Method And Device For Starting Driving System Of Motor Vehicle

A technology for motor vehicles and drive systems, which is applied to the arrangement of power plant control mechanisms, control devices, vehicle components, etc., to achieve the effect of reducing the speed drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

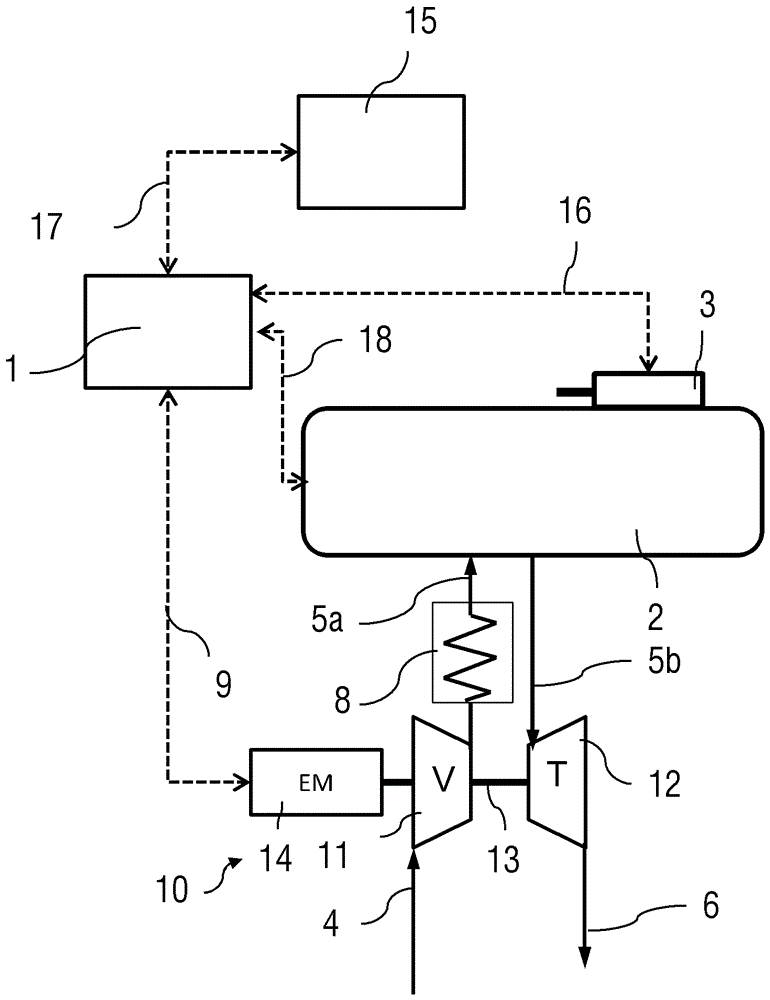

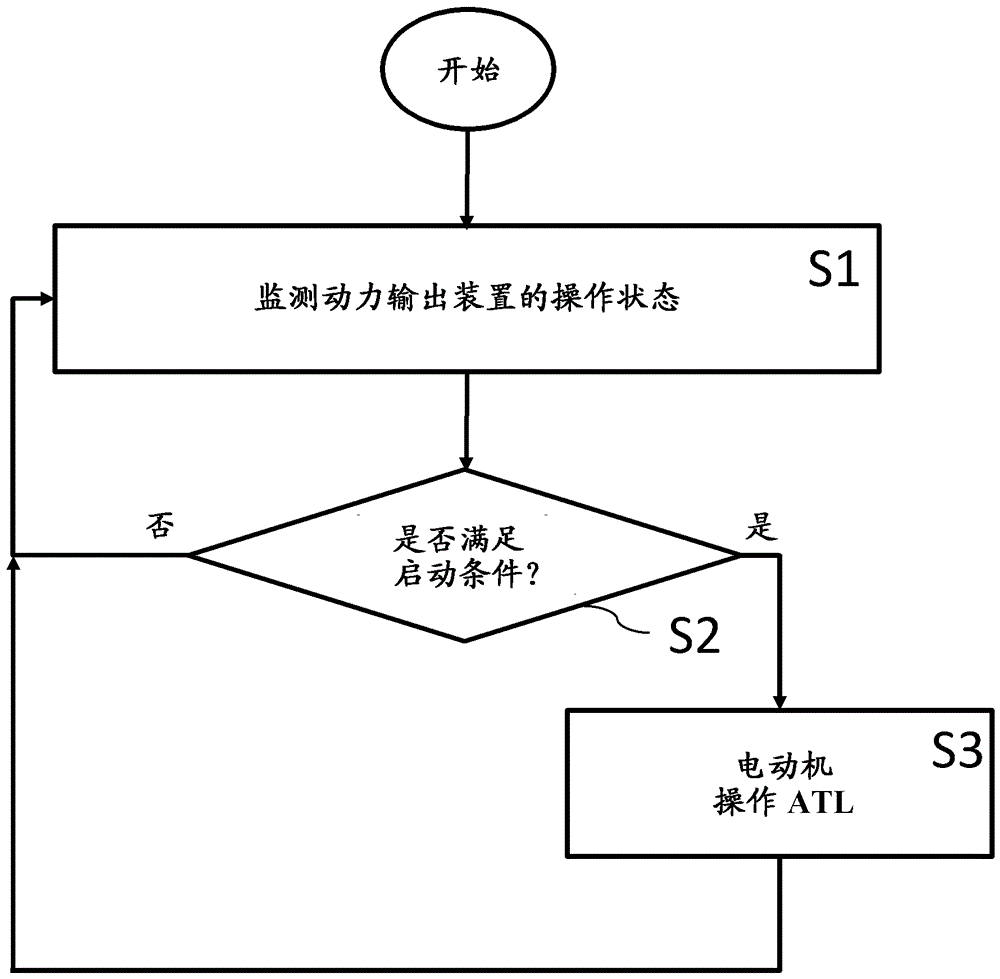

[0049] figure 1 The drive system of a commercial vehicle is shown in the form of a highly schematic block diagram. The drive system comprises a supercharged internal combustion engine 2 , usually a diesel engine, and an electrified exhaust-gas turbocharger 10 , hereinafter also referred to as ATL, assigned to it. The ATL 10 comprises a turbine 12 driven by the exhaust gases of the internal combustion engine 2 , which are fed to the turbine 12 via the exhaust line 5 b. Thereafter, the exhaust mixture flows via the turbine outlet into the exhaust line 6 to the exhaust port, and in doing so optionally also extends through an exhaust aftertreatment device (not shown).

[0050] The turbine 12 is connected to the compressor 11 by a shaft 13 . Fresh air is fed to the compressor 11 via the compressor inlet line 4 . The compressor 11 compresses charge air to be fed to the internal combustion engine 2 and thus increases the power output of the internal combustion engine 2 during norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com