Molding method of unidirectional reinforced composite material with carbon nanotubes perpendicular to fiber direction

A fiber-oriented and unidirectional reinforcement technology, applied in the field of materials and fiber-reinforced composite materials, can solve the problems of low strength, weak bearing capacity and small elongation, and achieve the effect of quick effect, easy control and high degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

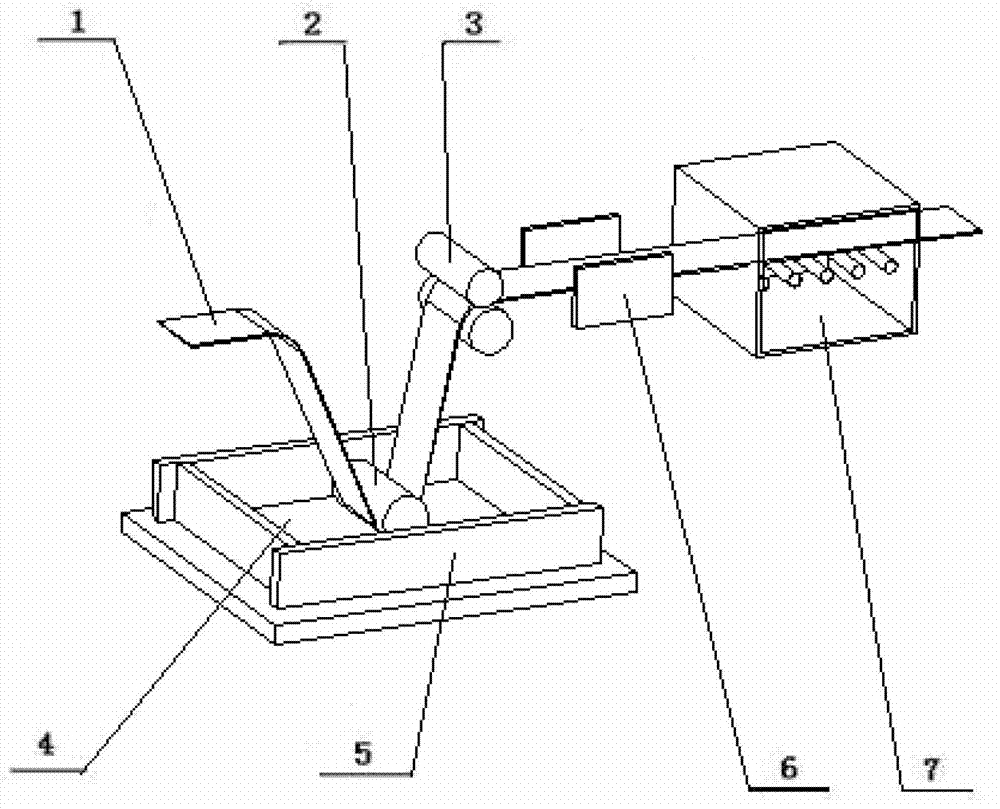

[0020] The technical scheme involved in the invention is described by taking the double-oriented CNTs / T700 carbon fiber reinforced epoxy unidirectional prepreg prepared by a winding machine equipped with drying equipment and a model of 4FW500 as an example. The structure of the orientation device is as follows: figure 2 shown.

[0021] A polytetrafluoroethylene rubber tank is used, and a DC electric field A is set in the rubber tank 4. The electric field A is composed of a pair of electrodes 5, the electrode area is 100mm×115mm, and the electrode distance is 100mm; the rubber roller 2 is placed in the electric field, and the axis direction of the rubber roller core is in line with The direction of the electric field is parallel, and the center of gravity of the rubber roller is located in the center between the two electrodes.

[0022] Set a DC electric field B at 200mm behind the squeeze roller 3 (between the squeeze roller 3 and the drying chamber 7). The electric field B i...

Embodiment 2

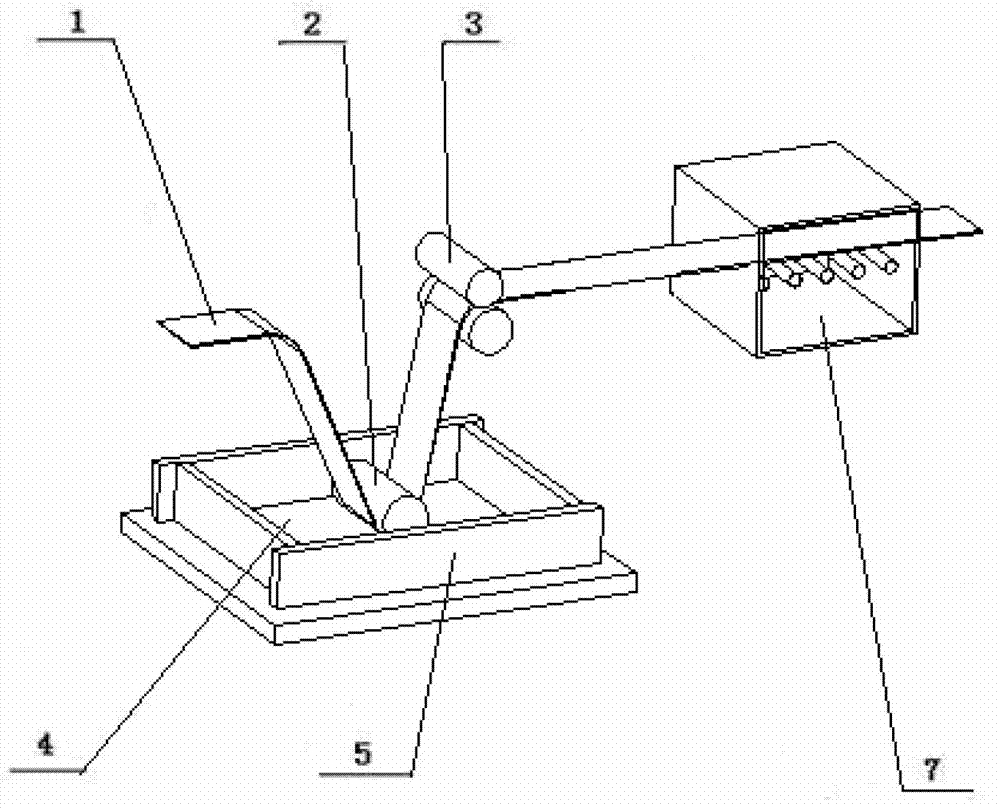

[0026] Taking the preparation of oriented CNTs-E glass fiber reinforced polyester unidirectional prepreg tape with drying equipment and model SKLCI50 / 500 winding machine as an example, the technical scheme involved in the invention is explained. The structure of the orientation device is as follows: figure 1 shown.

[0027] A ceramic glue tank 4 is used, and a direct current electric field A is set in the glue tank. The direct current electric field A is composed of a pair of electrodes 5, the electrode area is 415 mm long x 400 mm high, and the electrode distance is 400 mm; the rubber roller 2 is placed in the electric field, and the axis direction of the rubber roller core is in line The direction of the electric field is parallel, and the center of gravity of the rubber roller is located in the center between the two electrodes.

[0028] The glue is polyester resin system, solid 184 polyester, solid 199 polyester, diisophenyl peroxide DPO, dipropylene phthalate DAP, benzoyl...

Embodiment 3

[0031] Taking the preparation of oriented CNTs-S glass fiber reinforced polyester unidirectional prepreg tape with a set of drying equipment and model SKLCI50 / 500 winding machine as an example, the technical scheme involved in the invention is explained. The structure of the orientation device is as attached figure 1 shown.

[0032] A ceramic glue tank is used, and a DC electric field A is set in the glue tank 4. The electric field A is composed of a pair of electrodes 5. The electrode area is 415mm long × 400mm high, and the electrode distance is 400mm; The directions are parallel, and the center of gravity of the rubber roller is located in the center between the two electrodes.

[0033] The glue is an epoxy resin system, and the mass ratio of E20 epoxy resin, DDS, boron trifluoride monoethylamine, acetone, and acid-treated, amine-functionalized carbon nanotubes is 60:8:1:70:2. After mixing the resin according to a conventional method, stir it magnetically for 40 minutes an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric field strength | aaaaa | aaaaa |

| Electric field strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com