Fast composting system and technology

A composting and fast technology, applied in the fields of organic fertilizers, fertilization devices, preparation of organic fertilizers, etc., can solve the problems of low degree of automation, small processing capacity, slow fermentation speed, etc., to improve the decomposing efficiency, high degradation efficiency and oxygen content sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

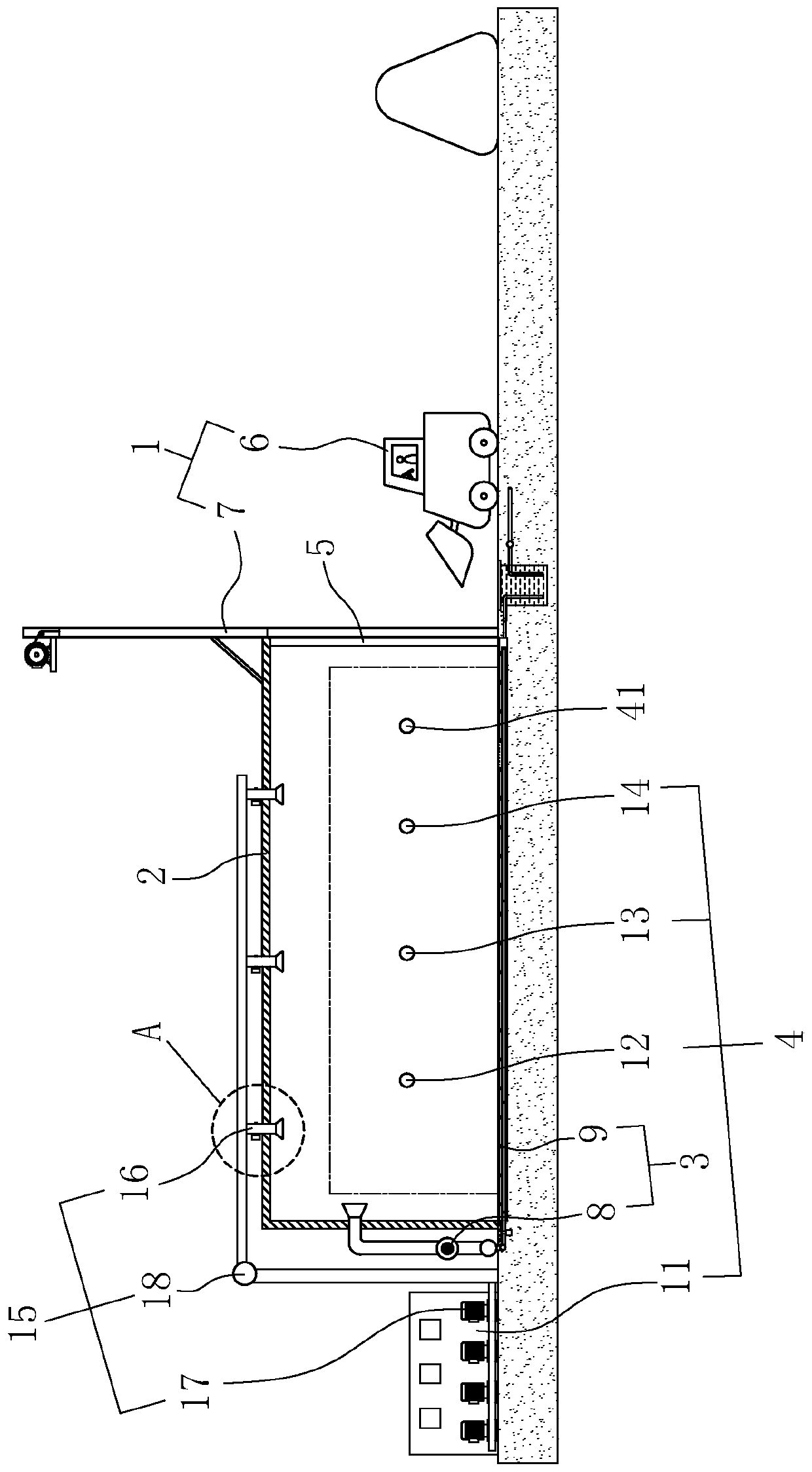

[0054] refer to figure 1 , a fast composting system, including a feeding and discharging system 1, a compost bin 2, an aeration system 3 and a compost control system 4; eight compost bins 2 are arranged side by side, and the size of the compost bin 2 is 15m*5m*5m. 2 is used to pile up organic waste, so that organic waste can be fermented and decomposed in a closed space; the side wall of the compost bin 2 is provided with an inlet and outlet 5 for feeding in and out of materials, mechanical equipment or vehicles; the inlet and outlet system 1 will The waste is transported to the compost bin 2 through the inlet and outlet 5, and after the composting is completed, the decomposed manure is transported out of the compost bin 2; the aeration system 3 is used to transport the air outside the compost bin 2 into the compost bin 2 , so that the oxygen, temperature and water vapor outside the compost bin 2 are exchanged with the outside, so as to ensure that the temperature, humidity an...

Embodiment 2

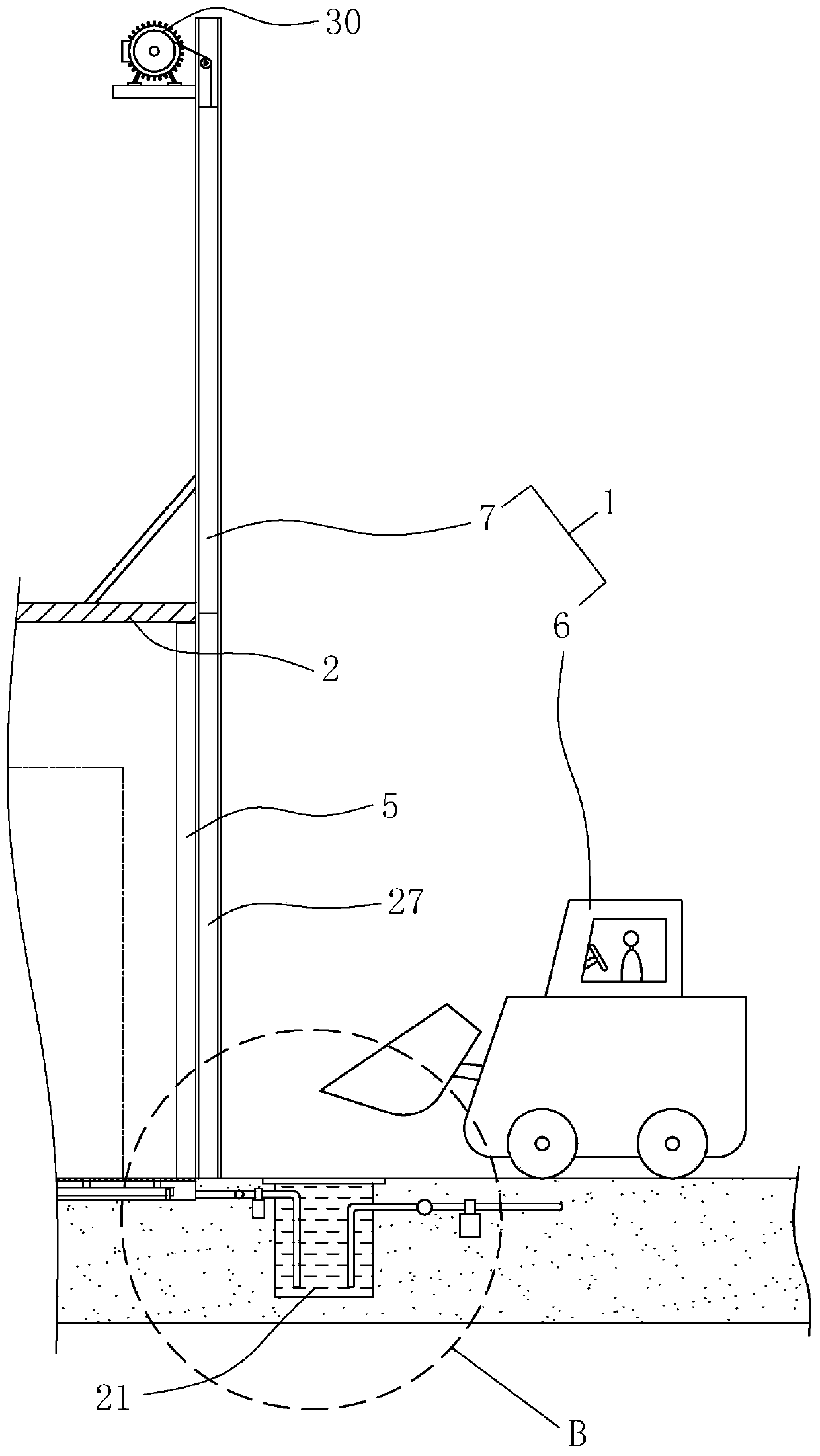

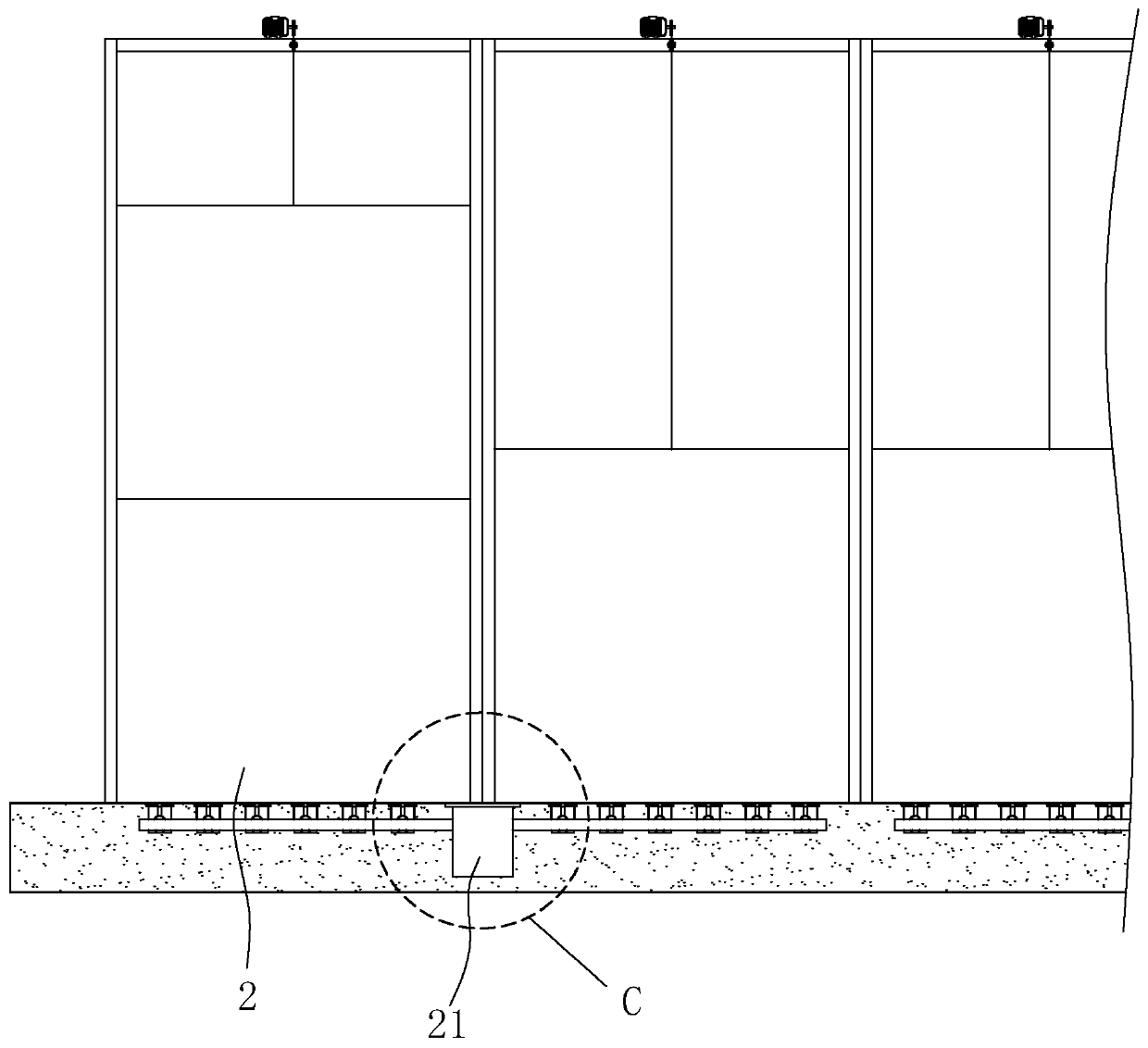

[0066] refer to Figure 9 , a fast composting system, the difference from Embodiment 1 is that the sliding guide rail 27 is arranged along the horizontal direction, two sliding guide rails 27 are arranged in parallel, and the door 7 is slidingly matched with the sliding guide rail 27; two adjacent The door 7 of the compost bin 2 is respectively arranged on two sliding guide rails 27, and the opposite sides of the two adjacent door 7 are fixed with a sealing strip 29, the sealing strip 29 is made of rubber, and the sealing strip 29 Sealing the gap between the two bin doors 7 better improves the sealing performance of the bin doors 7 to the compost bin 2 . The composting bin 2 is fixed with a traction motor 30 that pulls the door 7 to slide. The main shaft of the traction motor 30 is wound with a traction rope. The side of the compost bin 2 away from the traction motor 30 is rotated and connected with a reversing wheel 37, and the traction rope is wound on the reversing wheel 3...

Embodiment 3

[0069] refer to figure 1 and Figure 10 , a fast composting process, the steps are as follows:

[0070] Step 1, first use a garbage crusher to crush the organic waste, and control the particle size of the organic waste between 8-15mm;

[0071] Step 2, add conditioner to the organic waste obtained in step 1, the volume ratio of organic waste to conditioner is 1:0.5 to 1:0.2, then add exogenous bacteria, and combine conditioner, exogenous bacteria and Organic waste is mixed, and then stirred evenly with a mixer to obtain a mixture, and the conditioning agent is preferably sawdust or corn stalks or rice husks;

[0072] Step 3, on the basis of step 2, the mixture obtained in step 2 is transported to the compost bin 2 by transport equipment 6, and the transport equipment 6 is preferably a loader;

[0073] Step 4, on the basis of step 3, when the mixture in the compost bin 2 reaches the designed loading capacity, the size of the pile body is 8m*3m*3m, and the compost control host...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com