Mud-resistant cable sheath rubber material and preparation method thereof

A cable sheath, rubber material technology, applied in the direction of insulated cables, rubber insulators, cables, etc., can solve the problems of poor tear resistance, inability to meet, difficult to use on drilling platforms, etc., to achieve good anti-cracking performance and meet the use requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

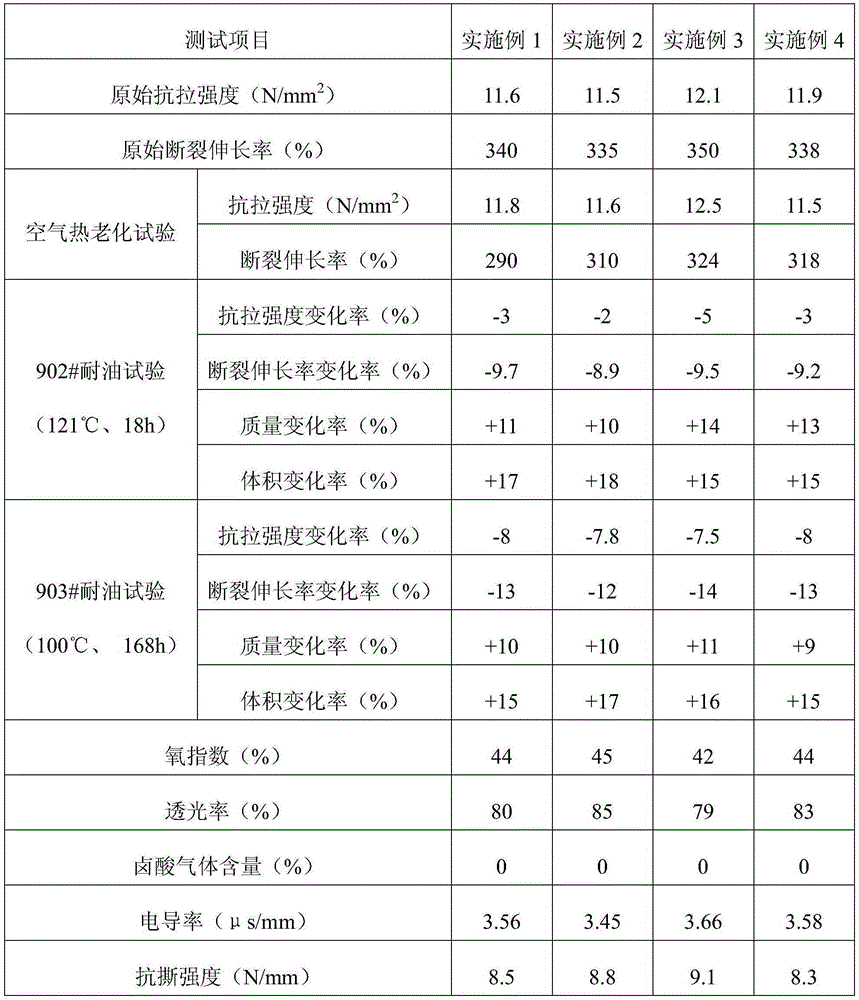

Examples

preparation example Construction

[0017] A preparation method of a mud resistant cable sheath rubber material, comprising the following steps:

[0018] (1) Raw rubber: take the Yihuaping rubber of the formula quantity and add it to the internal mixer or open mill for mastication, and add the release agent of the formula quantity during mastication to obtain the raw rubber;

[0019] (2) Mixing: After the plasticized raw rubber is pressed down for 30 seconds with the top bolt in the internal mixer, the formula amount of flame retardant Al(OH) 3 , stearic acid, anti-aging agent, plasticizer, reinforcing filler and half the weight of flame retardant Mg(OH) 2 Put it into the internal mixer and drop the top pin to mix for 30S, then lift up the top pin and add the remaining flame retardant Mg(OH) 2 , and press down the top bolt for 40 seconds, lift up the top bolt to clean the pressure hammer, then press down the top bolt until the temperature reaches 125°C to obtain a mixture;

[0020] (3) Put the mixed material p...

Embodiment 1

[0023] A mud-resistant cable sheath rubber material, comprising the following components by weight: 100 parts of Evapine rubber, 4.5 parts of DCP (dicumyl peroxide), 1 part of TRIM (trimethacrylate trimethacrylate) , Mg(OH) 2 120 parts, Al(OH) 3 20 parts, Aflux18 (Line powder) 1.5 parts, stearic acid 1.5 parts, TMQ (2,2,4-trimethyl-1,2-dihydroquinoline polymer) 0.5 parts, A-172 [vinyl tri (β-methoxyethoxy)silane] 1.5 parts, DOS (dioctyl sebacate) 2 parts, TOTM (trioctyl trimellitate) 6.5 parts, carbon black N220 6.0 parts.

Embodiment 2

[0025] A mud-resistant cable sheath rubber material, comprising the following components by weight: 100 parts of Evapine rubber, 2.5 parts of DCP (dicumyl peroxide), 1.5 parts of TRIM (trimethacrylate trimethacrylate) , Mg(OH) 2 100 parts, Al(OH) 3 10 parts, 1 part of Aflux18 (Rhein powder), 2 parts of stearic acid, 1 part of TMQ (2,2,4-trimethyl-1,2-dihydroquinoline polymer), A-172 [vinyl tri (β-methoxyethoxy)silane] 2 parts, DOS (dioctyl sebacate) 5 parts, TOTM (trioctyl trimellitate) 5 parts, carbon black N220 5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com