Tin stripping and tin plating liquid, preparing method of tin stripping and tin plating liquid and cyclic regeneration method for adopting tin stripping and tin plating liquid for recycling metal tin

A technology of tin plating solution and tin stripping, which can be applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems that metal tin has not been effectively regenerated and refined, waste tin stripping solution cannot be recycled, and resources are wasted, etc., to achieve Easy handling, high resistance to oxidative deterioration and high temperature resistance, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

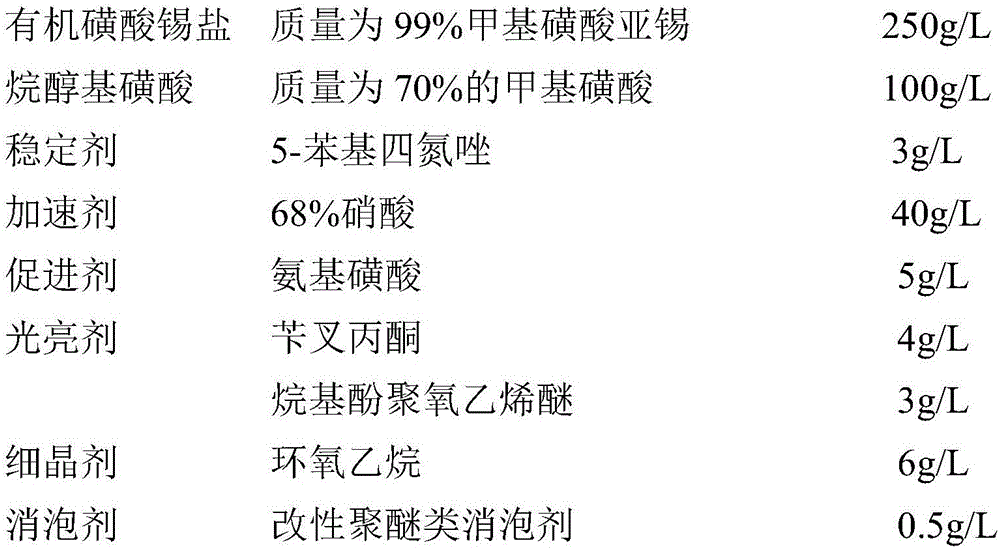

[0040] Each component and content of the stripping tin plating liquid of present embodiment 1 are as follows:

[0041]

[0042] The tin stripping tin plating solution preparation method of present embodiment 1 may further comprise the steps:

[0043] a1, according to the components and contents of the above-mentioned tin stripping and tin plating solution, weigh the alkanol group sulfonic acid, add it to the weighed deionized water, stir and cool, add the weighed organic sulfonic acid tin salt, mix well Obtain solution I;

[0044] a2. Weigh the accelerator, accelerator, brightener, fine crystal agent, antioxidant and defoamer, add them to the weighed deionized water, and mix well to obtain solution II;

[0045] a3. After mixing the above-mentioned solution I and solution II, add a stabilizer, and finally add deionized water, and stir evenly to obtain the tin stripping tin plating solution.

Embodiment 2

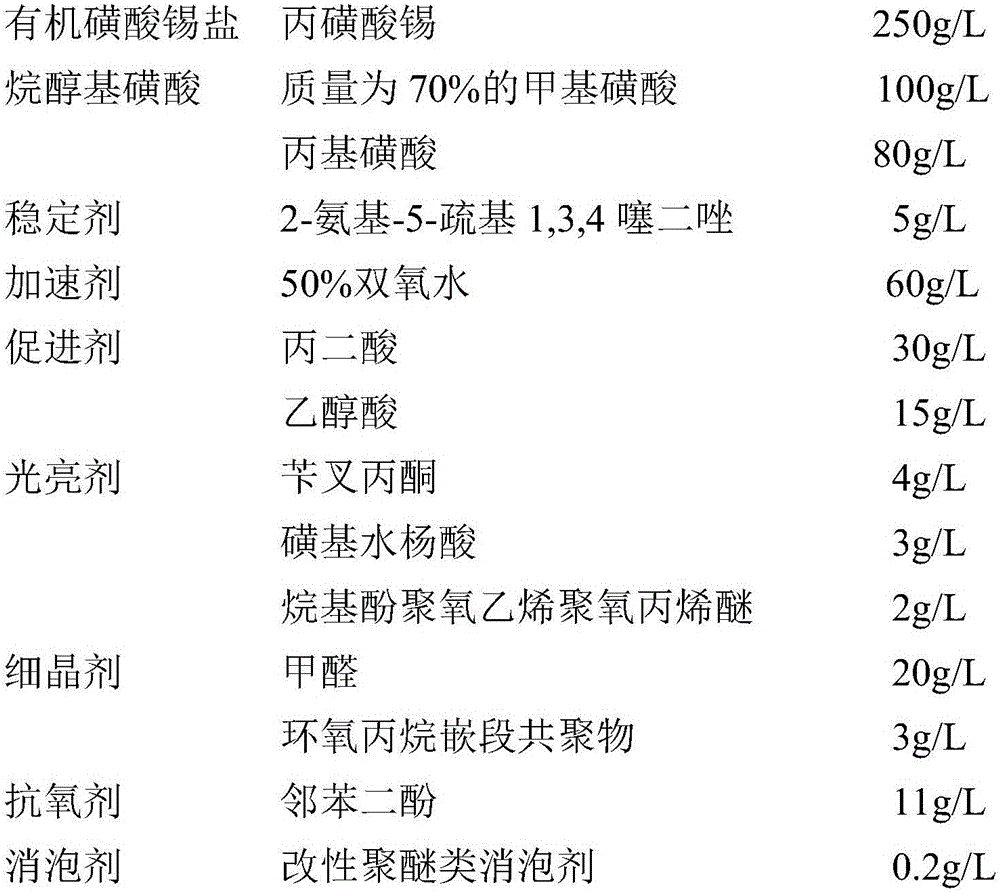

[0047] Each component and content of the tin stripping liquid of present embodiment 2 are as follows:

[0048]

[0049] The preparation method of the tin stripping and tin plating solution of this embodiment 2 is the same as that of embodiment 1, and will not be repeated here.

Embodiment 3

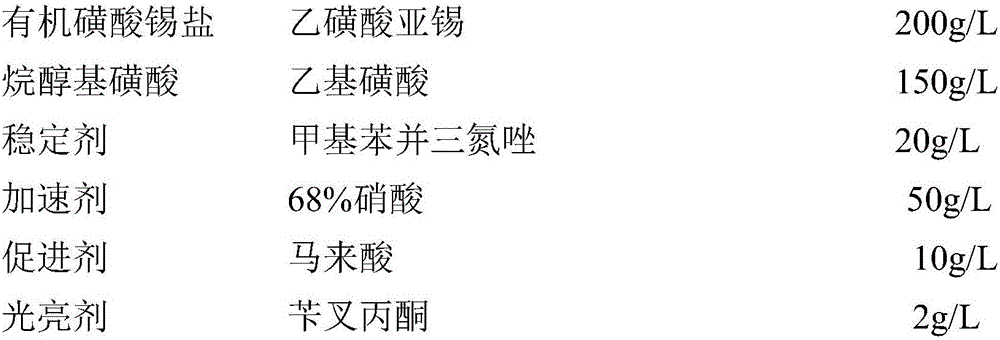

[0051] Each component and content of the stripping tin plating liquid of present embodiment 3 are as follows:

[0052]

[0053]

[0054] The preparation method of the tin stripping and tin plating solution of this embodiment 3 is the same as that of embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com