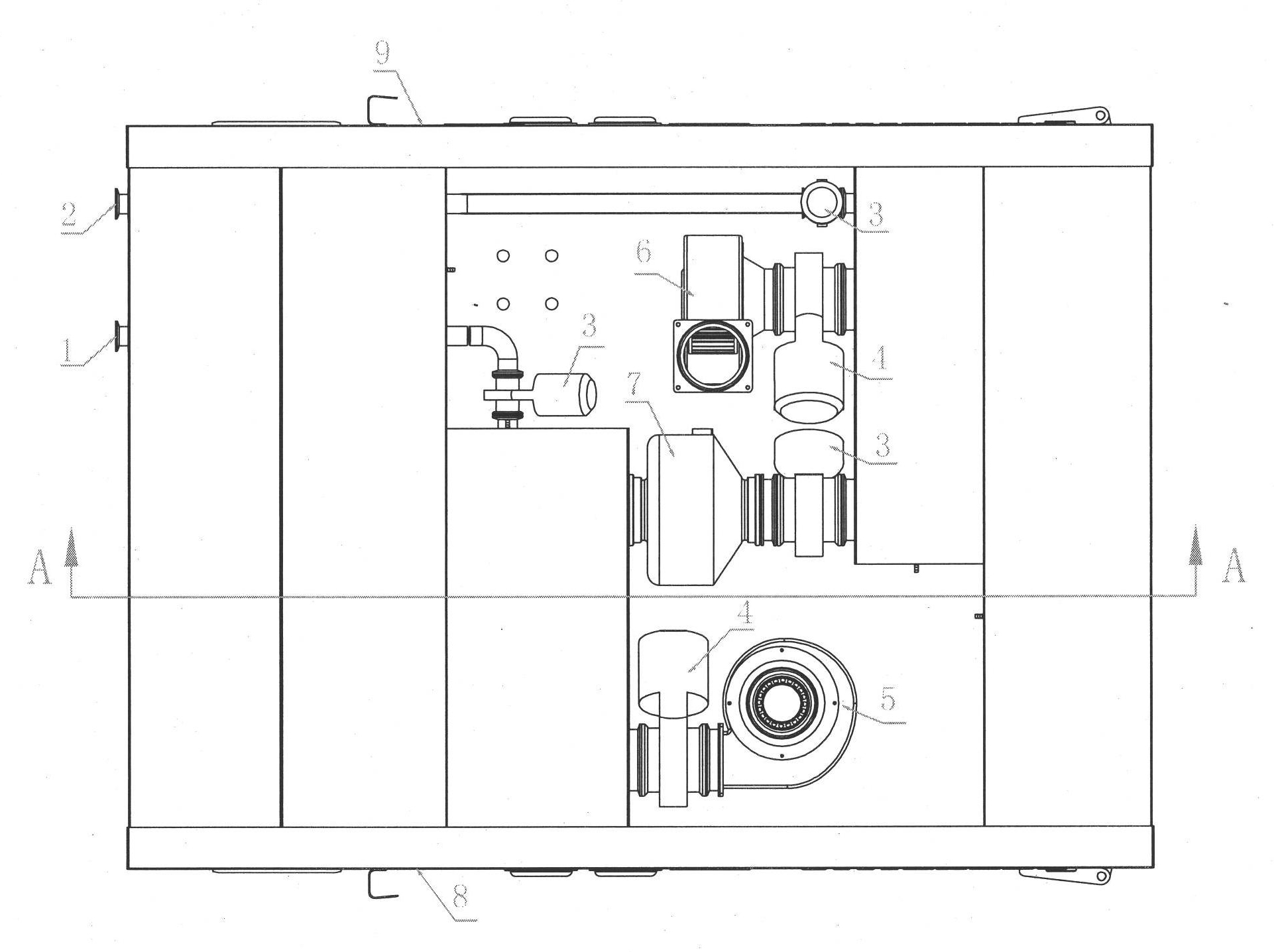

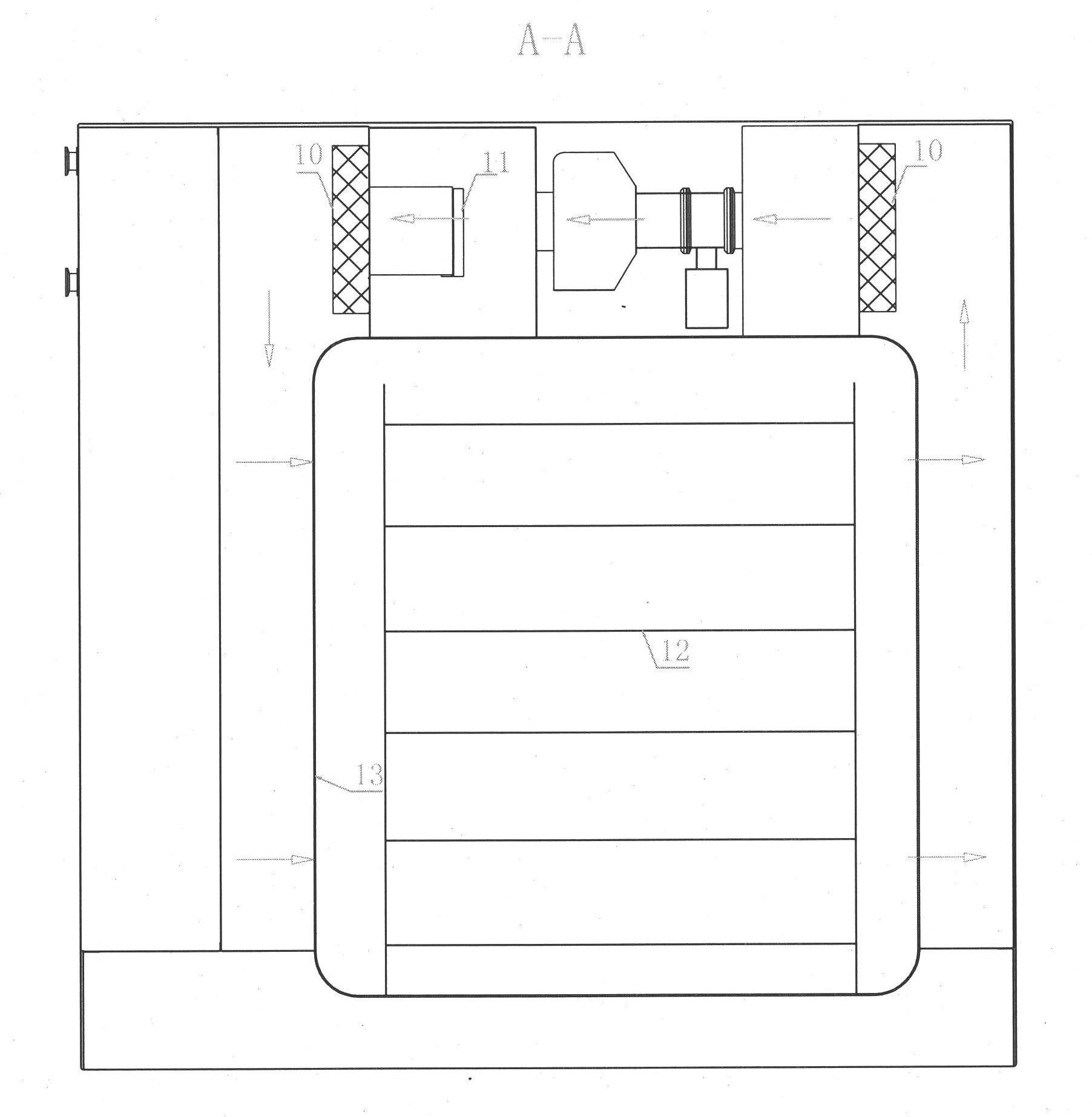

A transfer chamber with hydrogen peroxide biodecontamination function

A hydrogen peroxide and transfer cabin technology, applied in the field of transfer cabin, can solve the problems of difficulty in maintenance, high cost, aseptic production risk, etc., and achieve the effect of reducing production and maintenance costs and being easy to verify.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

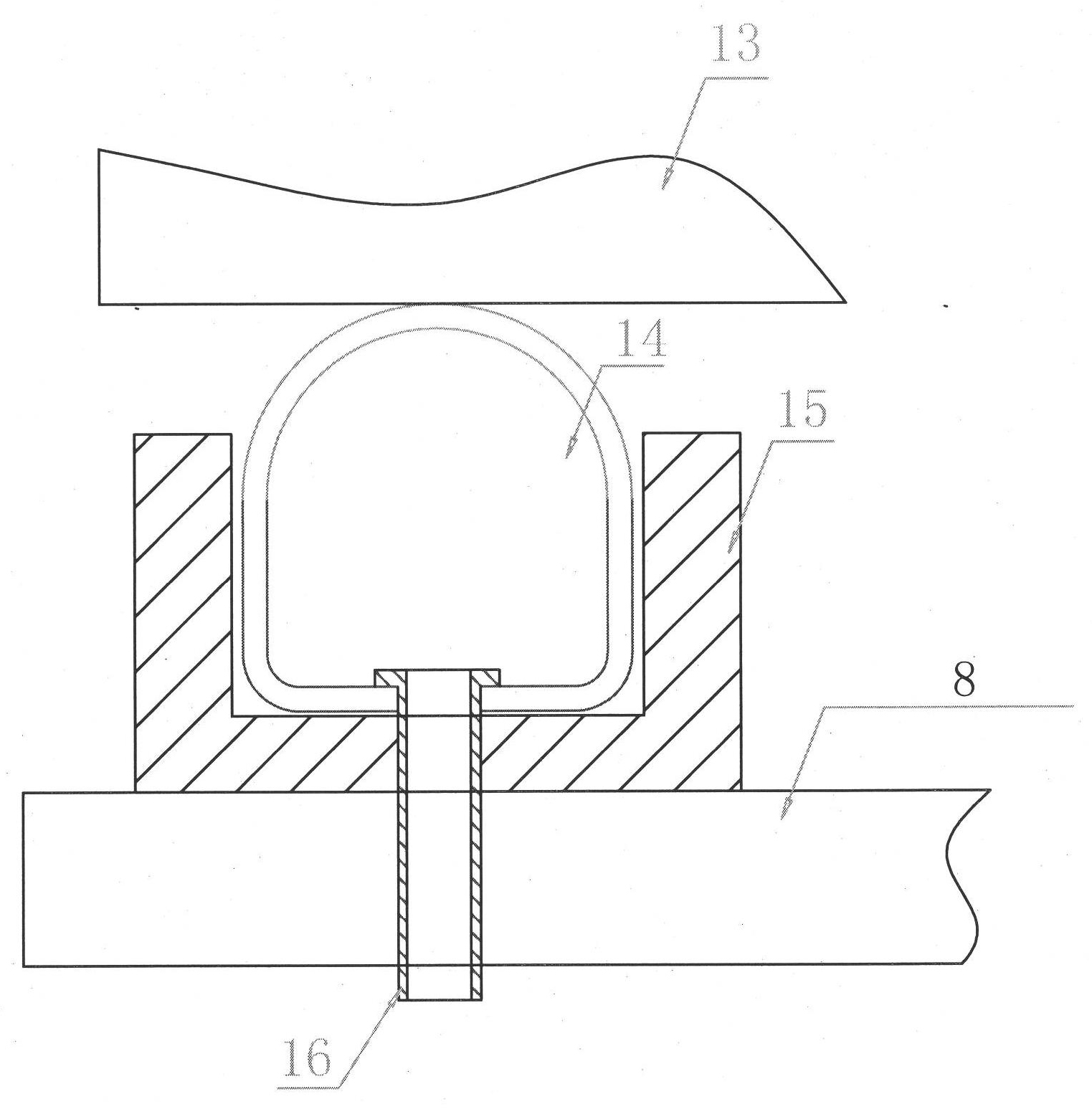

[0026] The front of the biological decontamination transfer cabin of the present invention is equipped with a man-machine operation touch screen, an emergency stop switch, a fault alarm, filter pressure monitoring, a seal inflation pressure display, a printer, and a discharge door switch, a sealing Inflation pressure display, running status indication, emergency stop switch. The work of the biodecontamination transfer cabin is divided into three stages:

[0027] The first stage: material incoming.

[0028] On the man-machine operation touch screen on the front of the biological decontamination transfer cabin, press the "open feed door" button, at this time the control signal is fed back to the feed door 8 and the exhaust valve of the inflatable sealing strip 14 is controlled to deflate, and the feed will be fed after a few seconds The locking mechanism of the door withdraws automatically, and now the feed door can be opened, and the material to be transferred / transferred is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com