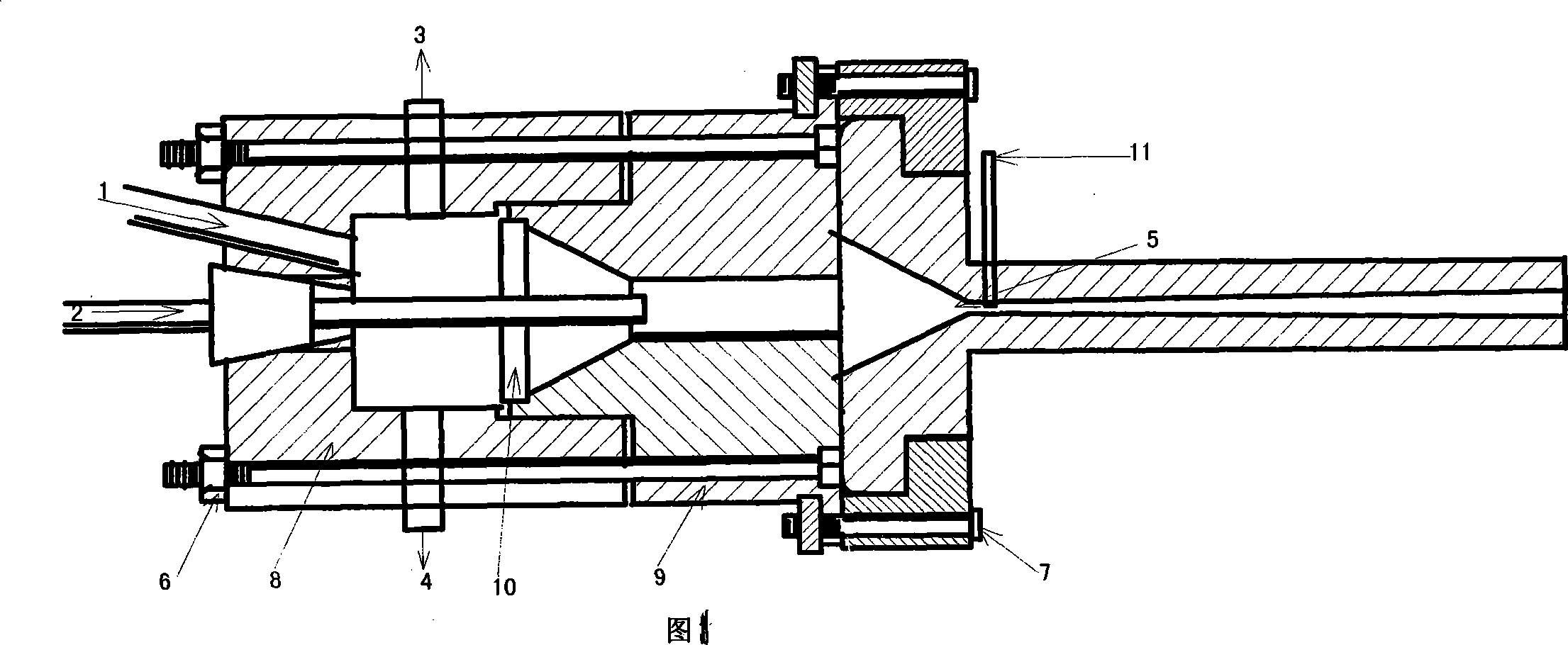

De-Laval-Type nozzle for cold spraying

A technology of cold spraying and nozzles, which is applied in the field of thermal spraying in surface treatment engineering, can solve the problems of cumbersome manufacturing process, no consideration of boundary effects, complex nozzle structure, etc., and achieve the effect of reducing speed drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] The nozzle designed and prepared according to the present invention has a supersonic portion of 180mm, a nozzle throat of Φ2, an outlet size of 2mm×10mm, a convergent section length of 40mm, and a convergent angle of 60°. The aluminum sample is sprayed at a carrier gas temperature of 200°C at room temperature, where the bonding force is greater than 20MPa, the deposition efficiency is greater than 80%, and the deposition part of the fixed-point spraying is about 5mm high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com