Method for producing golf club head and golf club head structure

A technology for golf club heads and manufacturing methods, which is applied in the field of golf club head manufacturing, and can solve problems such as welding bead flowing into the inside of the club head, affecting the service life of the club head, and failure to obtain ball hitting stability, etc., so as to improve Manufacturing efficiency, quality, metal combination, firm structure, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

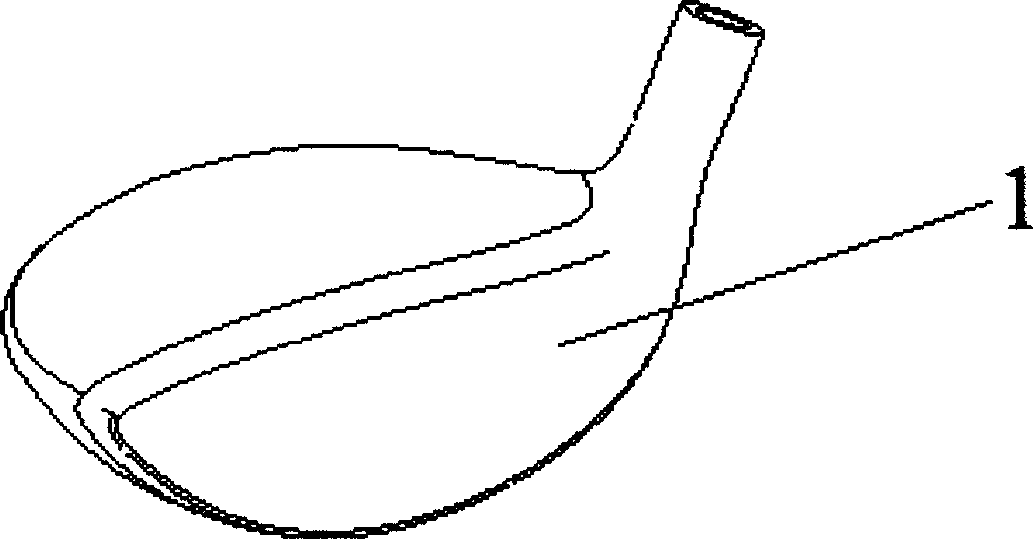

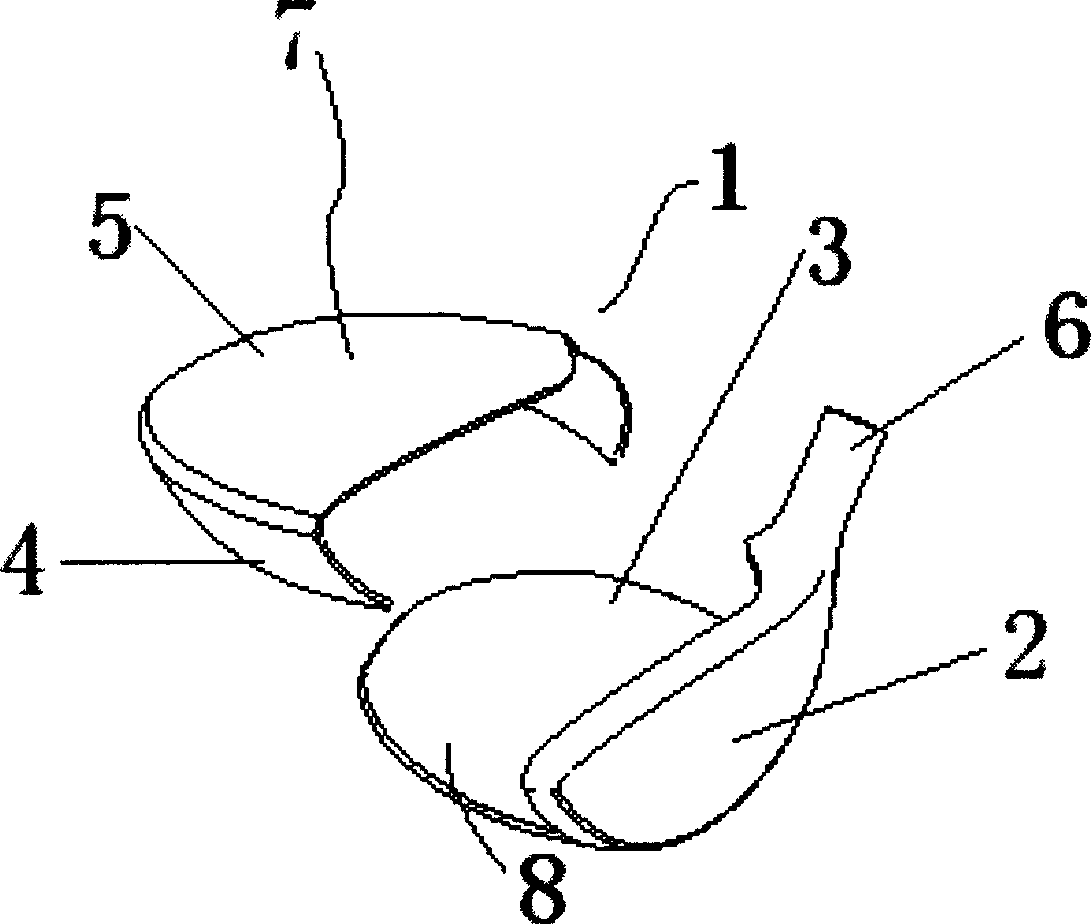

[0031] Embodiment 1: see figure 1 , figure 2 and Image 6 , a method for manufacturing a golf club head, comprising the steps of:

[0032] 1) A lower metal member 7 is formed by making the ball striking surface 2, the club head sole 3 and the club head tube 6 into one body. In this embodiment, the above-mentioned members are all made of stainless steel;

[0033] 2) Prefabricate a die-casting mold 11 that can be integrally die-casted with the club head side 4 and the ball cap 5. It can be divided into upper and lower halves 12, 13, and the hollow part 14 can be used to implant the aforementioned lower metal member 7;

[0034] 3) Fix the lower metal member 7 in the die-casting mold 11, and then put it into a high-temperature die-casting machine;

[0035] 4) pouring the metal liquid into the die-casting mold 11, and die-casting;

[0036] 5) After the metal is solidified, the die-casting mold 11 is separated to obtain the golf club head 1 .

[0037] The lower metal member 7...

Embodiment 2

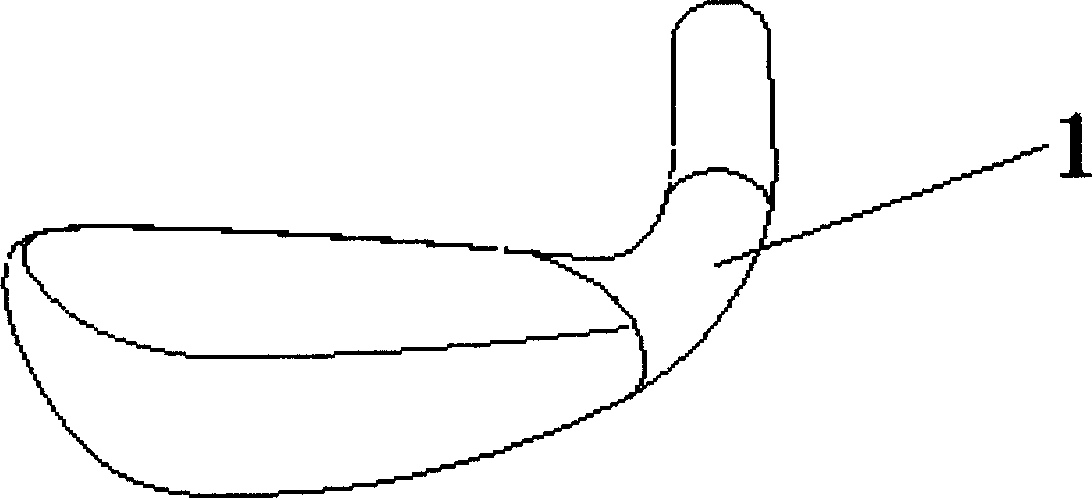

[0042] Example 2: see image 3 , Figure 4 , a method of manufacturing a golf club head, the basic steps of which are the same as those in Embodiment 1, the difference being that the step 2) also includes prefabricating a club head tube; the prefabricated mold can be The side part of the club head, the ball cover and the club head tube are jointly die-cast as one; the step 3) also includes the lower part of the club head tube and the club head bottom of the hitting surface. The metal component is fixed in the casting mold; the lower metal component is a multi-layer composite component made of elastic stainless steel.

[0043] An IRON-type golf club head structure manufactured by the aforementioned golf club head manufacturing method, its basic structure is the same as that of Embodiment 1, the difference is that the upper metal member 8 is connected with a An integrated club head tube 6; the overall outline of the club head 1 is flat, that is, an IRON type flat club head.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com