Cost-optimized traction mechanism

A technology of traction mechanism and traction device, which is applied in the direction of mechanical equipment, components with teeth, hoisting device, etc., can solve the problems of unfavorable service life of traction mechanism, unfavorable service life of traction device, increased loss of traction device, etc., and achieve reduction Danger of skipping teeth, cost optimization, effect of space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

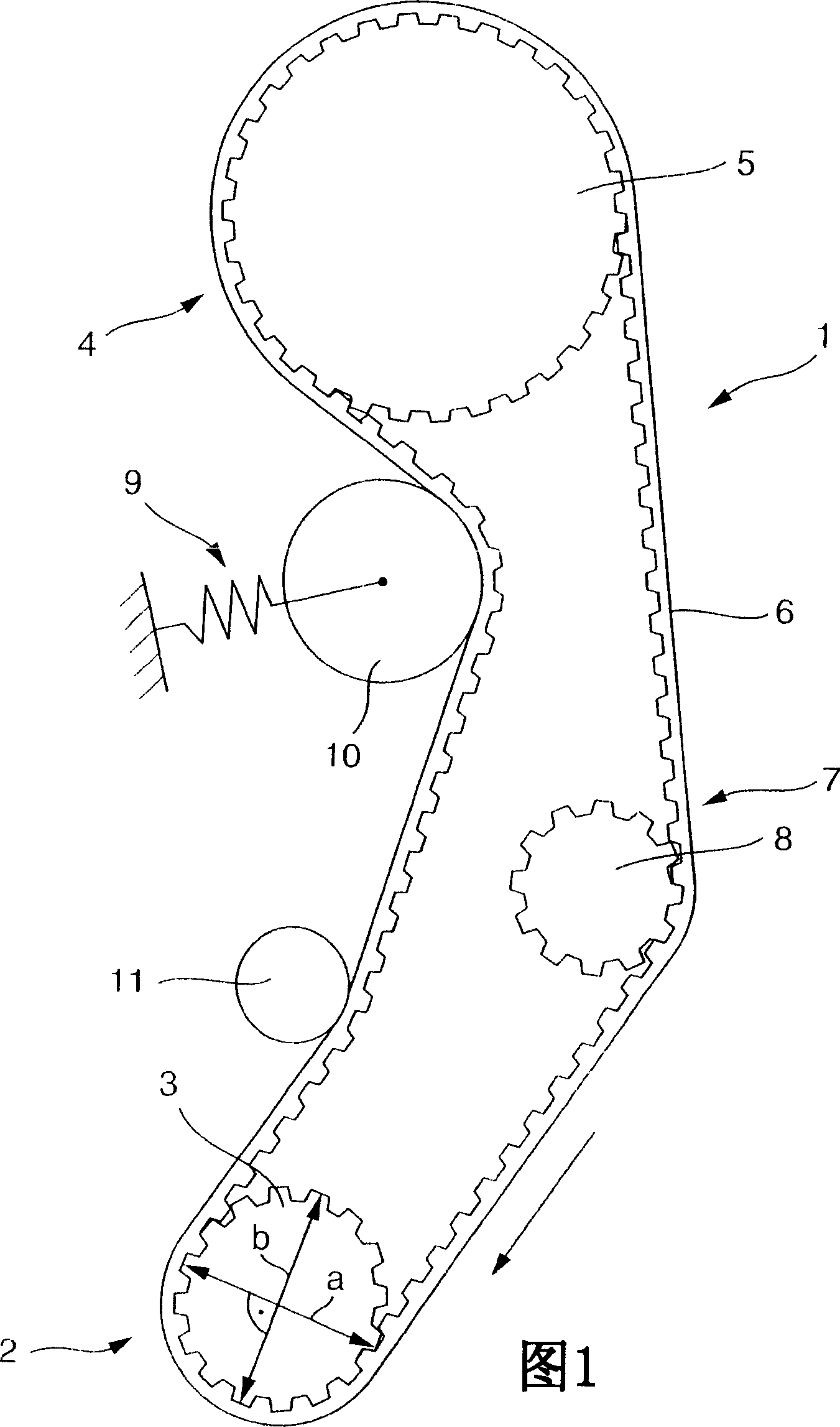

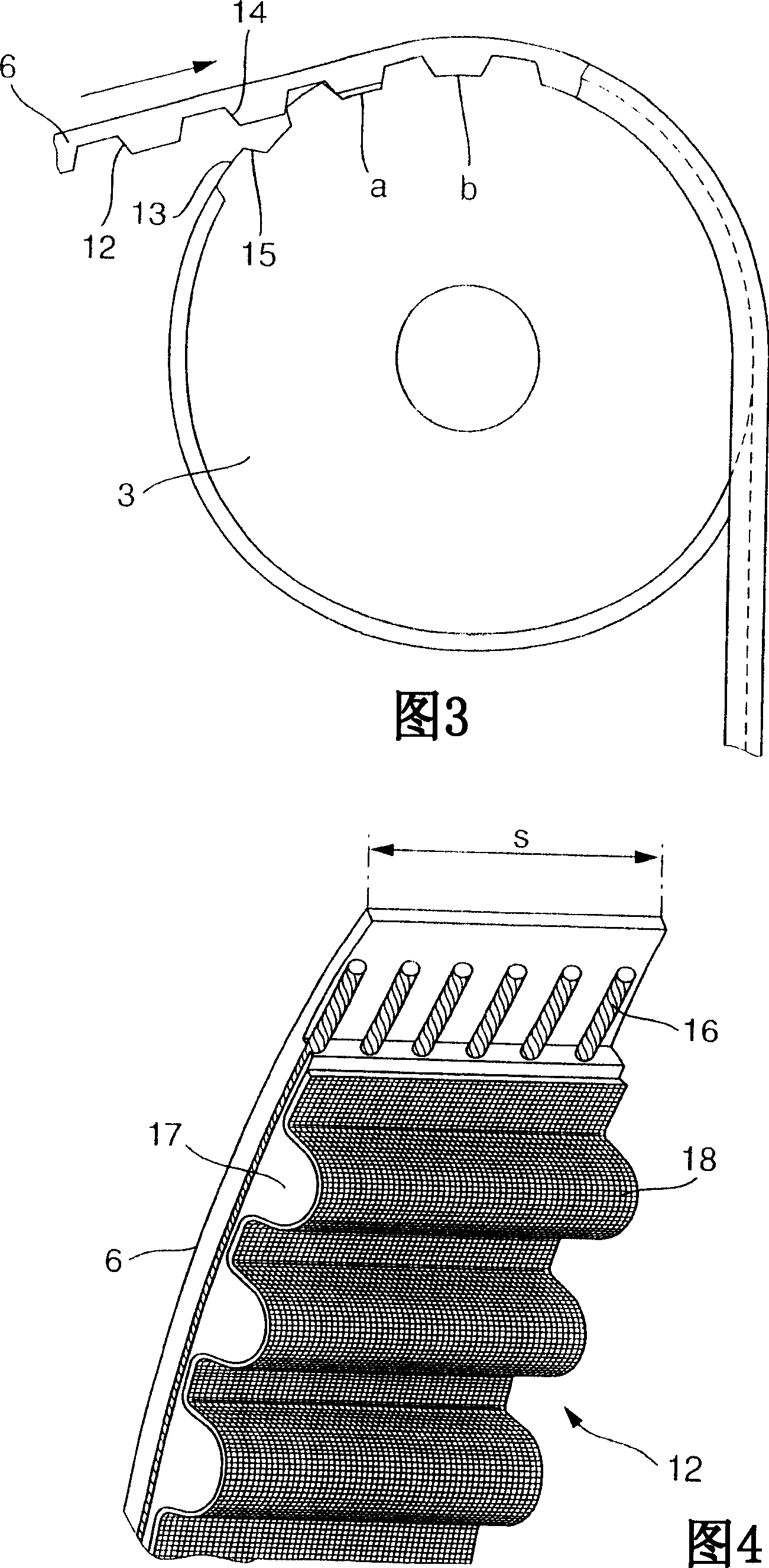

[0034] FIG. 1 shows a traction mechanism 1 of an internal combustion engine without further details thereof. The driven element 2 is provided by a toothed pulley 3 which is fixedly connected in rotation to the crankshaft of the internal combustion engine, not shown in FIG. 1 . The traction mechanism 1 serves to drive a crankshaft, a drive element 4 , which is equipped with a toothed pulley 5 . The configured traction means 6 are designed as toothed belts and endless belts at least partially surrounding the toothed pulleys 3 , 5 . Furthermore, the traction mechanism 1 is used to drive another active element 7, such as a water pump. The traction device 6 is guided against the toothed pulley 8 of the active element 7 . Also, on the idle side of the clockwise rotating traction mechanism 1 , adjacent to the toothed pulley 5 , the traction mechanism 1 is configured such that the tension adjuster 9 and the tension roller 10 acted by spring force are supported by the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com