VHP plasma aerosol generation method and device

A plasma gas generation device technology, applied in the field of ion aerosol generation methods and devices, can solve the problems of large sterilization energy consumption, wide particle size distribution range, large heating power consumption, etc., to overcome poor sterilization effect, High sterilization efficiency and stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

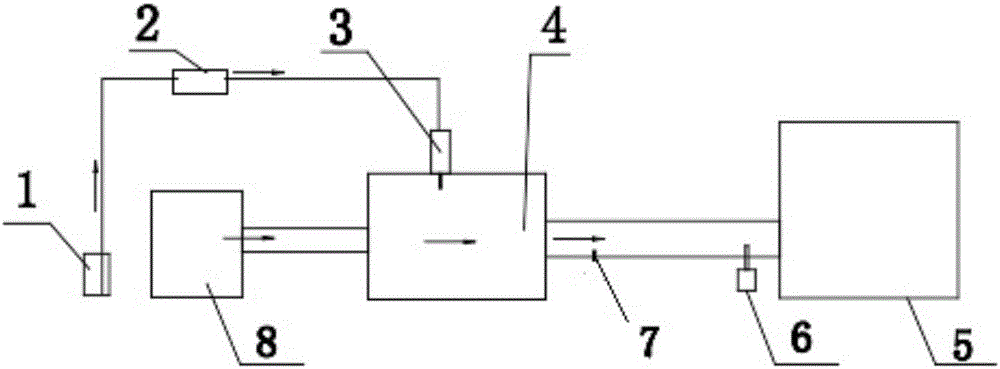

[0026] Such as figure 1 As shown, the VHP plasma aerosol generating device of the present invention comprises a VHP vaporizer 2, a plasma generator 3, a mixing cabin 4, an aerosol stabilizer input device 6, an air pump 8, and one end of the VHP vaporizer 2 is connected to a liquid hydrogen peroxide 1 The other end is connected with the plasma generator 3, and the other end of the plasma generator 3 is connected with the mixing cabin 4, and the mixing cabin 4 is also connected with an air pump 8 and an output channel 7, and an aerosol stabilizer is arranged on the output channel 7 The other end of the input device 6 and the output channel 7 is connected with the sterilization environment 5 .

[0027] The liquid hydrogen peroxide is processed by the VHP vaporizer into VHP particles with a particle size of 1-15um. After the electric field treatment (9500V) of the plasma generator, some VHP particles are transformed into positive and negative ions of VHP+ and VHP-, and positive an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com