MXene material reinforced conductive hydrogel

A conductive hydrogel and hydrogel technology, applied in the field of biomedical materials, can solve problems such as poor mechanical ability and poor conductivity, and achieve good biodescriptive properties, enhanced conductivity, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

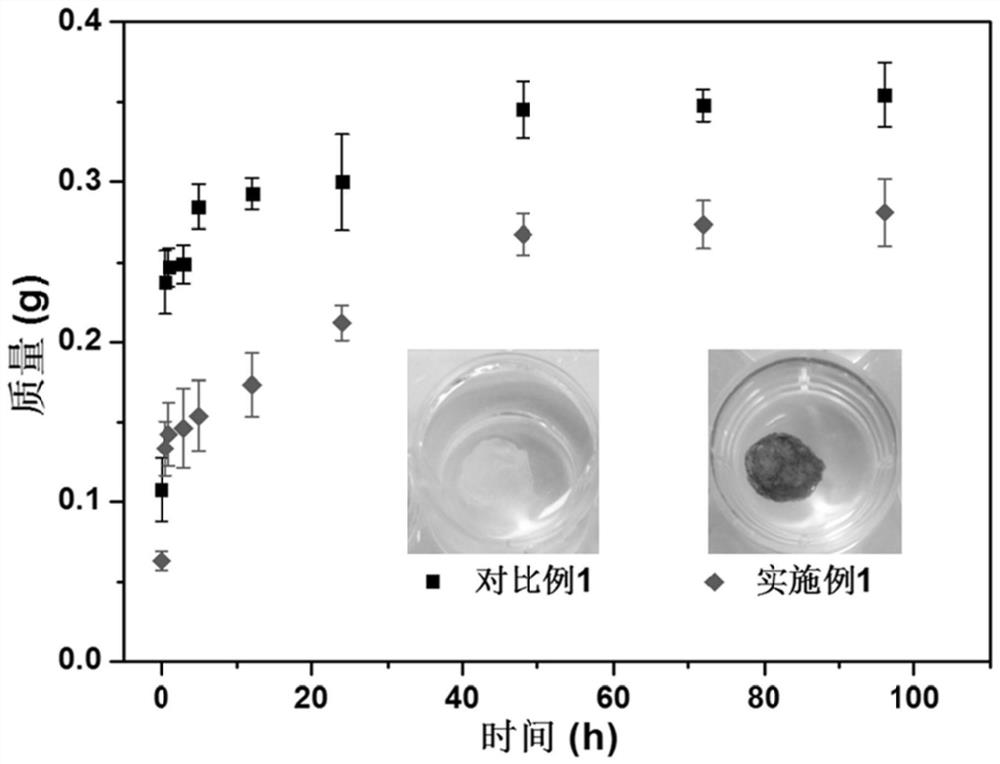

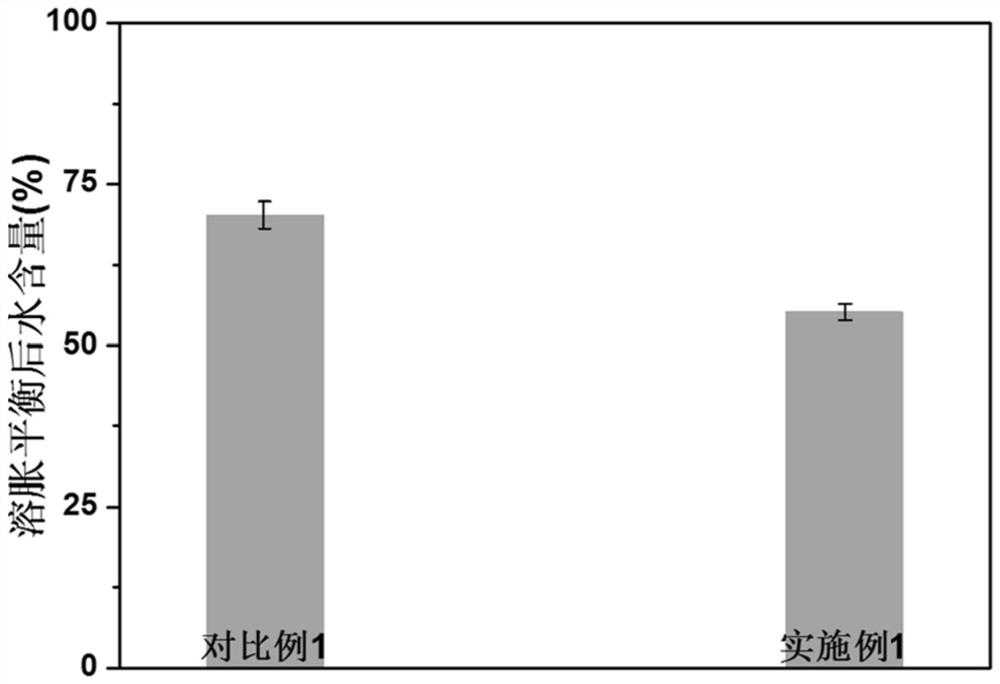

Embodiment 1

[0044] 1. Preparation of hydroxyl-rich (polyvinyl alcohol) hydrogels

[0045] Dissolve 2 g of polyvinyl alcohol in 10 mL of deionized aqueous solution, heat and stir at 95 °C for 3 h, the polyvinyl alcohol hydrogel is completely dissolved, and then add 10 mg / mL (5 mL) of Ti 3 C 2 After the nanosheet aqueous solution is completely dissolved, add 0.04M (mol / L) sodium borate aqueous solution, continue heating and stirring for 1h, cool to room temperature, and place it in a hydrogel template to obtain MXene-doped polyvinyl alcohol hydrogel . The size of MXene-doped polyvinyl alcohol hydrogel is 1 cm × 1 cm × 1.5 cm.

[0046] 2. Preparation of conductive hydrogels enhanced by MXene materials

[0047] Soak the MXene-doped polyvinyl alcohol hydrogel (0.1780g) obtained in step 1 in 20wt% ferrous chloride aqueous solution (1mL), ultrasonically disperse at room temperature for 10min, let it stand for 1 day, and rinse with deionized water After rinsing 3 times, the conductive hydroge...

Embodiment 2

[0049] 1. Preparation of hydroxyl-rich (polyvinyl alcohol) hydrogels

[0050] Dissolve 1 g of polyvinyl alcohol in 10 mL of deionized aqueous solution, heat and stir at 90 °C for 3 h, the polyvinyl alcohol hydrogel is completely dissolved, and then add 5 mg / mL (5 mL) of Ti 3 C 2 After the nanosheet aqueous solution is completely dissolved, add 0.04M (mol / L) sodium borate aqueous solution, continue heating and stirring for 2 hours, cool to room temperature, and place it in a hydrogel template to obtain MXene-doped polyvinyl alcohol hydrogel . The size of MXene-doped polyvinyl alcohol hydrogel is 1 cm × 1 cm × 1.5 cm.

[0051] 2. Preparation of conductive hydrogels enhanced by MXene materials

[0052] Soak the MXene-doped polyvinyl alcohol hydrogel (0.0890g) obtained in step 1 in 10wt% ferrous chloride aqueous solution (1mL), ultrasonically disperse at room temperature for 10min, let it stand for 1 day, and rinse with deionized water After rinsing 3 times, the conductive hyd...

Embodiment 3

[0054] 1. Preparation of hydroxyl-rich (polyvinyl alcohol) hydrogels

[0055] Dissolve 2 g of polyvinyl alcohol in 10 mL of deionized aqueous solution, heat and stir at 95 °C for 3 h, the polyvinyl alcohol hydrogel is completely dissolved, and then add 10 mg / mL (5 mL) of Ti 3 C 2 After the nanosheet aqueous solution is completely dissolved, add 0.04M (mol / L) sodium borate aqueous solution, continue heating and stirring for 1h, cool to room temperature, and place it in a hydrogel template to obtain MXene-doped polyvinyl alcohol hydrogel . The size of MXene-doped polyvinyl alcohol hydrogel is 1 cm × 1 cm × 1.5 cm.

[0056] 2. Preparation of conductive hydrogels enhanced by MXene materials

[0057] Soak the MXene-doped polyvinyl alcohol hydrogel (0.1780g) obtained in step 1 in a 30wt% aluminum chloride aqueous solution (1mL), ultrasonically disperse at room temperature for 10min, let it stand for 1 day, and rinse with deionized water 3 times, the conductive hydrogel enhanced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com