Hydrogen peroxide sterilization method

A sterilization method and hydrogen peroxide technology, applied in chemistry, sanitary equipment for toilets, water supply devices, etc., can solve the problems of hydrogen peroxide condensation, instrument interference, affecting the stability of sterilization devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

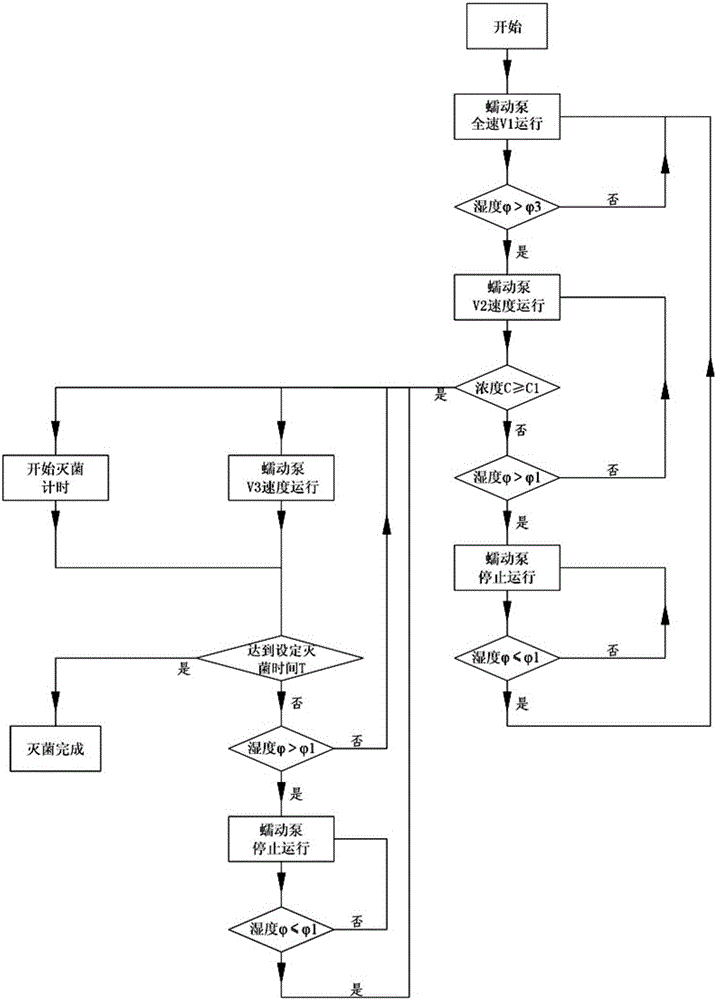

[0025] Fig. 1 has shown a kind of embodiment of hydrogen peroxide sterilization method of the present invention, and this hydrogen peroxide sterilization method needs to keep injecting compressed air in isolator, also comprises the following steps:

[0026] S1. Detect the humidity inside the isolator and hydrogen peroxide concentration C;

[0027] S2. Inject the hydrogen peroxide solution into the heated evaporator, and pass the gas generated by the evaporation of the hydrogen peroxide solution into the isolator;

[0028] S3, set the humidity value like Then go to step S4, if Then return to step S2;

[0029] S4, stop injecting the hydrogen peroxide solution into the evaporator;

[0030] S5. Set the hydrogen peroxide sterilization concentration value of the sterilization state as C1, if C≥C1, then enter step S6, if C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com