Acidic cleaning composition

A technology for cleaning compositions and acidic substances, which is applied in the direction of detergent compositions, bleaching agents for cleaning compositions, non-ionic surface active compounds, etc., and can solve problems such as the stability of hydrogen peroxide adducts that are not mentioned, and achieve bleaching The effect of improving the disinfection function and stabilizing the components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 55Wt.% Hydrogen peroxide 4Na 2 SO 4 . 2H 2 o 2 . NaCl, 5 Wt.% anhydrous sodium sulfate, 2 parts of zeolite (Zeolite NaA) and 38 Wt.% anhydrous citric acid were mixed, and the mixture was placed in an oven at 35-41°C to determine its stability. The hydrogen peroxide concentration of the product obtained was measured by iodine reduction titration. It can be observed that after the first day, because the hydrogen peroxide salt was not completely dried, the activity decreased by 17%, and decreased by 0.25% every day thereafter. The mixture has a great oxidizing ability and can oxidize KI dissolved in water into iodine.

Embodiment 2

[0043] 33 Wt.% hydrogen peroxide adduct 4Na 2 SO 4 . 2H 2 o 2 . NaCl, 26 Wt.% Sodium Sulfate, 2 Wt.% Zeolite (Zeolite NaA) and 2 Wt.% melted Plurafac SLF18 B45 were mixed and 37 Wt.% of anhydrous citric acid was added. Stability was determined by placing the mixture in an oven at 35-41°C. The hydrogen peroxide concentration of the product obtained was measured by iodine reduction titration. It can be observed that after the first day, because the hydrogen peroxide salt was not completely dried, it decreased by 10%, and the subsequent daily decrease hardly changed. The mixture has a great oxidizing ability, which can oxidize KI dissolved in water into iodine.

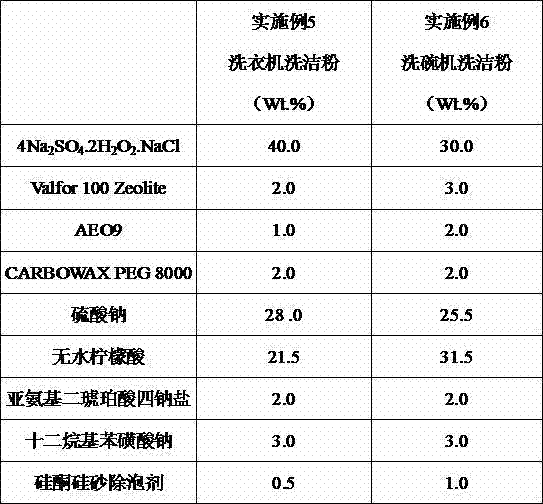

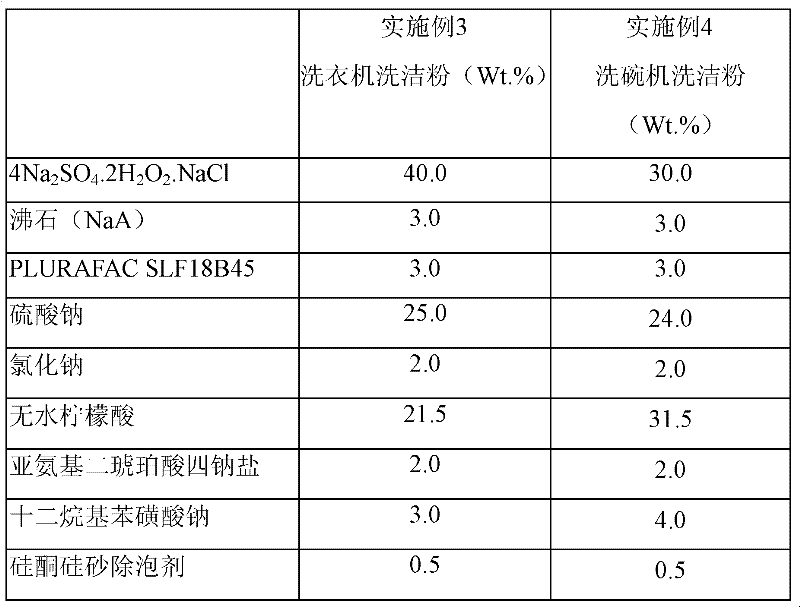

Embodiment 3-4

[0045] The following light-duty acid detergent powder is used to clean dishwashers and washing machines. Hydrogen peroxide adduct 4Na 2 SO 4 2H 2 o 2 · NaCl is coated with zeolite, and then melted Plurofac SLF18 B45 is added. The remaining components are added and mixed according to the following table sequence:

[0046]

[0047] The storage stability of light-duty acid cleaners is measured at 30-41°C. The activity of detergent powders for dishwashers and washing machines decreased by 0.1% and 0.2% per day, respectively, after more than four weeks of observation, showing a descaling capacity of 0.35 and 0.19 CaCO 3 / g detergent powder. The descaling ability is tested in an aqueous solution of one percent detergent powder. This result proves that this detergent powder has a good descaling ability. When tested by standard iodine reduction titration at room temperature, after 5 minutes of reaction without adding additional sulfuric acid, it can be titrated to 90% hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com