Water heat modification method for high dispersion magnesium hydroxide nanometer sheet

A technology of magnesium hydroxide and hydrothermal modification, applied in magnesium hydroxide and other directions, can solve the problems of environmental pollution, high cost, difficult industrial promotion, etc., and achieve the effects of easy industrial amplification, regular morphology and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a substrate double-injection-hydrothermal modification preparation method of highly dispersed magnesium hydroxide nanosheets, using inorganic magnesium salt as raw material, inorganic alkali as precipitant, inorganic chloride salt as substrate solution, and substrate The double-injection-hydrothermal modification method improves the structure of the product, thereby preparing highly dispersed magnesium hydroxide nanosheets. The specific steps are as follows:

[0021] 1) Prepare an inorganic magnesium salt solution and an inorganic alkali solution with a concentration of 0.5 to 5 mol / liter, and add the above magnesium salt and alkali solution simultaneously at a rate of 1 to 10 ml / min at 10 to 80° C. -5mol / L inorganic chloride salt solution, control the molar ratio of magnesium salt, alkali and chloride salt to 1:1-3:1-3, continue to react for 0.5-2 hours after the feeding is completed, and obtain a white milky slurry;

[0022] 2) adding the above ...

Embodiment 1

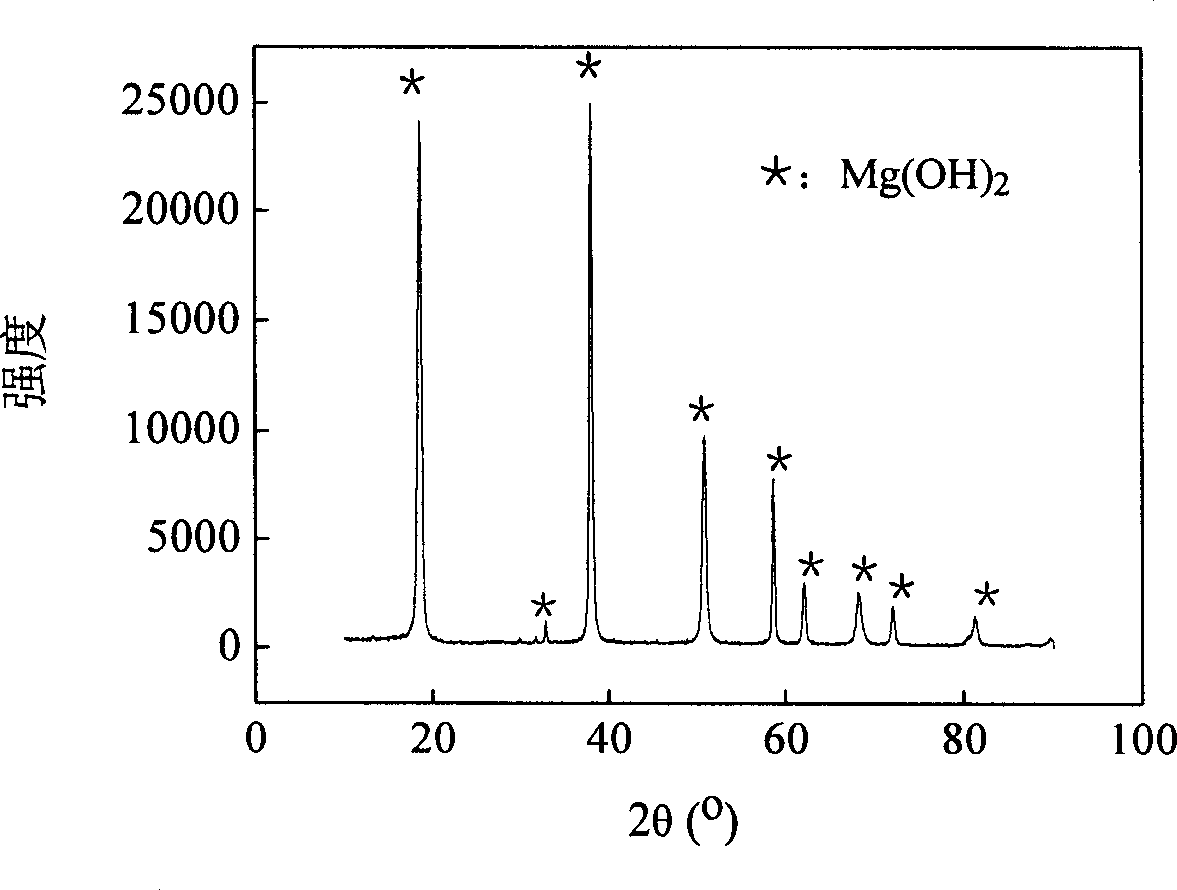

[0027] Prepare 100 milliliters of 0.5 mol / liter magnesium sulfate solution, 100 milliliters of 0.5 mol / liter sodium hydroxide solution, and inject the above solution into 100 milliliters of 0.5 mol / liter at a speed of 1 milliliter / minute under stirring (300 rpm) conditions Sodium chloride solution, continue to react for 2 hours after the feeding is completed, and obtain a white milky slurry; add the above-mentioned slurry to a hydrothermal reactor, stir at a constant temperature of 250 ° C (150 rpm) for 6 hours, then cool, filter, wash, dry, Pulverize to obtain magnesium hydroxide nanosheets with an average thickness of 50nm, an average diameter of 300nm, an average aggregate particle diameter of 100nm and a purity of 98.5%.

Embodiment 2

[0029] Prepare 100 milliliters of 5 mol / liter magnesium nitrate solution, 100 milliliters of 5 mol / liter potassium hydroxide solution, inject 100 milliliters 5 mol / liter of above-mentioned solution simultaneously with the speed of 10 milliliters / minute under stirring (300 rpm) conditions Potassium chloride solution, continue to react for 0.5 hours after feeding, to obtain a white milky slurry; add the above slurry to a hydrothermal reactor, stir at 100 ° C (150 rpm) for 1 hour, then cool, filter, wash, dry, Pulverize to obtain magnesium hydroxide nanosheets with an average thickness of 10nm, an average diameter of 100nm, an average aggregate particle size of 600nm and a purity of 98.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com