Soft-grip medical connector

a technology of medical connectors and soft grips, which is applied in the field of medical connectors, can solve the problems of increasing the difficulty of health care professionals grasping existing medical connectors, increasing the difficulty of medical professionals using them, and increasing the difficulty of patients using existing hard-surface medical connectors, so as to reduce the internal volume of the valve member, reduce the effect of fluid regression, and reduce the effect of pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

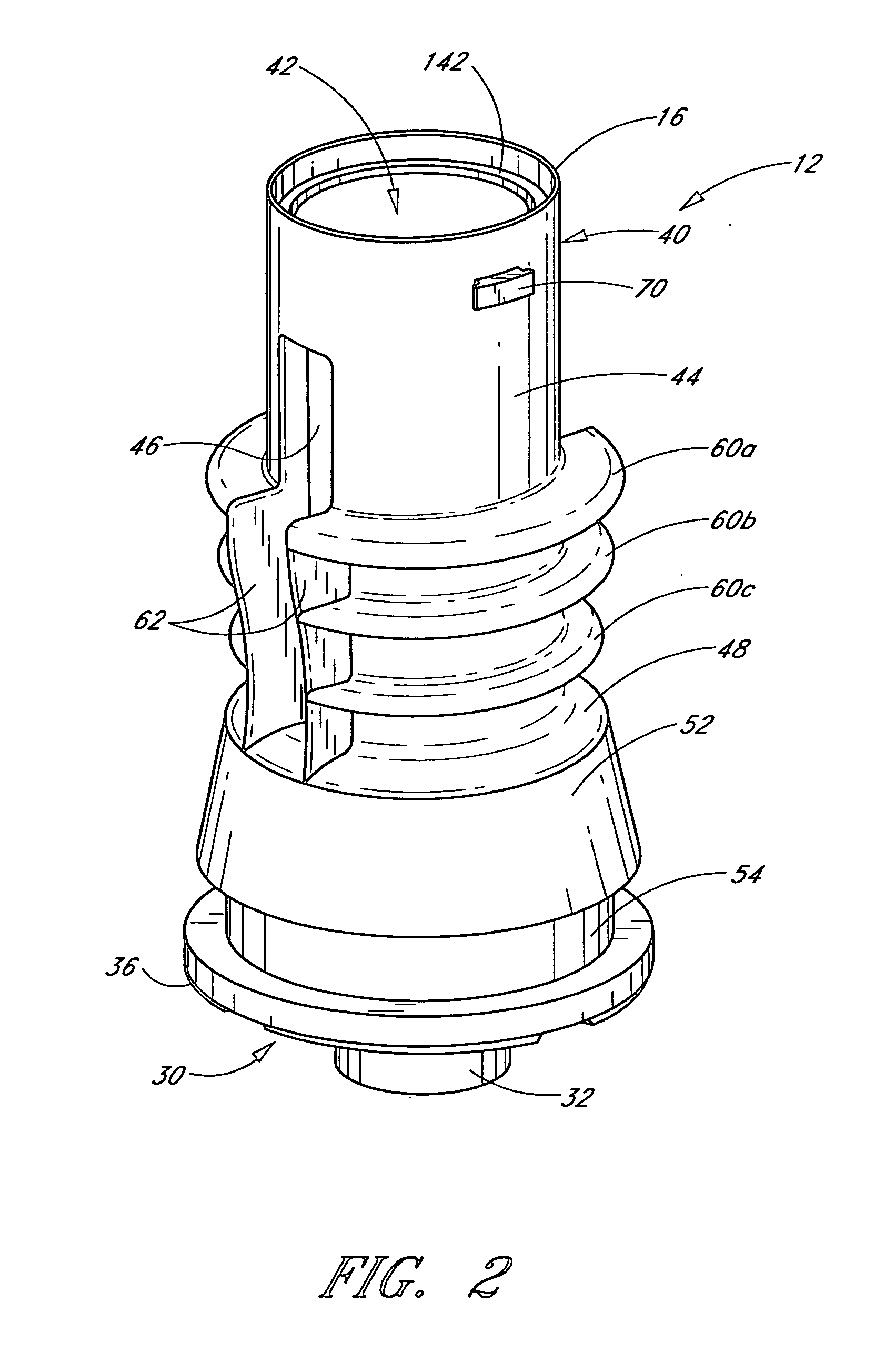

[0050] With reference to the attached figures, certain embodiments and examples of soft-grip medical connectors will now be described. Although certain embodiments and examples of a soft-grip connector are shown and described as including positive-flow valves, certain aspects and advantages of the systems and methods described herein can be advantageously applied to numerous other fluid connector designs including those without positive-flow characteristics.

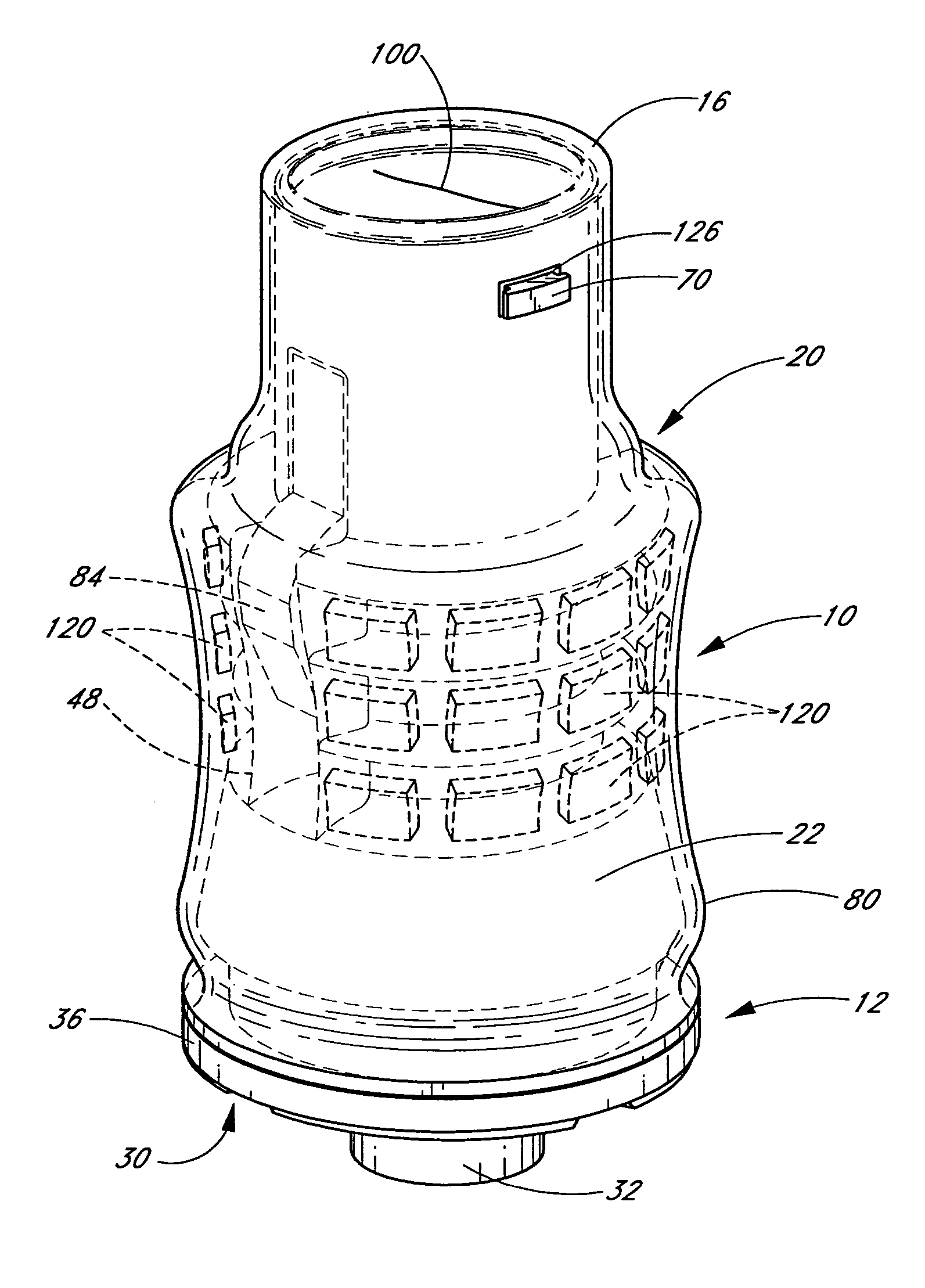

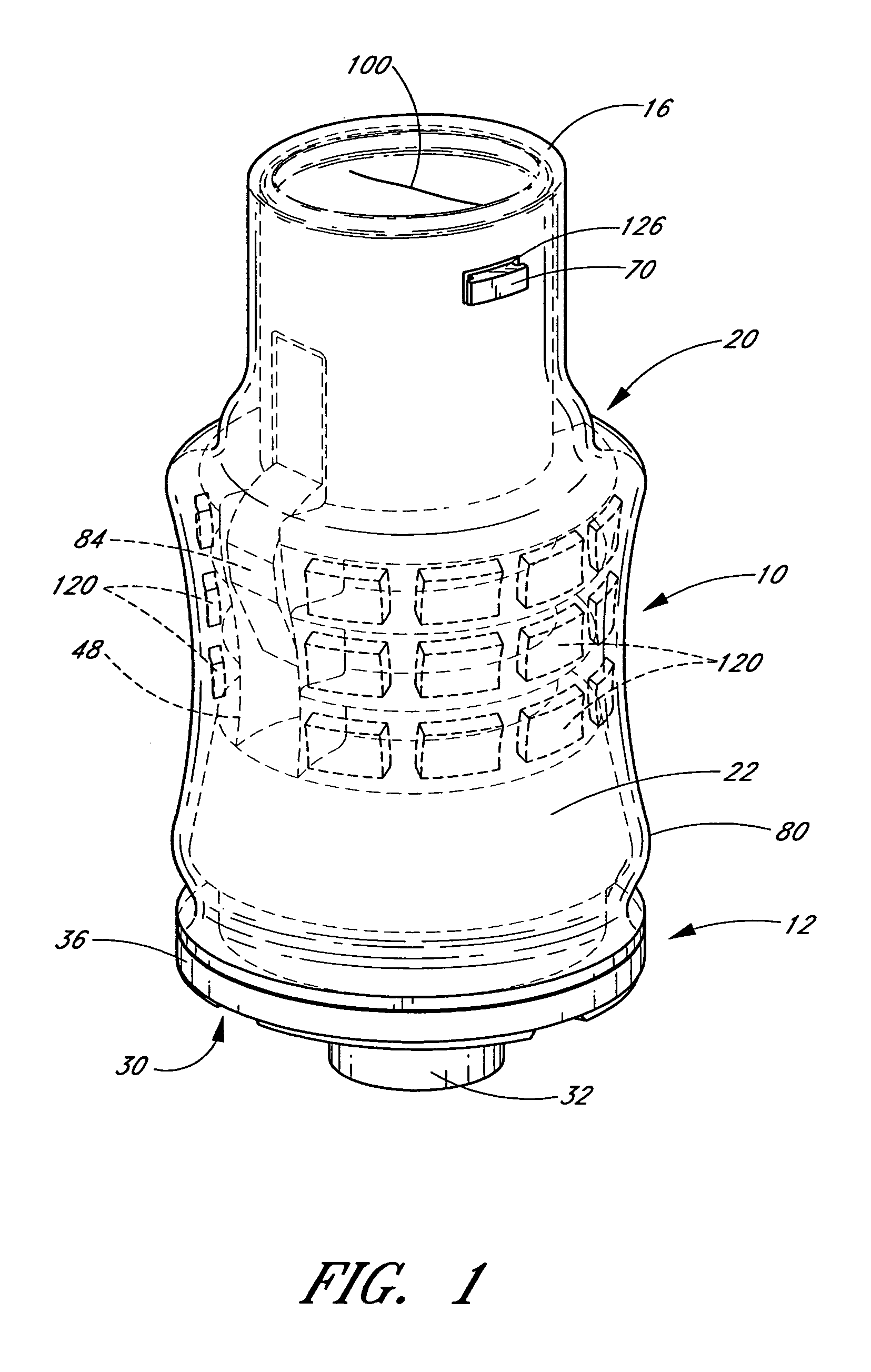

[0051] Referring now to FIG. 1, the illustrated embodiment of a medical connector 10 comprises a substantially rigid housing 12 with a flexible member 80 that has been stretched over the outer surface of the housing 12 to provide a soft, grippable outer surface 22. A slit opening 100 is formed at an upstream end 16 of the flexible member 80. The upstream end of the flexible member 80 surrounding the housing 12 provides a surface that is easily cleaned, and is substantially free from cavities or recesses in which contaminants may...

PUM

| Property | Measurement | Unit |

|---|---|---|

| movement | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com