Filling equipment

A filling equipment and filling technology, used in packaging, bottling machines, bottle filling and other directions, can solve the problems of non-recyclable water and disinfectants, unfavorable equipment processing and manufacturing, consumption of manpower and material resources, etc. Maintenance and residual reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

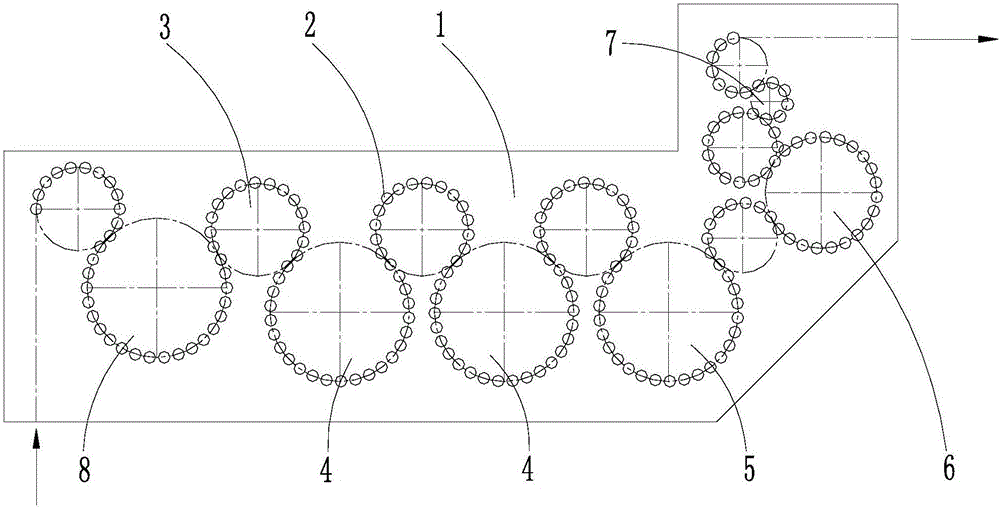

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] see figure 1 As shown, the above-mentioned filling equipment includes a frame 1 and a conveying mechanism 2 arranged on the frame 1 for conveying filling bottles.

[0021] The filling equipment also includes an ion gas purging mechanism 8, a hot air mechanism 3, a sterilizing mechanism 4, a drying mechanism 5, a filling mechanism 6 and a capping mechanism 7, which are successively arranged on the frame 1 along the conveying direction of the conveying mechanism 2. .

[0022] The ion gas purging mechanism 8 is used for static elimination of the filling bottle. In this embodiment, the ion gas purging mechanism 8 includes an electrostatic generating device and a compressed gas generating device. The static electricity generating device is used to generate charges opposite to the bottle wall of the filling bottle, and the compressed gas g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com