High-efficiency sterilization device of nano-mask

A technology for sterilization devices and masks, which can be used in water supply devices, sanitary equipment for toilets, buildings, etc., and can solve the problems of blocked air flow passages and poor sterilization efficiency on the bonding surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The fixed connection, fixed arrangement, and fixed structure mentioned in this embodiment are known technologies known to those skilled in the art, such as gluing, welding, screw connection, bolt and nut connection, and riveting.

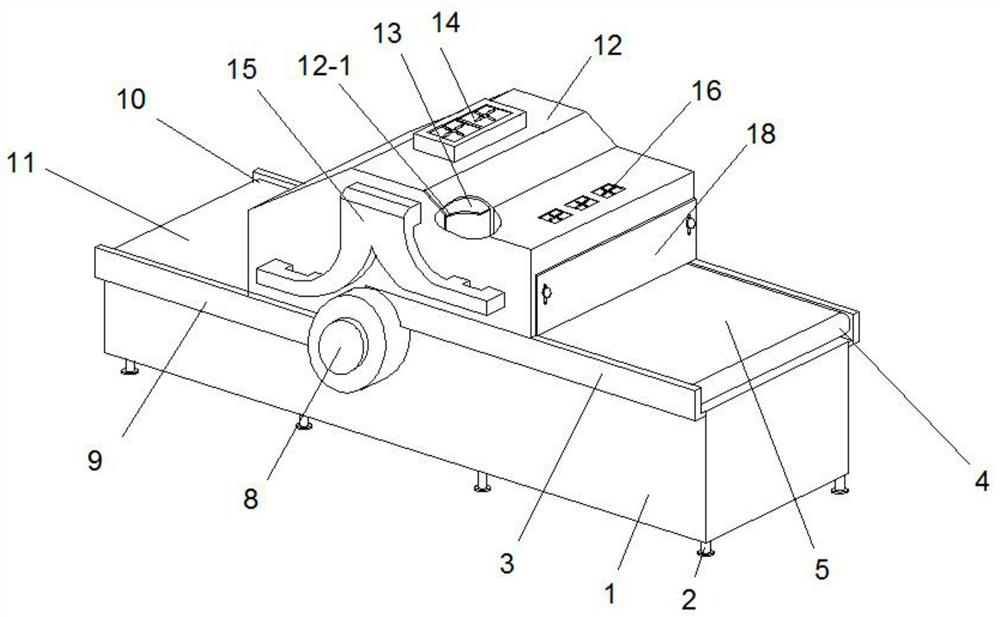

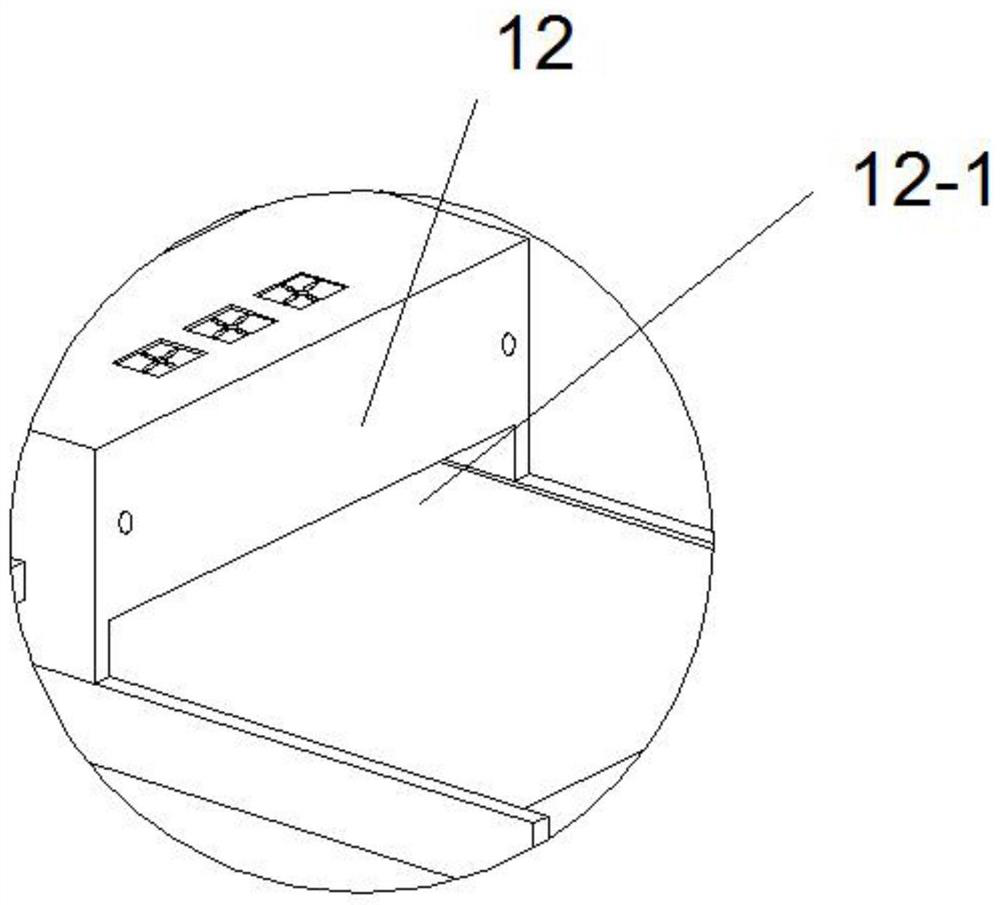

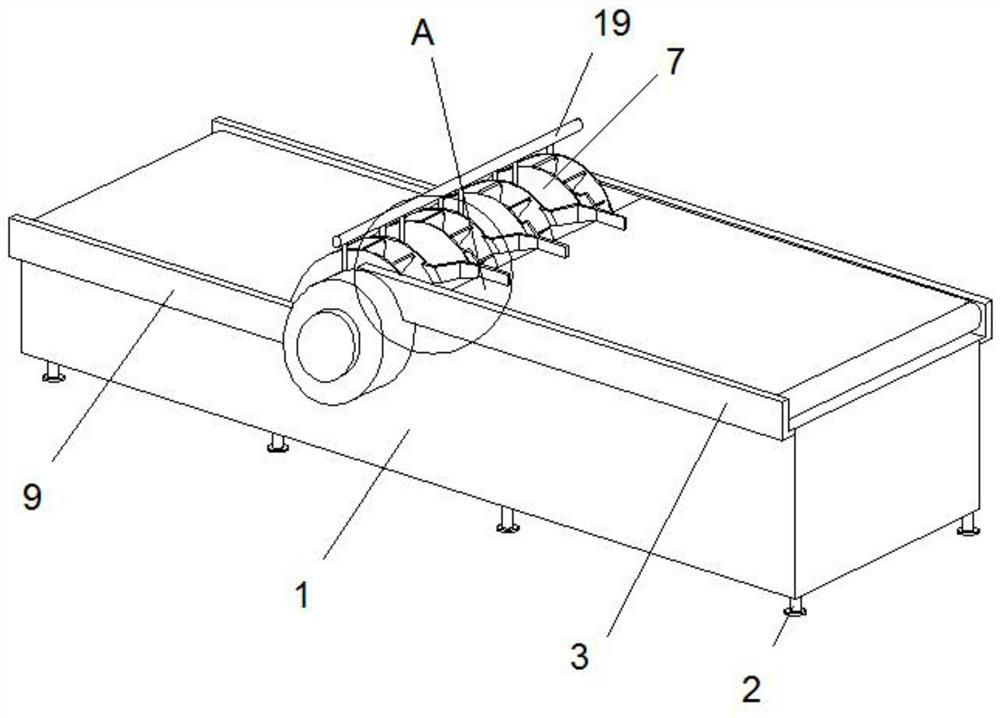

[0049]It can be seen from the accompanying drawings that a high-efficiency sterilization device for nano-masks includes a base 1, a foot 2, a front side frame 3, a front transmission roller 4, a front conveyor belt 5, a diversion partition 6, a runner 7, a shaft 8, Rear side frame 9, rear transfer roller 10, rear transfer belt 11, sterilization cover 12, top air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com