Polyolefine multiple micoporous film and preparing process thereof

A polyolefin and microporous technology, applied in polyolefin microporous membrane and its preparation, in the field of microporous polyolefin membrane, can solve the problems of complex production process, uniformity difference and high cost, achieve excellent performance, reduce The effect of high film thickness and elastic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

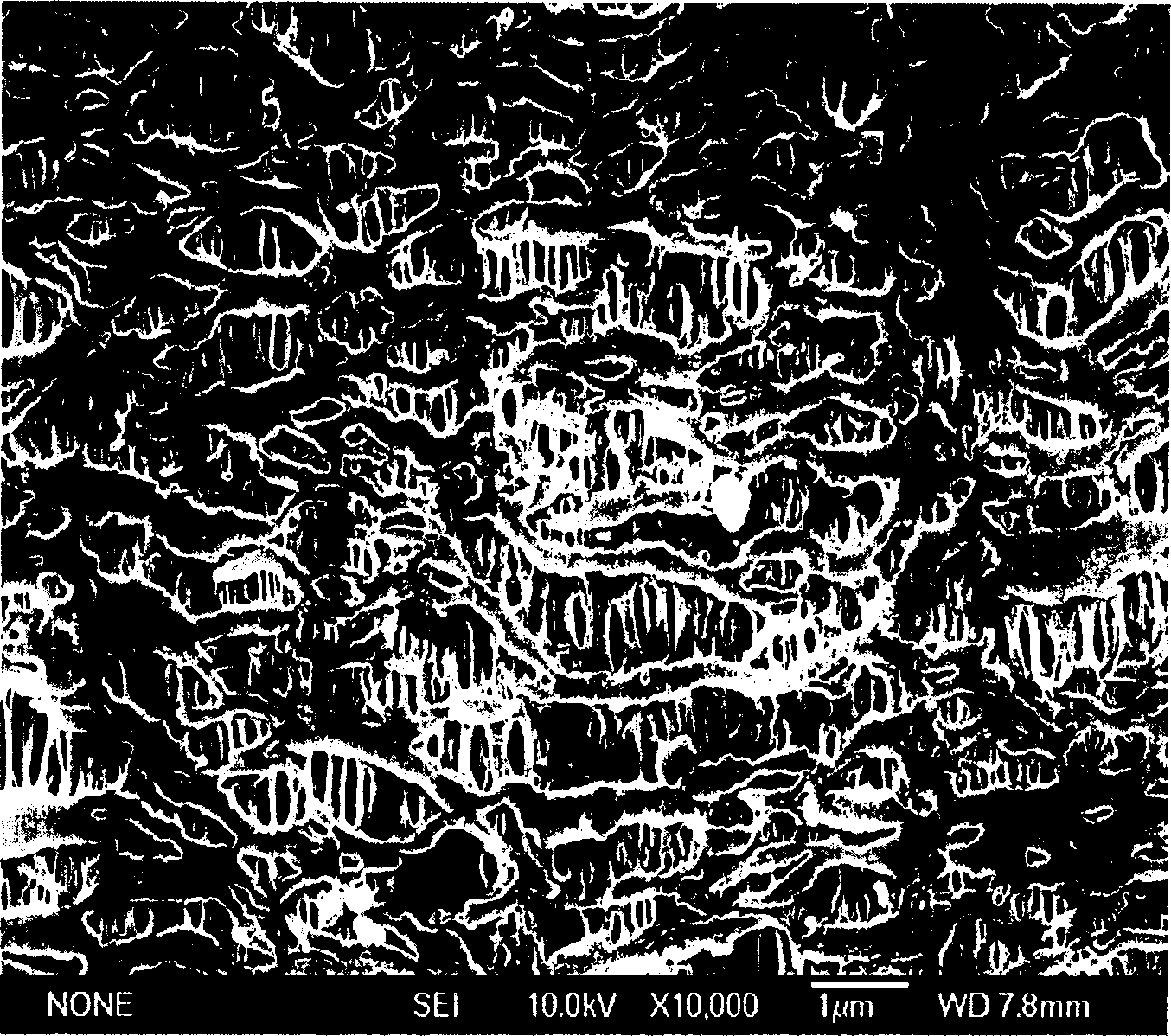

[0041]Linear polyethylene (Mw=230,000, Mw / Mn=2-8) was made into a raw film through a laboratory screw extruder at a temperature of 190°C and a stretch ratio of 16. The original film was annealed for 5 hours at a temperature of 120°C. Then, the original film with a width of 50 mm is cold-stretched longitudinally by 400%, at a stretching speed of 400% / min, at room temperature. The characteristics of the obtained film are as follows: porosity 60%, pore size 80-200nm, thickness 13μm, air permeability 15sec / 100cc, TD direction strength 2100kg / cm 2 , MD direction strength is 250kg / cm 2 , 100 ° C, 60 minutes free shrinkage rate of 35%. Its electron microscope pictures are as figure 1 .

Embodiment 2

[0043] Linear polyethylene (Mw=230,000, Mw / Mn=2-8) was made into a raw film through a laboratory screw extruder at a temperature of 190°C and a stretch ratio of 16. The original film was annealed for 5 hours at a temperature of 120°C. Then, the original film with a width of 50mm is cold-stretched longitudinally by 400%, at a stretching speed of 250% / min, at room temperature. The obtained microporous film was heat-set for 5 hours at a temperature of 105°C. The characteristics of the obtained film are as follows: porosity 50%, pore size 50-200nm, thickness 15μm, air permeability 23sec / 100cc, TD direction strength 1900kg / cm 2 , MD direction strength is 210kg / cm 2 , 100 ° C, 60 minutes free shrinkage rate of 38%.

Embodiment 3

[0045] Linear polyethylene (Mw=230,000, Mw / Mn=2-8) was made into a raw film through a laboratory screw extruder at a temperature of 200°C and a stretch ratio of 23. The original film was annealed for 5 hours at a temperature of 120°C. Then, the original film with a width of 50 mm is cold-stretched longitudinally by 200%, at a stretching speed of 800% / min, at room temperature. The obtained microporous film was heat-set for 5 hours at a temperature of 105°C. The characteristics of the obtained film are as follows: porosity 40%, pore size 20-200nm, thickness 10μm, air permeability 28sec / 100cc, TD direction strength 1700kg / cm 2 , MD direction strength is 180kg / cm 2 , 100 ° C, 60 minutes free shrinkage rate of 41%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com