Method for manufacturing oven food mould

A food and mold technology, which is applied in the field of food mold preparation, can solve the problems of difficult demoulding and easy sticking of raw materials to the mold, and achieve the effects of good mold release, good durability and good rubber elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

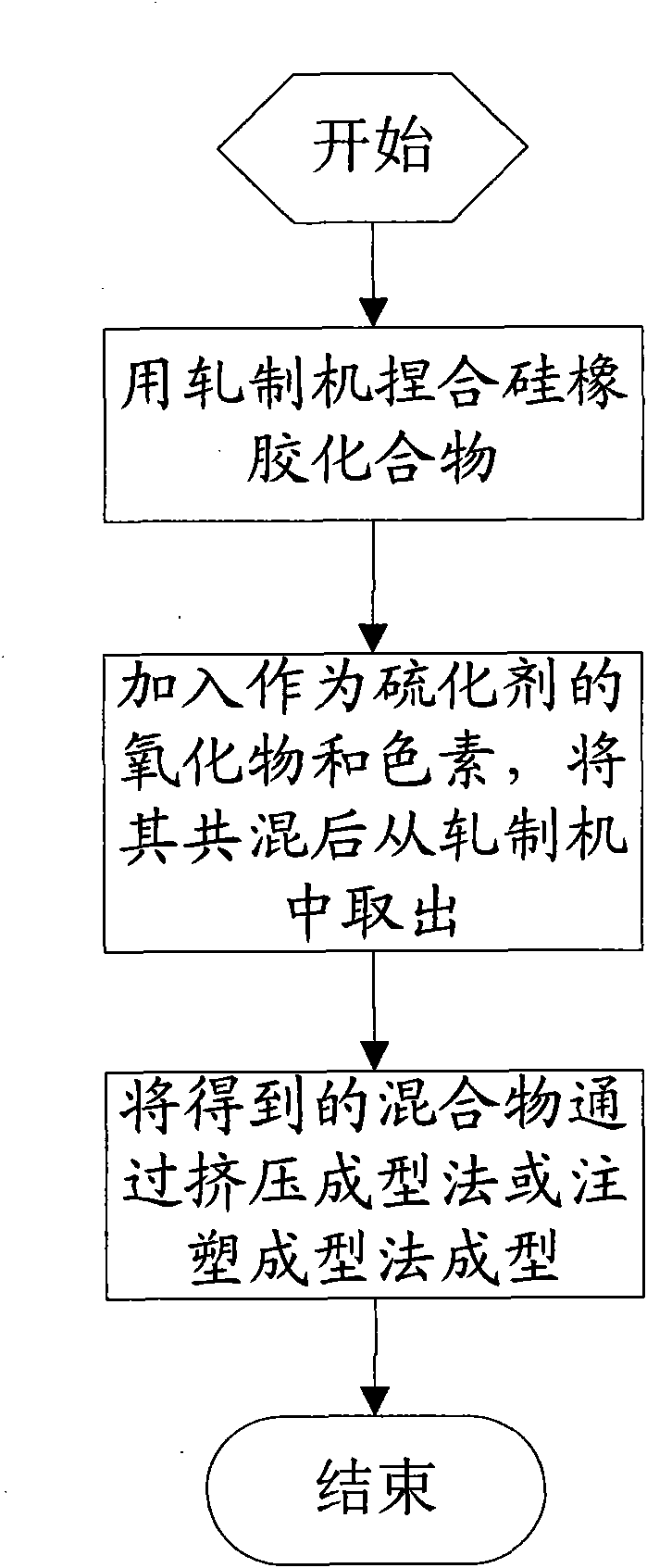

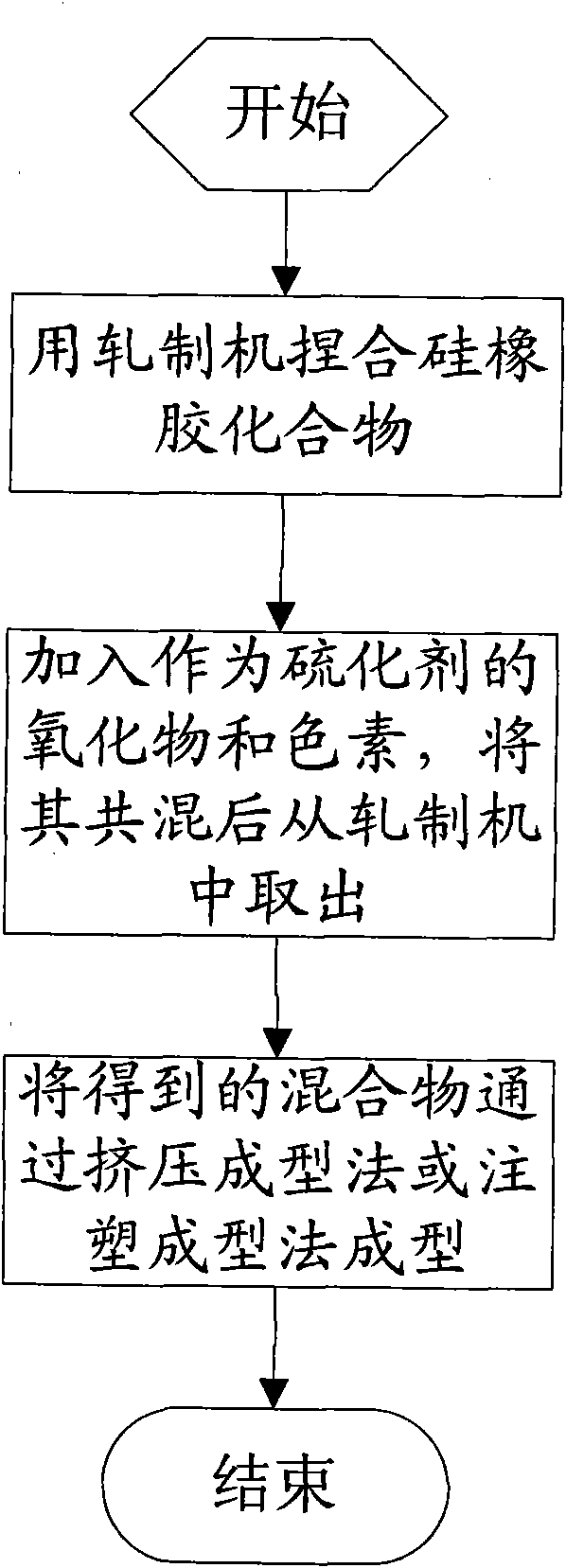

[0020] Such as figure 1 As shown, it is a schematic flow diagram of a method for preparing an oven food mold in a preferred embodiment of the present invention, and a method for preparing an oven food mold is provided, comprising the following steps:

[0021] a. Kneading the silicone rubber compound with a rolling mill;

[0022] b. Add oxides and pigments as vulcanizing agents, blend them and take them out of the rolling mill;

[0023] c. molding the obtained mixture by extrusion molding or injection molding.

[0024] First, use a rolling mill to knead the silicone rubber compound. The silicone rubber contains one of silicone oil or food oil. It is a silicone rubber with a JIS A hardness of 55-95 and a thermal conductivity of 0.15-0.50W / m.℃. Silicone rubber is mixed with fiber filler so that the elongation at break is reduced to 10-100%, then oxides and pigments are added as vulcanizing agents, blended and taken out of the rolling mill, and the resulting mixture is extruded ...

Embodiment 1

[0029] The siloxane compound is kneaded with a rolling machine. During the kneading process, 20 parts of quartz powder are added and kneaded to obtain the silicone rubber compound. Add oxides and pigments as vulcanizing agents, 2 parts by weight of silicone oil to 100 parts by weight of silicone rubber compound, and extrude at 170° C. for 10 minutes to prepare a circular oven food mold, and then two at 200° C. After 4 hours of secondary vulcanization, it can be made into oven food molds. The prepared oven food mold has the following physical properties: JIS A hardness is 75, thermal conductivity is 0.25 W / m.°C, and elongation is 45%. Put the bread ingredients into the oven food mold and bake at 230°C for 10 minutes, no deformation occurs, and the baked bread is very easy to demould.

Embodiment 2

[0031] Knead the siloxane compound with a rolling mill, add 15 parts of diatomaceous earth during the kneading process, and knead to obtain the silicone rubber compound. To 100 parts by weight of the silicone rubber compound, add oxides and pigments as a vulcanizing agent, 3 parts by weight of food oil, mix vinyl-containing polydimethylsiloxane and organohydrogenpolysiloxane to obtain a liquid mixture, and simultaneously The liquid mixture is injected into a star-shaped metal mold through an injection molding machine, extruded at 180°C for 8 minutes to prepare a star-shaped oven food mold, heated at 160°C for 1 minute, and the formed oven food mold Take it out, and then perform secondary vulcanization at 200°C for 4 hours to make an oven food mold. The prepared oven food mold has the following physical properties: JIS A hardness is 70, thermal conductivity is 0.20 W / m.°C, and elongation is 230%. Put the bread raw materials into the oven food mold and bake it at 230°C for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com