Pulse bag filter

A technology of pulse cloth bag and dust collector, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problem of dust pollution in the surrounding production environment that cannot be treated in a timely or perfect manner, reduces dust removal efficiency, and cleans In order to achieve the effect of widening the scope of use, improving reliability and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

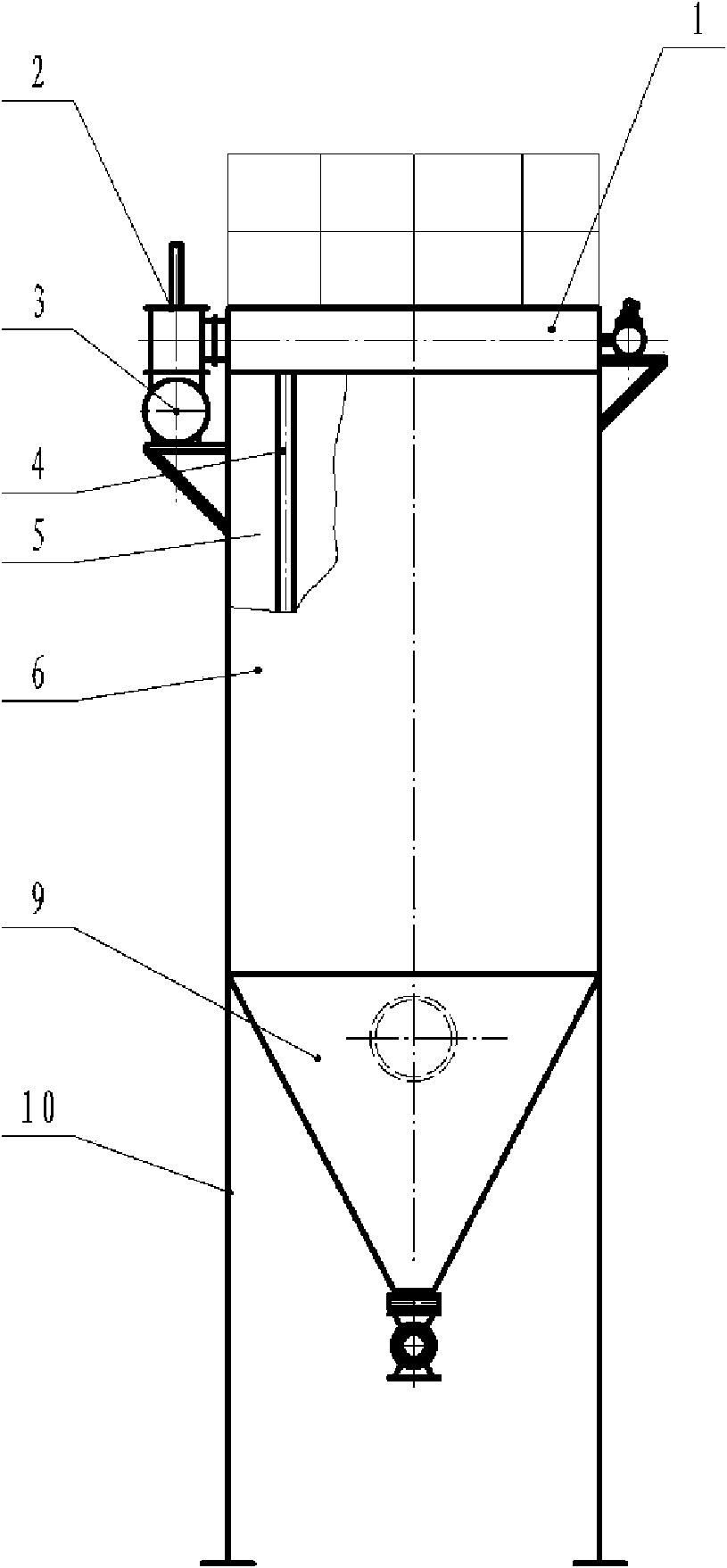

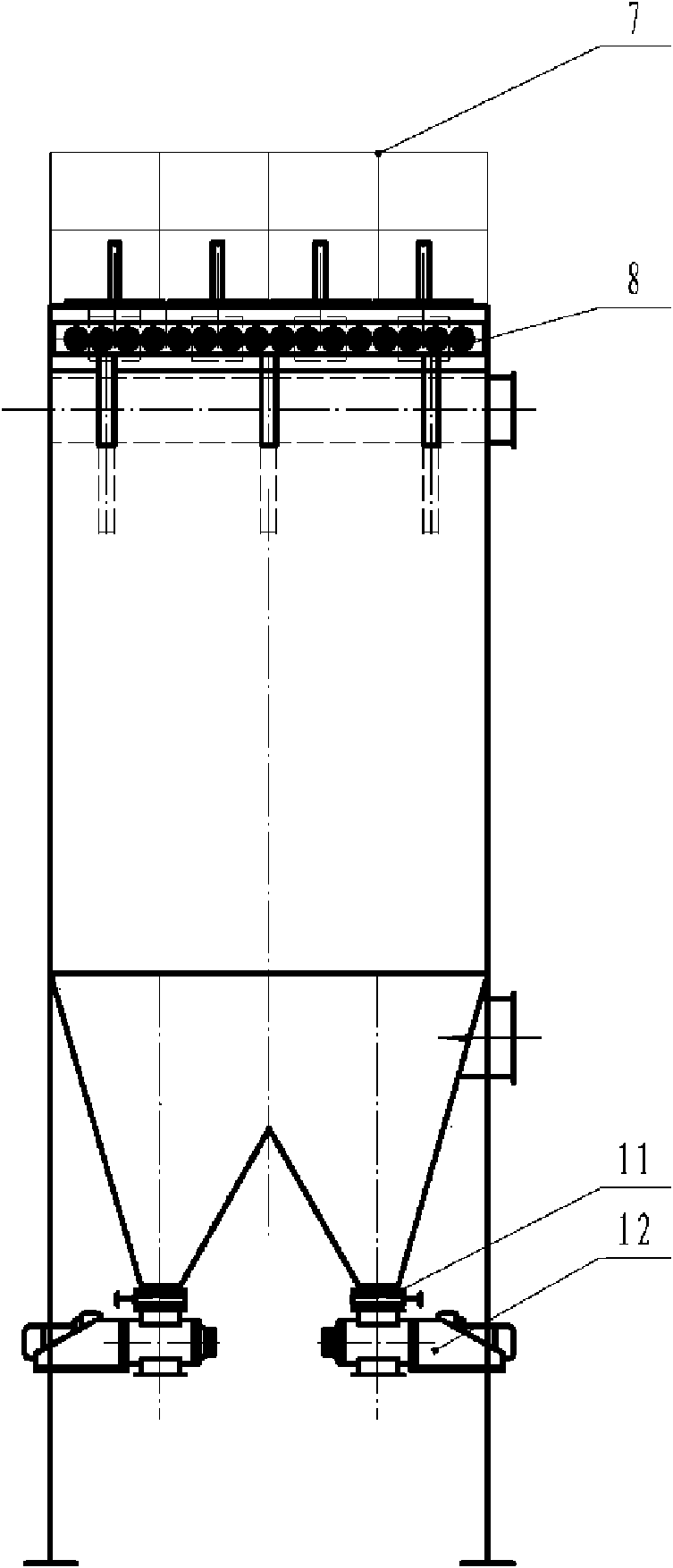

[0017] Embodiment 1: The present invention is composed of a clean air chamber 1, a filter bag 5, a filter bag skeleton 4, a filter bag 6, an injection device 8, an ash hopper 9, a bracket 10, a gate valve 11 and a star-shaped rotary valve 12, etc. Composition, and a Venturi tube is installed in the dust collector. The nozzle pipe of the injection device 8 is connected with a supersonic nozzle in a movable connection, and the centerline of the supersonic nozzle is aligned with the centerline of the bag hole.

[0018] The dust cleaning process of the general pulse bag filter is that the pulse air flow controlled by the pulse valve is injected into the filter bag through the injection hole (the hole drilled in the pipe) on the injection pipe. The filter bag is rapidly expanded, and when it expands to the limit, a large impact vibration is generated, so that the dust adhering to the filter bag is peeled off under the action of inertia, and settles in the ash hopper. When designing...

Embodiment 2

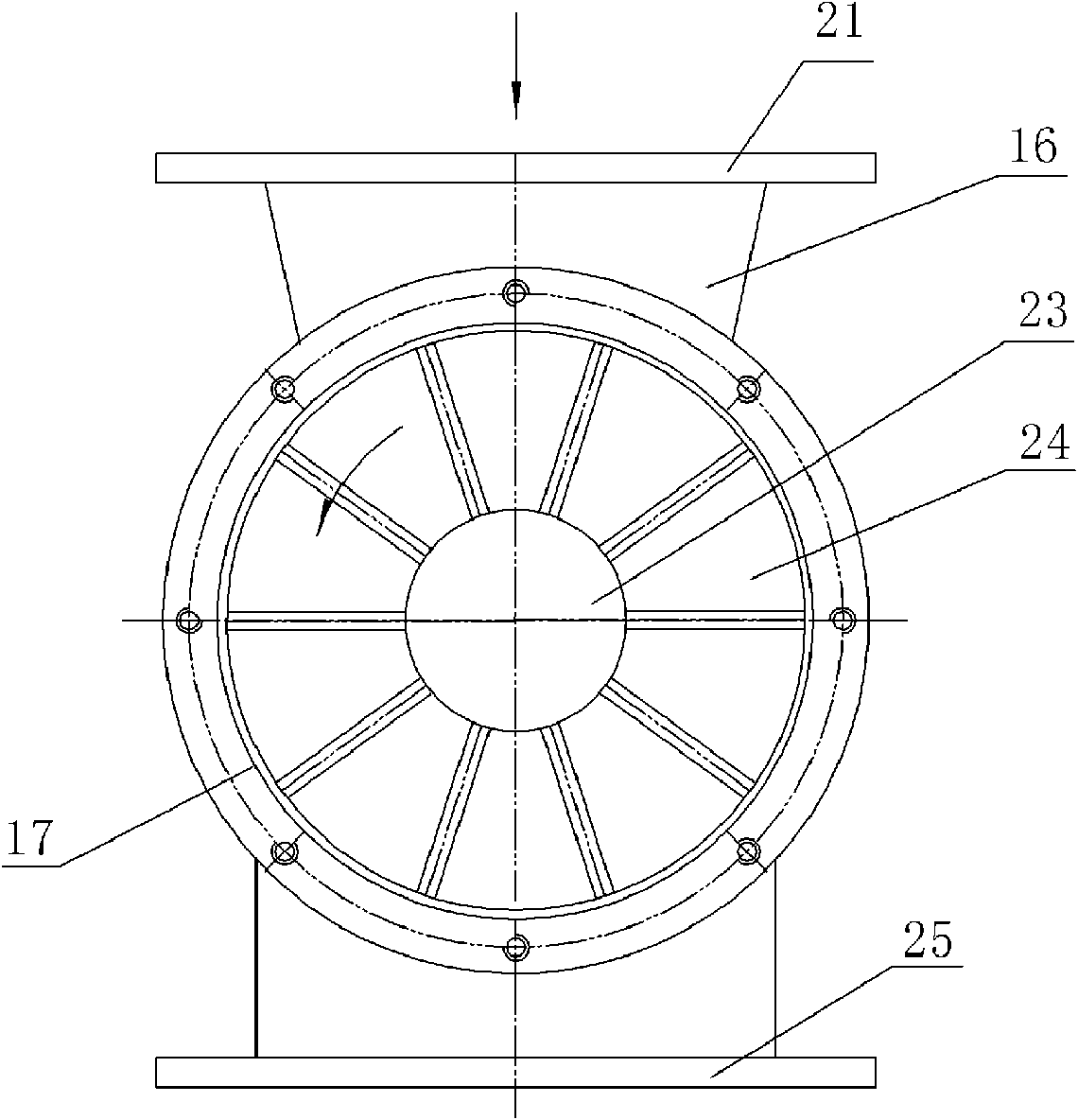

[0020] Embodiment 2: the present invention can also install venturi tube on the flower plate of the dust collector, and the described venturi tube adopts a trapezoidal venturi tube with a trapezoidal cross-sectional shape, and the upper diameter of the trapezoidal venturi tube is greater than the lower diameter, and The diameter of the lower part is consistent with the diameter of the filter bag.

[0021] The Venturi tube is an important accessory of the pulse bag filter. The longitudinal section shape of the traditional Venturi tube is close to a lowercase X shape. The more common Venturi tube is installed in the cage frame under the flower plate of the pulse bag filter. The purpose of using the Venturi tube on the pulse dust collector is to keep the blowing pressure, concentrate the diffused airflow, make the bottom of the Venturi tube form the maximum pressure airflow, and effectively transmit the cleaning pressure to the filter bag bottom for the purpose of dust removal. ...

Embodiment 3

[0025]Embodiment 3: the present invention can reasonably set the space distribution in the filter bag chamber, and the best way is to make the ratio of the space occupied by the clean air in the filter bag to the space occupied by the dust outside the filter bag (abbreviated as "clean, dust Space ratio") ranges from 0.2 to 0.45. The net-to-dust space ratio refers to the ratio of the space occupied by the clean air inside the filter bag to the space occupied by the dust outside the filter bag in the filter bag chamber of the pulse bag filter. This concept is summed up by the company's many years of experiments, research and engineering practice, and is used to guide the important parameter values of the filter bag room design. It is especially important to design a pulse dust collector that collects high-concentration, high-viscosity, high-grinding and ultra-fine dust. To improve the cleaning effect of the filter bag and reduce the resistance of the dust collector, in additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com