Extruded seal

a technology of extrusion and seal, applied in the direction of gravity filter, separation process, filtration separation, etc., can solve the problems of no longer fulfilling the required sealing task, absorbing moisture and forming deposits on the seal, etc., to achieve high sealing effect, shorten production time, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

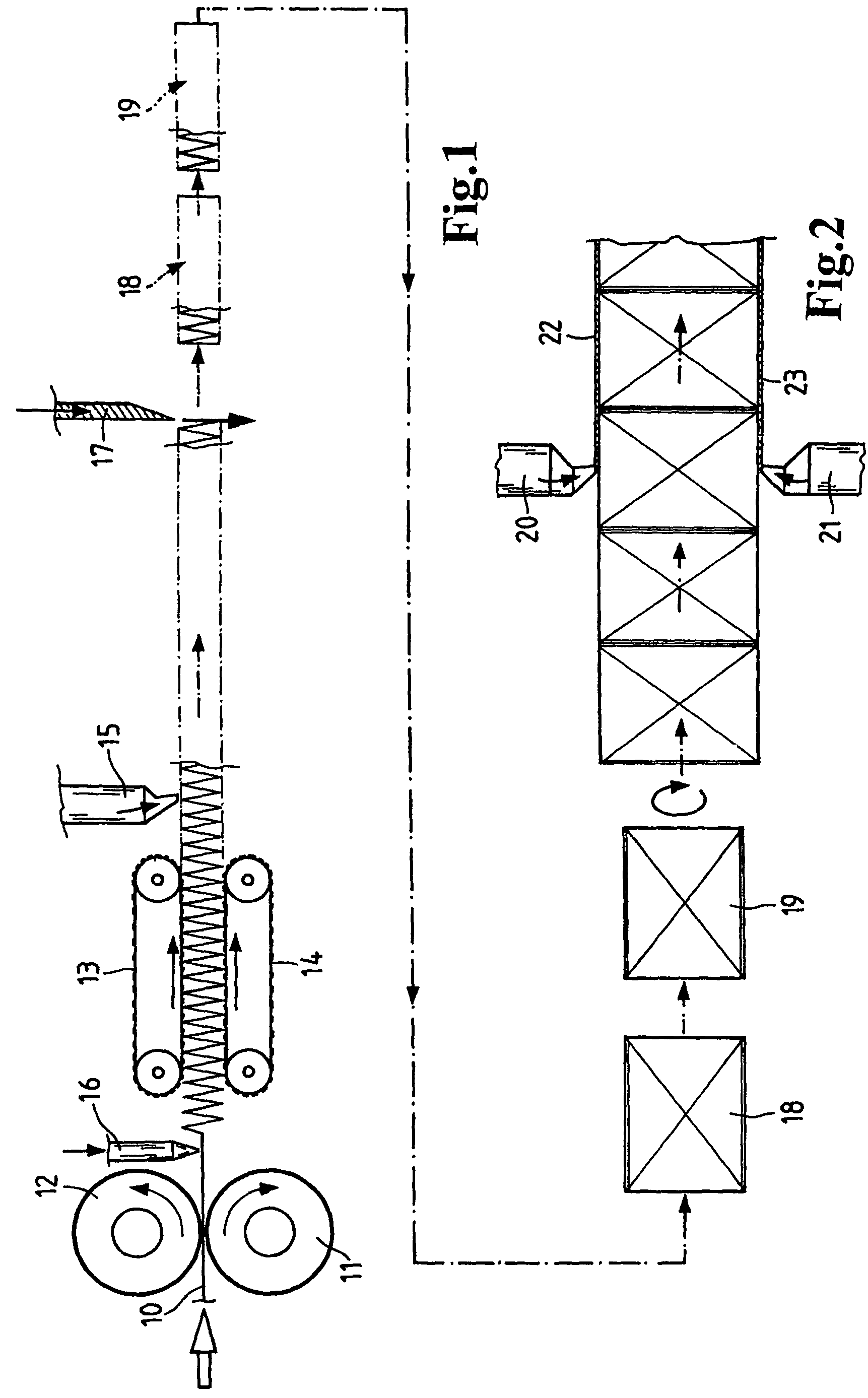

[0023]FIG. 1 shows a filter medium 10 which is supplied in the form of a web to two embossing rollers 11, 12. Crease edges are embossed into the filter medium in this area, the filter medium is subsequently erected to form a filter element folded in a zigzag shape, which is guided between two toothed belts 13, 14 and approaches extrusion heads 15 situated on both sides of the filter web. A glue bead is applied to both front faces of the filter medium after the embossing using a glue application head 16, which results in laterally sealed gluing of the folds upon the subsequent folding. Seal strands, which cool directly after the application and unfold their elastic properties, are applied to both sides of the filter web in the upper edge area of the filter web using the extrusion heads 15.

[0024]The next method step is an isolation of the filter elements, for this purpose a cutting device 17 is provided, which cuts the filter elements 18, 19 to the required length during the cutting p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| adhesive force | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com