Rapid hydrogen peroxide sterilization delivery window

A technology of hydrogen peroxide and transfer window, which is applied in the fields of chemistry, sanitary equipment for toilets, measuring devices, etc., can solve the problems of long sterilization cycle time and user influence, and achieve short sterilization process time, convenient and rapid sterilization Bacteria, the effect of saving sterilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

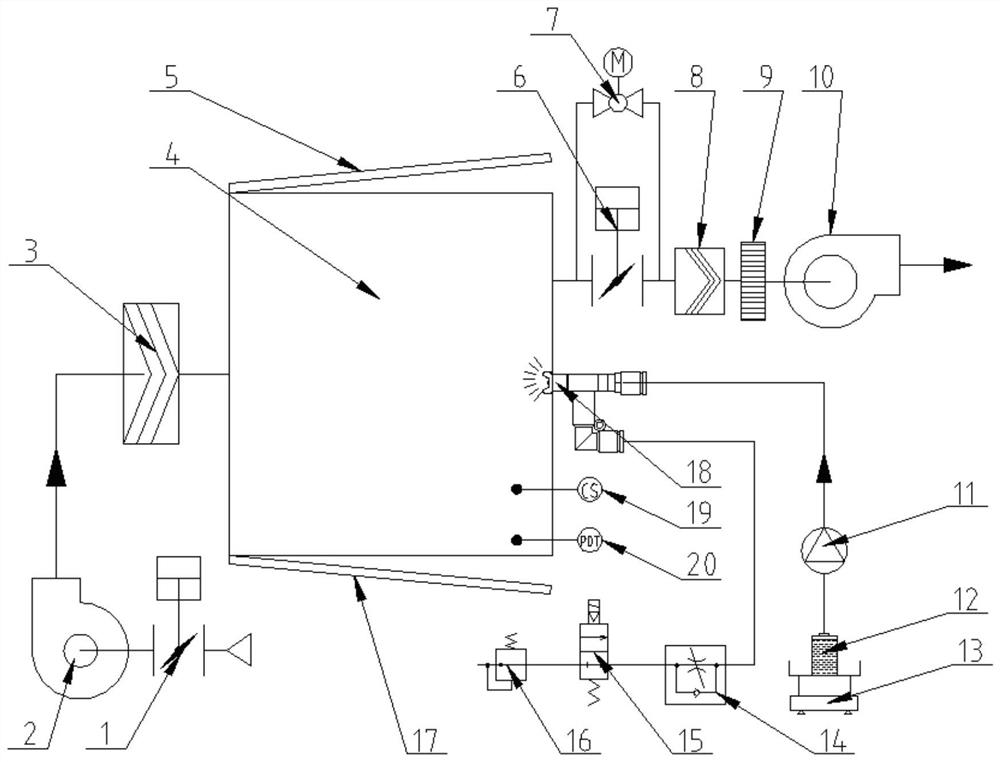

[0019] Such as figure 1 As shown, it is a structural schematic diagram of a rapid hydrogen peroxide sterilization transfer window provided in this embodiment, which includes a transfer window cavity 4, and the two sides of the transfer window cavity 4 along the material transmission direction are respectively provided with feed transfer The door 5, the discharge transfer door 17, and the transfer window cavity 4 communicate with the air intake system, the exhaust system, and the atomization control system respectively.

[0020] The intake system includes an intake valve 1 and an intake fan 2 communicated with an air source, and the transfer window cavity 4 communicates with the air source through the intake valve 1 and the intake fan 2 . An air intake high efficiency filter 3 is also provided between the transfer window cavity 4 and the air source. The positions of the intake valve 1, the intake fan 2, and the intake high-efficiency filter 3 can be interchanged without affect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com