Preparation method of polyurethane (PU) nano-encapsulated phase-change material (NEPCM)

A technology of phase change materials and nanocapsules, which is applied in the field of preparation of polyurethane nanocapsule phase change materials, can solve the problems of suspension rheological interference, dilution stability and poor redispersibility, and achieve good elasticity and mechanical strength, good weight The effect of dispersibility and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of amphiphilic polyurethane.

[0026] Mix a certain amount of toluene diisocyanate, polytetrahydrofuran diol and organotin catalyst dibutyltin dilaurate, react at a certain temperature for a period of time, add dimethylol propionic acid, and finally add β-hydroxyethyl methacrylate to seal end, resulting in amphiphilic polyurethane. The reaction is carried out in a nitrogen atmosphere, and the raw material composition mass fraction of amphiphilic polyurethane is as follows:

[0027] Toluene diisocyanate 100

[0028] Polytetrahydrofuran diol 77

[0029] Dimethylolpropionic acid 44

[0030] β-Hydroxyethyl Methacrylate 58

[0031] Dibutyltin dilaurate 0.4

[0032] Second, the preparation of emulsion.

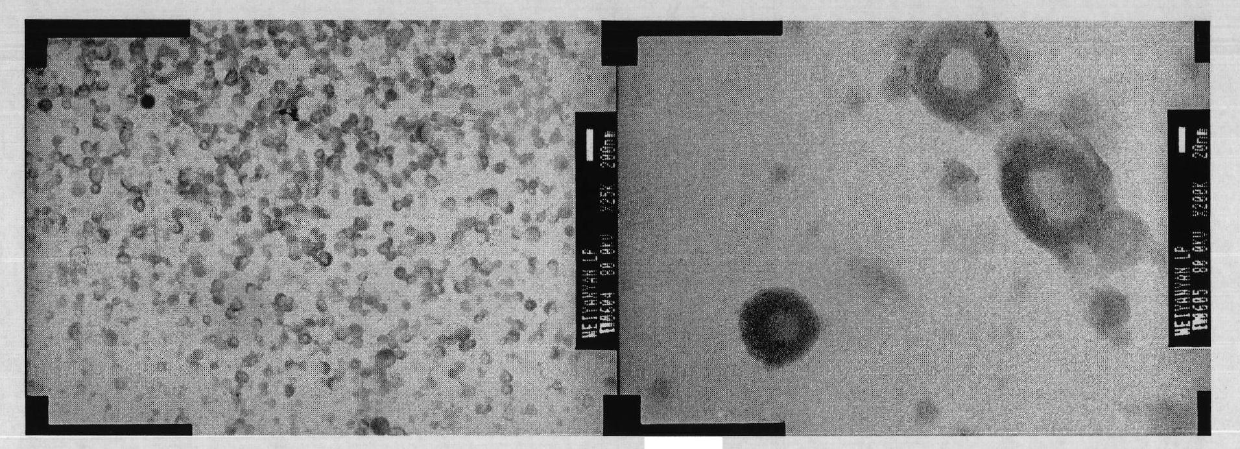

[0033] A certain amount of amphiphilic polyurethane is taken, and a certain amount of phase change material polytetrahydrofuran (molecular weight greater than 2000) and deionized water are added in proportion. Use a high-shear dispersing emulsifier at 10...

Embodiment 2

[0041] 1. Preparation of amphiphilic polyurethane.

[0042] Mix a certain amount of toluene diisocyanate, glycerol allyl ether and dibutyltin dilaurate, react at a certain temperature for a period of time, add dimethylol butyric acid / acetone solution, and finally add 1-dodecanol After the reaction, the acetone was distilled off to obtain amphiphilic polyurethane. The reaction is carried out in a nitrogen atmosphere, and the raw material composition mass fraction of amphiphilic polyurethane is as follows:

[0043] Toluene diisocyanate 100

[0044] Glycerol Allyl Ether 25

[0045] Dimethylolbutyrate 52

[0046] 1-Dodecanol 58

[0047] Dibutyltin dilaurate 0.3

[0048] Second, the preparation of emulsion.

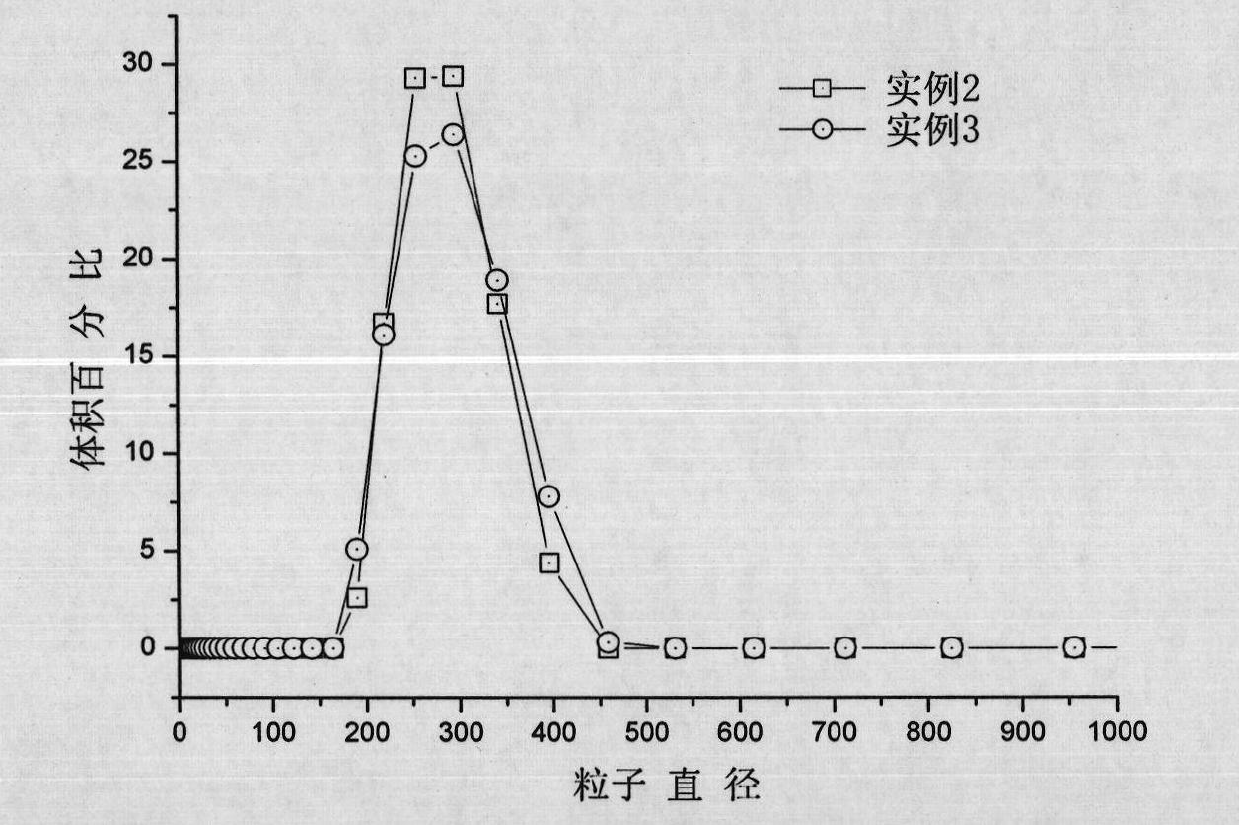

[0049] Take a certain amount of amphiphilic polyurethane, add a certain amount of solid paraffin and tripropylene glycol acrylate in proportion, heat and mix, and then add deionized water. Use a high-shear dispersing emulsifier at 10000r / min to emulsify to obtain a unif...

Embodiment 3

[0058] 1. Preparation of amphiphilic polyurethane.

[0059] Mix a certain amount of toluene diisocyanate, glycerol allyl ether and dibutyltin dilaurate, react at a certain temperature for a period of time, add dimethylol butyric acid / acetone solution, and finally add 1-dodecanol After the reaction, the acetone was distilled off to obtain amphiphilic polyurethane. The reaction is carried out in a nitrogen atmosphere, and the raw material composition mass fraction of amphiphilic polyurethane is as follows:

[0060] Toluene diisocyanate 100

[0061] Glycerol Allyl Ether 23

[0062] Dimethylolbutyrate 46

[0063] 1-Dodecanol 58

[0064] Dibutyltin dilaurate 0.3

[0065] Second, the preparation of emulsion.

[0066] Take a certain amount of amphiphilic polyurethane, add a certain amount of methyl stearate and tripropylene glycol acrylate in proportion, heat and mix, and then add deionized water. Use a high-shear dispersing emulsifier at 10000r / min to emulsify to obtain a unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com