Vacuum type transmission device for vaporization hydrogen peroxide sterilization

A hydrogen peroxide and delivery device technology, applied in the direction of chemistry, etc., can solve the problems of incapable sterilization process integration of eye drops, limited sterilization process, etc., and achieve the effect of low leakage possibility and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

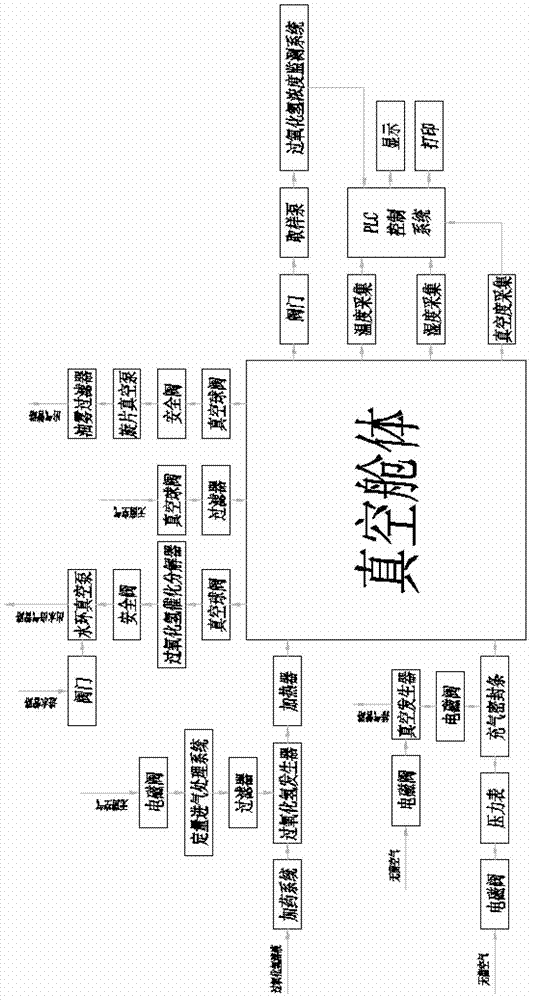

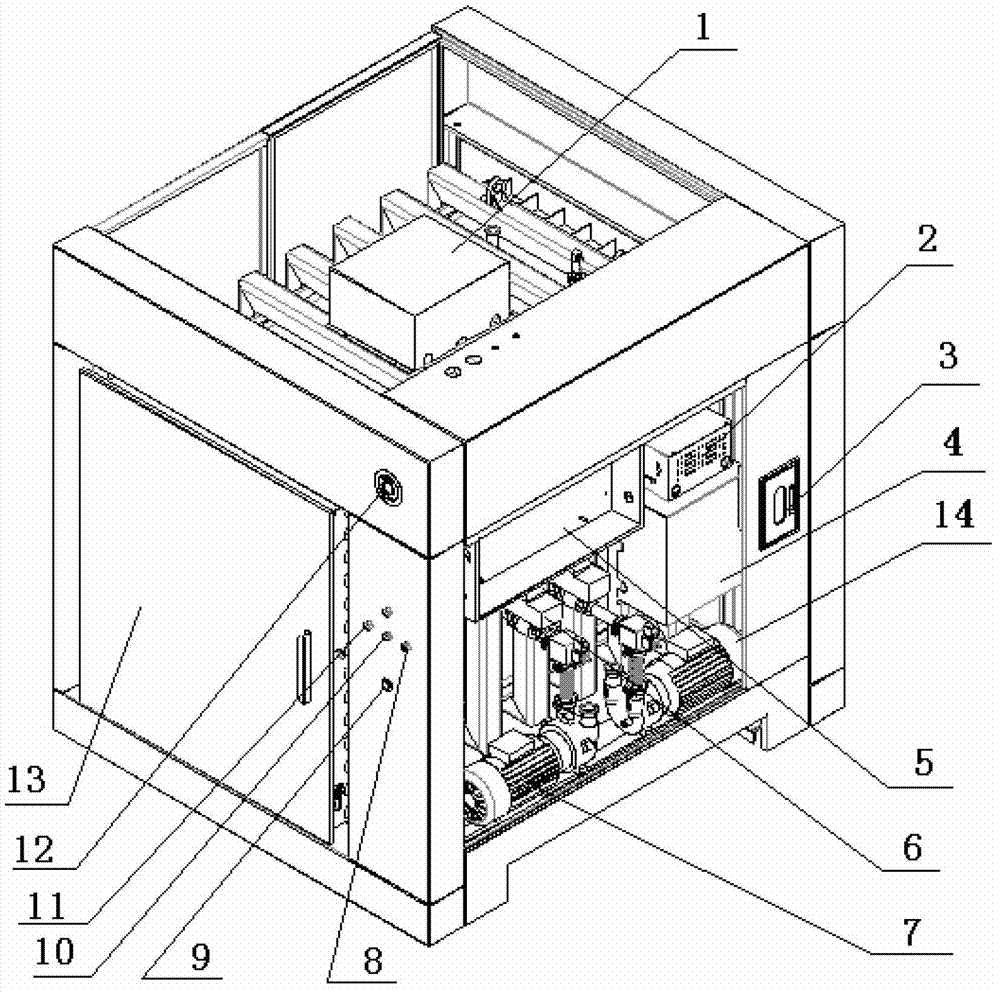

[0013] such as 1 and figure 2 As shown, this embodiment includes a vacuum chamber, a vaporized hydrogen peroxide generating device, a sealing device, a first high vacuum generator, a second high vacuum generator, an emptying device and a parameter monitoring device. The output end of the hydrogen peroxide generating device communicates with the vacuum cabin body, and the sealing device is used to seal the hatch in the vacuum cabin body; the first high vacuum generator and the second high vacuum generator make the vacuum cabin body in two kinds of vacuum respectively. degree state; the first high vacuum generator also has the function of discharging vaporized hydrogen peroxide in the vacuum cabin; the output end of the described venting device is communicated with the vacuum cabin; the parameter monitoring device is used to monitor the vacuum cabin Vaporized hydrogen perox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com