Application of thermoplastic elastomer on soft power cable for wind power generation

A thermoplastic rubber and power cable technology, applied in the direction of power cables, insulated cables, rubber insulators, etc., can solve carbon black pollution, carbon dioxide, sulfur dioxide and dust released by coal-fired boilers, low mechanical strength of cable insulation and sheath, Affect the service life of the cable and other issues, to achieve the effect of improved mechanical strength, excellent insulation and high strength, and improved twist resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

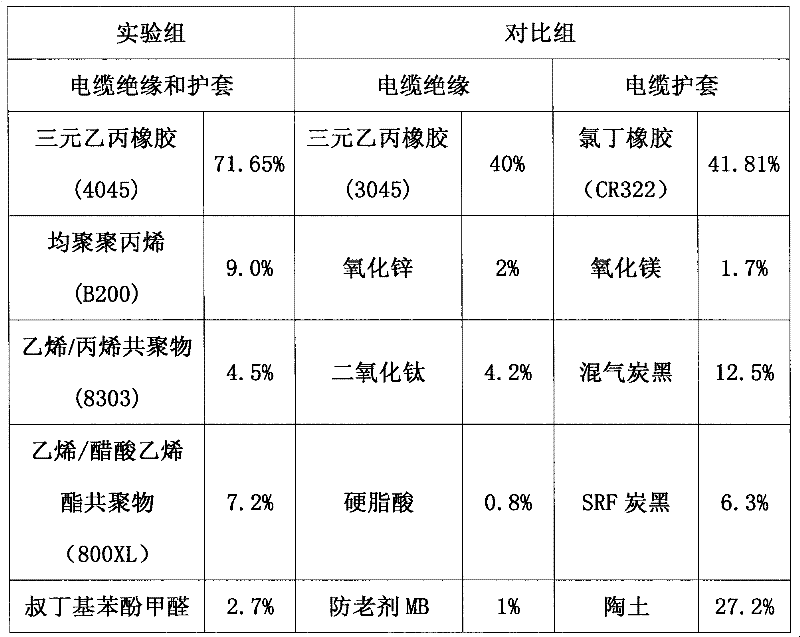

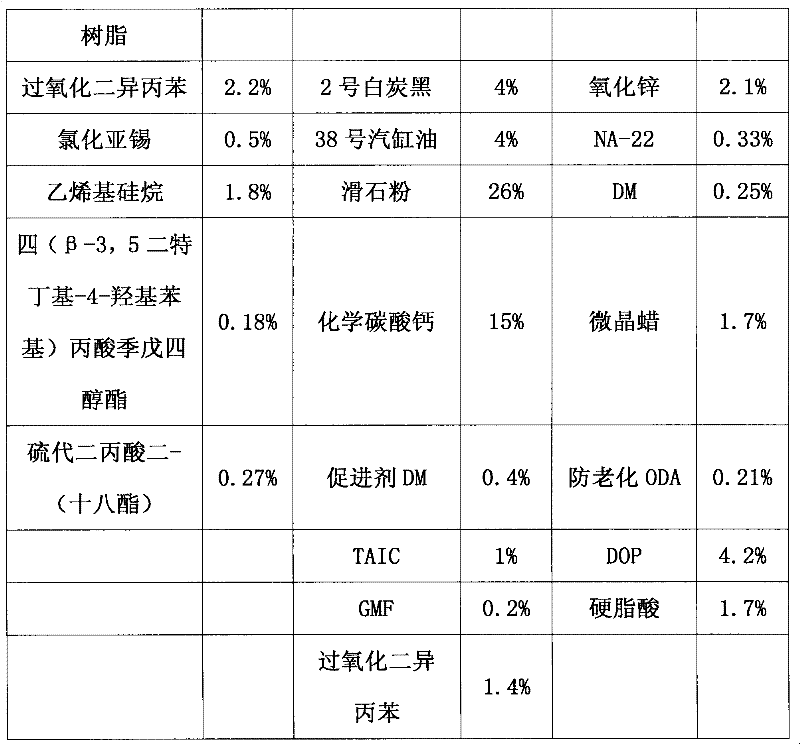

[0023] EPDM (4045) 71.65%

[0024] Homopolypropylene (B200) 9.0%

[0025] Ethylene / propylene copolymer (8303) 4.5%

[0026] Ethylene / vinyl acetate copolymer (800XL) 7.2%

[0027] Tert-butylphenol formaldehyde resin 2.7%

[0028] Stannous chloride 0.5%

[0029] Dicumyl peroxide 2.2%

[0030] Vinylsilane 1.8%

[0031] Pentaerythritol tetra(β-3,5-di-tert-butyl-4-hydroxyphenyl)propionate 0.18%

[0032] Di-(octadecyl)thiodipropionate 0.27%

[0033] The soft power cable for wind power generation made of the thermoplastic rubber of the present invention includes a copper conductor, the outer part of the copper conductor is cable insulation, the outer part of the cable insulation is a cable sheath, and both the cable insulation and the cable sheath are made of the thermoplastic rubber of the present invention .

[0034] Utilize the processing technology that the present invention prepares the flexible power cable for wind power generation to be:

[0035] 1. Processing of copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com