Tunnel-type hydrogen peroxide sterilization method and tunnel-type hydrogen peroxide sterilization device

A technology of hydrogen peroxide and sterilizing equipment, applied in chemistry and other fields, can solve problems such as cross-contamination, high labor intensity, and inability to meet the requirements of continuous production, and achieve the effect of ensuring sterility indicators and increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

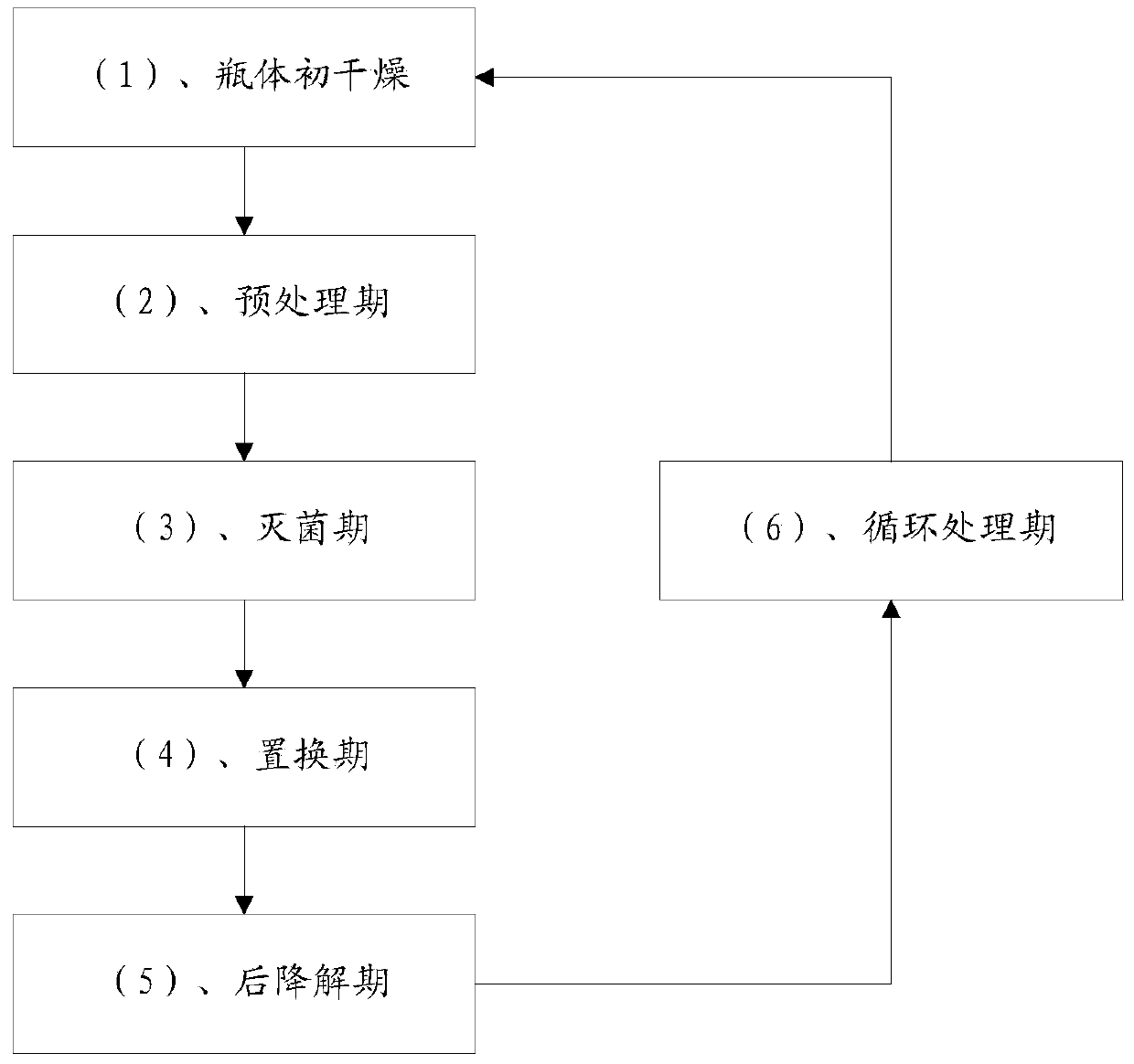

[0036] Such as figure 1 Shown, a kind of tunnel type hydrogen peroxide sterilization method comprises the following steps:

[0037] (1) Initial drying of the bottle body: First blow hot air at 60-70°C evenly into the tunnel-type hydrogen peroxide sterilizer, stop blowing hot air when the temperature inside the box is 60-70°C, and then clean the box body The interior is vacuumed to 50-100Pa, and the initial drying is completed. After this process, the water in the bottle is basically discharged;

[0038] (2) Pretreatment period: heating inside the hydrogen peroxide generator, heating the vaporization system of the hydrogen peroxide generator to the set working temperature;

[0039] (3) Sterilization period: Under the action of the hydrogen peroxide generator, the gaseous hydrogen peroxide vapor is pressed in for many times, and the concentration of the hydrogen peroxide vapor is maintained at a level lower than the saturated state to sterilize the bottle body in the box. Bact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com