Carbon fiber sizing agent and preparation method thereof

A carbon fiber and sizing technology, applied in the directions of carbon fiber, fiber processing, textiles and papermaking, can solve problems such as poor dispersibility, achieve good wettability and compatibility, good stability, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

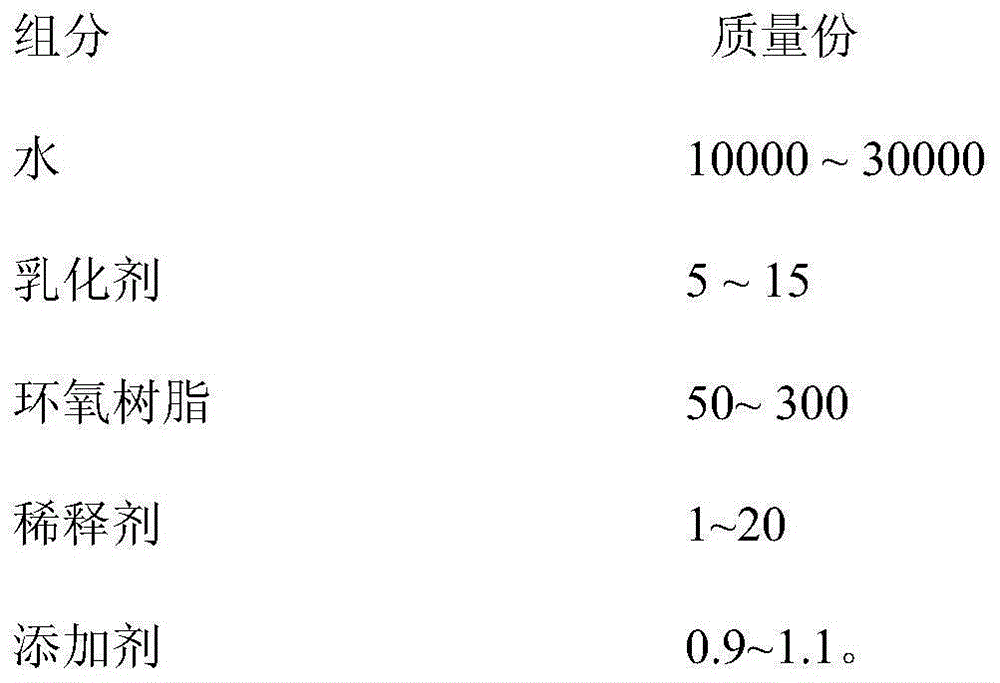

[0047] A carbon fiber sizing agent, the sizing agent is made of the following raw materials in parts by mass:

[0048]

[0049] The additive is epoxy oligomeric silsesquioxane C 28 h 58 0 13 Si 6 , the general expression is R' 2 R 4 [SiO 1.5 ] 6 .

[0050] where R=C 4 h 9 , whose molecular structure is R'=C 6 h 11 o 2 , whose molecular structure is

[0051] Mix the additive with 1,4-butanediol diglycidyl ether at a ratio of 1:8, stir for 20 minutes, add to 100 parts of 4,4'-diaminodiphenylmethane epoxy resin, and stir for 30 minutes to obtain a compound With resin.

[0052] Mix nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, and sorbitan fatty ester in a ratio of 2:1:4 and heat to 80°C with stirring to obtain a hydrophilic-lipophilic balance (HLB) of 8.43 mixed emulsifier.

[0053] Mix the above compounded resin and emulsifier at a ratio of 10:1, and stir evenly at 70°C, then add deionized water to it at a rate of 1mL / min until th...

Embodiment 2

[0058] A carbon fiber sizing agent, the sizing agent is made of the following raw materials in parts by mass:

[0059]

[0060] Epoxy oligomeric silsesquioxane C 36 h 76 o 13 Si 8 , the general expression is R'R 7 [SiO 1.5 ] 8 .

[0061] where R=C 4 h 9 , whose molecular structure is R'=C 8 h 13 O, whose molecular structure is

[0062] Mix the additive and neopentyl glycol diglycidyl ether in a ratio of 1.05:12, stir for 30 minutes and add it to 160 parts of multifunctional epoxy resin (AFG90) and bisphenol A epoxy resin (E44) in equal proportions The mixture was stirred for 30 minutes to obtain a composite resin.

[0063] Alkylphenol polyoxyethylene ether, 2,4-dicumyl polyoxyethylene ether, and polyoxyethylene sorbitan ester were mixed in a ratio of 1:2:1 and heated and stirred to obtain a hydrophilic-lipophilic balance value ( HLB) is a mixed emulsifier of 11.7. Mix the above compounded resin and emulsifier at a ratio of 9:1 and stir evenly at 80°C, then...

Embodiment 3

[0068] A carbon fiber sizing agent, the sizing agent is made of the following raw materials in parts by mass:

[0069]

[0070]

[0071] Epoxy oligomeric silsesquioxane C 36 h 76 o 13 Si 8 , the general expression is R'R 7 [SiO 1.5 ] 8 .

[0072] where R=C 4 h 9 , whose molecular structure is R'=C 8 h 13 O, whose molecular structure is

[0073] Mix the additive with neopentyl glycol diglycidyl ether in a ratio of 1:12, stir for 30 minutes and add it to 160 parts of multifunctional epoxy resin (AFG90) and bisphenol A epoxy resin (E44) in equal proportions The mixture was stirred for 30 minutes to obtain a composite resin.

[0074] Alkylphenol polyoxyethylene ether, 2,4-dicumyl polyoxyethylene ether, and polyoxyethylene sorbitan ester were mixed in a ratio of 1:2:1 and heated and stirred to obtain a hydrophilic-lipophilic balance value ( HLB) is a mixed emulsifier of 11.7. Mix the above compound resin and emulsifier at a ratio of 22:1 and stir evenly at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com