Method and device for starting a drive system of a motor vehicle

A technology for drive systems and motor vehicles, applied to the layout of power plant control mechanisms, control devices, vehicle components, etc., to achieve the effect of reducing the speed drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

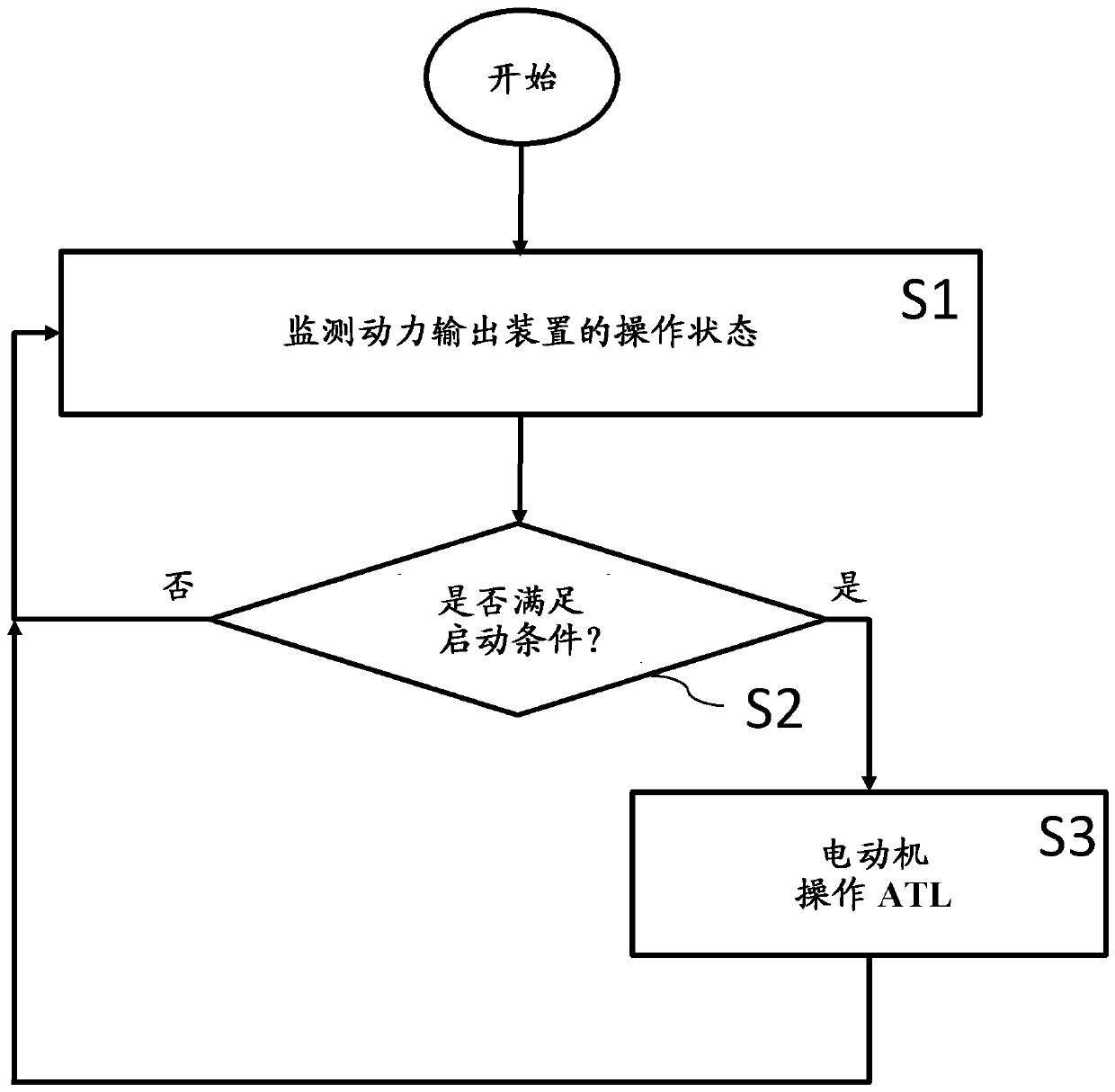

Method used

Image

Examples

Embodiment Construction

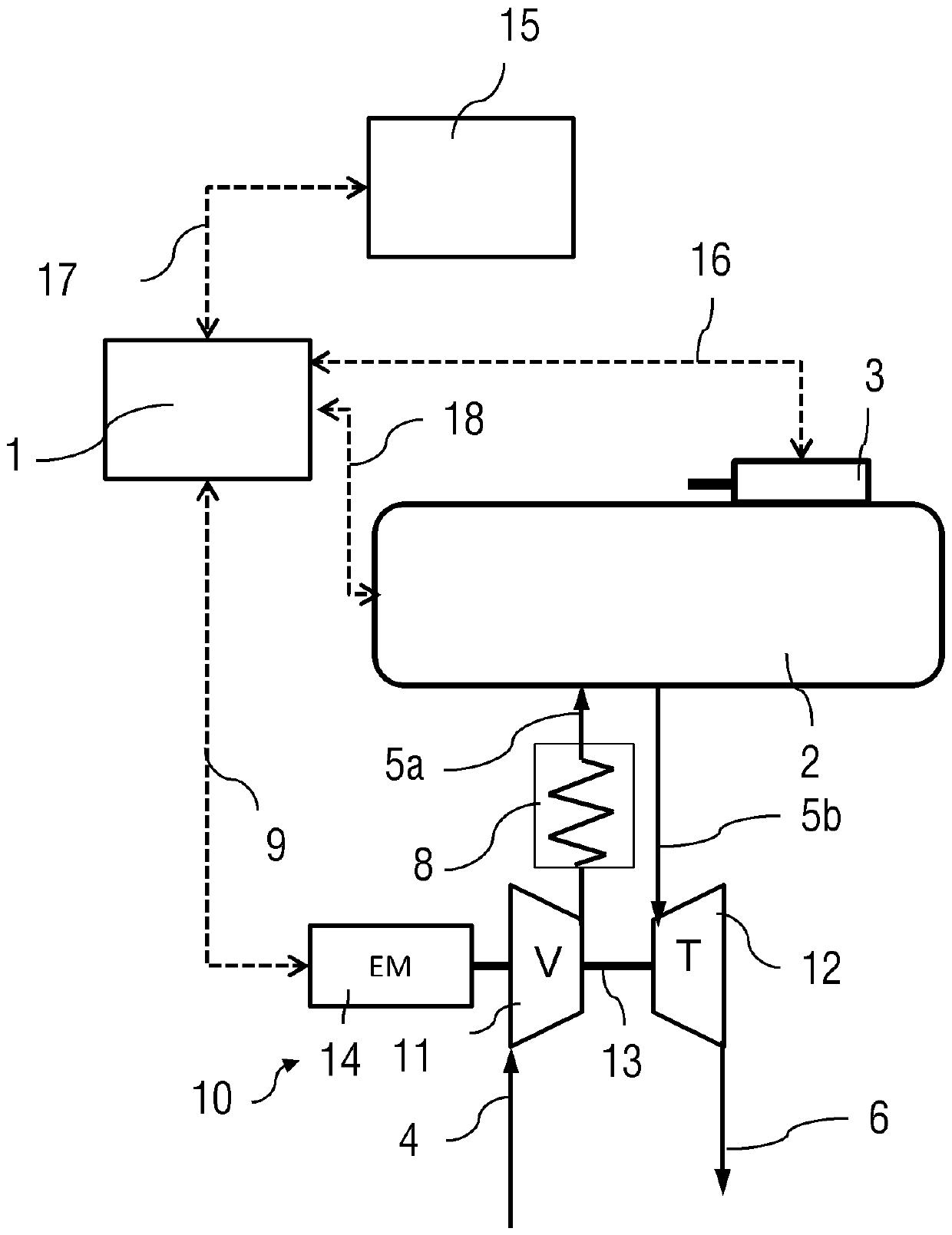

[0049] figure 1 The drive system of a commercial vehicle is shown in the form of a highly schematic block diagram. The drive system comprises a supercharged internal combustion engine 2 , usually a diesel engine, and an electrified exhaust-gas turbocharger 10 , hereinafter also referred to as ATL, assigned to it. The ATL 10 comprises a turbine 12 driven by the exhaust gases of the internal combustion engine 2 , which are fed to the turbine 12 via the exhaust line 5 b. Thereafter, the exhaust mixture flows via the turbine outlet into the exhaust line 6 to the exhaust port, and in doing so optionally also extends through an exhaust aftertreatment device (not shown).

[0050] The turbine 12 is connected to the compressor 11 by a shaft 13 . Fresh air is fed to the compressor 11 via the compressor inlet line 4 . The compressor 11 compresses charge air to be fed to the internal combustion engine 2 and thus increases the power output of the internal combustion engine 2 during norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com