Metal weaving type conductive silica gel sleeve and preparation method thereof

A conductive silicone, metal braiding technology, applied in adhesives, electrical components, magnetic field/electric field shielding, etc., can solve the problem of difficult balance between the electrical properties and elasticity of silicone materials, and achieve the effects of weight reduction, low surface resistance, and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

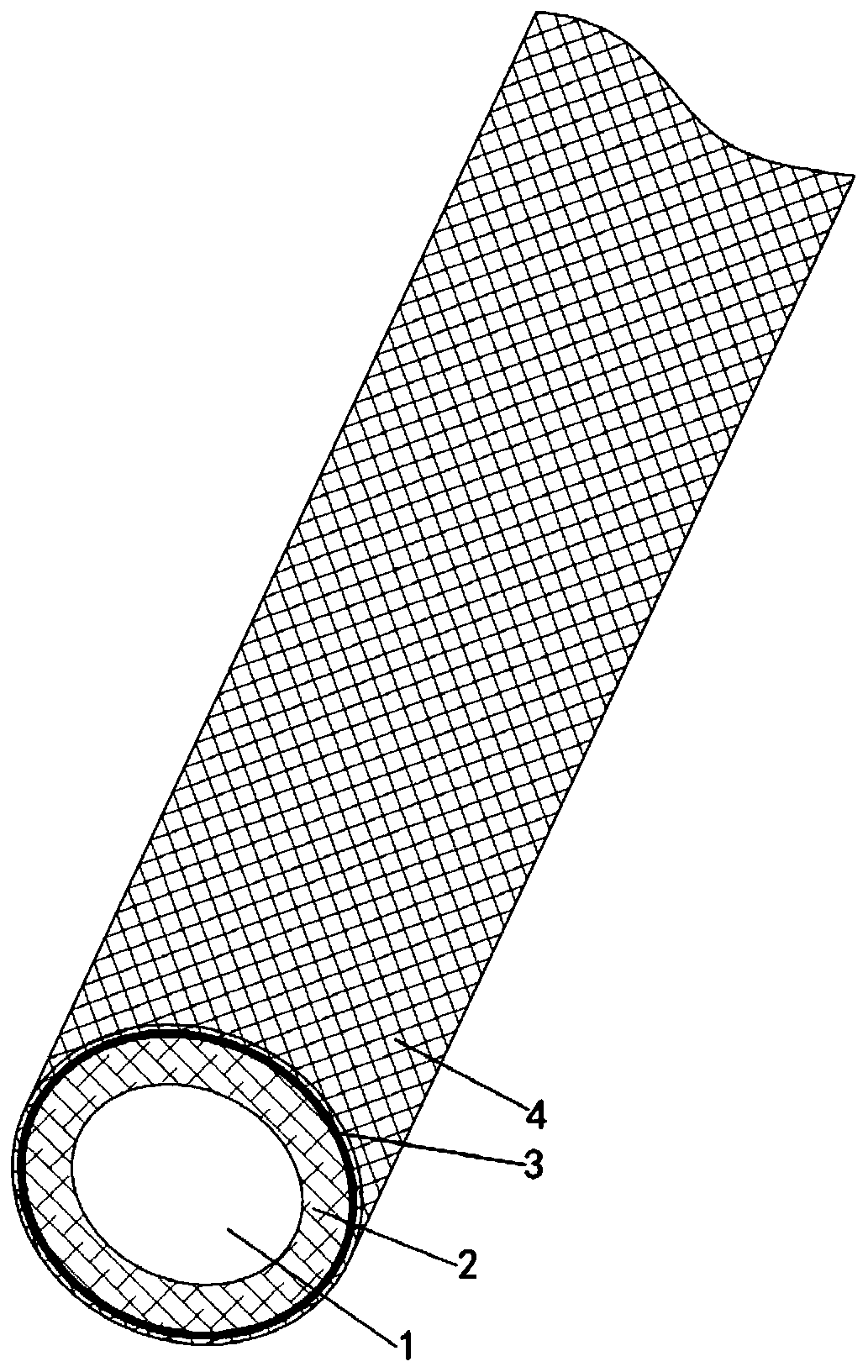

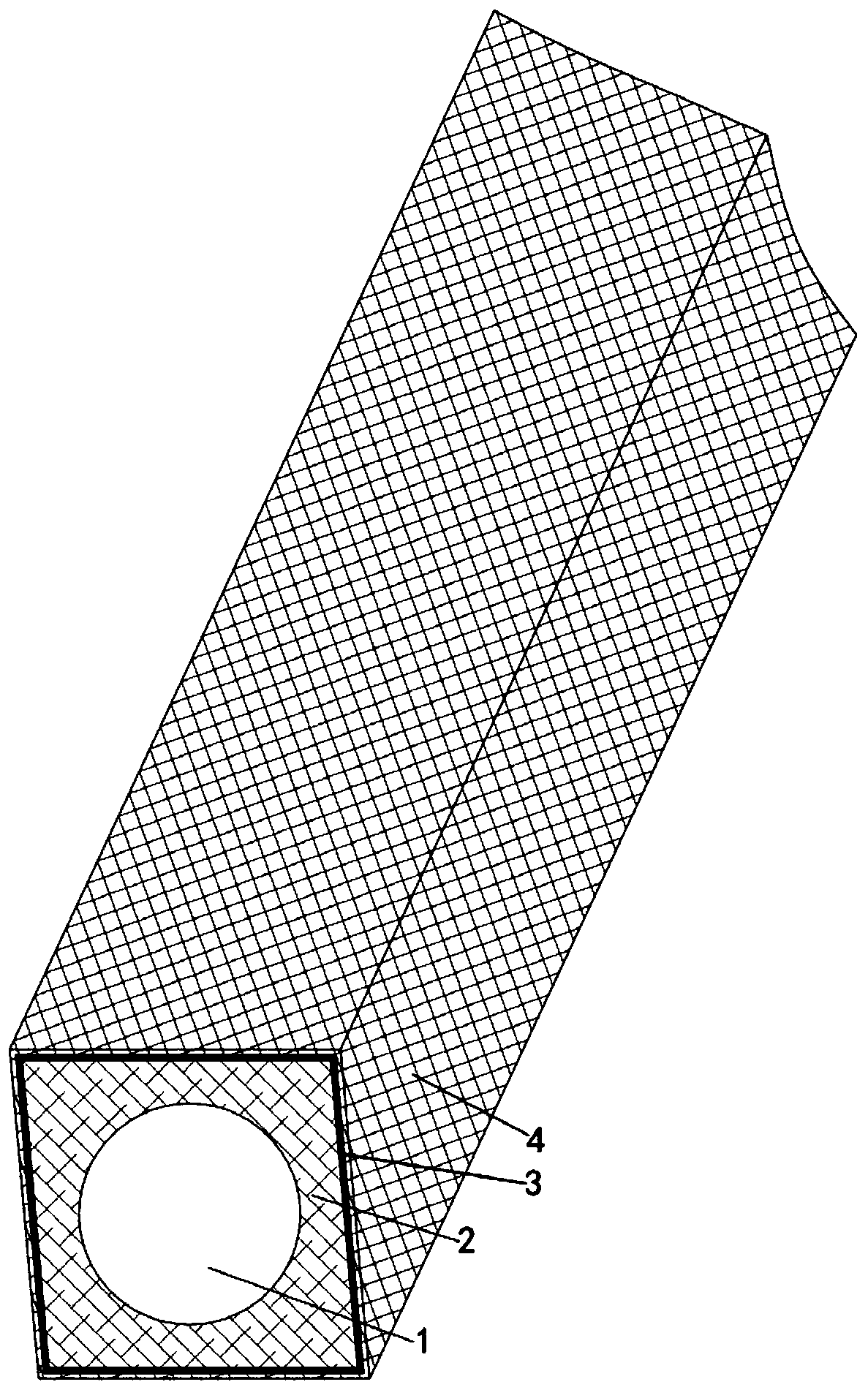

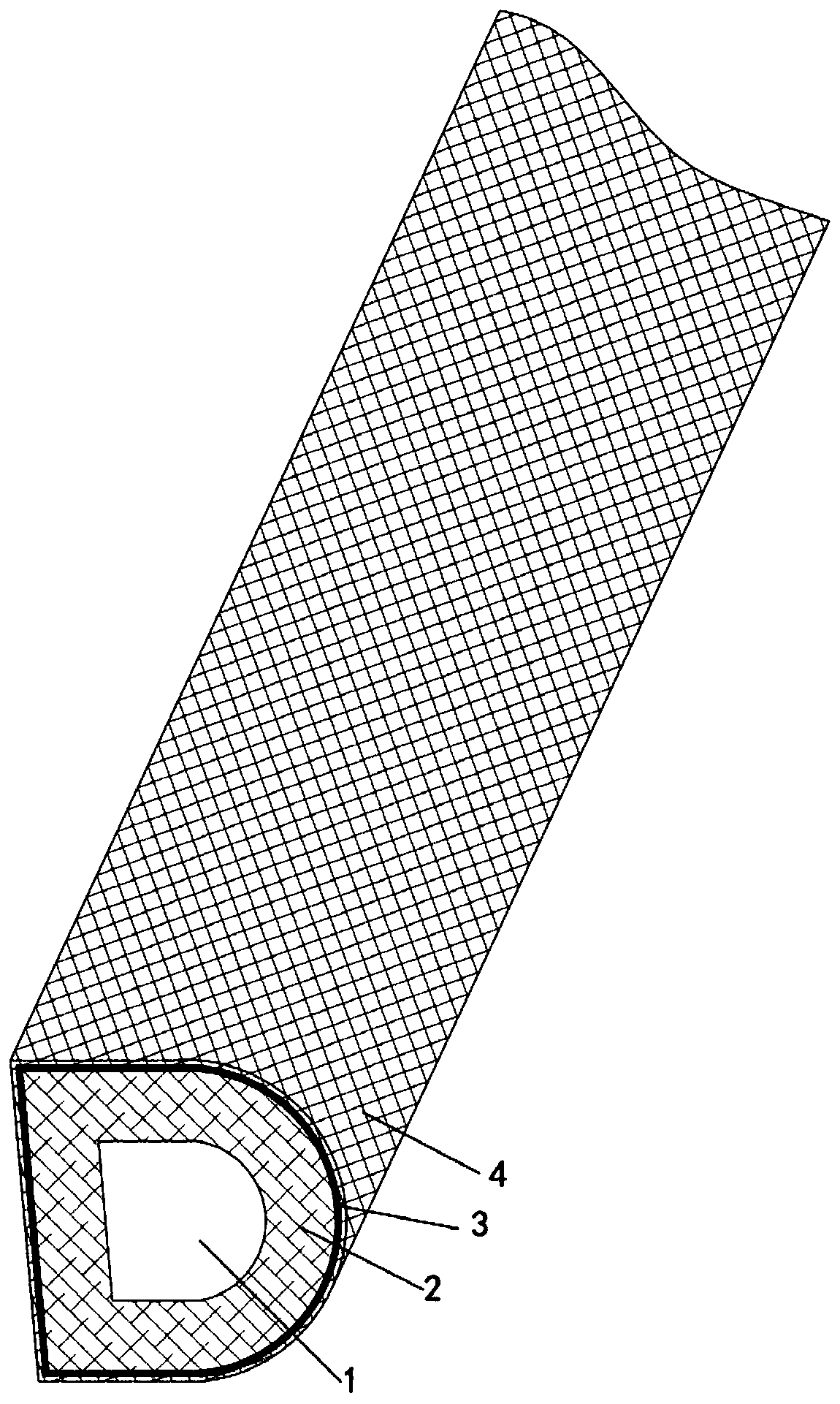

[0030] A metal braided conductive silicone sleeve, including a core material, an adhesive layer and an electromagnetic shielding layer arranged sequentially from the inside to the outside; the core material is a pipe extruded from high-elastic silicone rubber through an extruder; the adhesive layer is The high-strength silicone adhesive layer sprayed on the surface of the core material, the thickness of the adhesive layer is 0.05mm; the electromagnetic shielding layer is a metal braid layer compounded on the surface of the core material through the adhesive layer. The shaft core of the core material is provided with a hollow part, and the shape of the hollow part is O-shaped or D-shaped or dumbbell-shaped or double O-shaped. The metal braiding layer is formed by braiding copper wire, and the surface of the copper wire is nickel-plated or gold-plated or tin-plated.

[0031] The preparation method of the above-mentioned metal braided conductive silicone sleeve comprises the foll...

Embodiment 2

[0039] A metal braided conductive silicone sleeve, including a core material, an adhesive layer and an electromagnetic shielding layer arranged sequentially from the inside to the outside; the core material is a pipe extruded from high-elastic silicone rubber through an extruder; the adhesive layer is The high-strength silicone adhesive layer sprayed on the surface of the core material, the thickness of the adhesive layer is 0.05mm; the electromagnetic shielding layer is a metal braid layer compounded on the surface of the core material through the adhesive layer. The shaft core of the core material is provided with a hollow part, and the shape of the hollow part is O-shaped or D-shaped or dumbbell-shaped or double O-shaped. The metal braiding layer is formed by braiding copper wire, and the surface of the copper wire is nickel-plated or gold-plated or tin-plated.

[0040] The preparation method of the above-mentioned metal braided conductive silicone sleeve comprises the foll...

Embodiment 3

[0048]A metal braided conductive silicone sleeve, including a core material, an adhesive layer and an electromagnetic shielding layer arranged sequentially from the inside to the outside; the core material is a pipe extruded from high-elastic silicone rubber through an extruder; the adhesive layer is The high-strength silicone adhesive layer sprayed on the surface of the core material, the thickness of the adhesive layer is 0.05mm; the electromagnetic shielding layer is a metal braid layer compounded on the surface of the core material through the adhesive layer. The shaft core of the core material is provided with a hollow part, and the shape of the hollow part is O-shaped or D-shaped or dumbbell-shaped or double O-shaped. The metal braiding layer is formed by braiding copper wire, and the surface of the copper wire is nickel-plated or gold-plated or tin-plated.

[0049] The preparation method of the above-mentioned metal braided conductive silicone sleeve comprises the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com