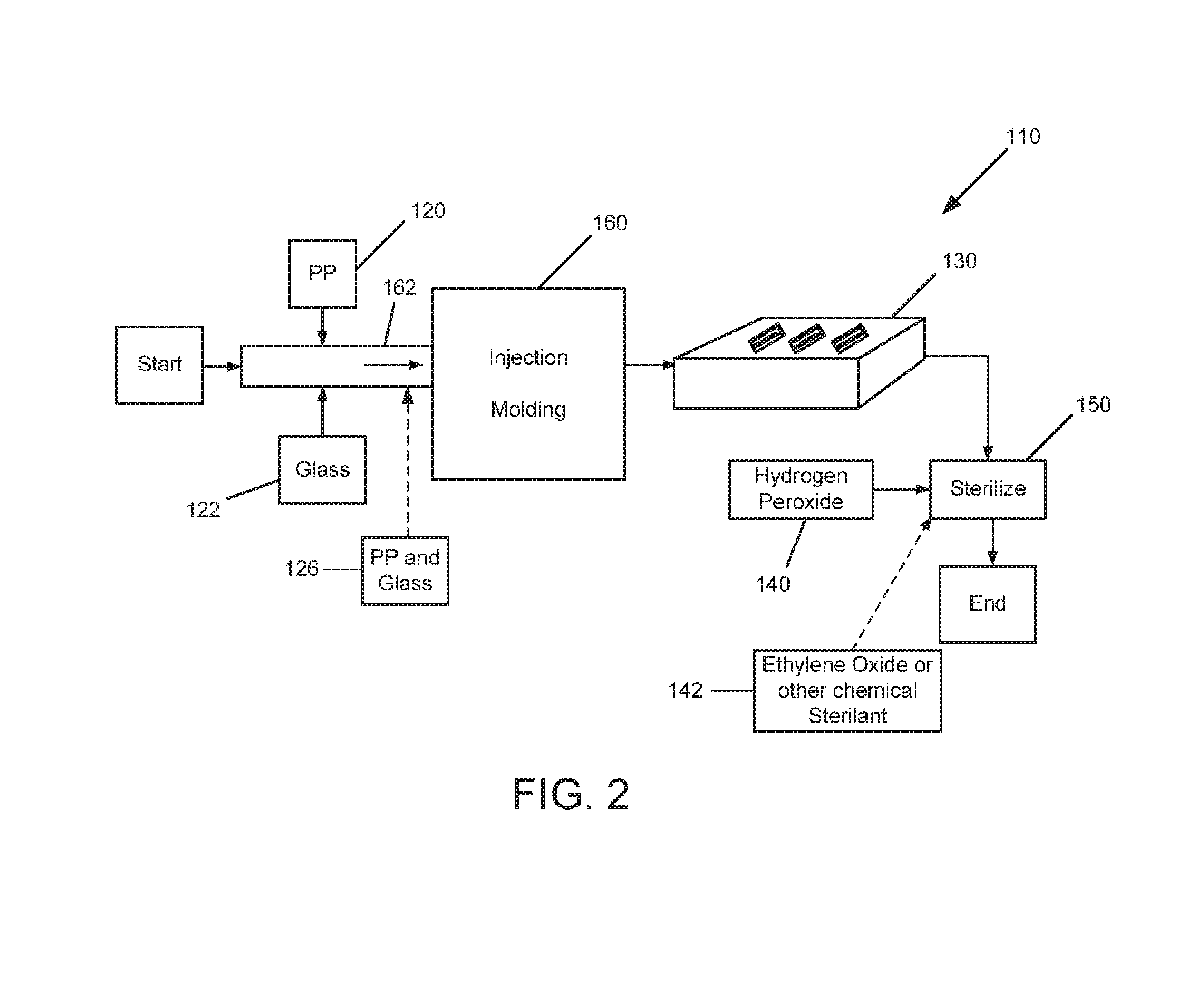

System and Method for Sterilization of Medical Instruments within a Hydrogen Peroxide Sterilization Process

A system and method of sterilization for medical instruments within a hydrogen peroxide sterilization process is provided. A medical instrument is housed in a sterilization tray, wherein the sterilization tray is formed from polypropylene and a glass material. The medical instrument and sterilization tray are subjected to a hydrogen peroxide sterilant.

Owner:SYMMETRY MEDICAL MFG INC

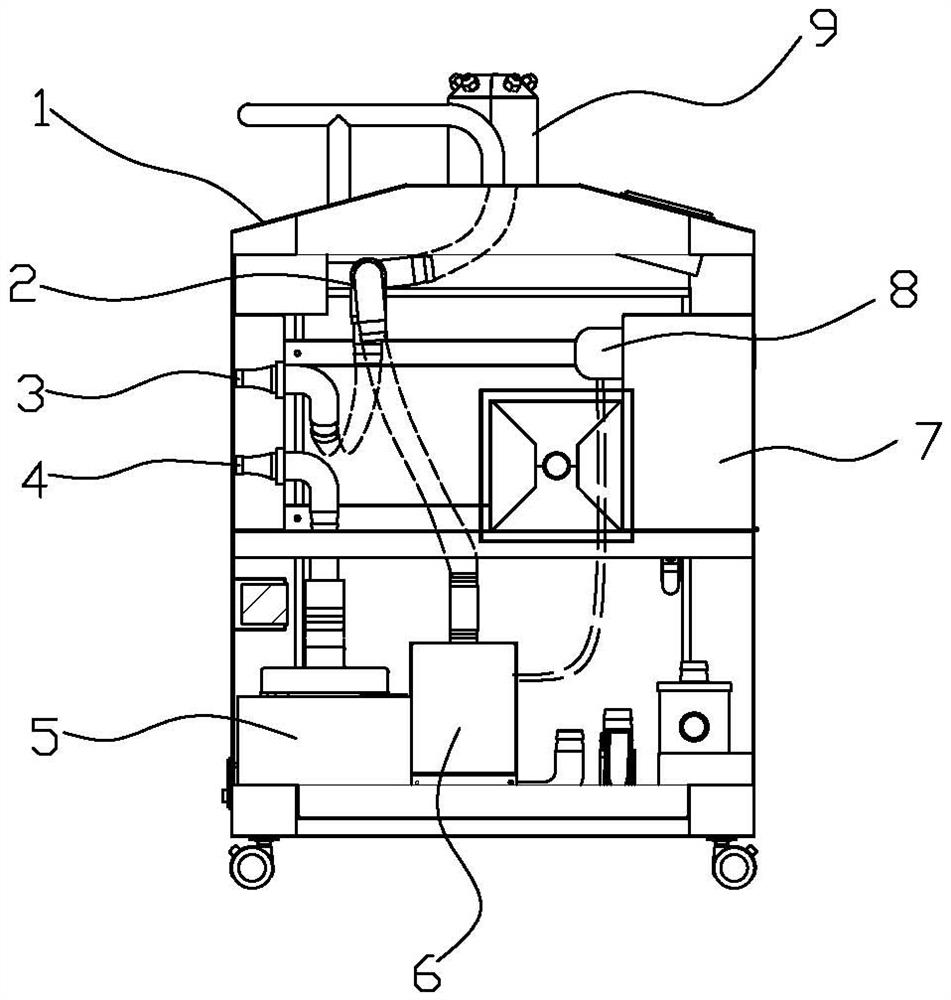

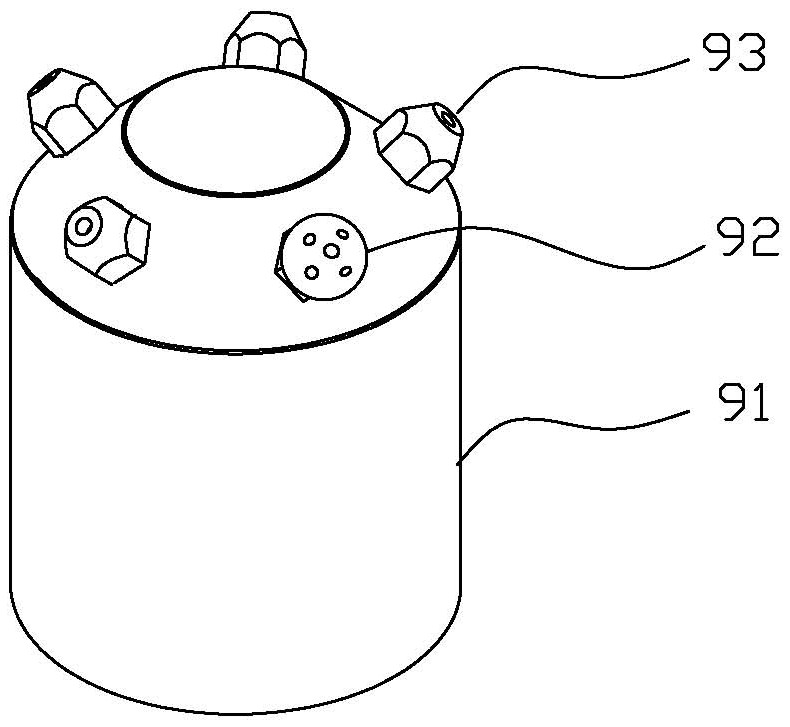

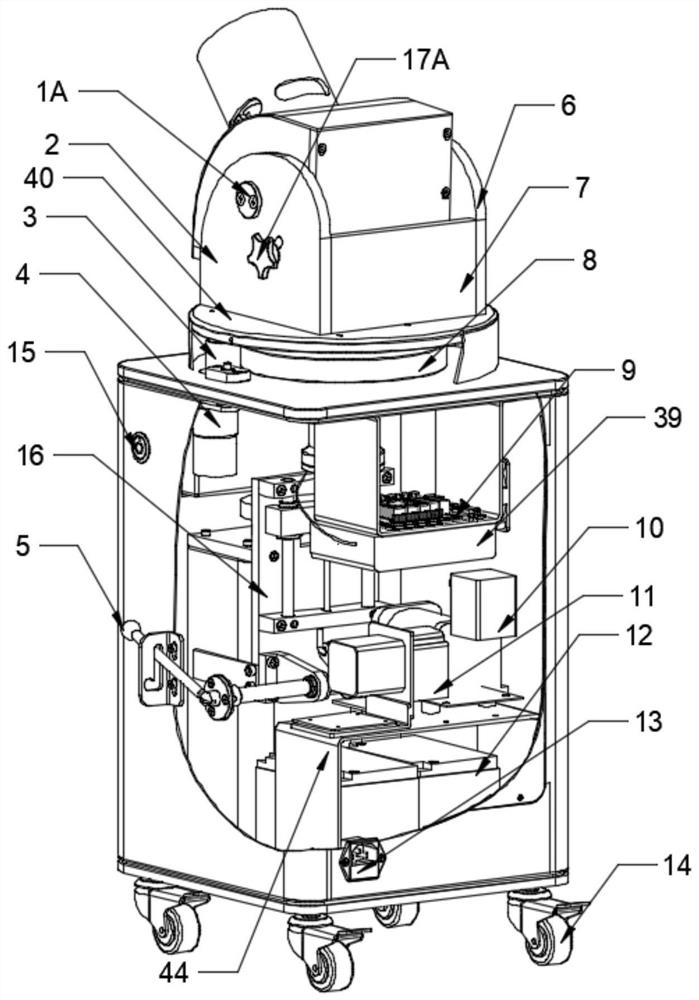

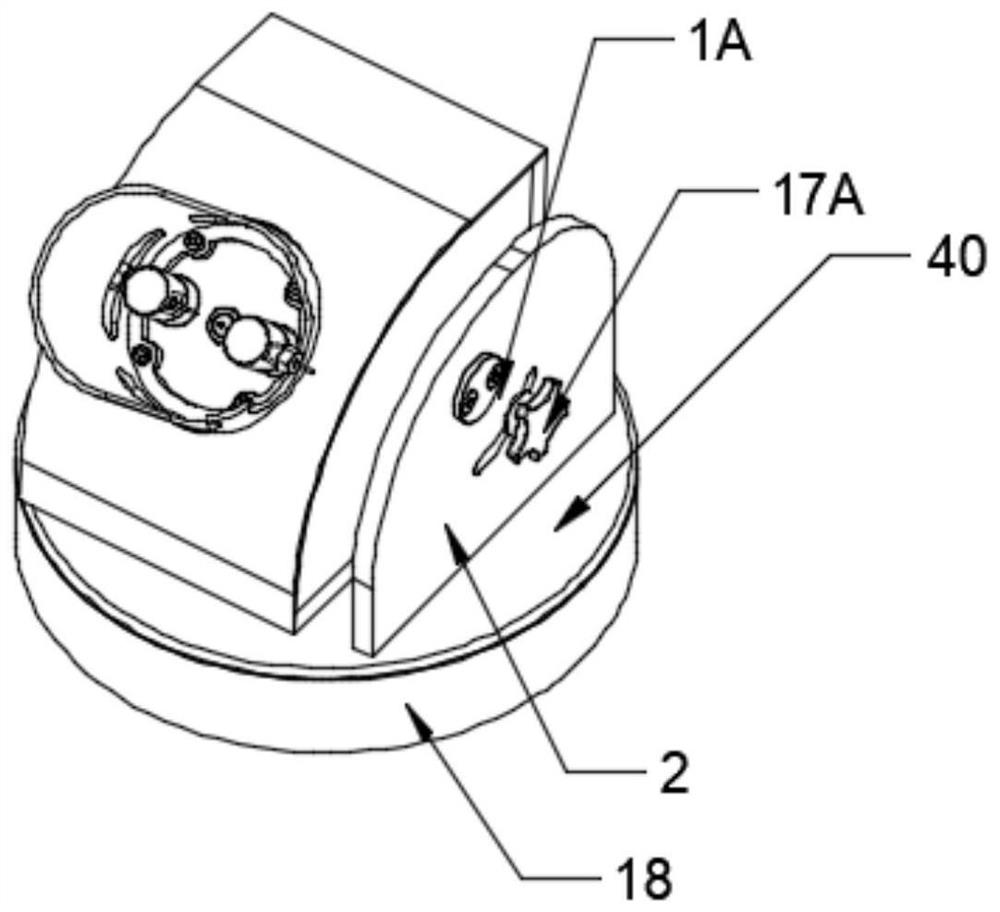

Vaporized hydrogen peroxide sterilizer

PendingCN111249501AImprove sterilization efficiencyAid in diffusionLavatory sanitoryChemicalsElectric machineryEngineering

The invention relates to the technical field of medical disinfection and sterilization, and in particular to a vaporized hydrogen peroxide sterilizer. The sterilizer comprises a shell, wherein an upper end of the shell is rotatably connected with a rotating diffuser head, inside of the shell is provided with a hydrogen peroxide storage tank, a liquid level sensor, a liquid pump, a mixing tank, a fan, a vacuum pump, a battery, and an electric heating tube, and a dual-axis motor is provided in the rotating diffuser head; one side wall of the shell is fixedly connected with a singlechip control panel, the singlechip control panel is provided with a display screen, the other side wall of the shell is provided with a maintenance port, and the upper end of the maintenance port is hinged with a cover plate. The sterilizer has compact structure and low cost, is convenient to carry and is suitable for popularization and use.

Owner:JIANGSU INST OF NUCLEAR MEDICINE +1

Hydrogen peroxide sterilization detection indicator card and preparation method thereof

InactiveCN111220603AMaterial analysis by observing effect on chemical indicatorLavatory sanitoryBiochemical engineeringProcess engineering

The invention provides a hydrogen peroxide sterilization detection indicator card and a preparation method thereof. The indicator card comprises a detection card body, the detection card body comprises a condition judgment area and a sterilization detection area, the condition judgment area is coated with color lump ink, and the sterilization detection area is provided with a biological indicator.The manufacturing method comprises the steps of preparing the color lump ink, preparing the biological indicator and arranging the color lump ink and the biological indicator on the detection card body.

Owner:SUZHOU LOSH BIOTECH CO LTD

A method for improving the quality of aquaculture products

ActiveCN103651194BResidue reductionMeet the health standards for consumptionClimate change adaptationPisciculture and aquariaWater dischargeHazardous substance

The invention discloses a method for improving the quality of aquaculture products, and relates to the technical field of aquaculture. The method particularly includes the steps of placing aquatic product living bodies in a circulating water aquaculture system for aquaculture; filtering water discharged form an aquaculture pond with a solid-liquid separator, wherein the hole diameter of a filtering net ranges from 20 micrometers to 100 micrometers; enabling filtered clean water to enter a microorganism biochemical water processing system; conducting peroxidation processing on clean water after biochemical water processing in a hydrogen peroxide-ozone oxidation pond; conducting ultraviolet sterilization processing in an ultraviolet sterilizer on clean water after the hydrogen peroxide-ozone oxidation processing , enabling the clean water to return to the aquaculture pond, and achieving cyclic utilization of aquaculture water. The method is easy and convenient to operate, 2-methylisoborneol, dimethyl naphthalene alcohol and generated microorganism sources of the 2-methylisoborneol and the dimethyl naphthalene alcohol which cause peculiar smells such as the earthy smell are directly or indirectly eliminated under the synergistic effect of ozone, the ultraviolet technology and the hydrogen peroxide sterilization technology, residues of hazardous substances such as a plurality of kinds of heavy metal and pesticides are remarkably reduced, ad the quality and the value of the products are improved.

Owner:SUZHOU FISHSEEDS BIOLOGICAL TECH CO LTD

VHP plasma aerosol generation method and device

InactiveCN105879801AStable stateImprove sterilization efficiencyDeodrantsColloidal chemistry detailsLiquid hydrogenHydrogen Peroxide Sterilization

The invention provides a VHP plasma aerosol generation method. The method comprises the steps that liquid hydrogen peroxide is processed by a VHP vaporizer to form VHP particles; the VHP particles is processed through an electric field to form VHP+ and VHP- ions; the VHP+ and VHP- ions and the VHP particles are mixed to form a VHP+ and VHP- plasma; an aerosol stabilizer is added into the VHP+ and VHP- plasma to form VHP plasma aerosol. The invention further provides a VHP plasma aerosol generation device. The obtained VHP plasma aerosol is stable in status, high in sterilization efficiency and not prone to sedimentation, does not corrode an instrument, and overcomes the defects that in the prior art, the hydrogen peroxide sterilization efficiency is low, the hydrogen peroxide residual quantity is large, and hydrogen peroxide is likely to be sedimented on the surface, and an instrument is corroded.

Owner:SUZHOU INDAL PARK HJCLEAN TECH

Hydrogen peroxide sterilization device for space sterilization and equipment sterilization and control method thereof

InactiveCN113476633AChange delivery rateChange concentrationMechanical apparatusLighting and heating apparatusPeristaltic pumpProcess engineering

The invention relates to a hydrogen peroxide sterilization device for space sterilization and equipment sterilization and a control method thereof. The hydrogen peroxide sterilization device comprises a shell, a dehumidification heating module, a fan assembly, a valve and a peristaltic pump; the dehumidification heating module comprises a shell, and a heating block is arranged in the shell; the valve is provided with a plurality of ports; the shell is provided with an inlet and an outlet; the inlet is communicated with the air outlet of the fan assembly; the outlet is communicated with a first port of the valve; the peristaltic pump is respectively communicated with a hydrogen peroxide storage device and the dehumidification heating module through pipelines; the shell is provided with at least one outlet quick coupler and at least one inlet quick coupler; the outlet quick coupler and the inlet quick coupler are respectively communicated with a second port of the valve and an air inlet of the fan assembly; at least one diffusion nozzle is arranged on the shell; and the diffusion nozzle is communicated with a third port of the valve. According to the invention, the sterilization modes can be switched, and the requirements of space sterilization and equipment sterilization are met.

Owner:MAYAIR TECH (CHINA) CO LTD

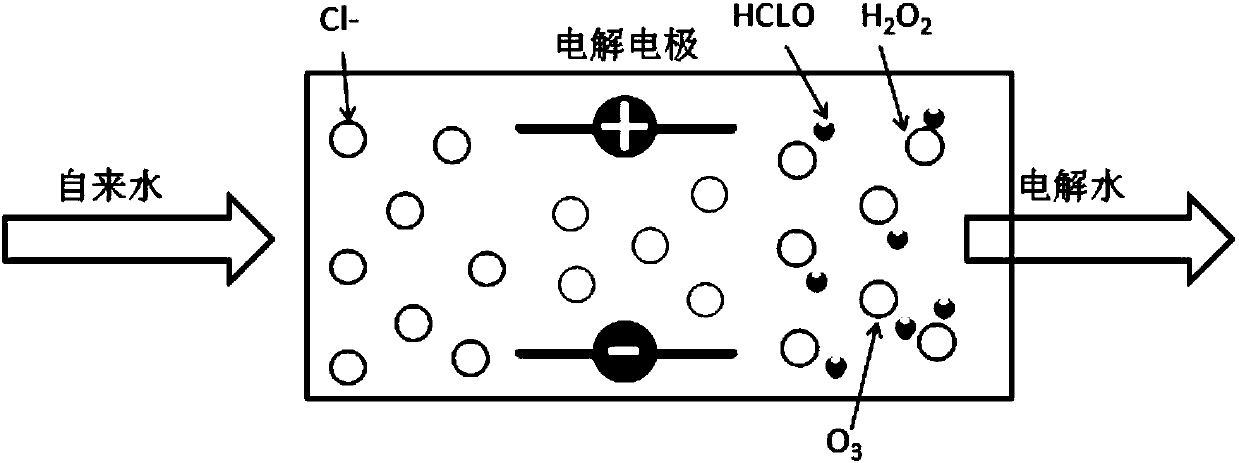

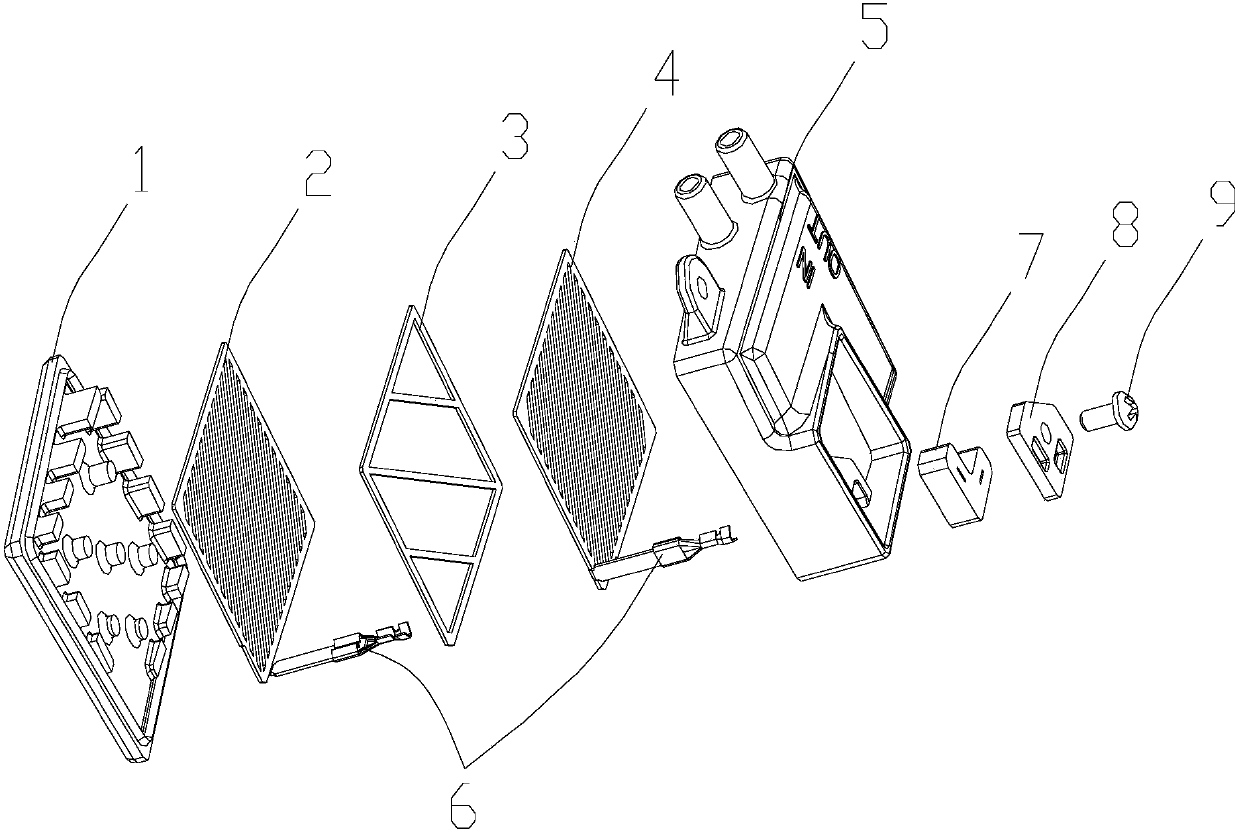

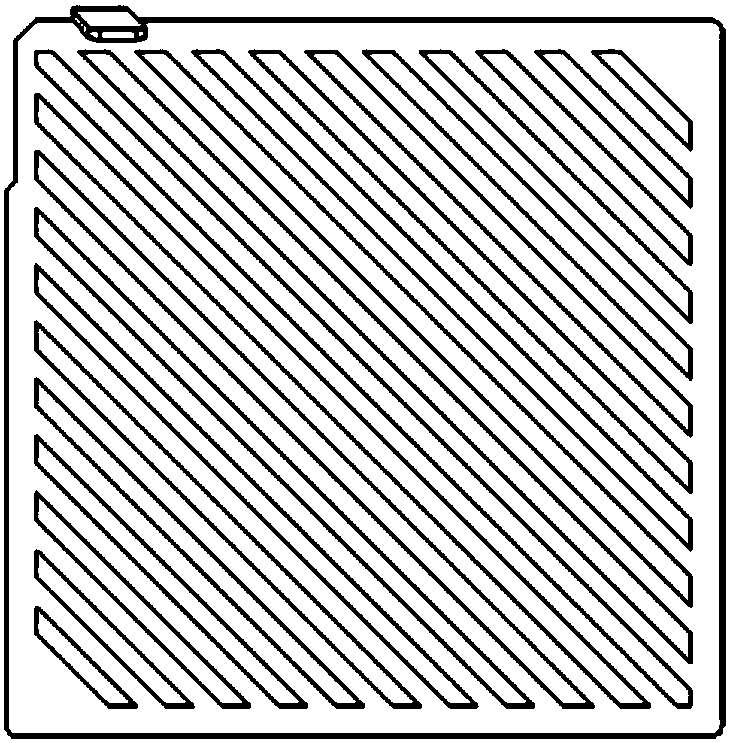

Electrolyzed water sterilization device and sterilization method

PendingCN106698602AAchieve bactericidal effectImprove design reliabilitySpecific water treatment objectivesWater/sewage treatmentWater qualityChloride

The invention provides an electrolyzed water sterilization device, which comprises a shell, wherein an upper electrode and a lower electrode are arranged in the shell; an electrode isolating plate used for isolating a cathode and an anode of the electrodes and keeping a distance between the electrodes is arranged between the upper electrode and the lower electrode. After the device is electrified, the upper electrode and the lower electrode decompose a water molecule into an hydrogen ion (H+) and an oxygen ion (O-), the oxygen ion used as a negative ion is reacted with other peripheral water molecules to generate hydroxide radical (OH-), at the time, a small amount of sodium hypochlorite (HOCL) containing microamount chloride components existed in tap water is also decomposed into HCL+ and O-, and dissolved oxygen (O-, O3-) negative ions and hydrogen peroxide sterilization substances are produced, so that water is sterilized. The electrolyzed water sterilization device provided by the invention is applied in titanium electrode electrolysis, can achieve a sterilization effect without influencing water quality. The device has high design reliability, a long life, a good sterilization effect, low cost, no need for adding a sterilizing agent, and no secondary pollution.

Owner:昆山泰瑞克智能科技有限公司

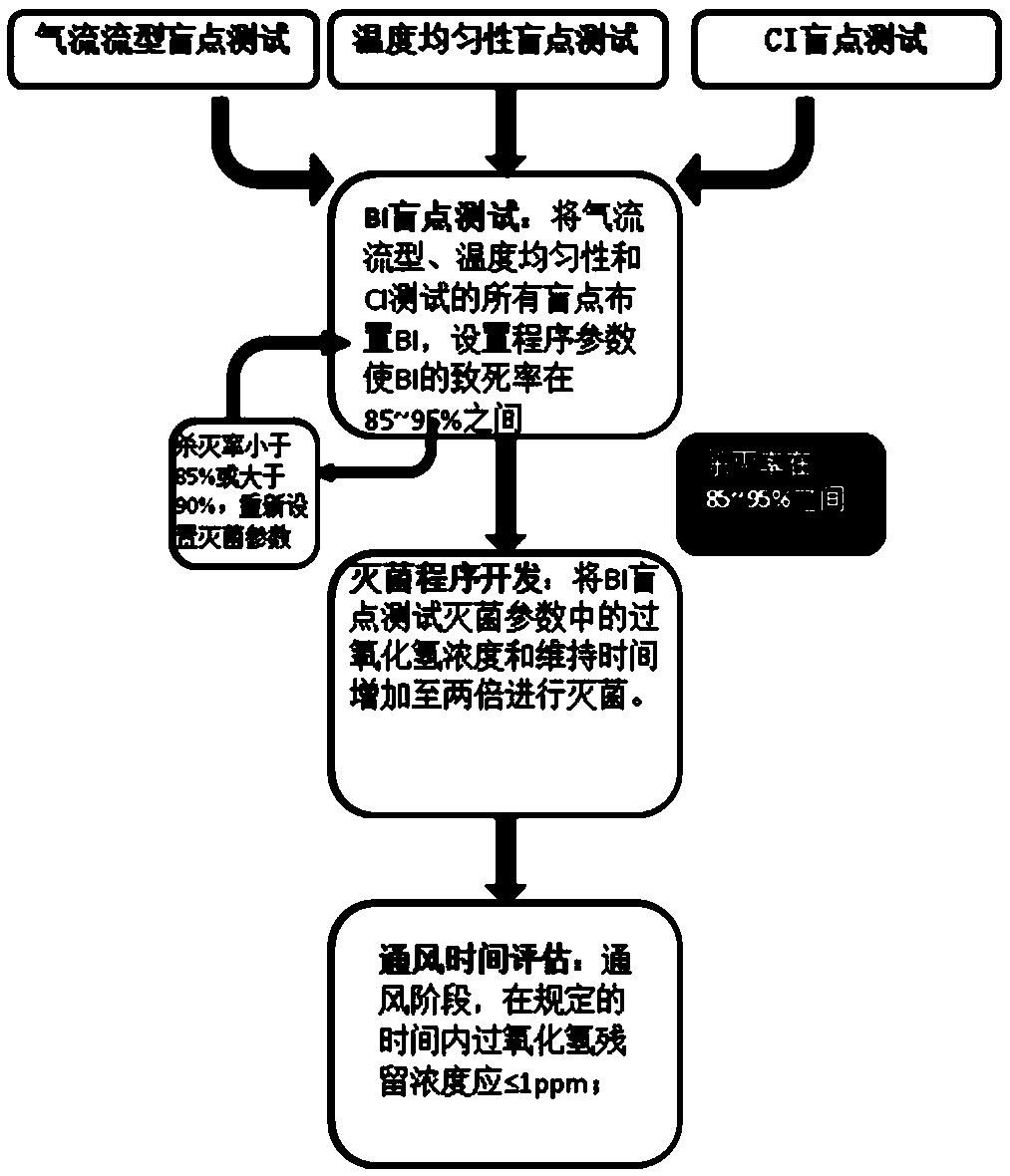

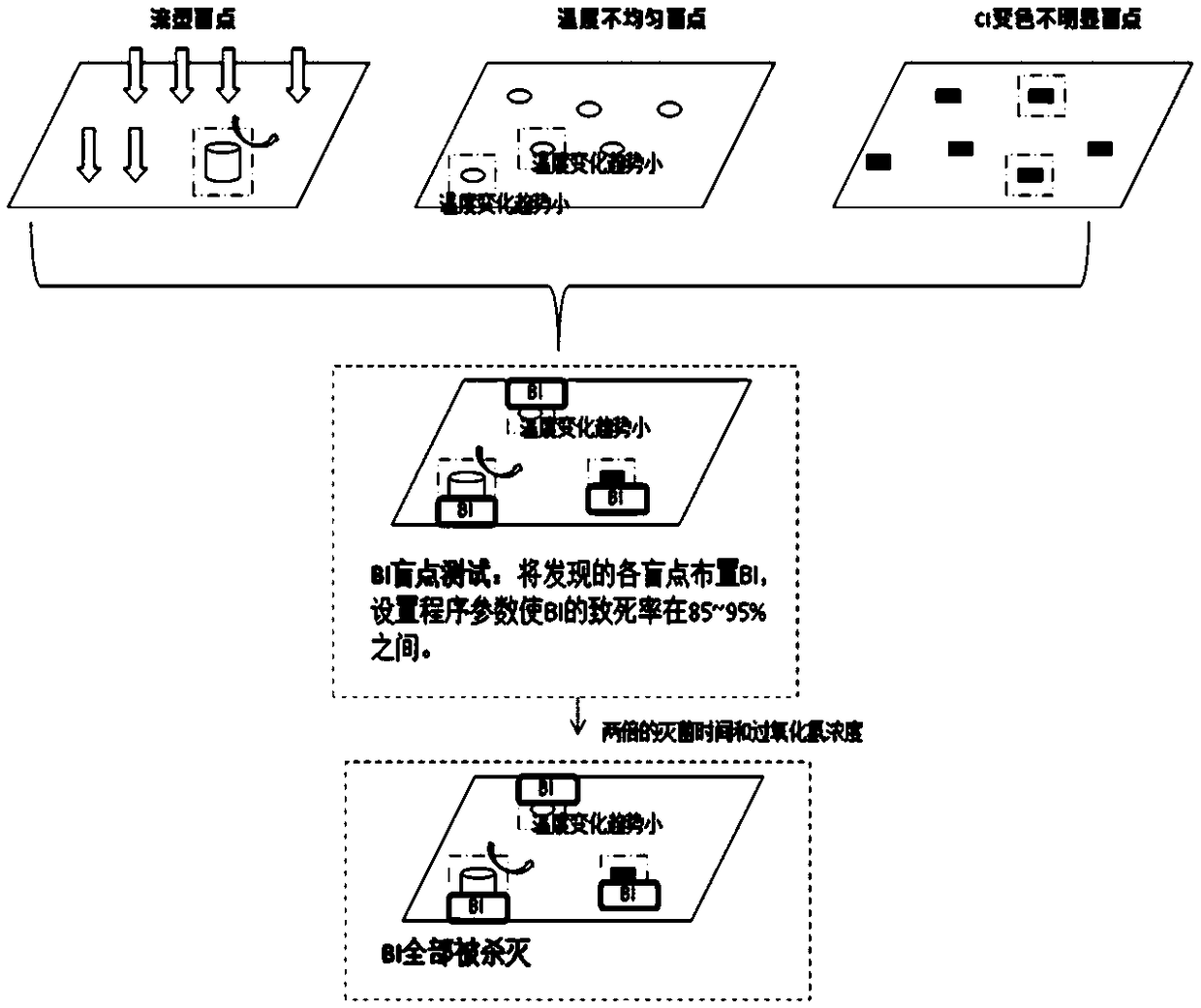

Hydrogen peroxide sterilization verification method

ActiveCN109395134AReduce usageReasonable usageLavatory sanitoryChemicalsTest objectHydrogen Peroxide Sterilization

The invention discloses a hydrogen peroxide sterilization verification method. The hydrogen peroxide sterilization verification method comprises the following steps: acquiring an airflow stream pattern blind spot and / or a temperature uniformity blind spot in a to-be-tested object; CI blind spot testing: starting hydrogen peroxide sterilization on the to-be-tested object, and acquiring a CI blind spot, wherein CI is a chemical indicator; BI blind spot test: arranging BI at the positions of the CI blind spot and the airflow stream pattern blind spot and / or the temperature uniformity blind spot which are obtained in the steps in the to-be-tested object, wherein the BI is a biological indicator; after setting a set of hydrogen peroxide sterilization parameters, starting hydrogen peroxide sterilization, after sterilization is completed, judging whether fatality rate of BI reaches a set threshold value or not, and if the fatality rate of BI reaches the set threshold value, then completing sterilization verification of the set of hydrogen peroxide sterilization parameters; and if the fatality rate of BI does not reach the set threshold value, correcting the hydrogen peroxide sterilizationparameter, and restarting hydrogen peroxide sterilization until the set threshold value is reached. The hydrogen peroxide sterilization verification method has the advantages of simplicity in principle, simplicity and convenience in operation, capability of achieving the optimal hydrogen peroxide sterilization effects and the like.

Owner:TRUKING TECH LTD

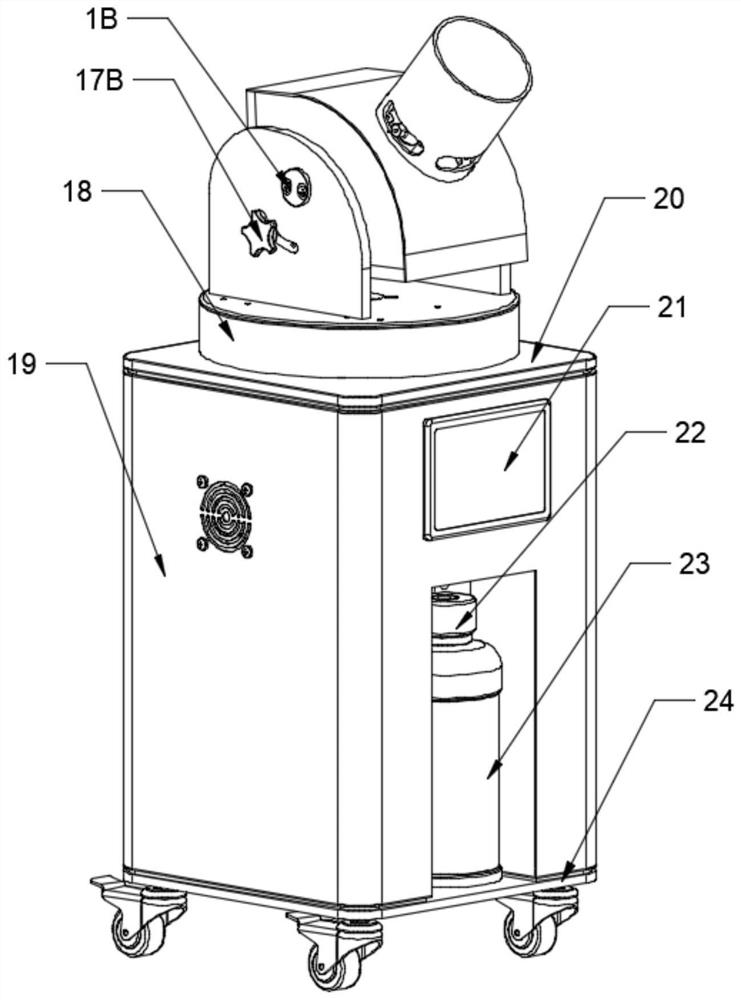

Hydrogen peroxide sterilizer based on high-frequency high-voltage arc technology

PendingCN111686284AEasy maintenance and repairNo confusionMovable spraying apparatusLavatory sanitoryReal-time dataEngineering

The invention discloses a hydrogen peroxide sterilizer based on the high-frequency high-voltage arc technology. The hydrogen peroxide sterilizer comprises a left rotating shaft, a right rotating shaftand a box body, wherein the left rotating shaft is movably connected with a left side plate of a swing support, and the right rotating shaft is movably connected with a right side plate of the swingsupport; a left side plate of a nozzle support is movably connected with one side of the left side plate of the swing support, a right side plate of the nozzle support is movably connected with one side of the right side plate of the swing support, a bottom plate of the nozzle support is fixedly installed at the bottom end of the right side plate of the nozzle support, and the left side plate of the nozzle support is fixedly installed on the side, away from the right side plate of the nozzle support, of the bottom plate of the nozzle support. According to the hydrogen peroxide sterilizer, a solution in a solution bottle can be sprayed out through the nozzle, the angle of the nozzle can be controlled by swinging the support rotary disc, real-time data of equipment can be visually operated and observed through a touch screen, used parts can be arranged inside through the box body, and thus use is convenient.

Owner:HANGZHOU GEEVO TECH

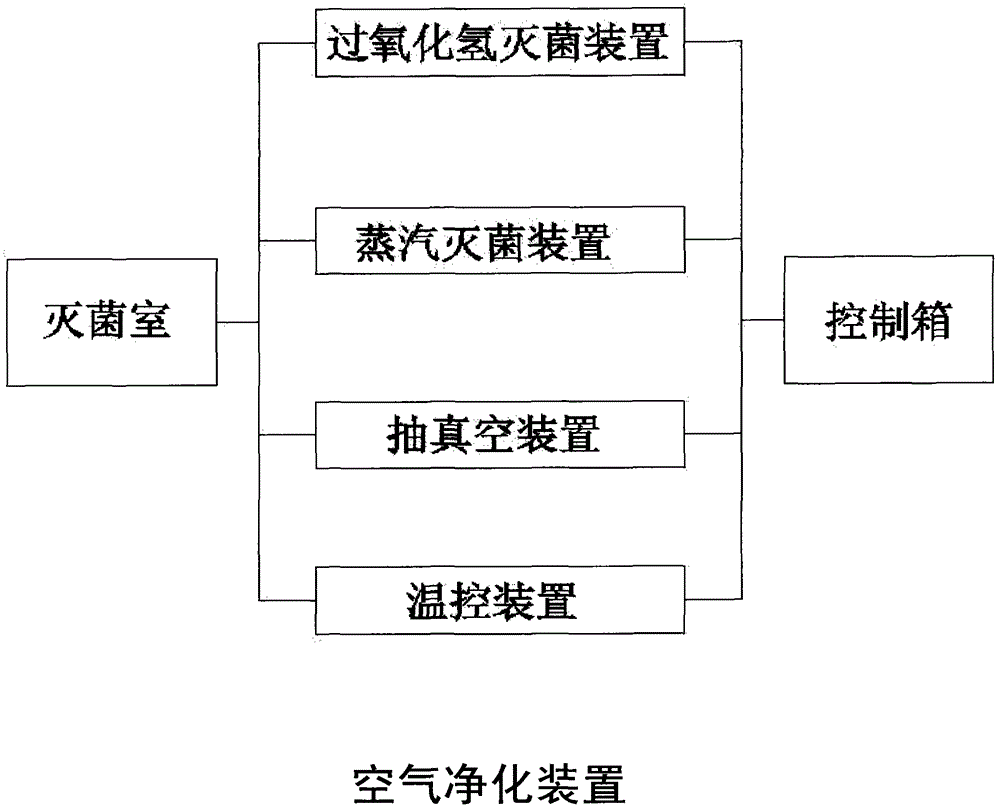

Multi-purpose sterilization method and multifunctional sterilizer thereof

The invention discloses a multi-purpose sterilization method. The multi-purpose sterilization method includes the following steps: (1) setting a sterilization room, (2) setting a vacuum supply device, (3) setting a temperature control device, (4) setting a hydrogen peroxide sterilization device, (5) setting a steam sterilizer, (6) setting an air cleaning device, (7) setting a control box, and (8) sterilizing. The invention further discloses a multifunctional sterilizer which is made with the multi-purpose sterilization method. The multi-purpose sterilization method is simple in steps, easy to achieve, high in efficiency and various in functions and the effects of low temperature type sterilization or high temperature type sterilization can be achieved. The multifunctional sterilizer is ingenious in design, reasonable in structure, the hydrogen peroxide sterilization device and the steam sterilizer are arranged, the low temperature type sterilization function and the high temperature type sterilization function are integrated, and the corresponding effect of low temperature type sterilization or high temperature type sterilization can be chosen according to required device types which need sterilization. The multifunctional sterilizer is convenient to use, wide in application, use costs of healthcare organizations are effectively reduced and the multifunctional sterilizer is beneficial for wide promotion and application.

Owner:钱军

Hydrogen peroxide sterilization method

A metering unit is provided for metering hydrogen peroxide into an evacuated vessel, for controlling the concentration of hydrogen peroxide in the vessel. The metering unit includes a body defining a metering passage having a fixed volume and upstream and downstream ends, an upstream connection for connecting the upstream end to a hydrogen peroxide supply, a downstream connection for connecting the downstream end to a hydrogen peroxide vaporizer, an upstream valve for selectively closing the upstream end and a downstream valve for selectively closing the downstream end, and a controller for operating the valves in a non-overlapping and opposite manner for selectively preventing opening of both valves at the same time. With the metering unit of this disclosure, expensive peroxide concentration measurement systems are replaced with an economical monitoring of the number of injection cycles using a passage of fixed volume.

Owner:STRYKER CORP

Hydrogen peroxide sterilization method

A method of metering of hydrogen peroxide gas into an evacuated sterilization chamber is disclosed. The method includes the steps of continuously monitoring a pressure in the sterilization chamber; connecting a passage of known volume to the evacuated chamber for evacuating the passage; sealing the passage; connecting the evacuated passage to a supply of hydrogen peroxide solution for a time sufficient to draw the hydrogen peroxide solution into and fill the passage; sealing the passage; and repeating those steps until a preselected pressure increase in the sterilization chamber is detected. The pressure increase is preferably 19 Torr. The known volume of the metering passage is preferably between 75 μL and 15 μL to control unwanted condensation of hydrogen peroxide in the sterilization chamber. Expensive peroxide concentration measurement systems are replaced with an economical low cost pressure sensor for control of the hydrogen peroxide concentration.

Owner:STRYKER CORP

Packaging paper sterilization device for filling machine

PendingCN109455324AIncrease the lengthImplement storageWrapping material feeding apparatusPackage sterilisationUltravioletPulp and paper industry

The invention discloses a packaging paper sterilization device for a filling machine, relates to filling machines, and aims to solve the problem that packaging paper is not effectively sterilized by filling machines in the prior art. According to the technical scheme, the packaging paper sterilization device for the filling machine comprises a hydrogen peroxide sterilization box, an ultraviolet sterilization box and a sterile traction box; the hydrogen peroxide sterilization box is provided with a first paper feeding groove and a first paper discharging groove; the hydrogen peroxide sterilization box is rotationally connected to an immersion guiding roller; the ultraviolet sterilization box is provided with a protruding portion; the protruding portion is provided with a second paper feeding groove; an ultraviolet lamp is arranged in an inner cavity of the ultraviolet sterilization box; the ultraviolet sterilization box is rotationally connected with two stroke extension rollers; and the ultraviolet sterilization box is provided with a second paper discharging groove. According to the packaging paper sterilization device for the filling machine, packaging paper is driven by a driving roller to sequentially pass through the hydrogen peroxide sterilization box and the ultraviolet sterilization box, thus, double sterilization of the packaging paper is achieved, and the packaging paper sterilization effect is effectively ensured.

Owner:浙江旭翔机械科技有限公司

Rapid hydrogen peroxide sterilization delivery window

InactiveCN111658803APromote decompositionAchieve sterilization effectMeasurement devicesLavatory sanitoryExhaust valveControl system

The invention discloses a rapid hydrogen peroxide sterilization delivery window. The rapid hydrogen peroxide sterilization delivery window is characterized by comprising a delivery window cavity; a feeding delivery door and a discharging delivery door are arranged at the two sides of the delivery window cavity respectively; the delivery window cavity is communicated with an air inlet system, an exhaust system and an atomization control system respectively; the air inlet system comprises an air inlet valve and an air inlet fan, which are communicated with an air source; the delivery window cavity is communicated with the air source through the air inlet valve and the air inlet fan; the exhaust system comprises an exhaust fan; the exhaust fan is connected with the delivery window cavity through an exhaust valve and a pressure release valve, which are connected in parallel; the atomization control system comprises an atomization nozzle arranged in the delivery window cavity; and the atomization nozzle is connected with a storage tank filled with hydrogen peroxide liquid through a delivery pump. According to the rapid hydrogen peroxide sterilization delivery window in the invention, broad-spectrum sterilization and natural diffusion of hydrogen peroxide vapor can be realized under the conditions of normal temperature and normal pressure; gas circulation loss of hydrogen peroxide vapor is not needed; the sterilization process is short in time and residue-free; and production arrangement is facilitated.

Owner:上海东富龙爱瑞思科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com