Preparation method for glycolide

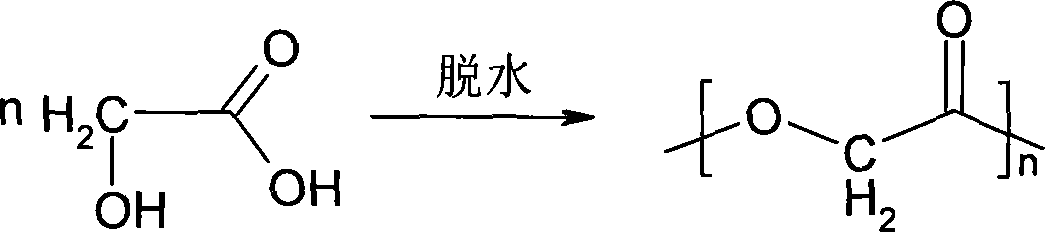

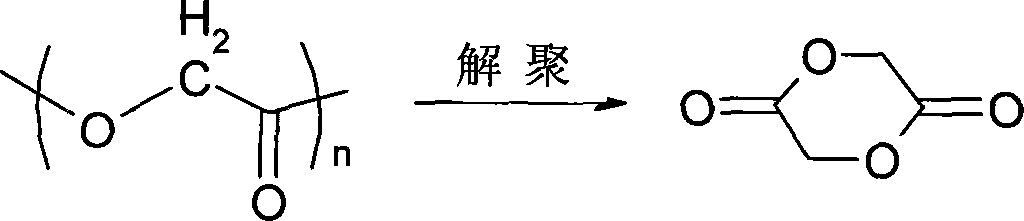

A technology of glycolide and glycolic acid, applied in directions such as organic chemistry, to achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

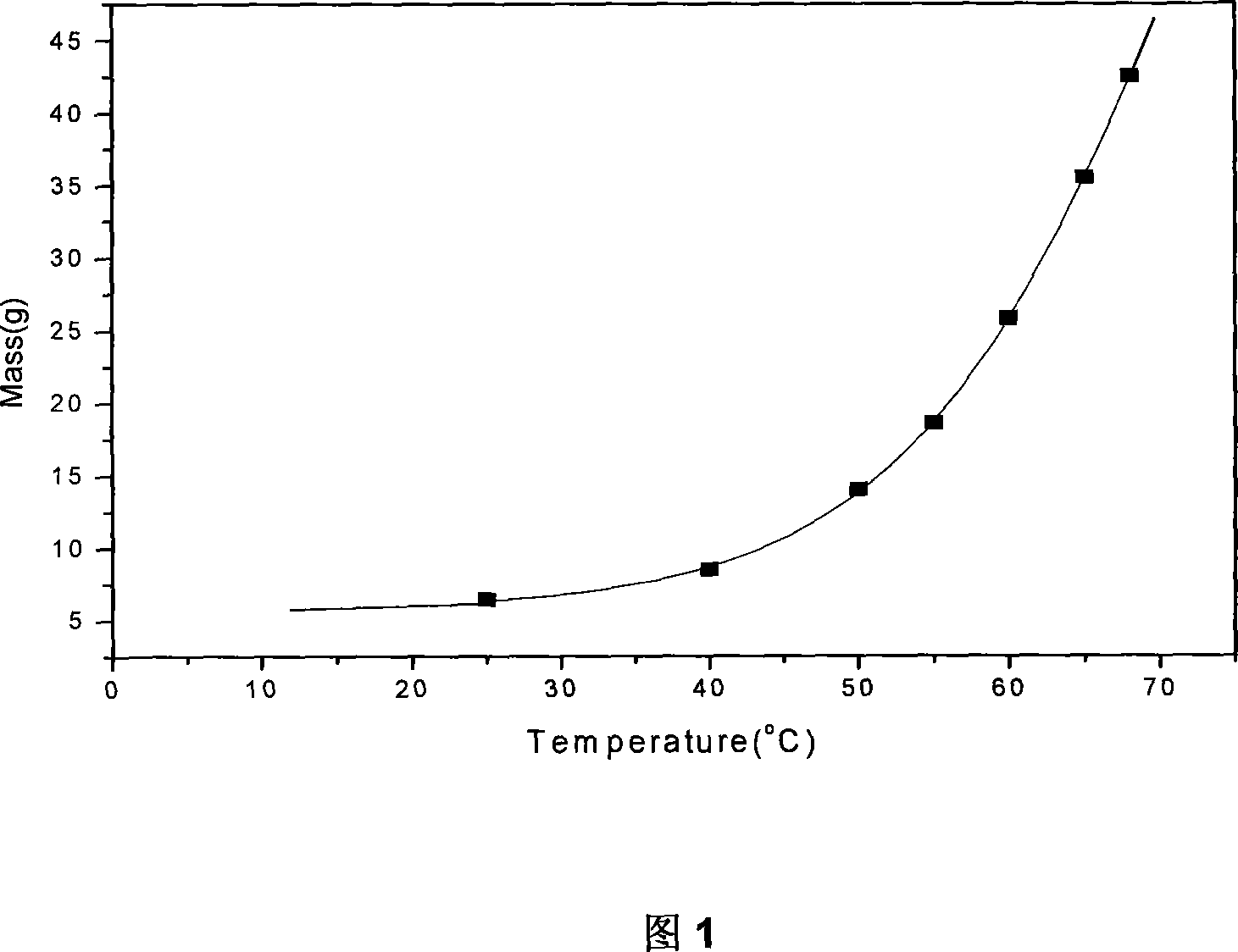

[0051] Add 553.1 g of 99.5% glycolic acid crystals and 1.66 g of catalyst Sb to a 500 ml single-necked flask 2 o 3, put it in an oil bath, the temperature rises from room temperature to 90 ℃, after the dissolution is complete, start to slowly vacuumize, and the liquid is continuously evaporated, and the reaction is solidified at a heating rate of 5-10 ℃ / h until it turns milky white, until no liquid evaporates. The temperature was raised to 210-220°C and the reaction was continued for 4 hours. The vacuum degree was controlled at 1-3KPa during this process, and a total of 119ml of light yellow liquid was collected in the single-neck receiving flask. Then use an air condenser and a three-necked flask to receive the product, the reaction temperature gradually rises from 220 ° C to 260 ° C, and the vacuum degree is also increased to between 10-300 Pa, and the crude product of light yellow glycolide is steamed out continuously until no glycolide is present. The reaction was stop...

Embodiment 2

[0053] 470.7g of 99.5% glycolic acid crystals and 2.829g of catalyst Sb were added to a 500ml one-neck flask 2 O 3 , the experimental device and conditions after that are the same as in Example 1, and the reaction time is extended for 10h in the high-temperature melt polycondensation stage at 210-220 ° C. The subsequent experimental device and conditions are also the same as in Example 1, and the crude product of glycolide is 300.2 g, 84% yield. Put the crude glycolide product into a single-necked flask, pour 270 ml of ethyl acetate, raise the temperature and stir to dissolve, and continuously add 90 ml of acetone dropwise at the same time. When the temperature reaches 65 °C, the crystals of glycolide are completely dissolved, and it is colorless, clear and transparent. solution. Then cool down to 50-55°C to form a supersaturated solution of glycolide, drop a few drops of 0.1-1ml ether, a small amount of crystals will be precipitated on the liquid surface or in the solution,...

Embodiment 3

[0055] 333.1 g of 99.5% glycolic acid crystals and 2.0 g of catalyst Sb were added to a 500 ml one-neck flask 2 O 3 , put it in an oil bath, the temperature rises from room temperature to 90 ℃, after the dissolution is complete, start to slowly vacuumize, and the liquid is continuously evaporated, and the reaction is solidified at a heating rate of 5-10 ℃ / h until it turns milky white, until no liquid evaporates. 3.331g of stannous octoate catalyst was added to the reaction system, and then the temperature was raised to 210-220° C. to continue the reaction for 3 hours, and the vacuum degree in this process was controlled at 1-3KPa. Then use an air condenser and a three-necked flask to receive the product, the reaction temperature gradually rises from 220 ° C to 260 ° C, and the vacuum degree is also increased to between 10-300 Pa, and the crude product of light yellow glycolide is steamed out continuously until no glycolide is present. The reaction was stopped when the este...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com