Hydrogen peroxide sterilization verification method

A technology of hydrogen peroxide and verification methods, which is applied in chemistry, sanitary equipment for toilets, water supply devices, etc., can solve problems such as lack of verification methods, decline in sterilization effect, and affect the service life of equipment, so as to avoid production costs and Waste of human resources, reduce the possibility of positive growth, the effect of achieving corporate profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

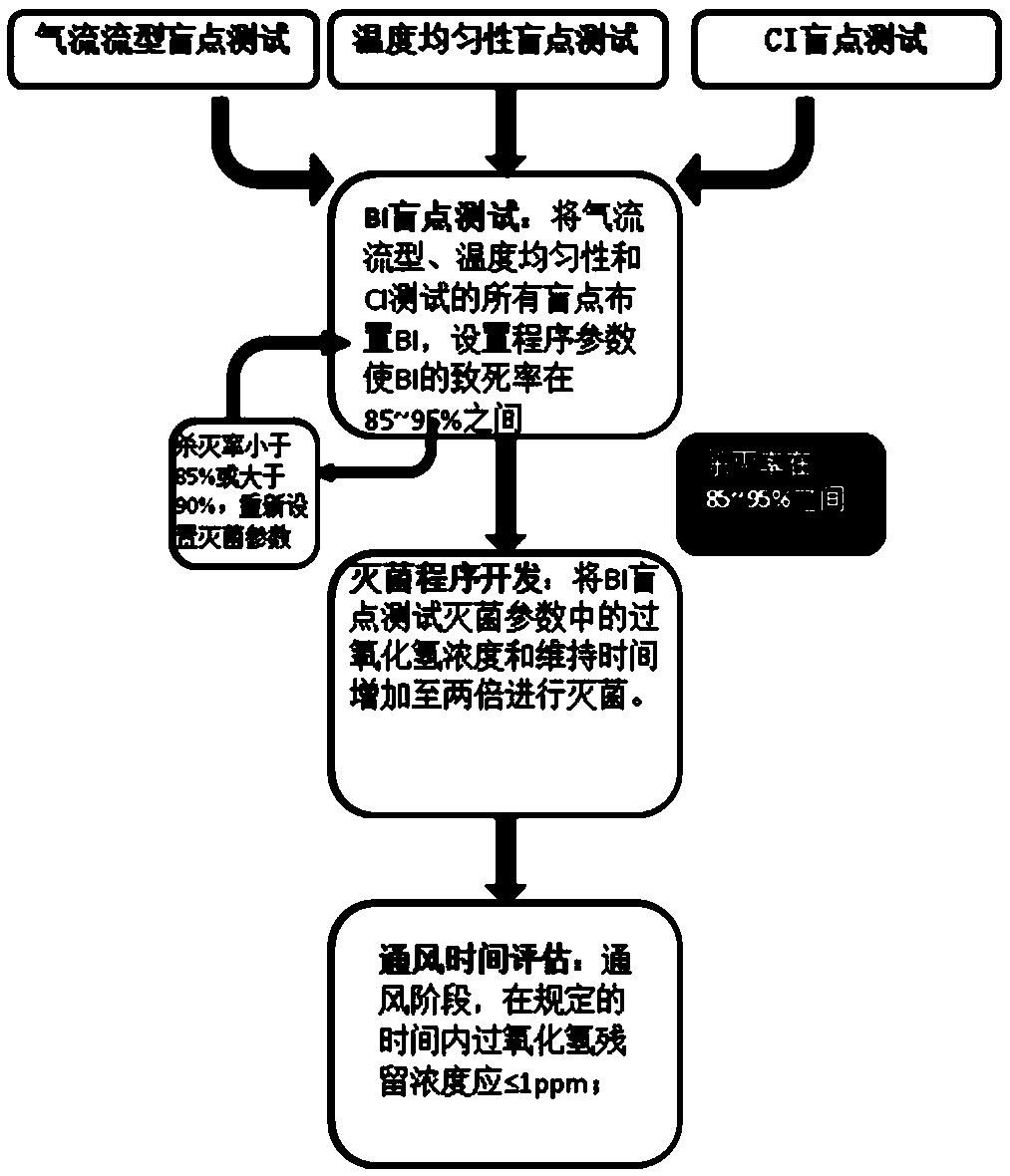

[0026] Such as figure 1 and figure 2 Shown, a kind of hydrogen peroxide sterilization verification method of the present invention is applicable to the airtight equipment that adopts hydrogen peroxide sterilization; Its steps comprise:

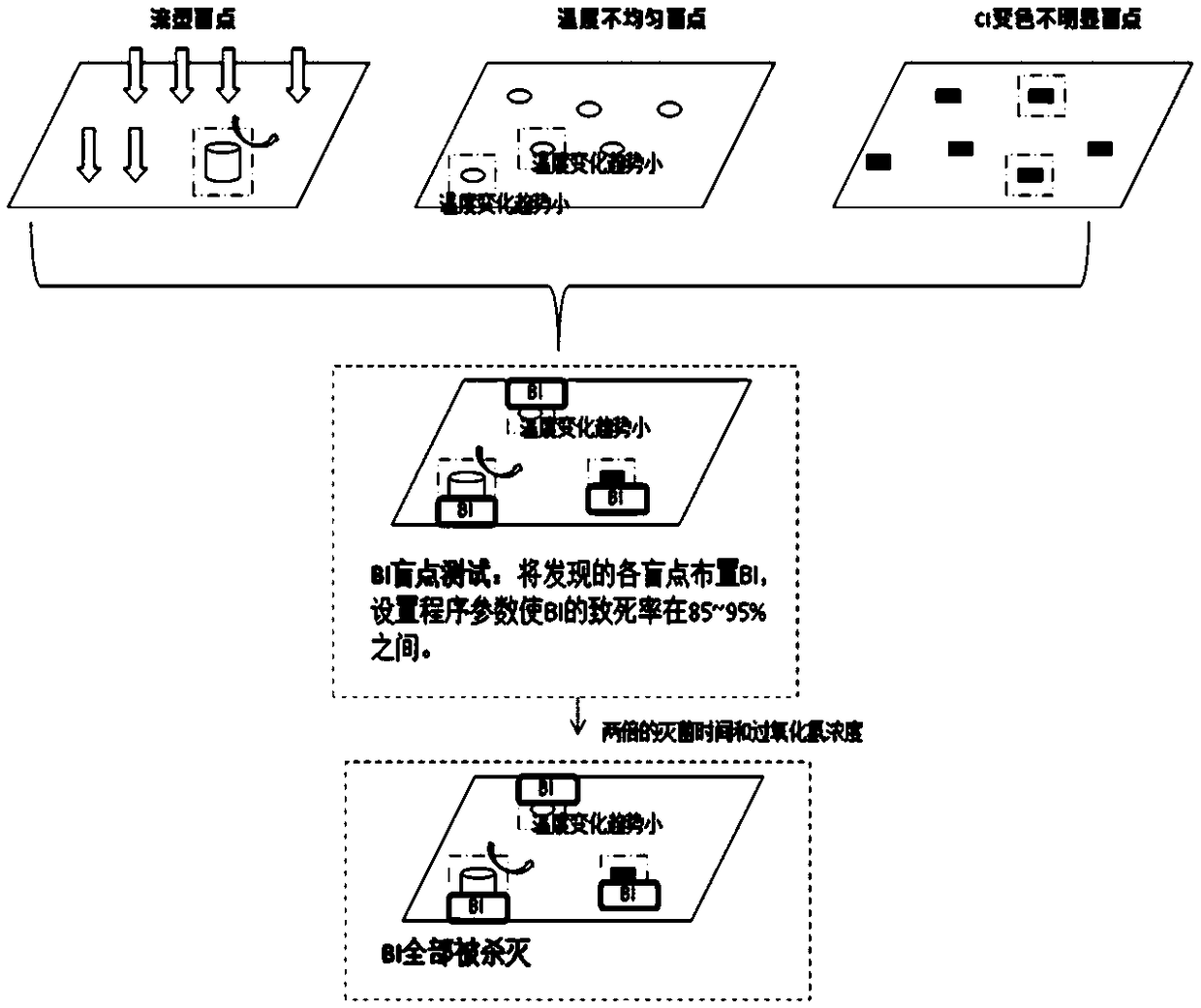

[0027] Collect air flow pattern blind spots and / or temperature uniformity blind spots in the object to be measured;

[0028] CI blind spot test: the object to be tested starts hydrogen peroxide sterilization, and collects CI blind spots; the CI is a chemical indicator;

[0029] BI blind spot test: in the object to be tested, set BI at the position of the CI blind spot obtained through the above steps, as well as the blind spot of the air flow pattern and / or the blind spot of temperature uniformity, and the BI is a biological indicator; set a set of peroxide After hydrogen sterilization parameters,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com