Electrocaloric effect refrigeration composite thick film material

A technology of electric card effect and thick film, which is applied in the field of electric card effect refrigeration composite thick film materials and antiferroelectric thick film refrigeration, and can solve problems such as dead layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

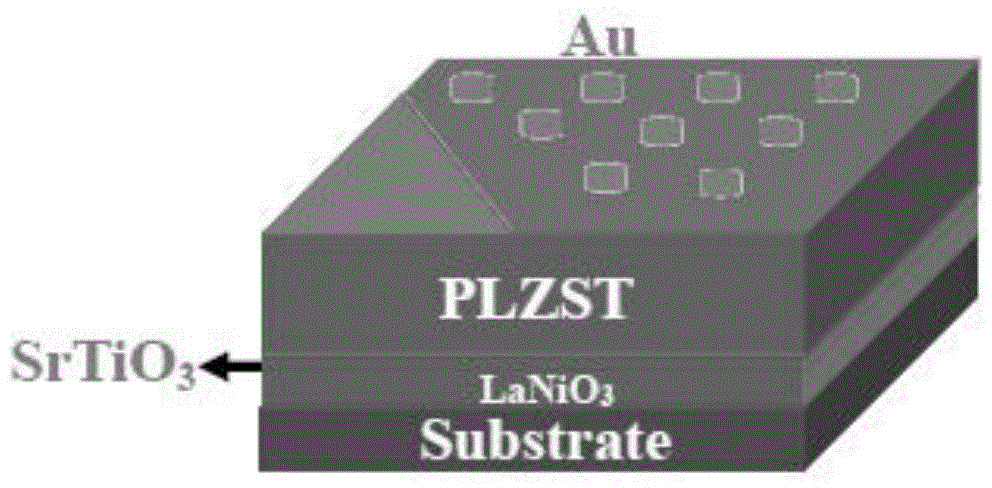

[0049] 1. Choose LaNiO as the bottom electrode 3 / Si electrode;

[0050] 2. Pb 0.97 La 0.02 (Zr0.57 sn 0.38 Ti 0.05 )O 3 Preparation of antiferroelectric composite thick film

[0051] 1) SrTiO 3 Precursor Solution Preparation

[0052] Strontium acetate and tetra-n-butyl titanate are used as raw materials, ethylene glycol methyl ether and acetylacetone are used as solvent and chelating agent respectively, and glacial acetic acid is used as catalyst. Strontium acetate [Sr(OOCCH 3 ) 3 ·H 2 O] dissolved in ethylene glycol methyl ether, add acetic acid and acetylacetone, stir at room temperature for 20 minutes, add tetra-n-butyl titanate [Ti(OC 4 h 9 ) 4 )], the molar ratio is: strontium acetate: tetra-n-butyl titanate = 1:1, ethylene glycol methyl ether: glacial acetic acid: tetra-n-butyl titanate: acetylacetone = 1:1:1:0.5, room temperature Stir for 30 minutes to get stable SrTiO 3 Precursor solution, the molar concentration is controlled at 0.02mol / L, and it is us...

Embodiment 2

[0064] 1. Choose LaNiO as the bottom electrode 3 / Si electrode;

[0065] 2. Pb 0.91 La 0.06 (Zr 0。95 Ti 0.05 )O 3 Preparation of antiferroelectric composite thick film

[0066] 1) SrTiO 3 Precursor Solution Preparation

[0067] Strontium acetate and tetra-n-butyl titanate are used as raw materials, ethylene glycol methyl ether and acetylacetone are used as solvent and chelating agent respectively, and glacial acetic acid is used as catalyst. Strontium acetate [Sr(OOCCH 3 ) 3 ·H 2 O] dissolved in ethylene glycol methyl ether, add acetic acid and acetylacetone, stir at room temperature for 30 minutes, add tetra-n-butyl titanate [Ti(OC 4 h 9 ) 4 )], the molar ratio is: strontium acetate: tetra-n-butyl titanate = 1: 1, ethylene glycol methyl ether: glacial acetic acid: tetra-n-butyl titanate: acetylacetone = 0.9:0.5:1:0.6, room temperature Stir for 40 minutes to get stable SrTiO 3 Precursor solution, the molar concentration is controlled at 0.2mol / L, and it is used ...

Embodiment 3

[0079] 1. Choose LaNiO as the bottom electrode 3 / Si electrode;

[0080] 2. Pb(Zr 0。98 Ti 0.02 )O 3 Preparation of antiferroelectric composite thick film

[0081] 1) SrTiO 3 Precursor Solution Preparation

[0082] Strontium acetate and tetra-n-butyl titanate are used as raw materials, ethylene glycol methyl ether and acetylacetone are used as solvent and chelating agent respectively, and glacial acetic acid is used as catalyst. Strontium acetate [Sr(OOCCH 3 ) 3 ·H 2 O] was dissolved in ethylene glycol methyl ether, added acetic acid and acetylacetone, stirred at room temperature for 40 minutes, added tetra-n-butyl titanate [Ti(OC 4 h 9 ) 4 )], the molar ratio is: strontium acetate: tetra-n-butyl titanate = 1: 1, ethylene glycol methyl ether: glacial acetic acid: tetra-n-butyl titanate: acetylacetone = 0.8:0.3:1:0.3, room temperature Stir for 60 minutes to get stable SrTiO 3 Precursor solution, the molar concentration is controlled at 0.05mol / L, and it is used afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com