Automobile hot-melt lamp adhesive

A hot-melt and lamp technology, applied in the direction of adhesives, etc., can solve the problems of poor bonding effect of glass lamps, complicated production process of hot-melt adhesive, high melting viscosity of hot-melt adhesive, etc., to achieve improved wettability and low styrene content , Good colloidal flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

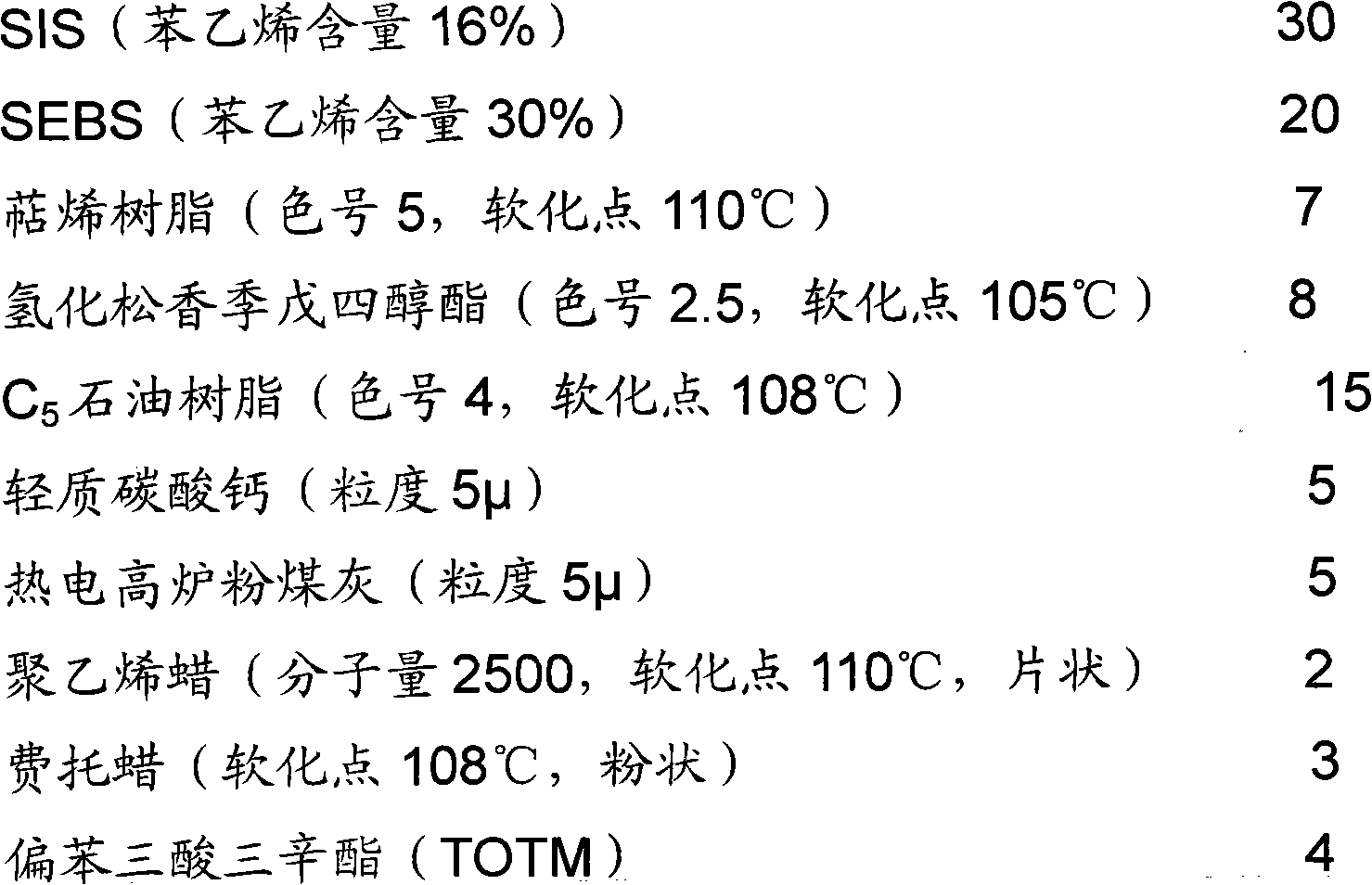

[0023] Embodiment 1, automobile hot-melt lamp glue component ratio (mass %)

[0024]

[0025]

[0026] SIS, SEBS, TOTM and Antioxidant 1010 were weighed in proportion and added to a horizontal kneader that had been preheated for 60 minutes (wall temperature 180°C), kneaded for 40 minutes and then added proportionally weighed terpene resin and hydrogenated rosin Pentaerythritol ester, C 5 Petroleum resin, polyethylene wax, Fischer-Tropsch wax, light calcium carbonate and thermoelectric blast furnace fly ash were kneaded at high temperature (175°C) for 60 minutes. Pour into a 25cm×15cm×7cm cube box (lined with high-temperature release paper) in a molten state, and wrap it with release paper after cooling.

Embodiment 2

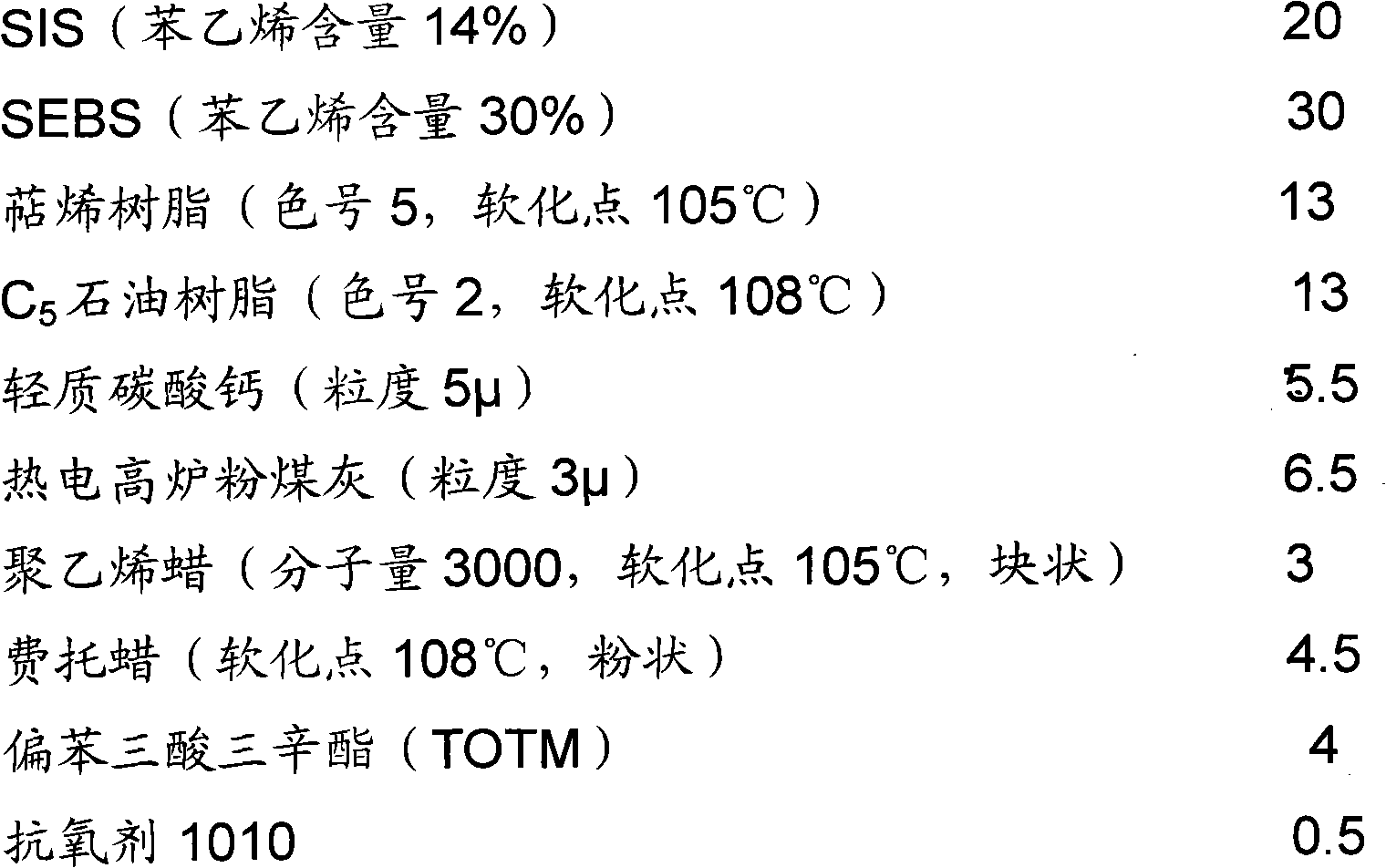

[0027] Embodiment 2, automobile hot-melt lamp glue component ratio (mass %)

[0028]

[0029] SIS, SEBS, TOTM and antioxidant 1010 were weighed in proportion and added to a horizontal kneader that had been preheated for 80 minutes (wall temperature 190°C), kneaded for 50 minutes, and then added in proportion to terpene resin, C 5 Petroleum resin, polyethylene wax, Fischer-Tropsch wax, light calcium carbonate and thermoelectric blast furnace fly ash were kneaded at high temperature (185°C) for 80 minutes. Pour into a 25cm×15cm×7cm cube box (lined with high-temperature release paper) in a molten state, and wrap it with release paper after cooling.

Embodiment 3

[0030] Embodiment 3, automobile hot-melt lamp glue component ratio (mass %)

[0031]

[0032]

[0033] SIS, SEBS, TOTM and antioxidant 1010 were weighed in proportion and added to a horizontal kneader that had been preheated for 60 minutes (wall temperature 200°C), kneaded for 40 minutes and then added hydrogenated rosin pentaerythritol ester, C 5 Petroleum resin, polyethylene wax, Fischer-Tropsch wax, light calcium carbonate and thermoelectric blast furnace fly ash were kneaded at high temperature (180°C) for 65 minutes. Pour into a 25cm×15cm×7cm cube box (lined with high-temperature release paper) in a molten state, and wrap it with release paper after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com