Patents

Literature

41results about How to "Effective stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

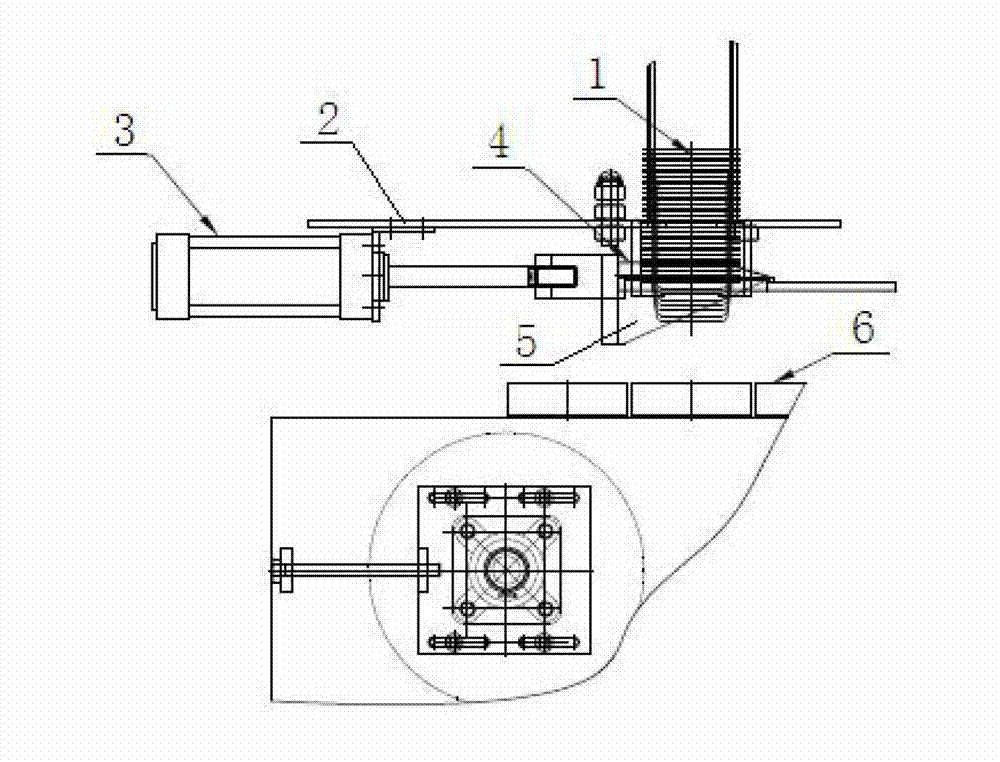

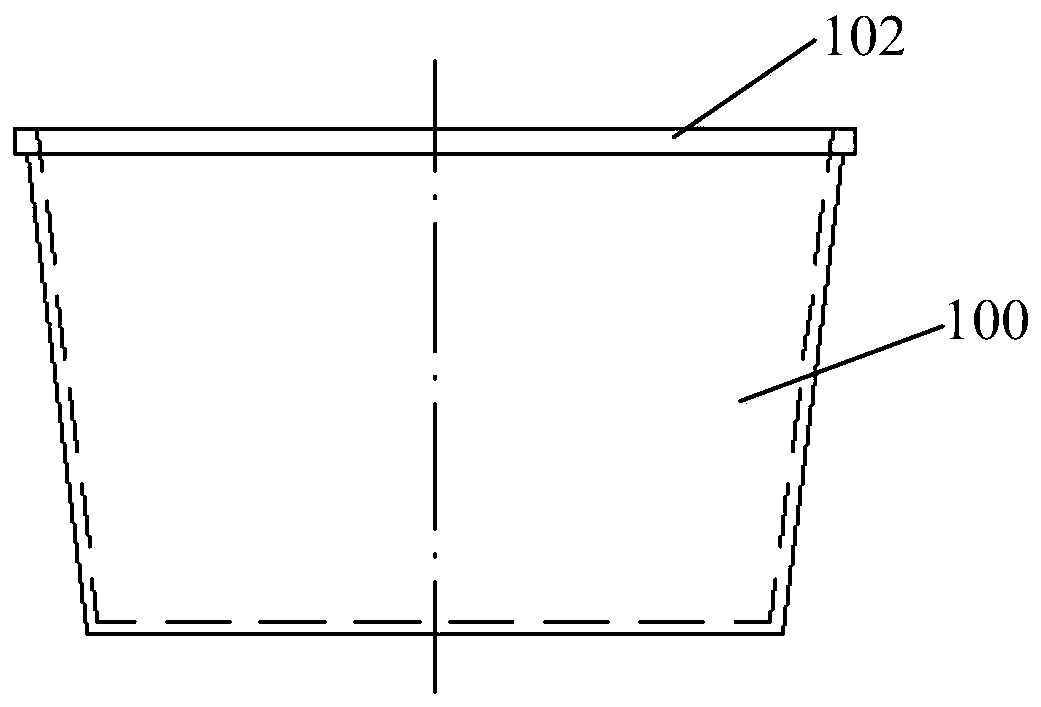

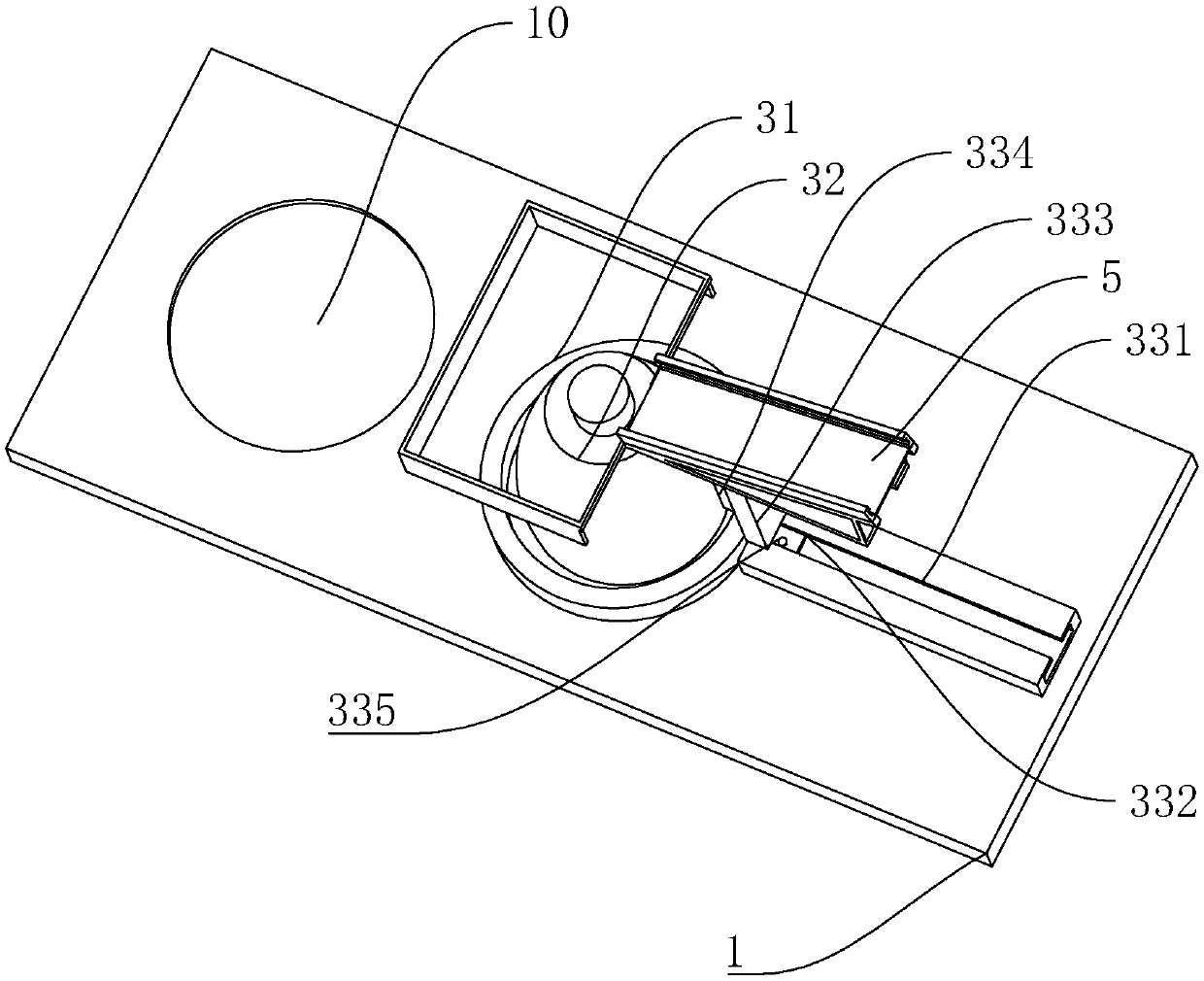

Cup falling device for food boxes

InactiveCN102897350AAvoid adsorptionEffective stackingPackagingDe-stacking articlesEngineeringStructural engineering

The invention discloses a cup falling device for food boxes. The cup falling device comprises a support, a guide sleeve for the food boxes, a cylinder, a shift fork for the food boxes and a separation plate for the food boxes, wherein the cylinder is horizontally fixed at the rear end of the support, the guide sleeve for the food boxes is vertically fixed at the front end of the support, the shift fork for the food boxes is connected with the front end of a push rod of the cylinder, and the separation plate for the food boxes is triangular and arranged at the bottom of the shift fork for the food boxes. The device can automatically feed the food boxes, effectively stack the food boxes and prevent adsorption between the food boxes caused by static electricity.

Owner:JIANGSU XINGMALI TECH

Rapid beef slitting device

ActiveCN109676657AEasy to processImprove cleanupMetal working apparatusMeat shaping/cuttingEngineeringMachining

The invention discloses a rapid beef slitting device, and relates to the technical field of food processing. The device comprises a supporting mechanism and a conveying mechanism, a driving mechanismis arranged in the middle end of the top of the supporting mechanism, the conveying mechanism is arranged at the bottom of the supporting mechanism, the supporting mechanism is fixedly connected withthe driving mechanism through a screw, and the front face of the driving mechanism is provided with a hydraulic air cylinder. The device has the beneficial effects that according to the rapid beef slitting device, through slitting blades and a mounting sliding block, a worker refers to numerical value on a graduation ruler in advance and marks the needed slitting interval numerical value on the front face of the slitting mechanism through a corresponding marking tool, through the manual control sliding method, each slitting blade is sequentially drawn to be adjusted to the corresponding slitting interval segment point through the mounting sliding block, and through changing of the interval numerical value of each slitting blade in the sliding adjusting process, the device can convenientlyachieve cutting machining of beef needing different slitting intervals.

Owner:济南高投能源发展有限公司

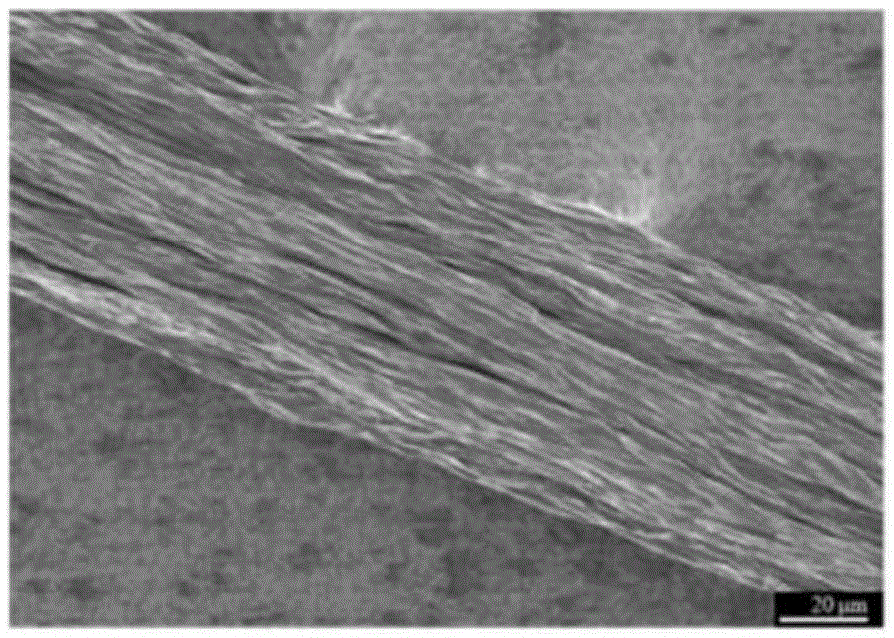

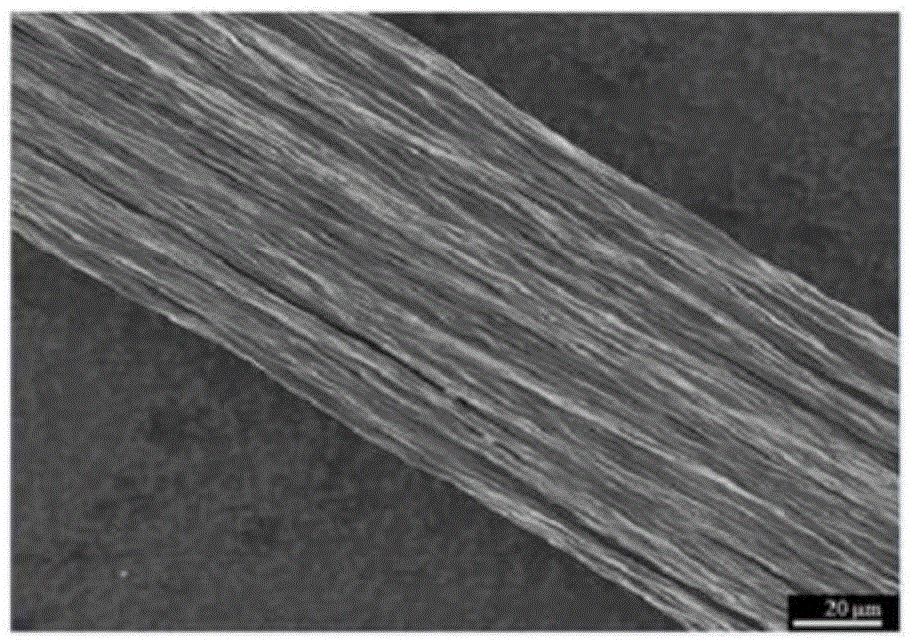

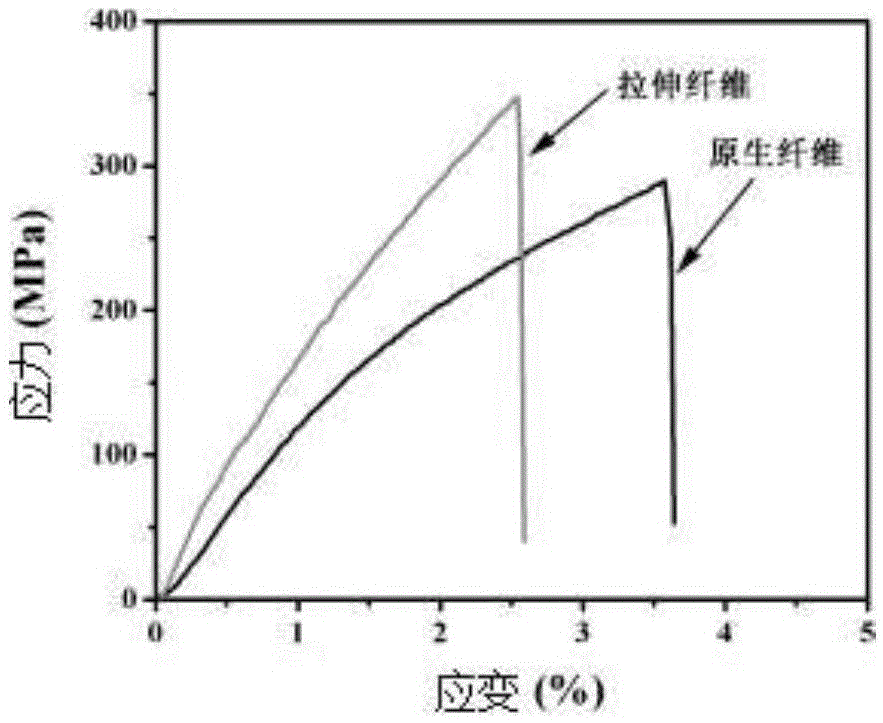

Preparing method for oriented graphene oxide fibers

InactiveCN105603580AImprove mechanical propertiesEffective stackingFibre chemical featuresWet spinning methodsFiberCvd graphene

The invention belongs to the technical field of preparation of graphene fiber materials and particularly relates to a preparing method for oriented graphene oxide fibers. The preparing method comprises the following steps that graphene oxide is prepared with lamellar graphene as a raw material, and a graphene oxide spinning solution is prepared; with a wet spinning method, the graphene oxide spinning solution flows into a solidifying solution, and primary graphene oxide fibers are prepared; at a certain temperature, the graphene oxide fibers are subjected to radial stretching and drying, and the oriented graphene oxide fibers are obtained. The preparing method is easy to implement and low in cost, the stretching rate of the fibers can be precisely controlled, and a good stretching effect can be achieved. The oriented graphene oxide fibers prepared through the method are significantly improved on the aspect of tensile strength compared with the primary graphene oxide fibers, a simple and effective method is provided for preparing high-performance fiber materials based on graphene, and the application of the graphene fibers in practical production and living can be promoted.

Owner:YANCHENG ZENGCAI SCI & TECH

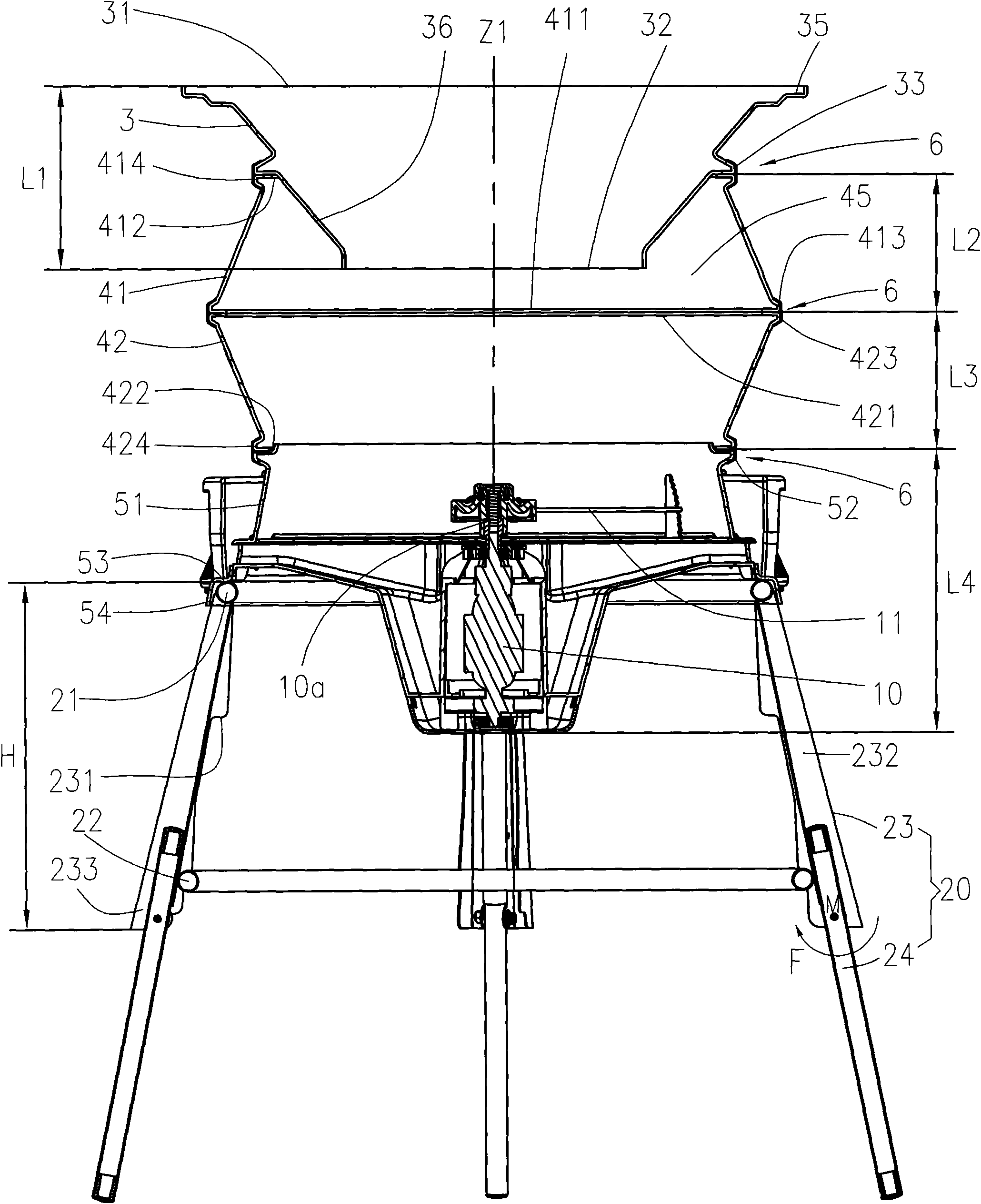

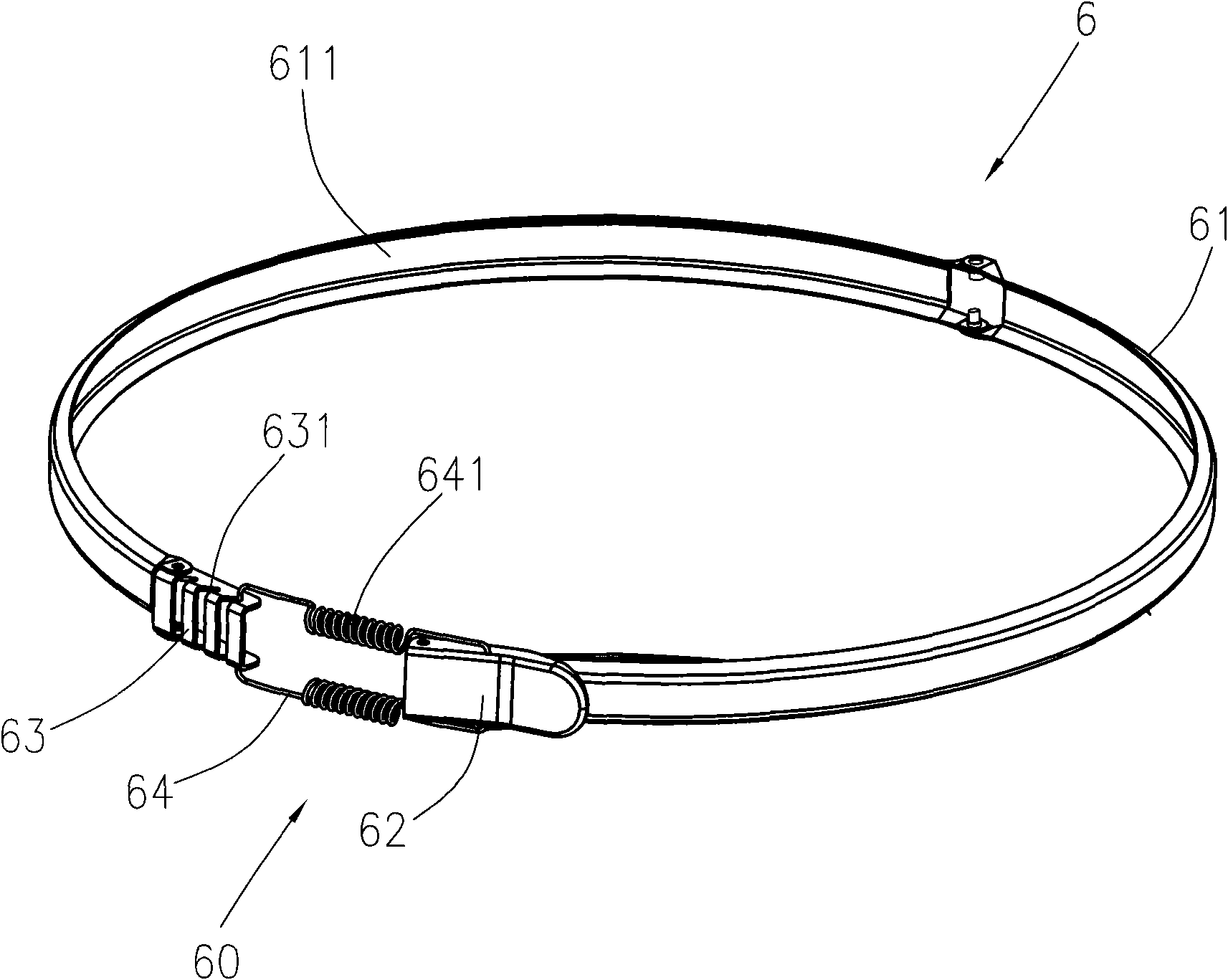

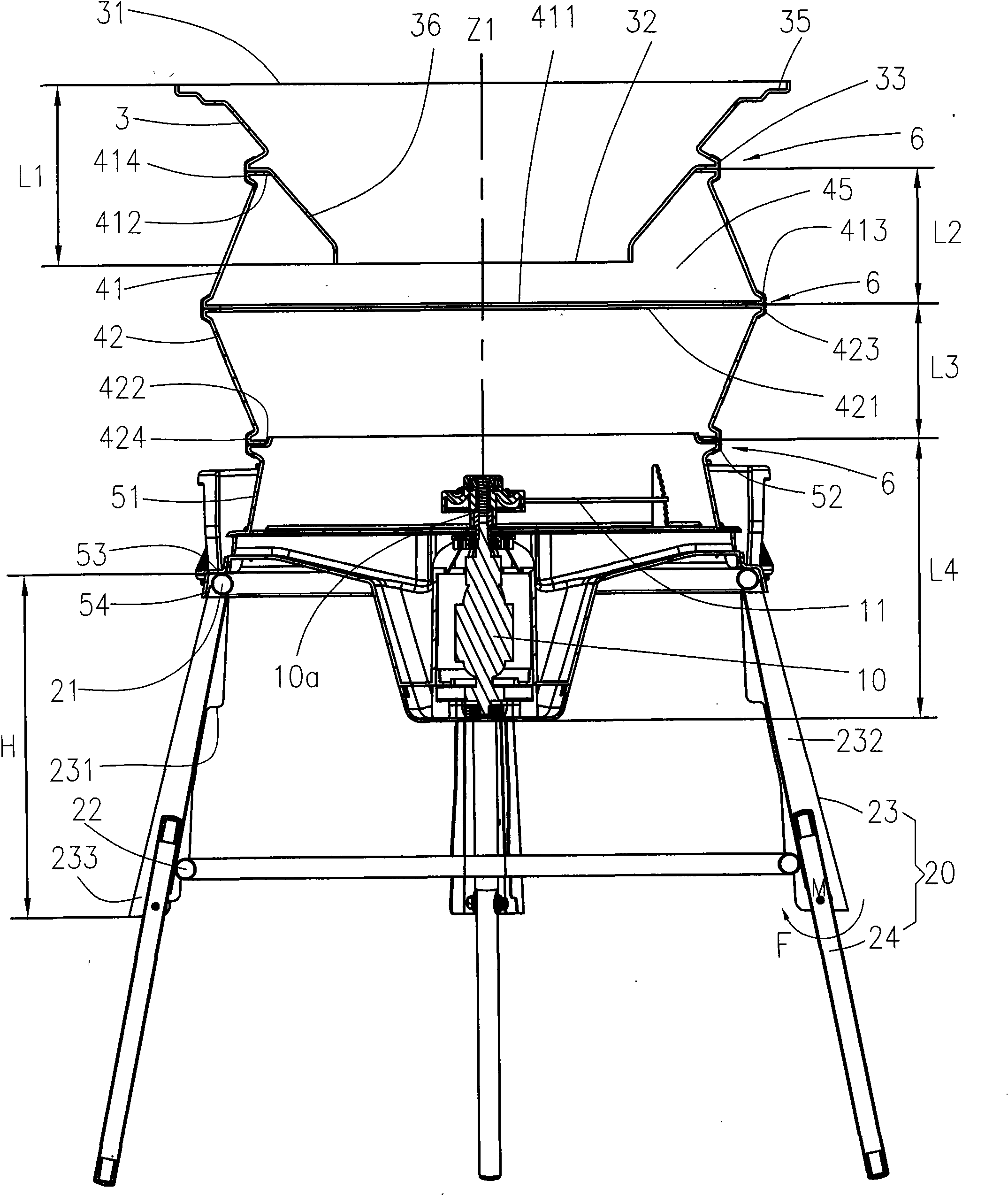

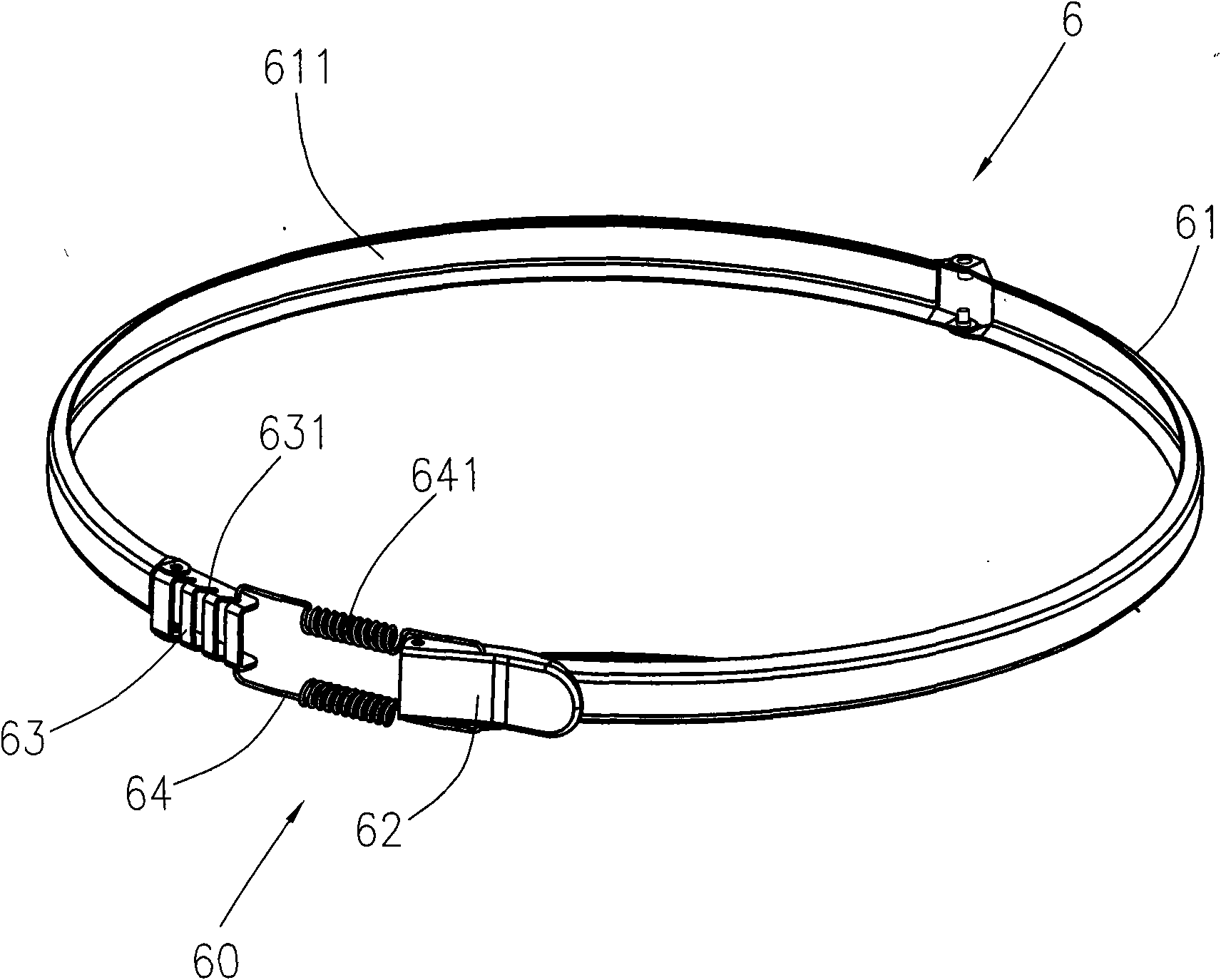

Frame for a folding table

ActiveCN103120475AReduce intensityReduce stiffnessFoldable tablesStowable tablesEngineeringMechanical engineering

Owner:LIFETIME PRODUCTS

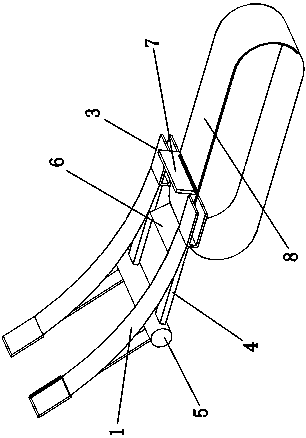

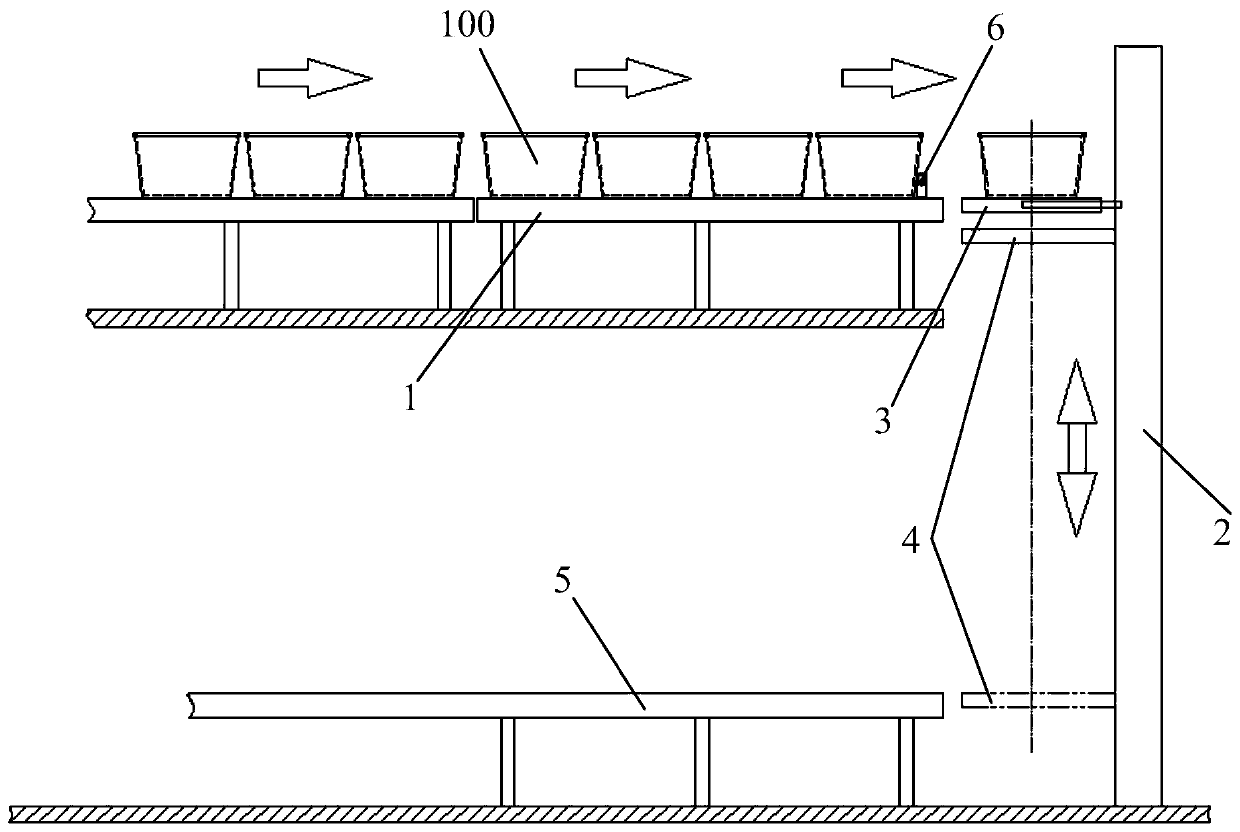

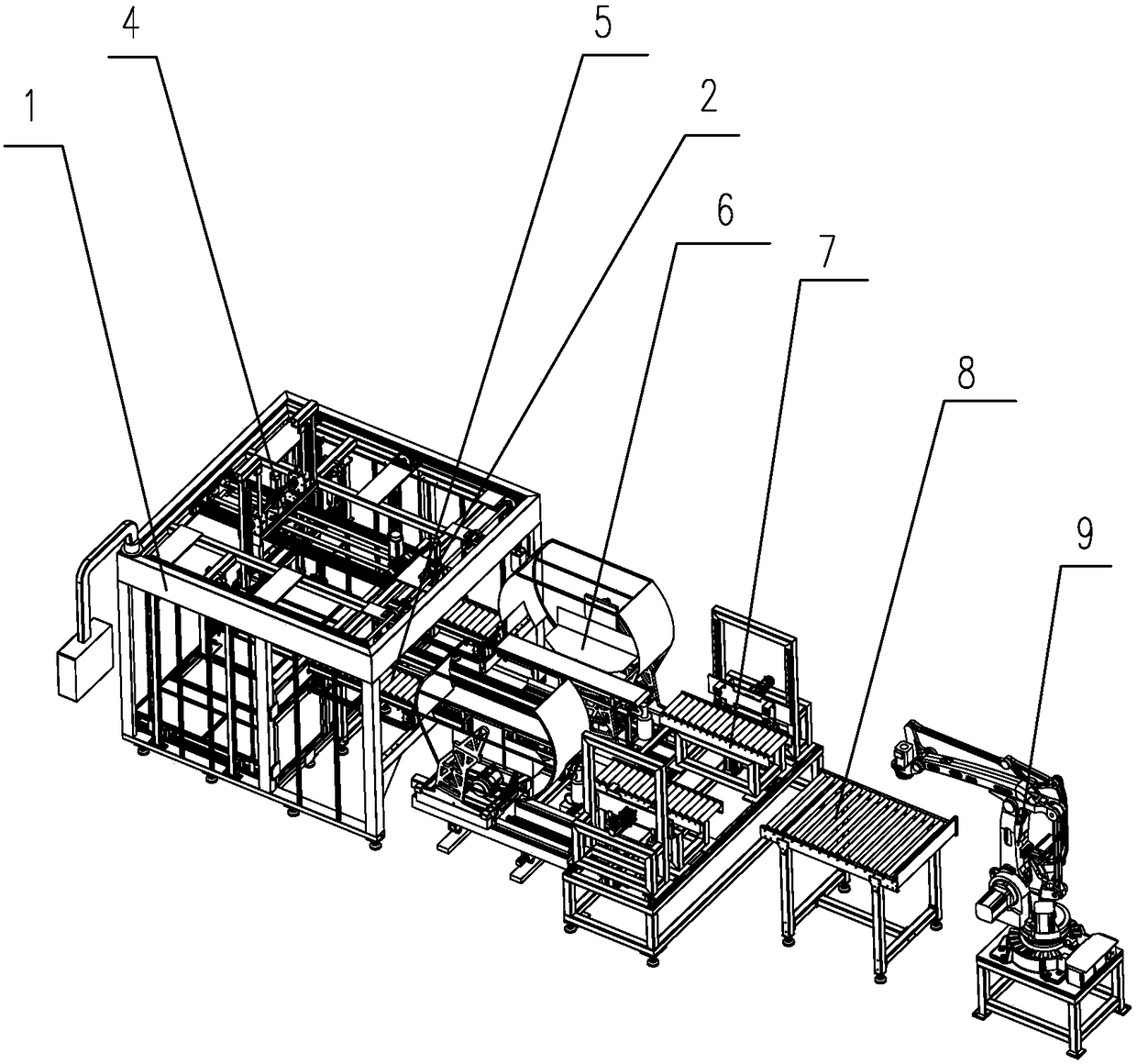

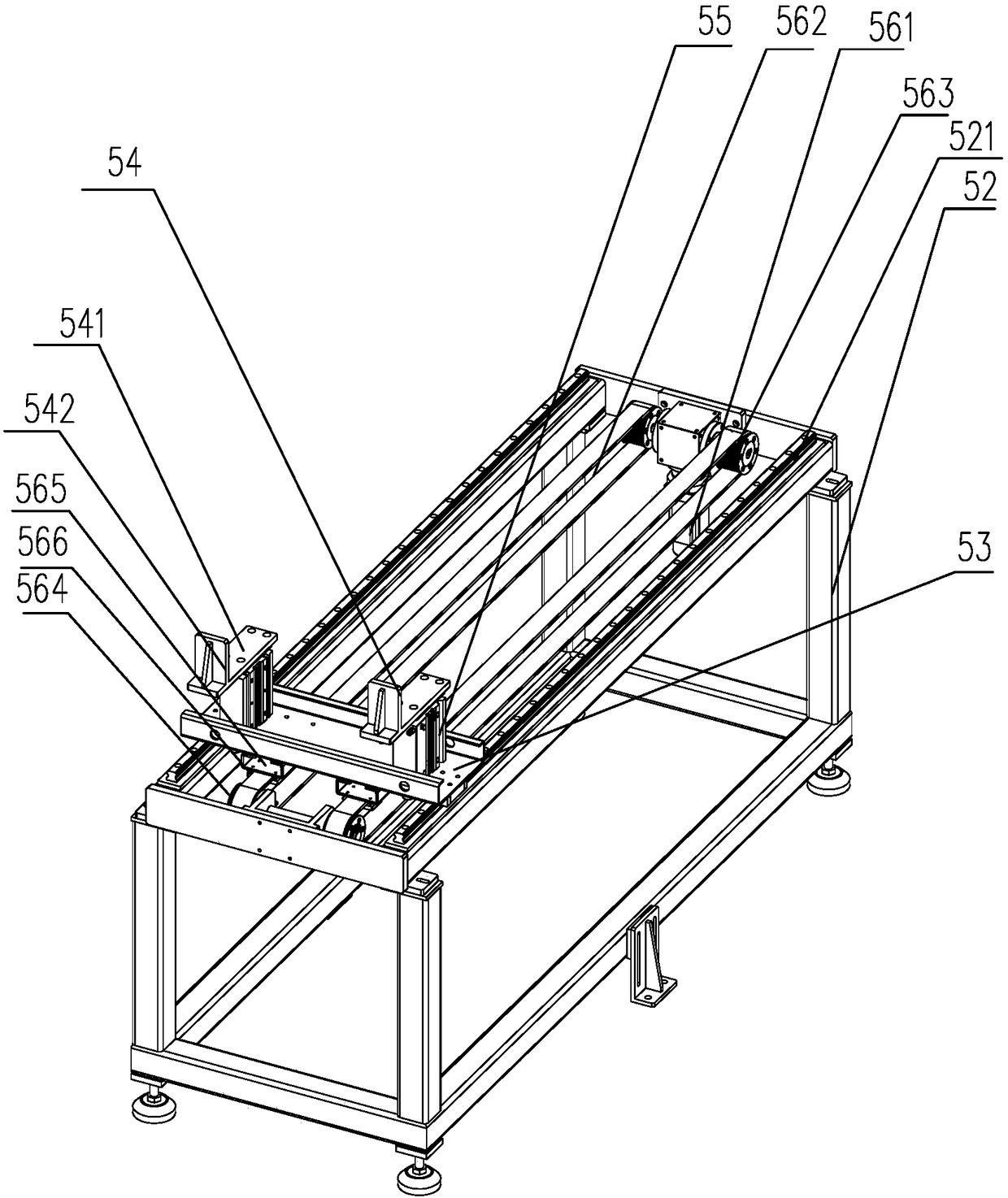

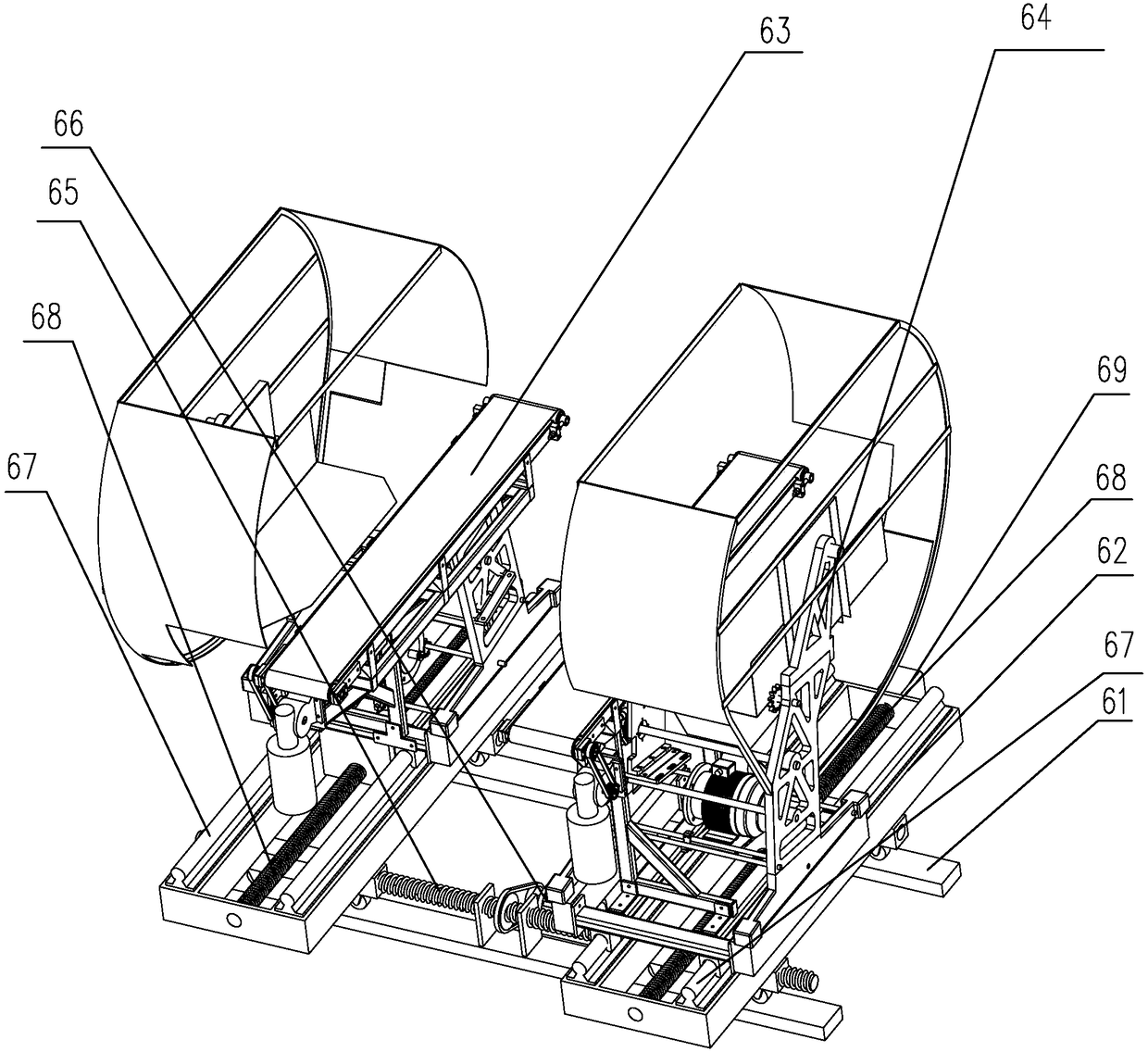

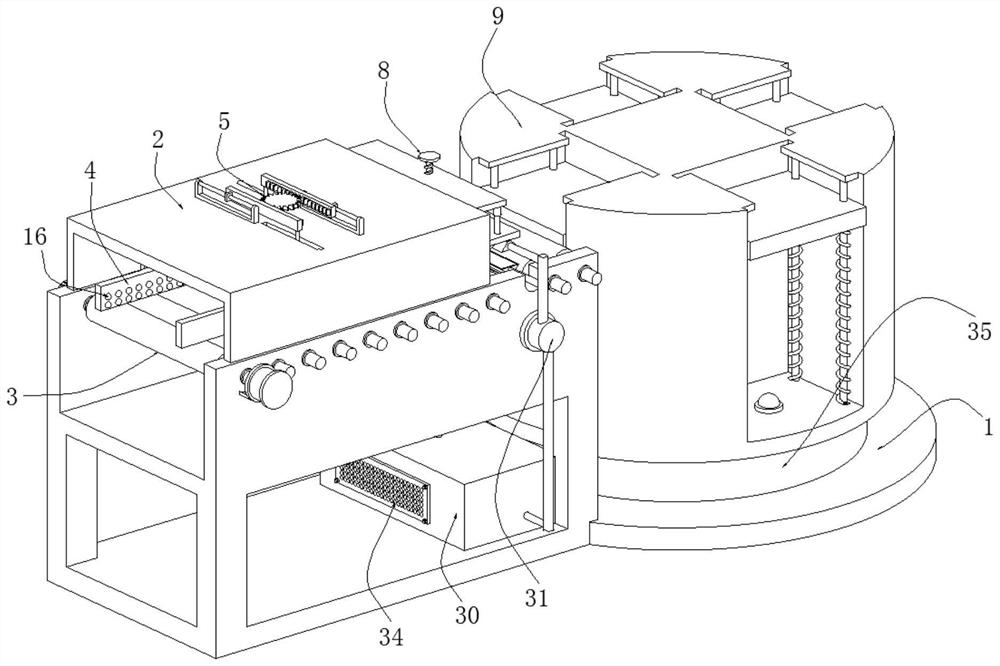

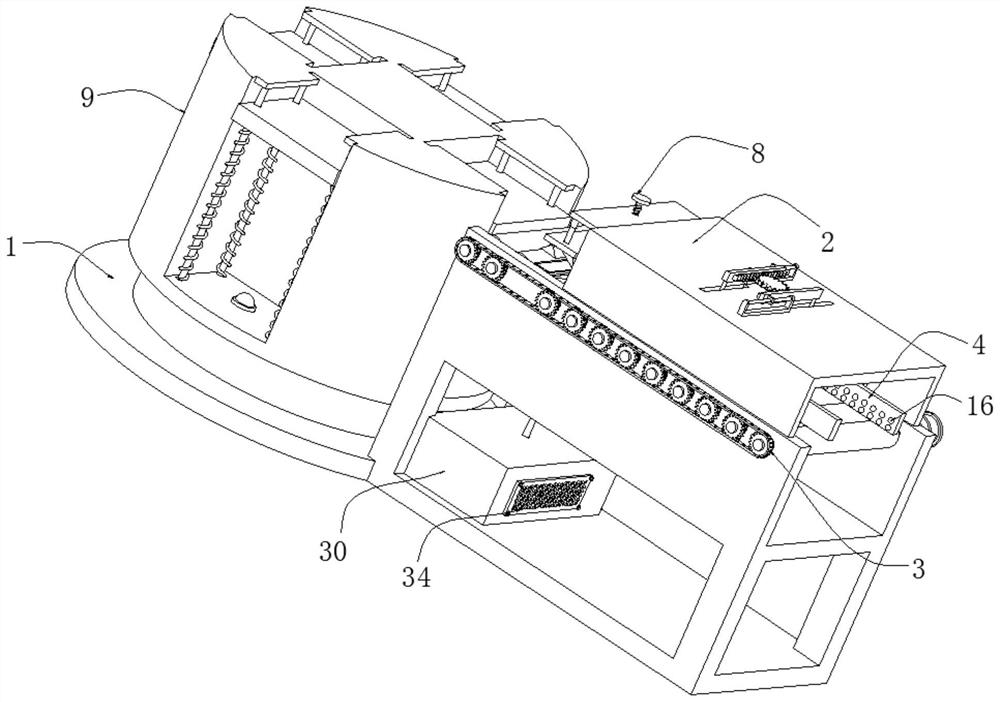

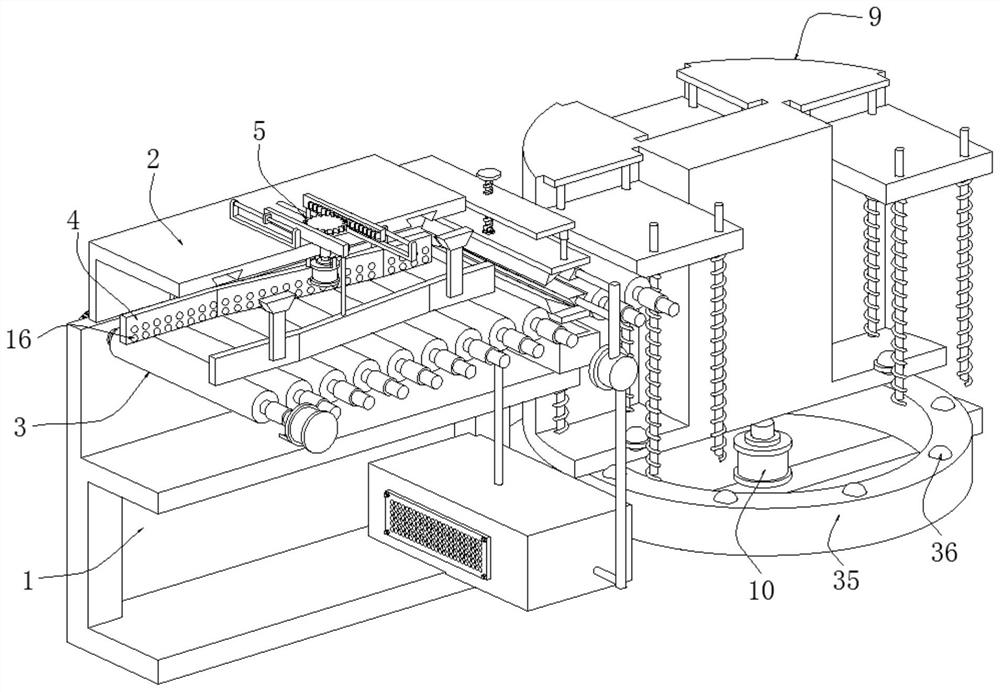

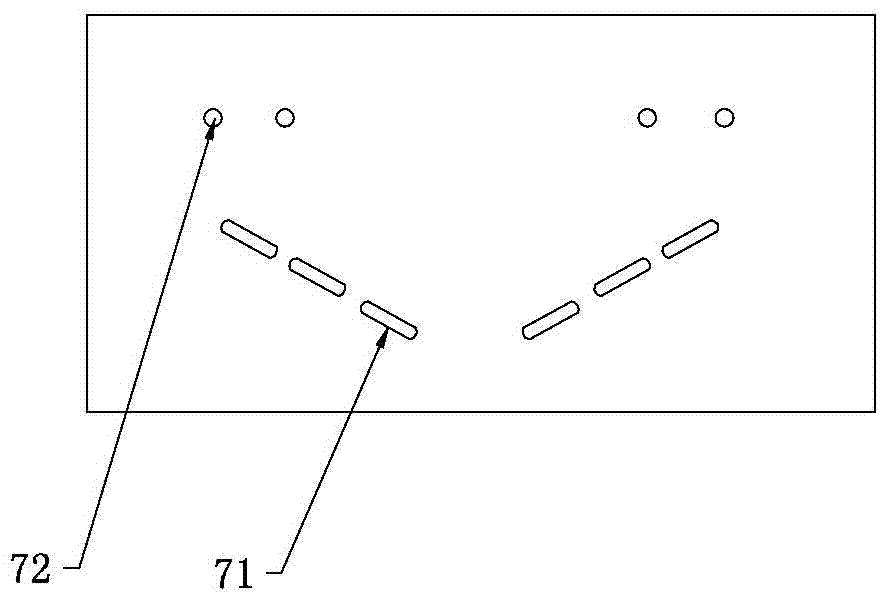

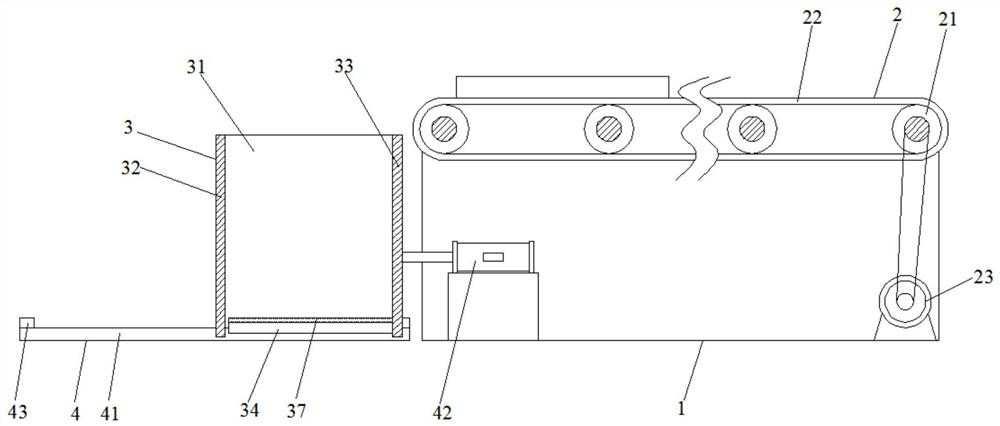

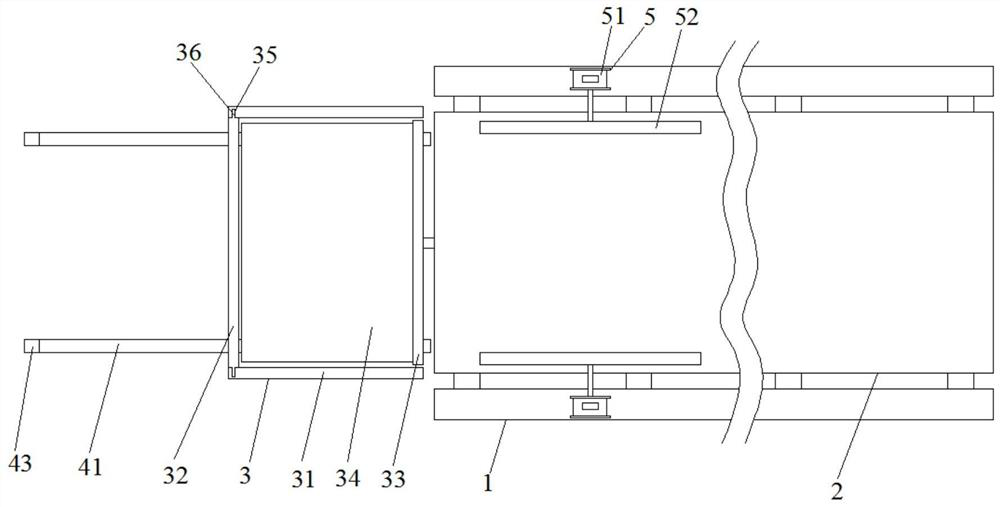

Forward and backward stacking method and stacking device for assembly lines

PendingCN108529181AEffective stackingGuaranteed accuracyStacking articlesConveyor partsEngineeringAssembly line

The invention discloses a forward and backward stacking method and stacking device for assembly lines. The device comprises a first conveying belt, a turnover mechanism and a second conveying belt, wherein the first conveying belt is connected with the previous assembly line, the second conveying belt is connected with the next assembly line, and the turnover mechanism is arranged between the first conveying belt and the second conveying belt and is connected with the two conveying belts. The stacking method and the stacking device disclosed by the invention are used for assembly lines with orderly forward and backward stacking processes for two workpieces in a manufacturing plant, and can be used for automatically performing orderly forward and backward stacking on the two workpieces on the assembly lines and delivering the two workpieces to the next process. The stacking device is simple in structure and low in repair difficulty, and the production cost is effectively reduced.

Owner:LISHUI UNIV

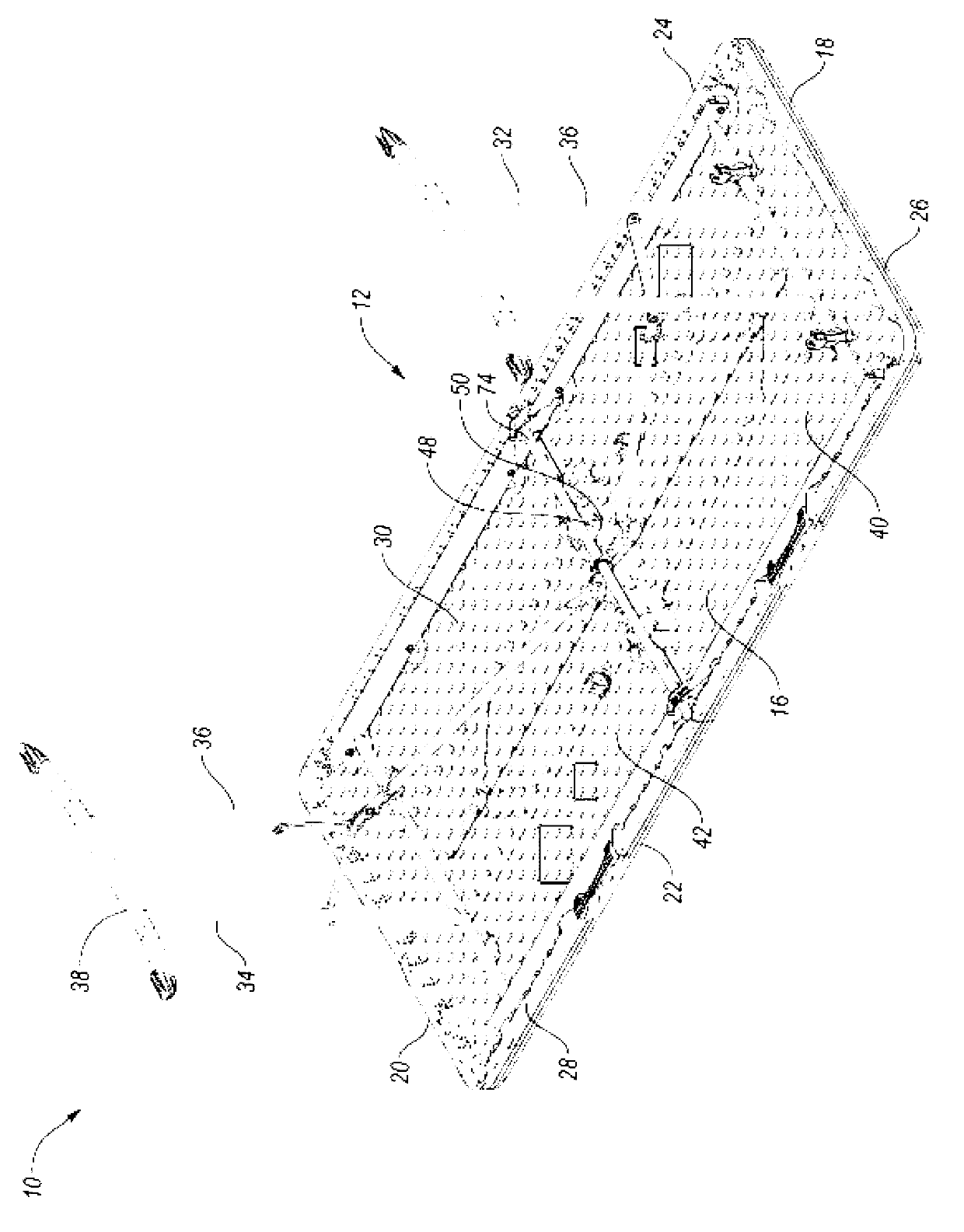

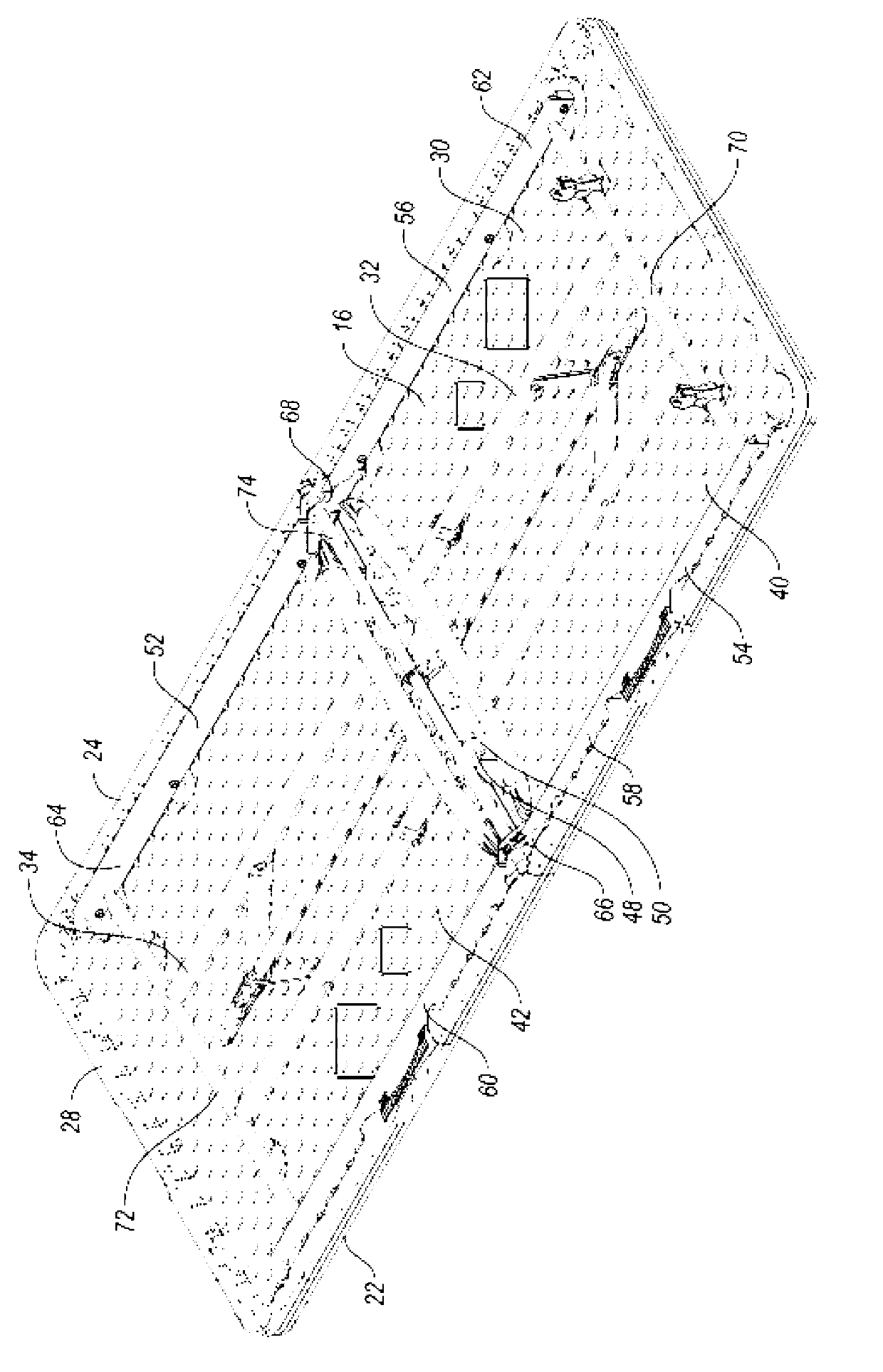

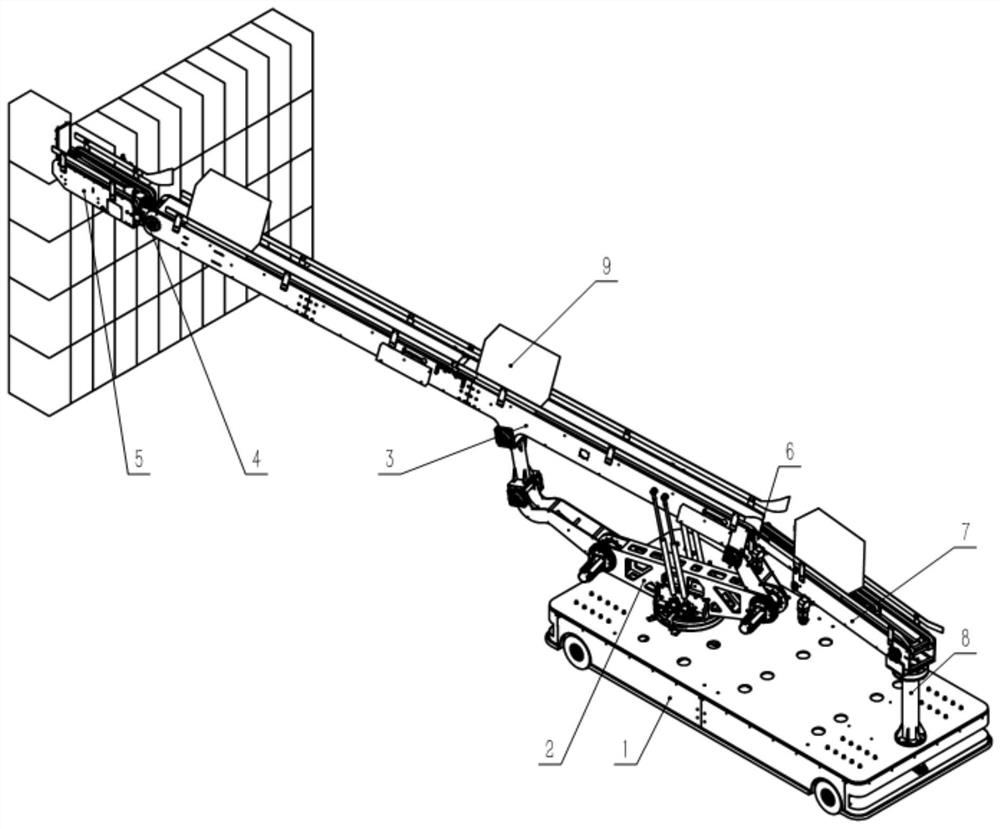

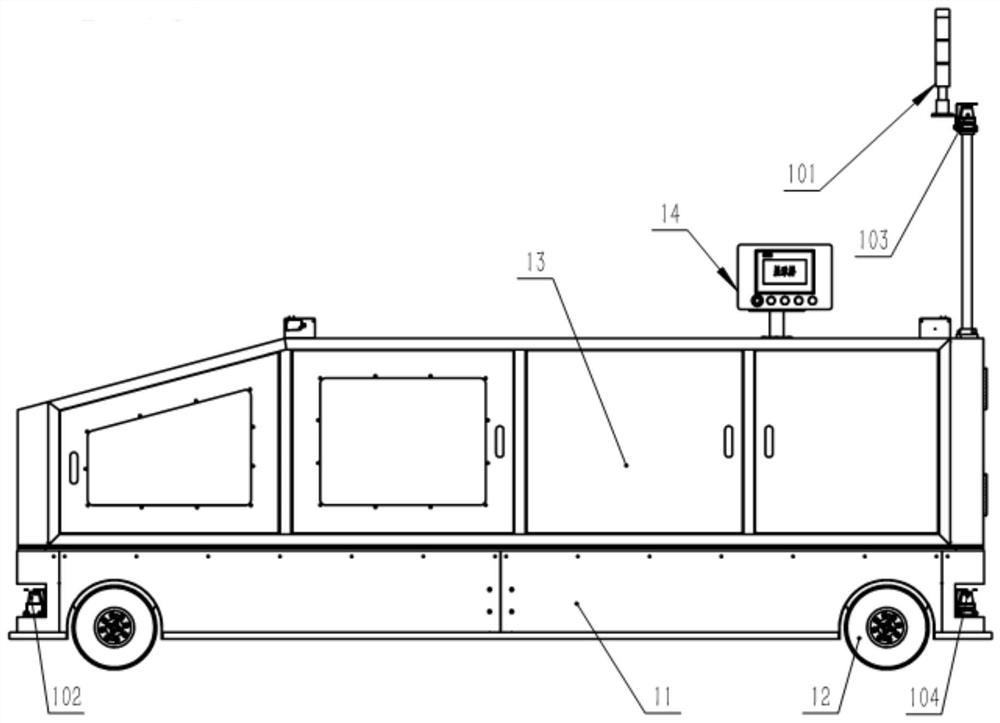

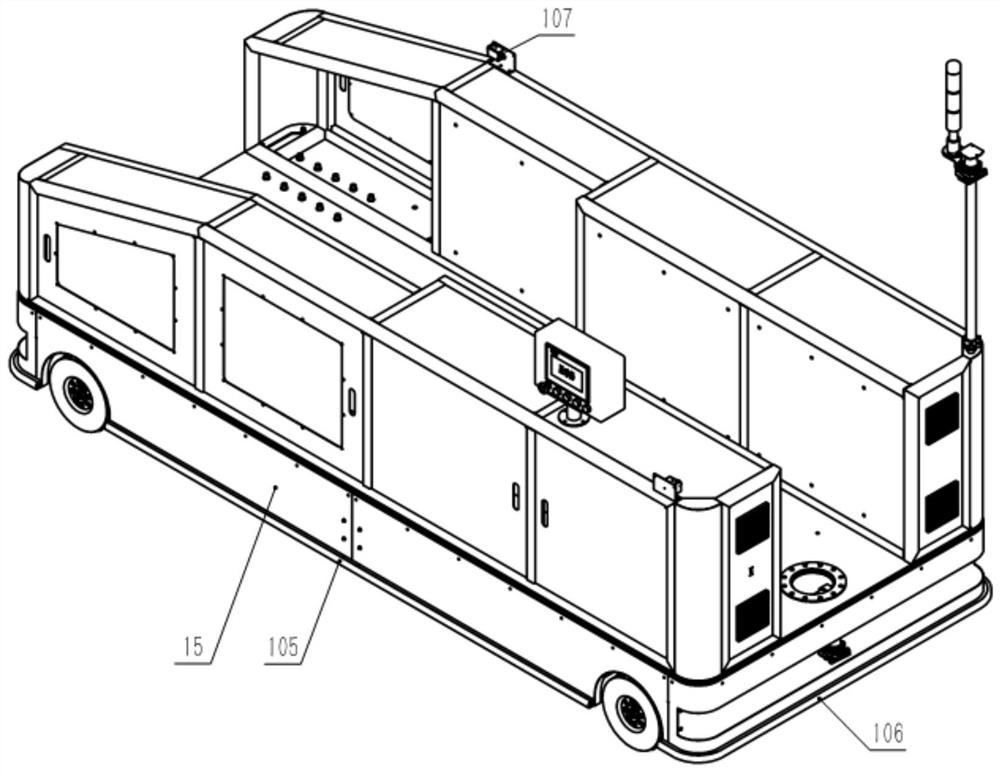

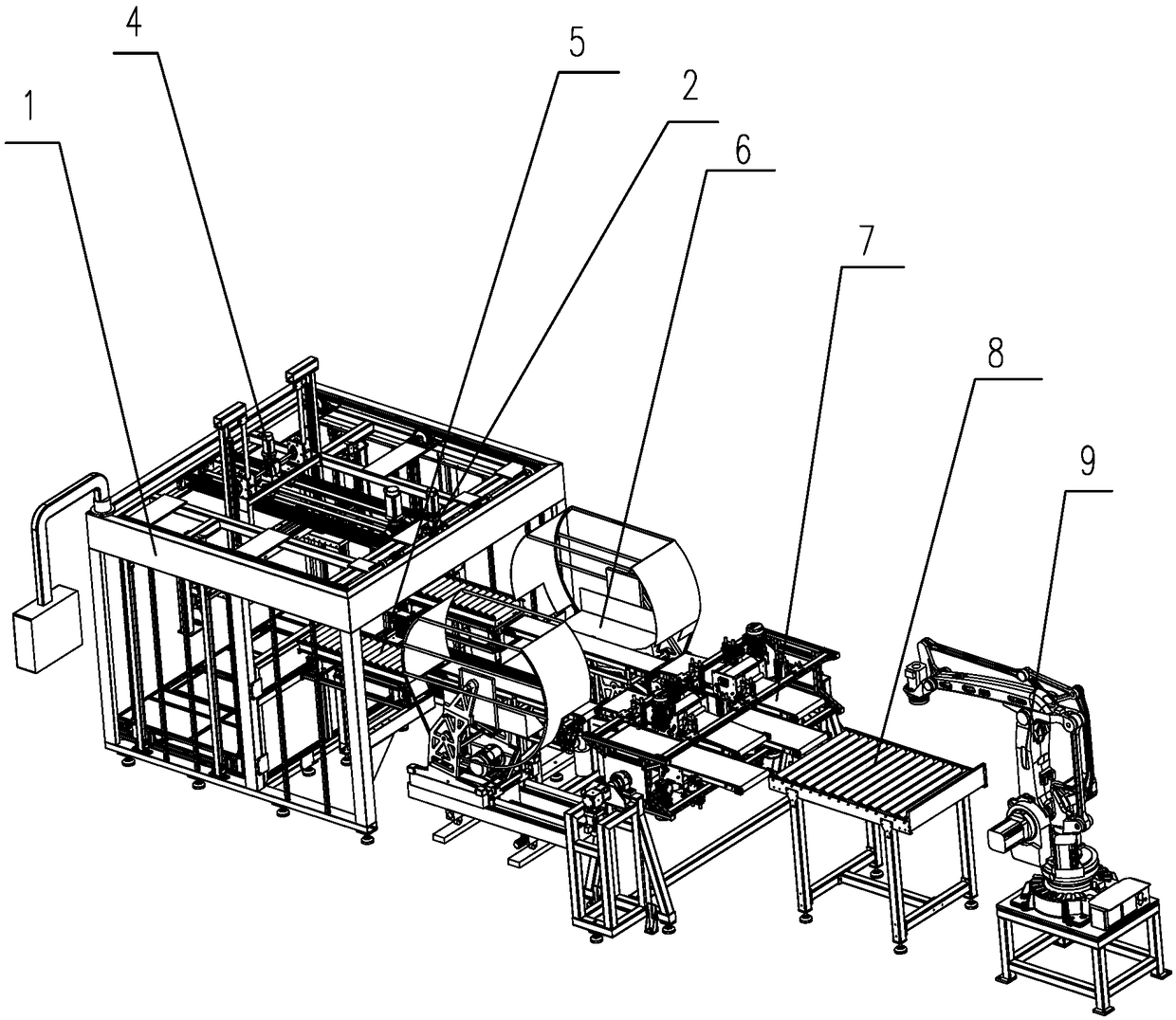

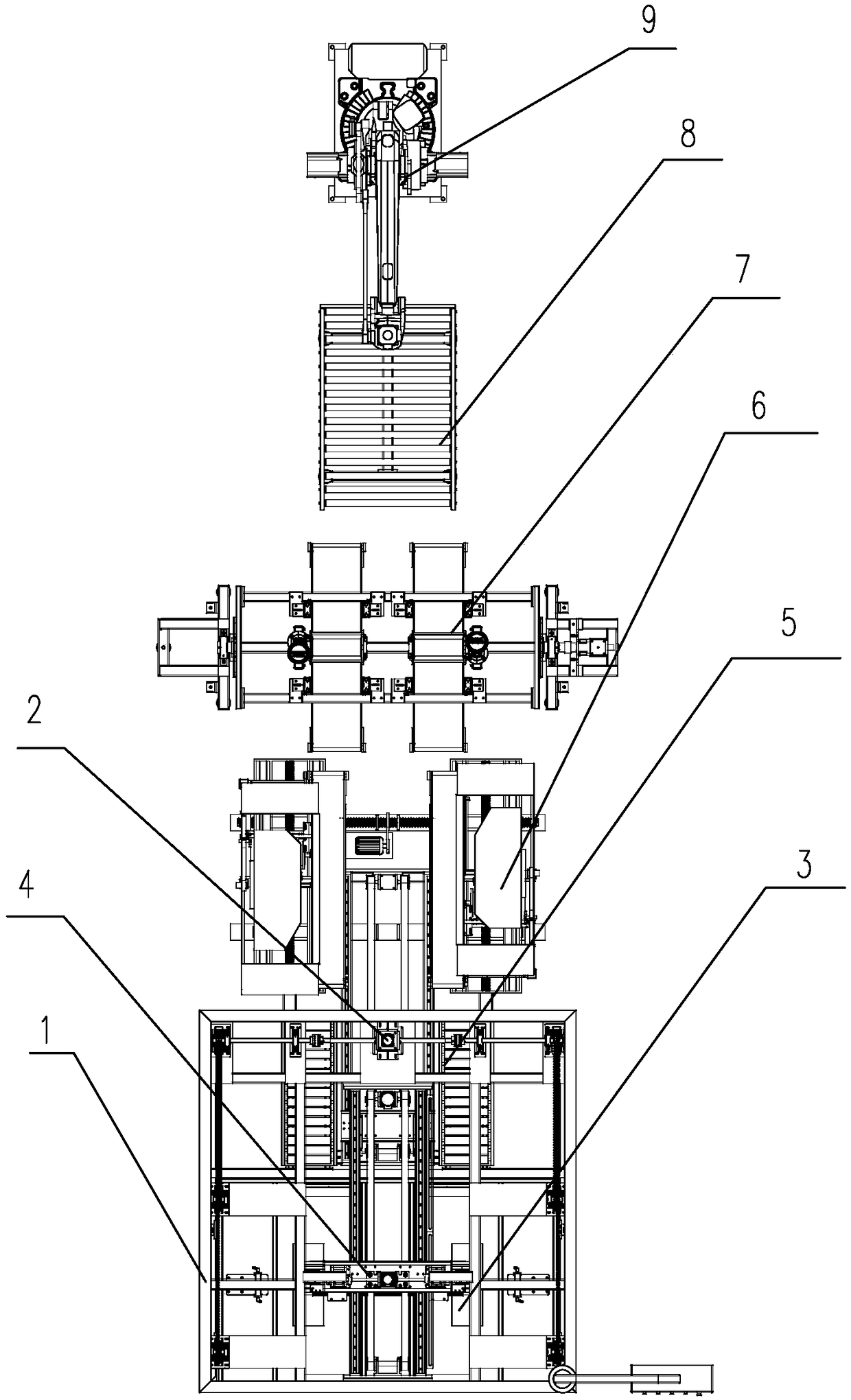

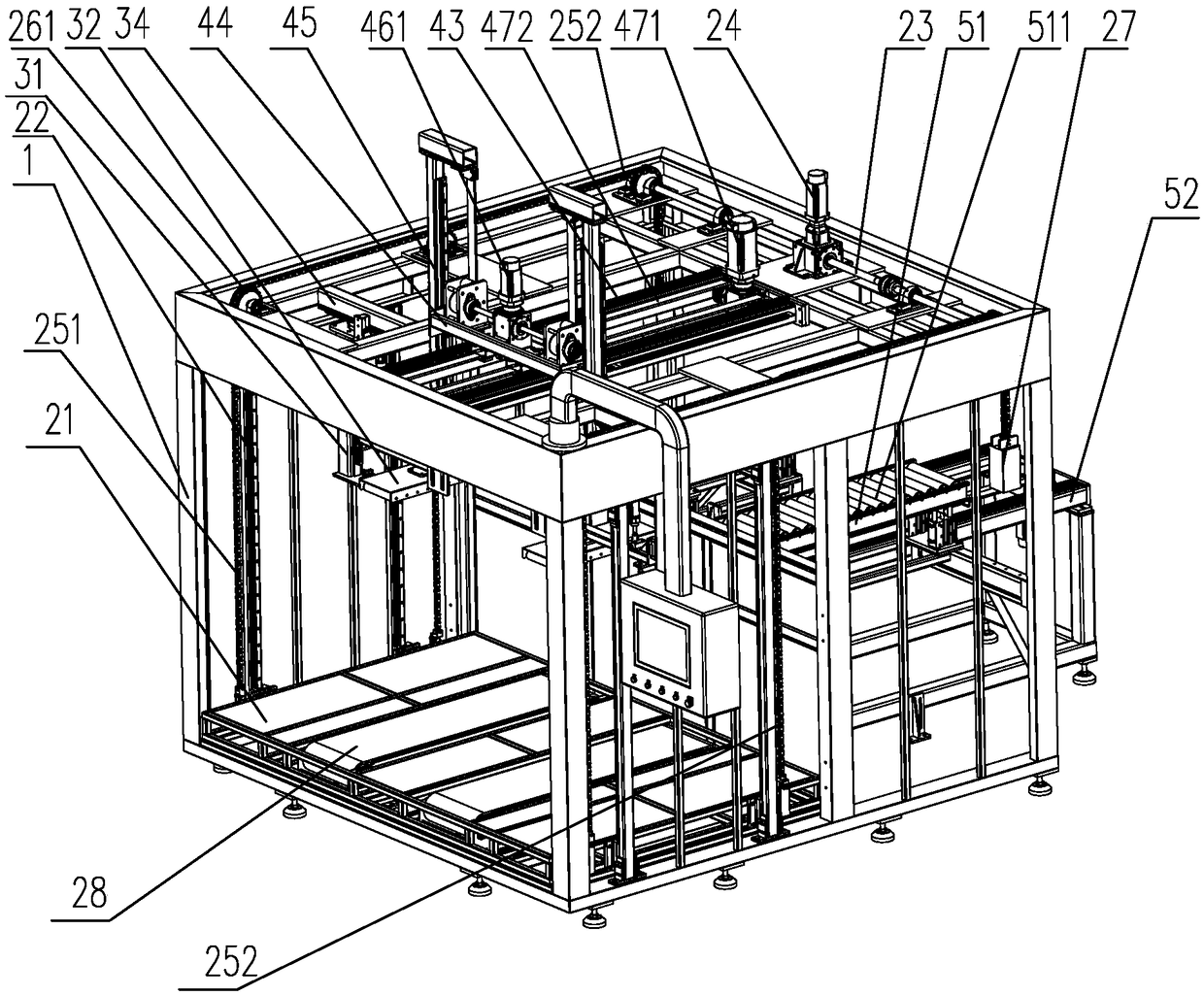

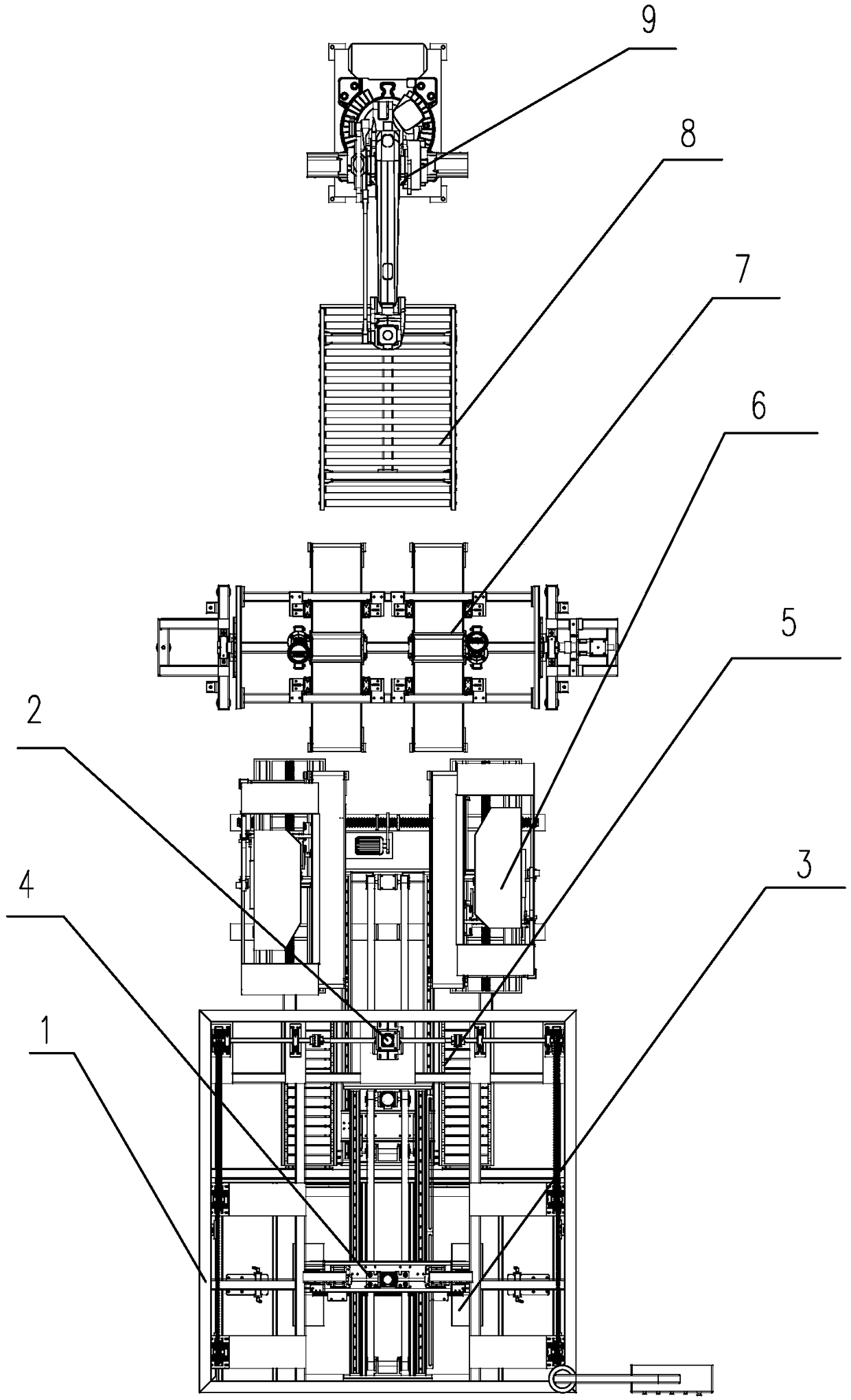

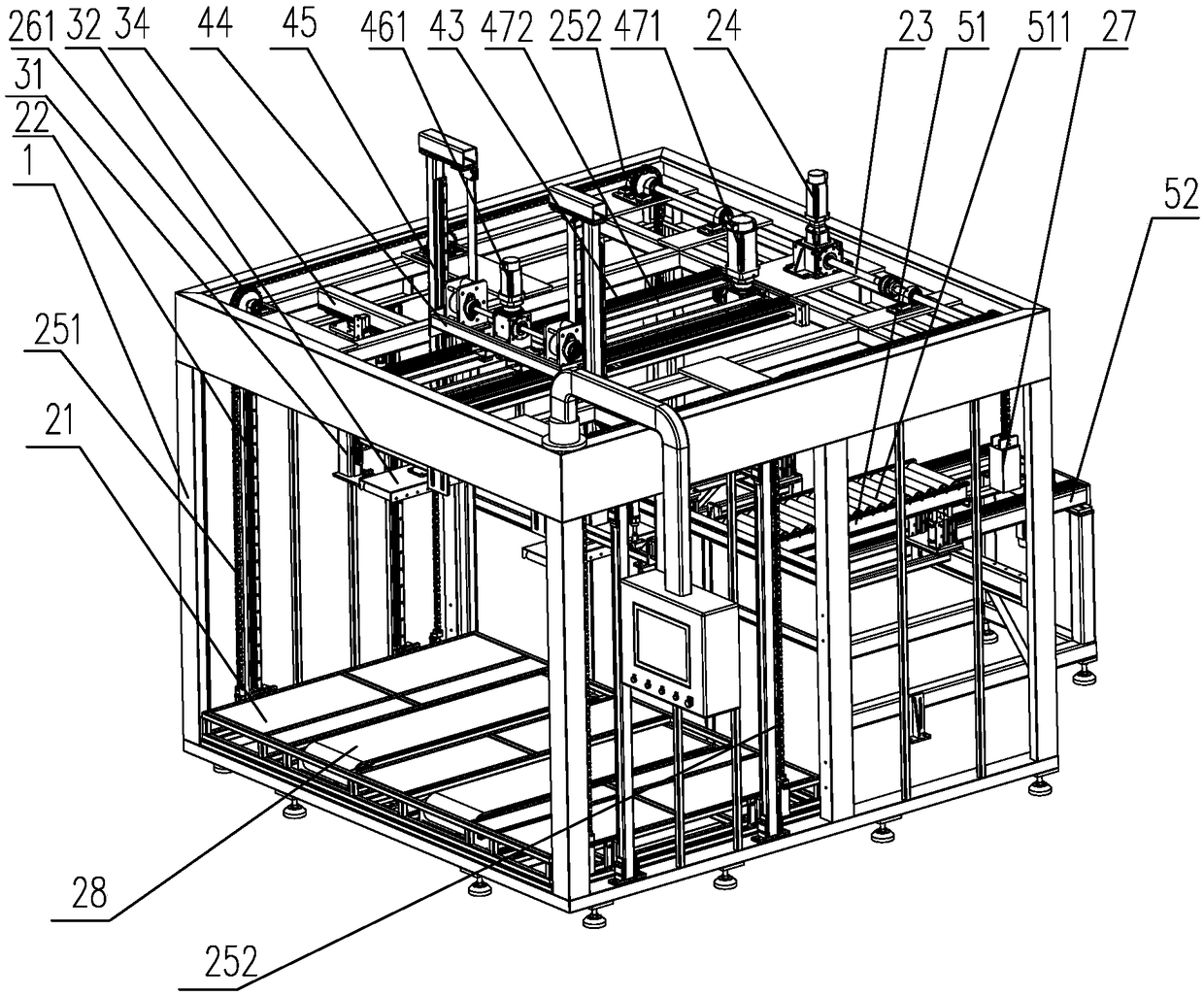

Self-adaptive trolley loading and unloading system

PendingCN113525557AReduce investmentReduce labor costsControl devices for conveyorsStacking articlesRadarLaser scanning

The invention discloses a self-adaptive trolley loading and unloading system. The system comprises a Mecanum wheel trolley assembly, a rotary supporting joint assembly, a middle-section conveying belt machine assembly, a cross hinged rotary joint assembly, a front-end unstacking and stacking assembly, a cross hinged rotary follow-up joint assembly, an inlet telescopic belt machine assembly, an inlet belt machine supporting column assembly and box-type materials. The Mecanum wheel trolley assembly comprises a front laser scanning radar, a rear laser positioning radar, a rear anti-collision radar and AGV anti-collision strips on the two sides. The device is an integrated box-type material conveying, unstacking and stacking integrated device, and suitable materials are box-type materials; the equipment is provided with a trolley navigation system, so that unstacking and stacking of materials within a certain area range can be realized, and unstacking and stacking of materials on a truck can also be realized; according to the design, material unstacking and stacking on a truck are mainly achieved, and the device is provided with a trolley omni-directional walking device and can be driven into the truck to achieve the functions of unstacking, stacking and transporting box type materials.

Owner:玉溪市新特科技有限公司

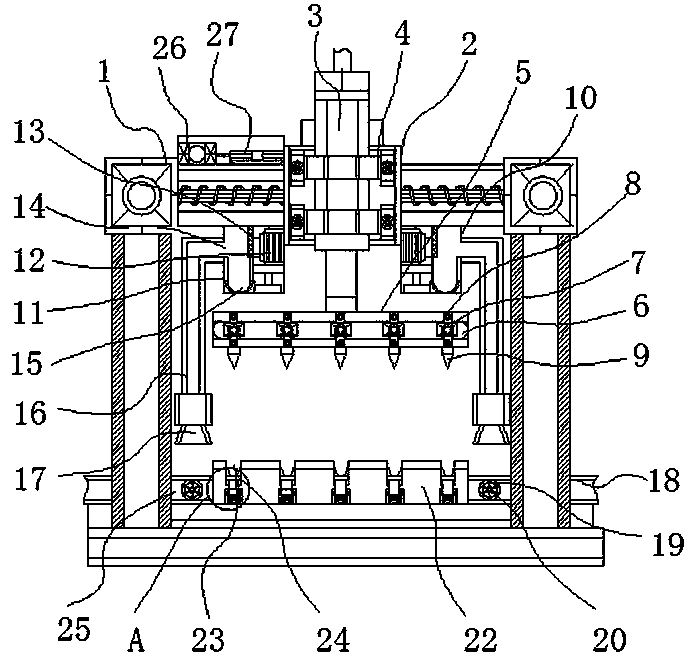

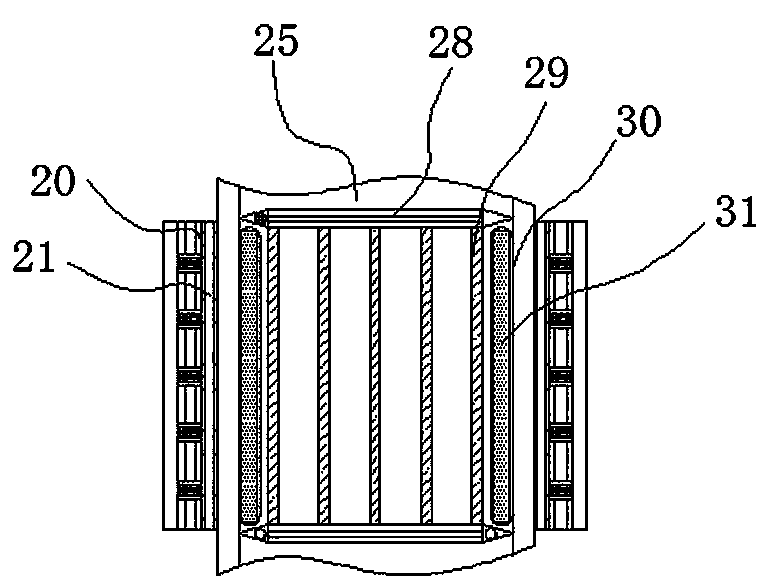

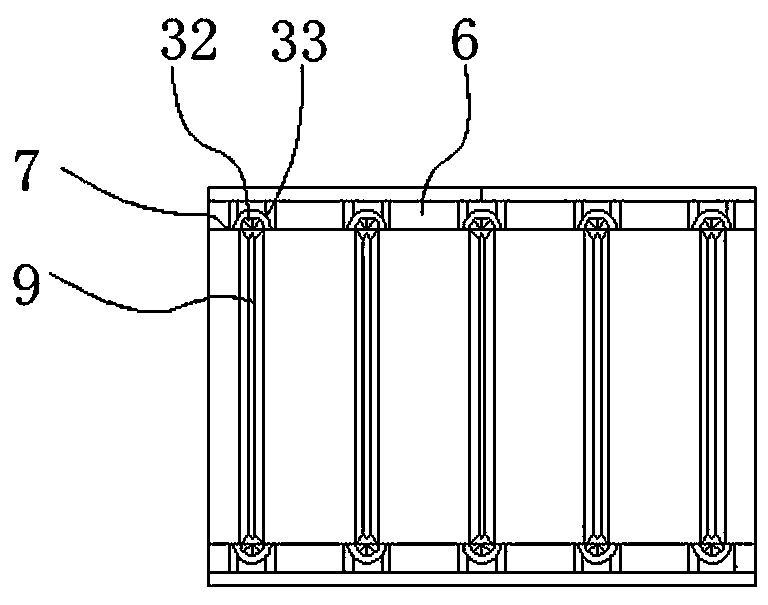

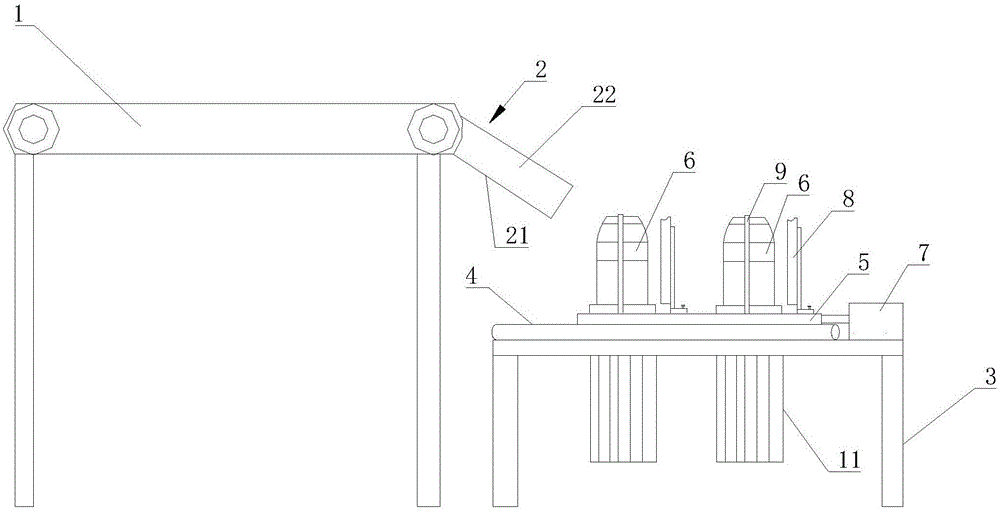

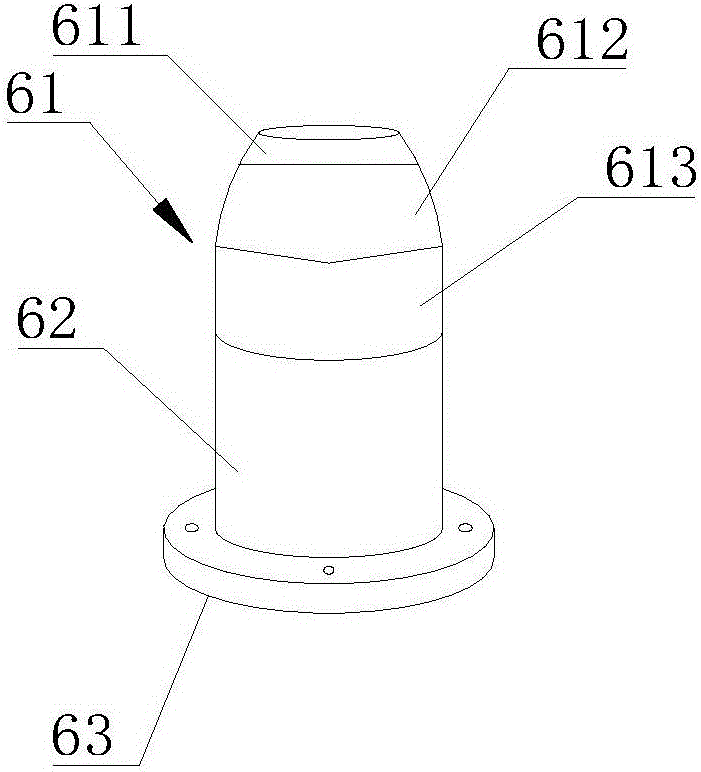

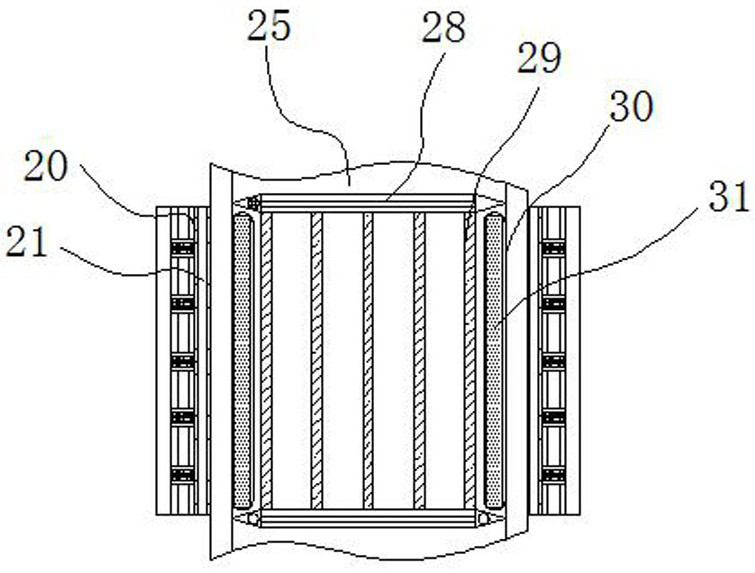

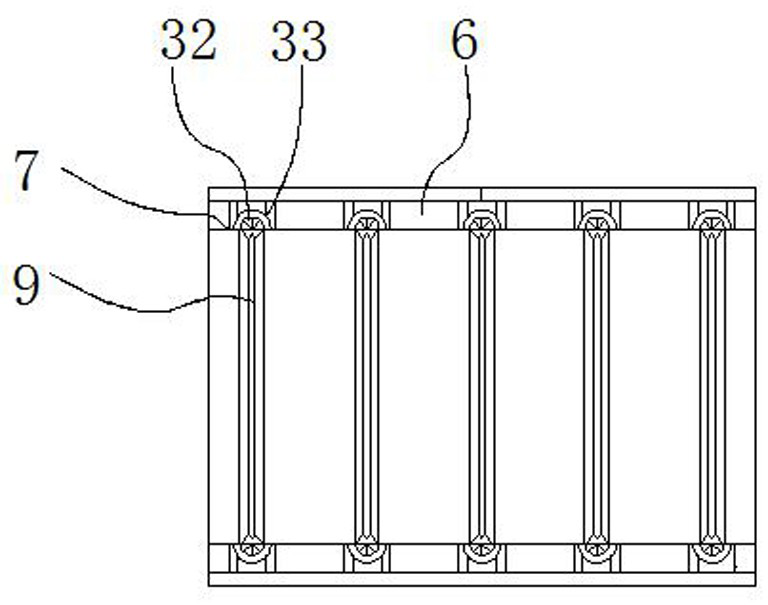

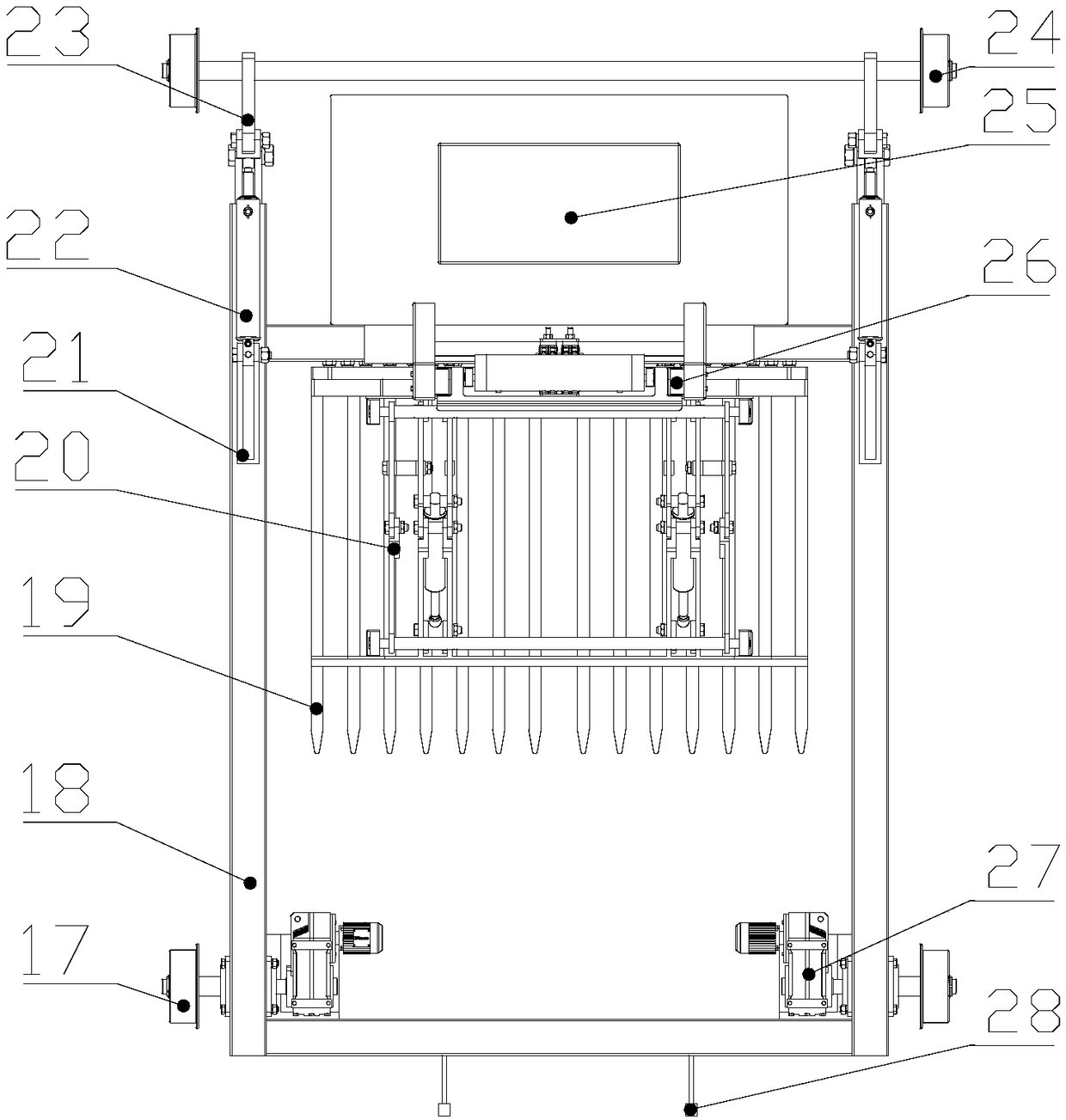

Motor rotor plate conveying and stacking equipment

InactiveCN106743689ARealize automatic stackingImprove stacking efficiencyStacking articlesEngineeringConveyor belt

The invention discloses motor rotor plate conveying and stacking equipment. The motor rotor plate conveying and stacking equipment is characterized in that a slideway inclined downwards is arranged at the tail end of a conveyor belt, and rotor plate stacking pillars and driving devices fixedly mounted on a rack are arranged at the tail end of the slideway; each rotor plate stacking pillar comprises a guiding body at the upper end and a cylindrical stacking body at the lower end, wherein the guiding body comprises an arc-shaped guide part arranged at the upper part, the lower end of the guide part is fixedly connected with a cylindrical cylinder part, the sectional diameter of the guide part is gradually increased from top to bottom, and the diameter of the cylinder part is consistent with that of the corresponding stacking body; the stacking bodies are fixedly mounted on the rack, and a penetration hole is formed in the central part of each stacking body in the axial direction; power output shafts of the driving devices penetrate the penetration holes to be fixedly connected with the guiding bodies; and the external diameters of the stacking bodies adapt to the apertures of rotor shaft holes of motor rotor plates to be stacked. The motor rotor plate conveying and stacking equipment can realize automatic stacking of the motor rotor plates, and the production efficiency is improved.

Owner:荣成恒鑫动力科技股份有限公司

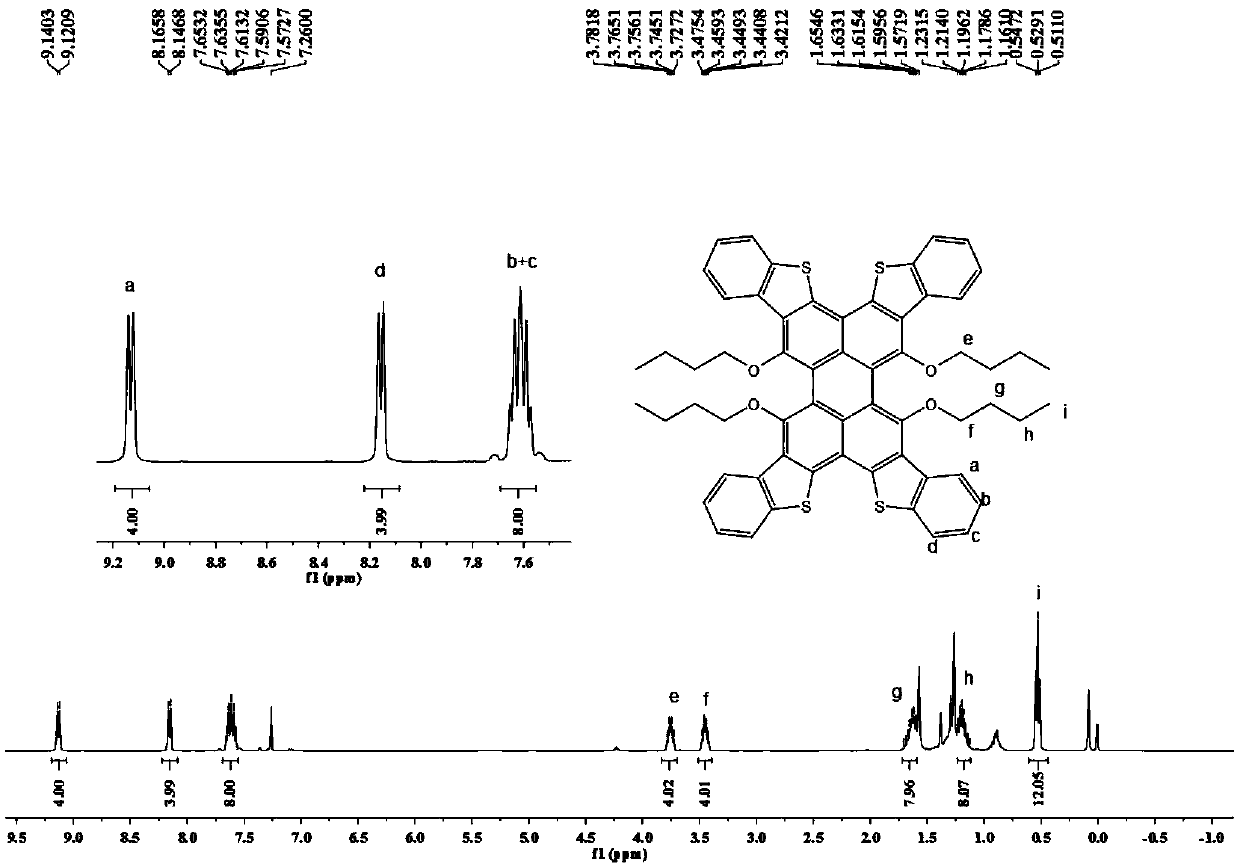

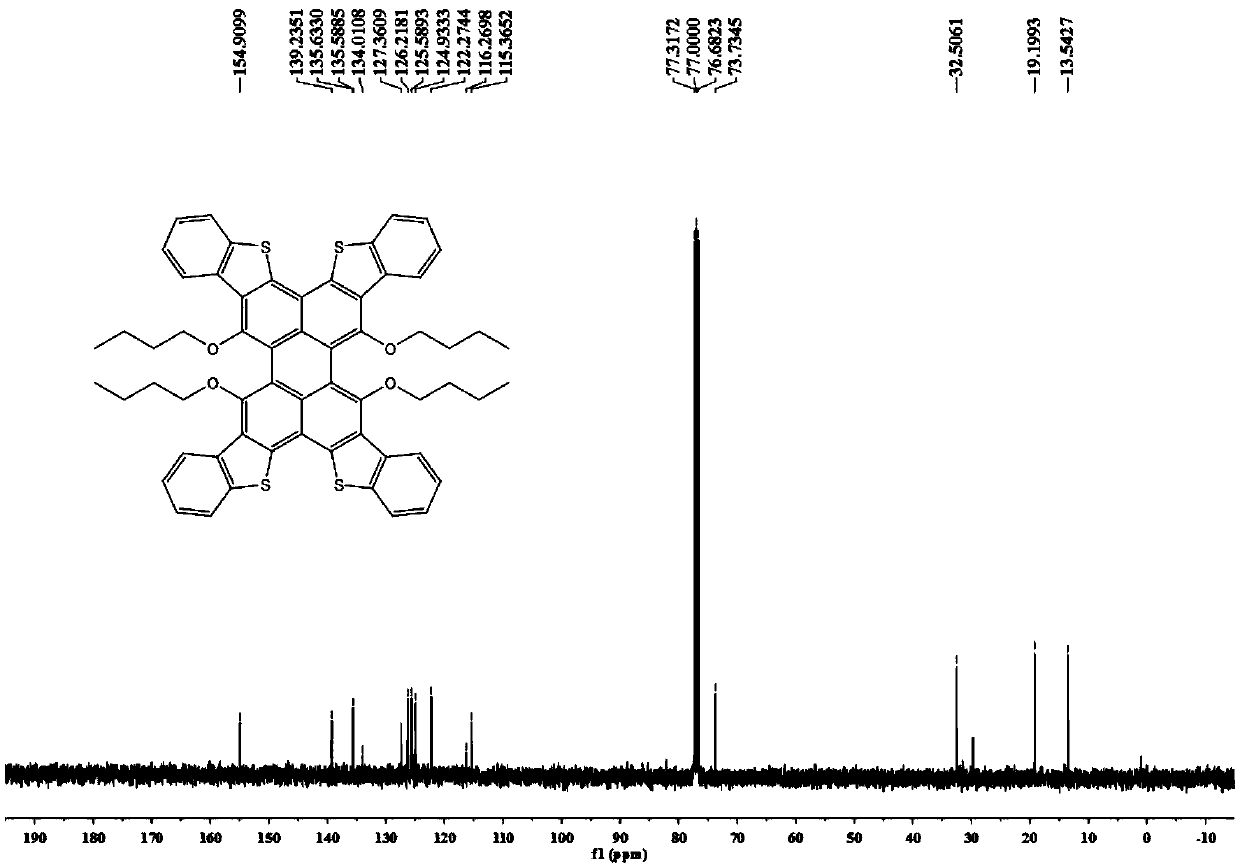

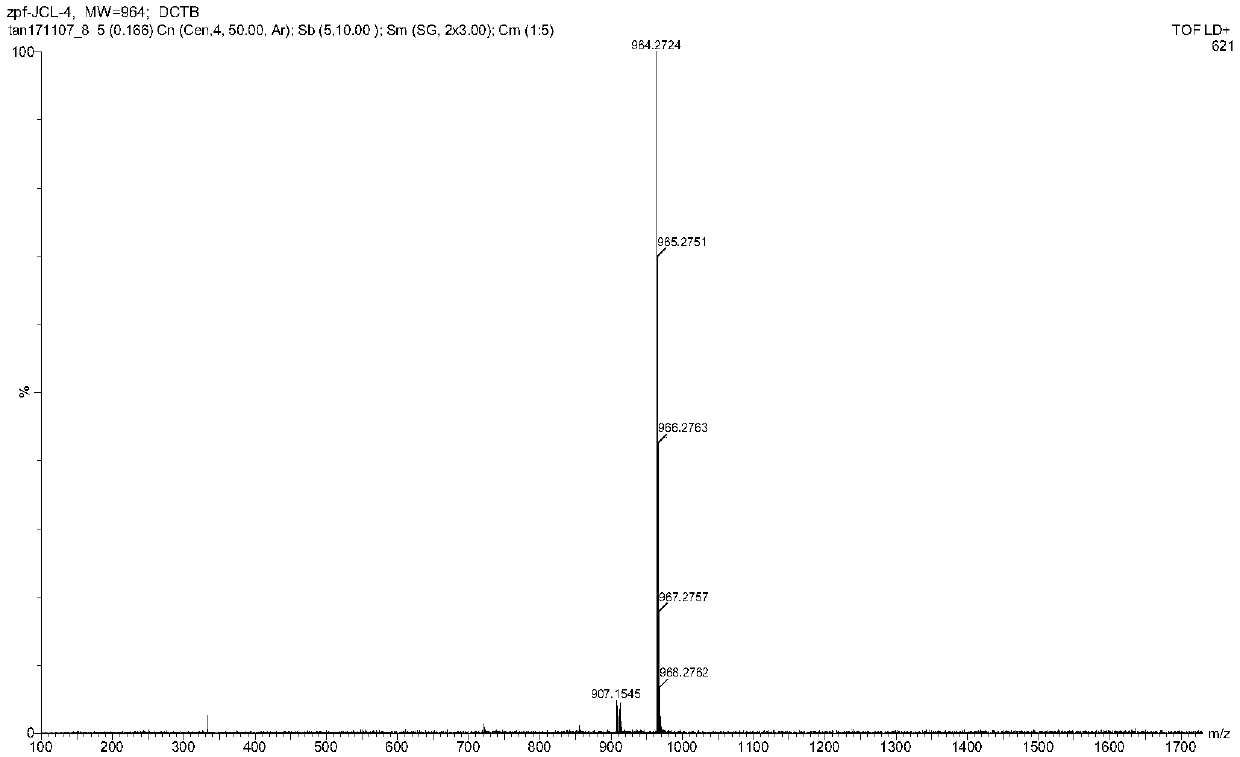

Dihelicene functional molecular material of X-type heterocyclic perylene aromatic hydrocarbon, as well as preparation and application thereof

ActiveCN109593095ARealize integrated controlEasy to operateOrganic chemistryLuminescent compositionsFluorescenceConjugated system

The invention belongs to the field of photoelectric materials, and particularly discloses a dihelicene functional molecular material of X-type heterocyclic perylene aromatic hydrocarbon, as well as apreparation method and application method thereof. According to the preparation method, perylene and a conjugated system are condensed in a three-dimensional space, the dihelicene functional molecularmaterial of X-type heterocyclic perylene aromatic hydrocarbon is constructed by a heterocycle mode, the pi electron conjugated structure and physical property of a conjugated molecule are regulated,so that the dihelicene functional molecular material is a multifunctional integrated organic molecular material with solid fluorescence, charge transfer, chiral light absorption and chiral circularlypolarized luminescence. The dihelicene functional molecular material can be applied to electronic devices, chiral optical elements and the like for multifunctional materials.

Owner:HUNAN UNIV

Automatic box stacking system of turnover boxes

InactiveCN110077858ASave manpower and costHigh degree of automationConveyorsStacking articlesElectrical controlSpace elevator

The invention discloses an automatic box stacking system of turnover boxes. The automatic box stacking system involves a stepping conveyor, a reciprocating type elevator, a roller type conveyor, and an electrical control system; a plurality of the turnover boxes to be stacked are arranged on the stepping conveyor at intervals along the starting end to the tail end direction of the stepping conveyor; the reciprocating type elevator is provided with a material receiving mechanism and a cargo carrying table, the material receiving mechanism is in butt joint with the tail end of the stepping conveyor, the cargo carrying table is arranged on the reciprocating type elevator in an up-and-down lifting mode and is positioned right below the material receiving mechanism; the starting end of the roller type conveyor is in butt joint with the cargo carrying table; and the electrical control system is electrically connected with the above-mentioned mechanisms. According to the automatic box stacking system, the problem that the turnover boxes are randomly stacked is solved, the turnover boxes can be effectively stored through the system, the unnecessary labor and cost are saved, further the automation degree of the whole system is improved, and the method has an obvious effect on improving the operation efficiency, saving resources and the like.

Owner:YUNNAN UNIVERSITY OF FINANCE AND ECONOMICS

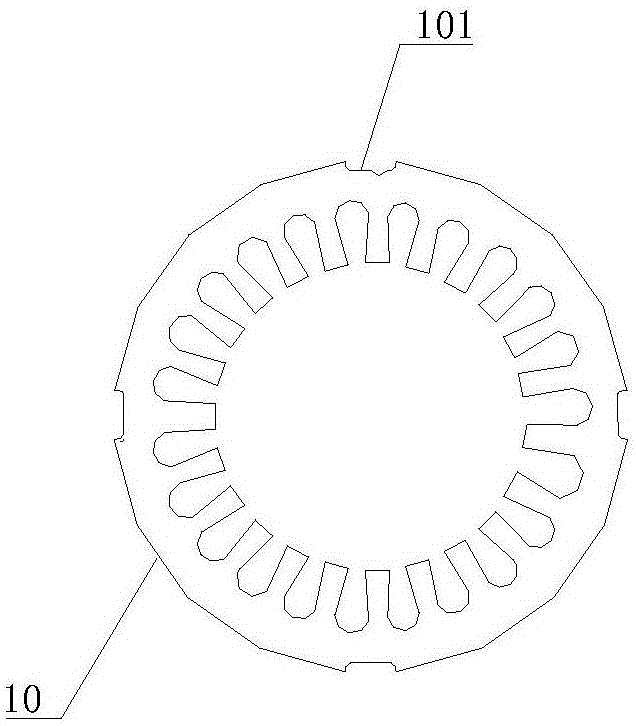

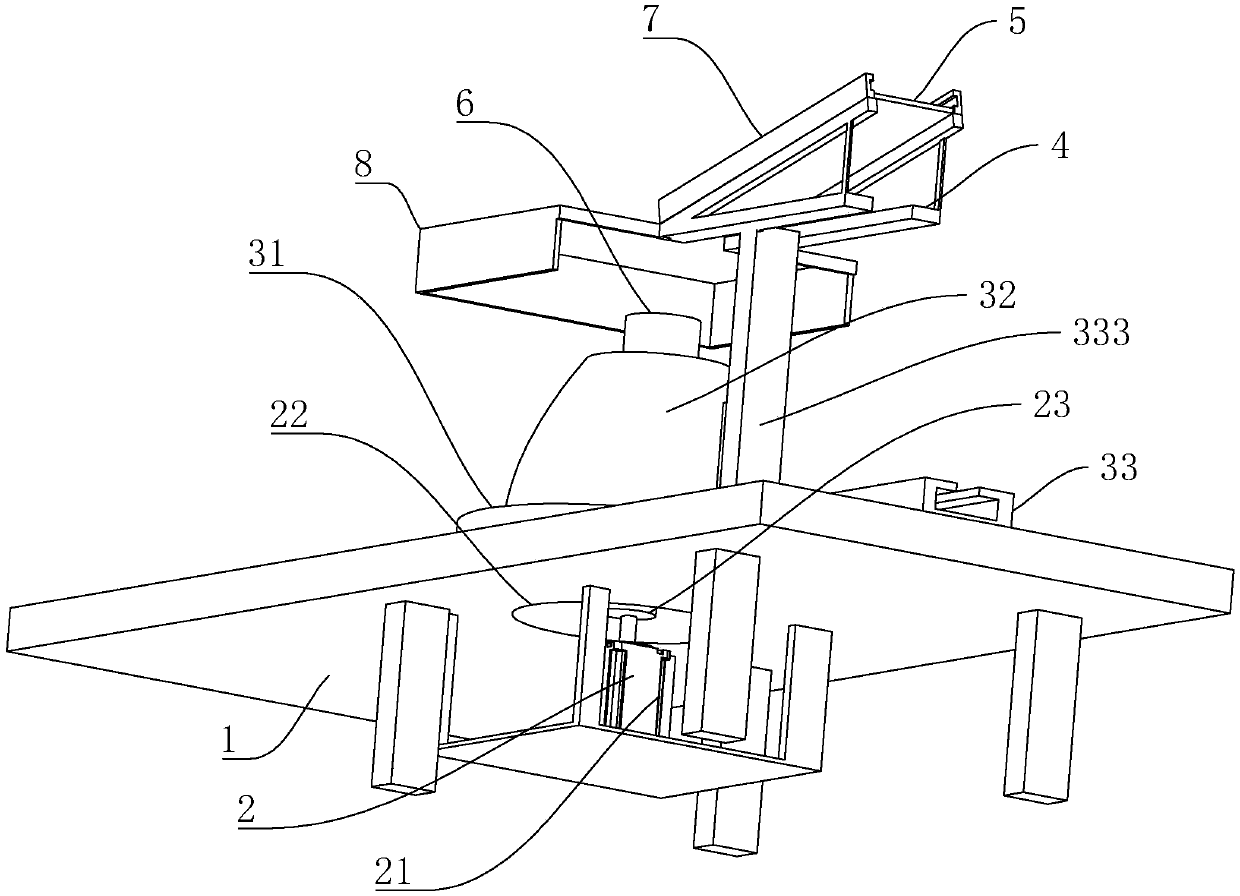

Stator sheet collecting device

PendingCN109639072AEffective placementEffective stackingManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention discloses a stator sheet collecting device, so as to provide a collecting device for stacking stators effectively. In the technical scheme, the stator sheet collecting device comprises abase; a rotating device is arranged on the base; a placing device is also arranged on the rotating device; the placing device comprises a placing disc located on the rotating device, a rotating roller located on the placing disc and connected with the rotating device and a limiting device located at one side of the placing disc; and the limiting device comprises a sliding groove located at one side of the placing disc, a sliding block located in the sliding groove, a supporting rod located at one end, close to the placing disc, of the sliding block, a limiting block located at one side, closeto the placing disc, of the supporting rod and a limiting screw rod located on the sliding block and passing through the sliding block to the bottom part of the sliding groove.

Owner:无锡新瑞驰科技有限公司

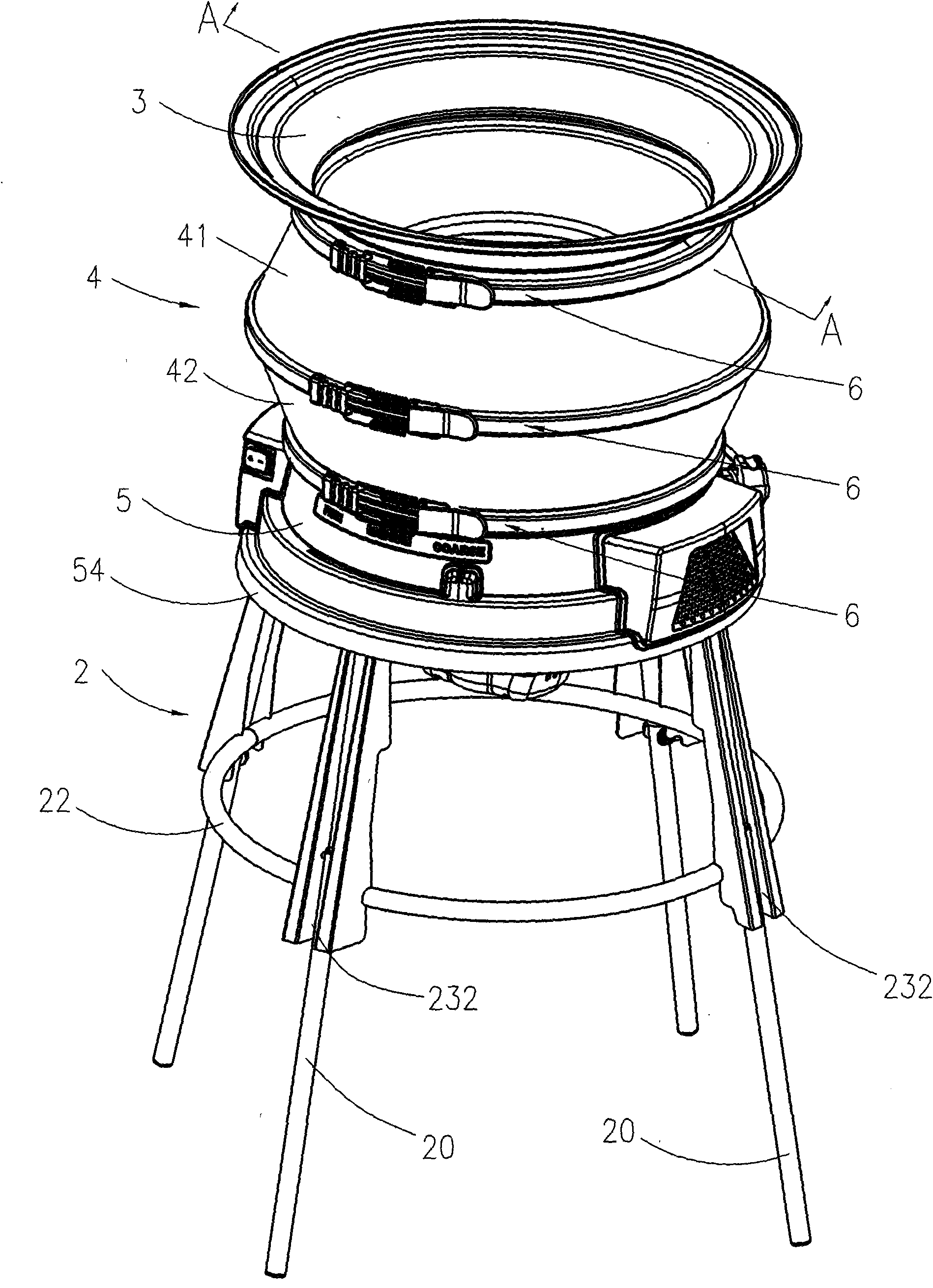

Gardening grinder

ActiveCN101992144AReduce the space required for storageEffective stackingGrain treatmentsMechanical engineeringPulverizer

The invention relates to a gardening grinder comprising a main body (5a), a motor (10) arranged in the main body (5a), a cutting mechanism (11) rotating around a rotary central axis (Z2) under the drive of the motor, and a material receiving container (4a) capable of being detachably assembled on the main body (5a) along the direction of the rotary central axis, wherein the material receiving container is provided with an opening (31a) for receiving grinded materials; the main body is provided with a grinded material discharge mouth arranged below the cutting mechanism; and the material receiving container (4a) is provided with a containing space (45a) for storing the main body (5a). All the components of the gardening grinder can be effectively piled together so that the packaging size and the storage space can be reduced to the maximum extent and the production cost is lowered.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

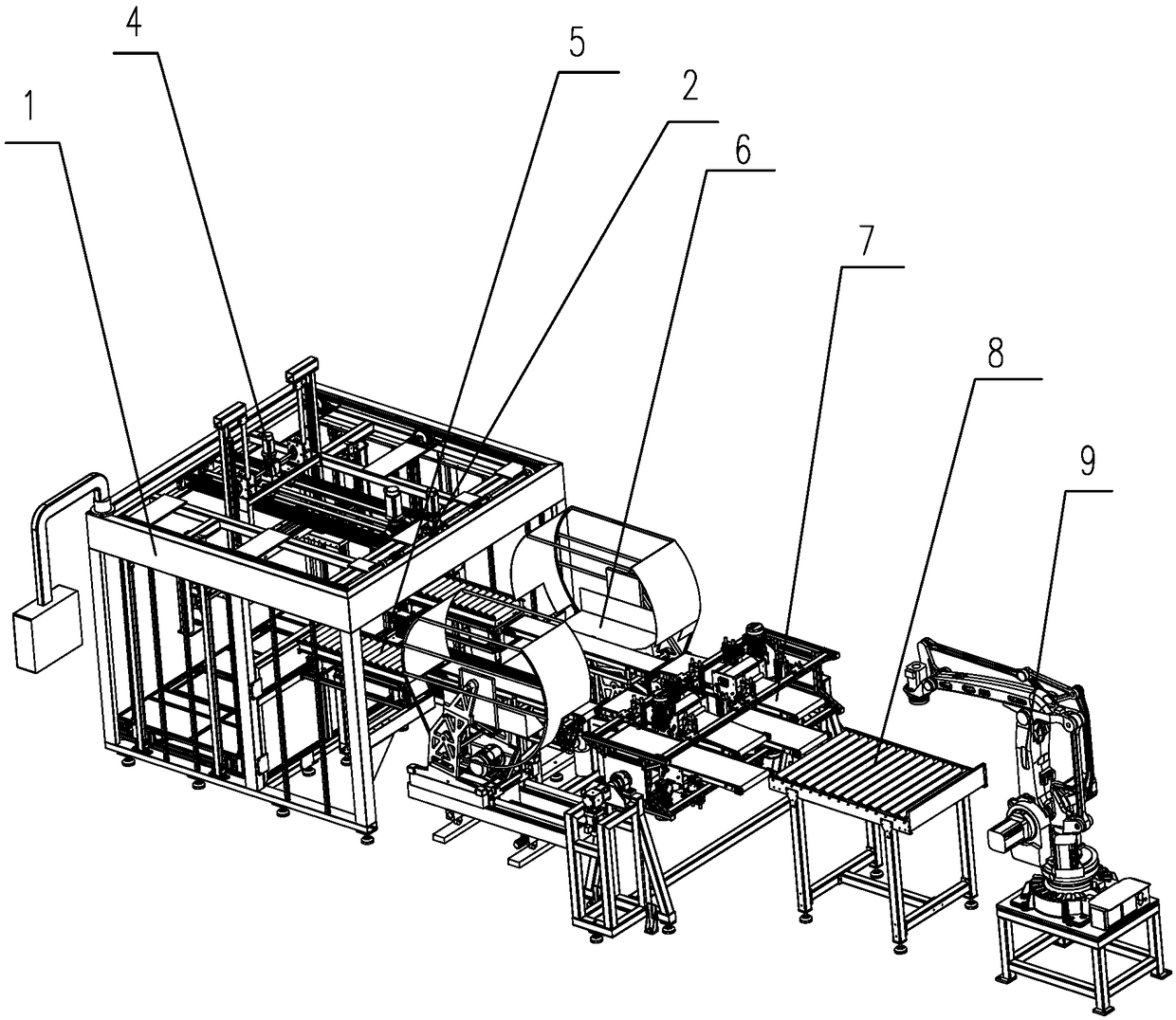

Paperboard counting, bundling and turning device

PendingCN108820378AGuaranteed stabilityGood synchronizationPackaging automatic controlStacking articlesTurning framesPaperboard

The invention discloses a paperboard counting, bundling and turning device. The paperboard counting, bundling and turning device comprises a support, a counting mechanism, a pushing mechanism, a bundling mechanism, a turning mechanism and a lifting mechanism. The lifting mechanism comprises a base plate and a first driving part. The base plate is slidably arranged on the support. The pushing mechanism comprises a discharging frame. The bundling mechanism comprises a collection frame. A collection platform is arranged on the collection frame and is flush with the discharging frame. The turningmechanism comprises a turning frame and a conveying frame. Turning bases are slidably arranged on the turning frame and are located on the two sides of the conveying frame. A turning clamping piece isrotatably arranged on each turning base. The base plate, the discharging frame, the collection frame and the conveying frame are sequentially arranged. The counting mechanism comprises a pressing assembly and a transfer assembly. The pressing assembly comprises a pressing plate and a mounting base. The mounting base is arranged on the support. The pressing plate is slidably arranged on the mounting base. A positioning table is formed on the mounting base and is located below the pressing plate. A counter is arranged on the positioning table. By adoption of the paperboard counting, bundling and turning device, paperboards can be accurately counted, bundled and finally turned to be stacked.

Owner:ZHEJIANG DONGJIN TECH CO LTD

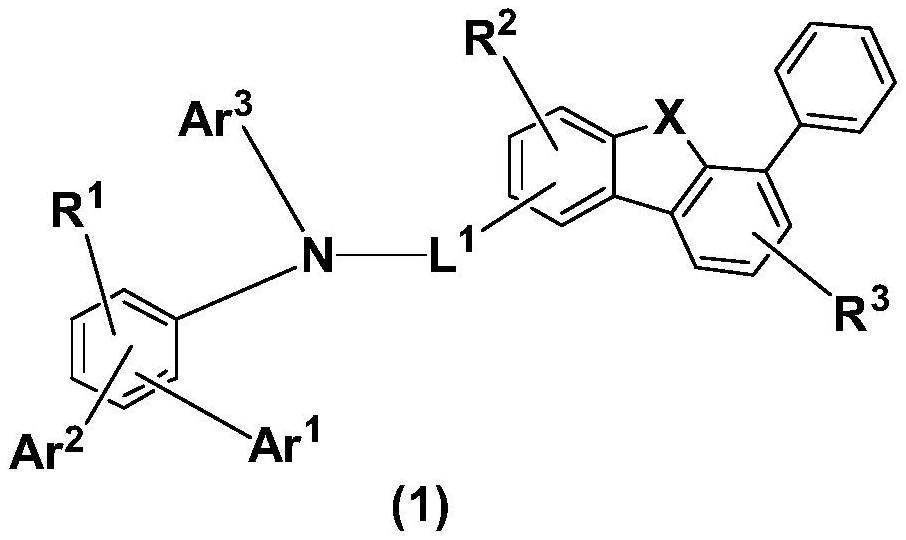

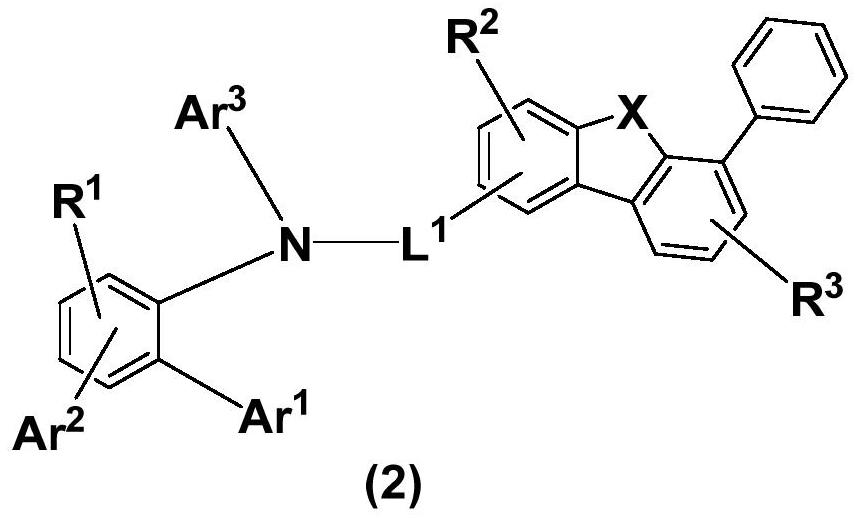

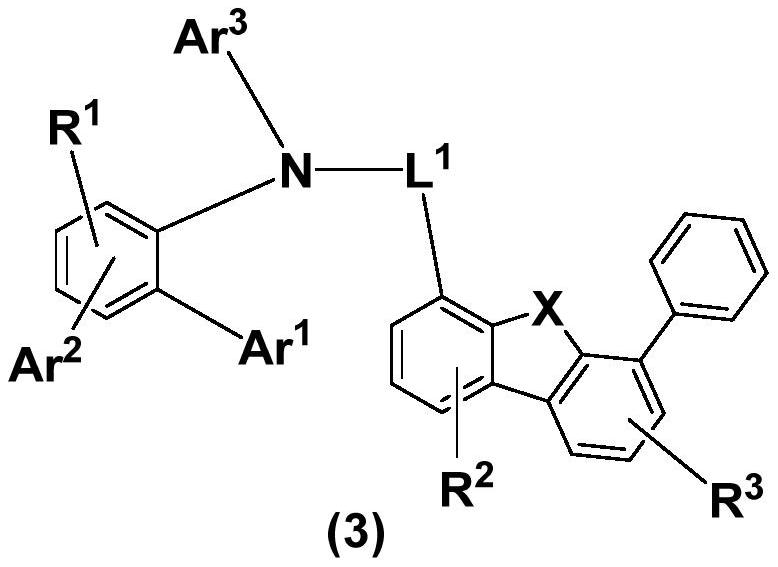

Compound, application thereof and organic light-emitting device comprising compound

PendingCN112125880AImprove thermal stabilityExtend your lifeOrganic chemistrySolid-state devicesOrganic electroluminescenceElectron blocking layer

The invention relates to a compound, application thereof and an organic light-emitting device comprising the compound. The compound has a structure as shown in the following formula (1), wherein X isselected from O, S or Se; L1 is selected from substituted or unsubstituted arylene groups of C6-C30; Ar1-Ar3 are each independently selected from one of a substituted or unsubstituted C6-C30 aryl group and a substituted or unsubstituted C3-C30 heteroaryl group, and R1 to R3 each independently represent a monosubstituted group to a maximum permissible substituent group, and each is independently selected from one of hydrogen, C1-C30 alkyl, C1-C30 alkoxy, halogen, cyano, nitro, hydroxyl, silyl, amino, substituted or unsubstituted C6-C30 arylamino, substituted or unsubstituted C3-C30 heteroarylamino, substituted or unsubstituted C6-C30 aryl and substituted or unsubstituted C3-C30 heteroaryl. When the compound provided by the invention is used as a hole transport layer material or an electronblocking layer material in an OLED device, excellent device performance and stability are shown. The invention also discloses an organic light-emitting device adopting the compound with the general formula.

Owner:BEIJING ETERNAL MATERIAL TECH

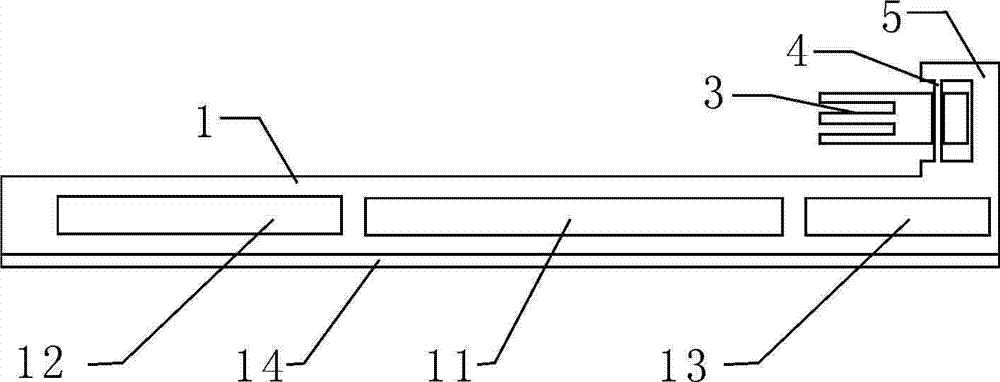

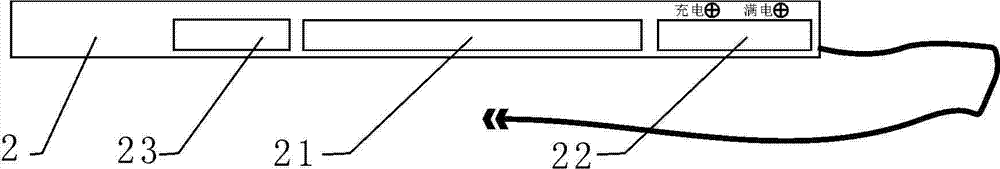

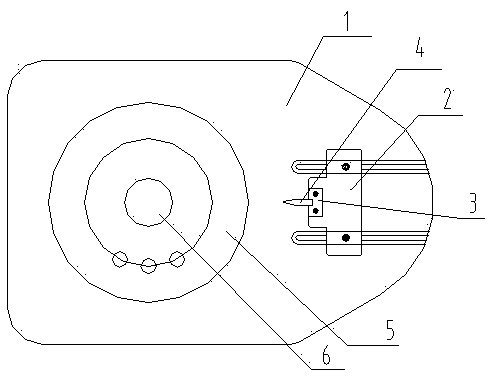

Wireless charger for mobile phone

InactiveCN104505898AChange wired charging modeRealize wireless charging functionCircuit monitoring/indicationDifferent batteries chargingCharge controlMobile phone

The invention provides a wireless charger for a mobile phone. The charger has the function of changing the existing wired charging mode of the mobile phone to enable the wired charging mobile phone to be charged by a wireless manner. According to the technical scheme, the charger is that a plug is plugged into a charging socket of the mobile phone, and then the mobile phone drives the plug to downwards rotate until the rear surface of the mobile phone is integrally clung to the charger. The charger is characterized in that two sliding shafts are vertically arranged in a rear seat of the charger; the plug can slide up and down about the sliding shafts; the sliding shafts, a secondary coil, a generation rotating wheel and a solar panel are connected with a charging control device; when in a static state, the mobile phone is charged through the solar panel; when in a moving state, the mobile phone is charged under the swinging effect of the rotating wheel; the mobile phone is charged by the wireless manner through a recharge stand at night; the three charging modes are combined to effectively prolong the service time and service life of a battery of the mobile phone; in addition, the charger and the recharge stand are effectively overlapped through a turnplate, so as to improve the wireless charging efficiency.

Owner:NANAN GAOJIE ELECTRONICS TECH

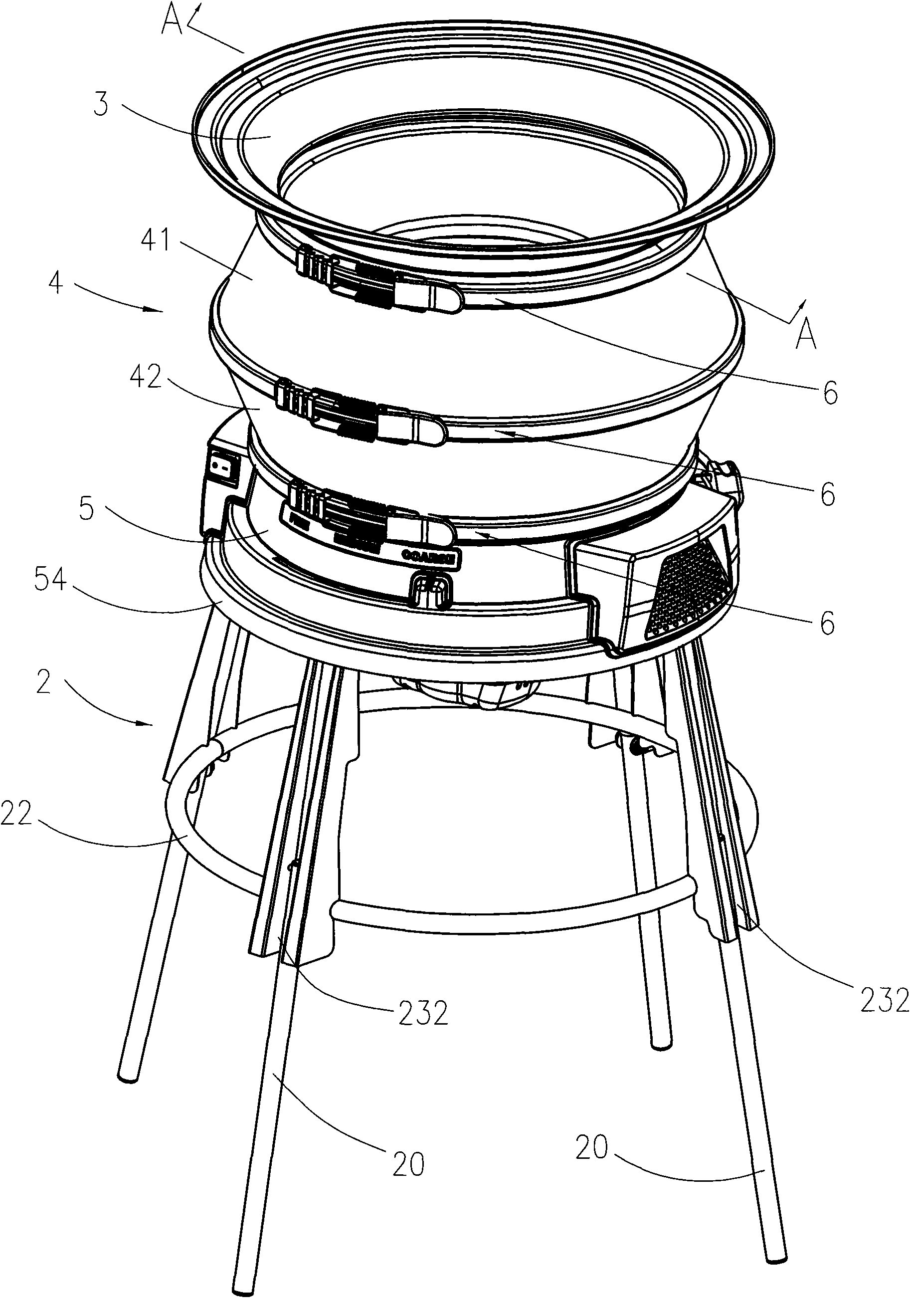

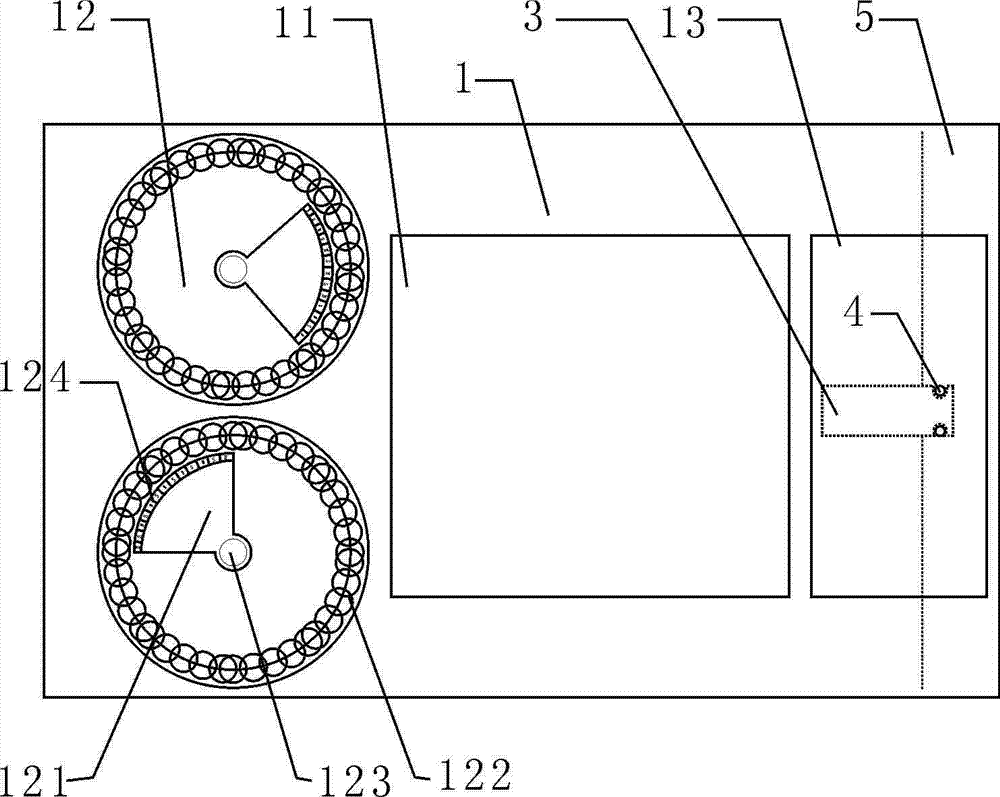

Gardening crusher

ActiveCN101992145AEffective stackingReduce the space required for storageGrain treatmentsEngineeringCrusher

The invention discloses a gardening crusher, comprising a main body (5a) and a material collecting container (4a). The main body (5a) is internally provided with a motor (10) and a cutting mechanism (11) which rotates around a central axis (Z2) under the drive of the motor, the material collecting container (4a) is detachably and adaptively connected above the main body (5a) along the rotating central axis and comprises a tapered material guide hopper (3a), the material guide hopper is provided with an opening for collecting crushed materials, the main body is also provided with a crushed material discharge port located below the cutting mechanism, the material collecting container is further provided with at least one of the tapered charging tanks (41 and 42) detachably and adaptively connected with the material guide hopper, and the material guide hopper can be effectively piled up with the main body after the material guide hopper is dismounted from the charging tanks. The invention can maximally decrease the packing size and storage space and reduce production cost.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

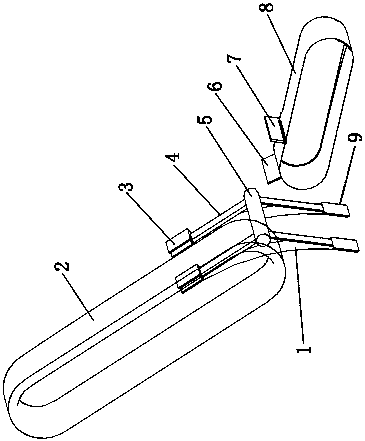

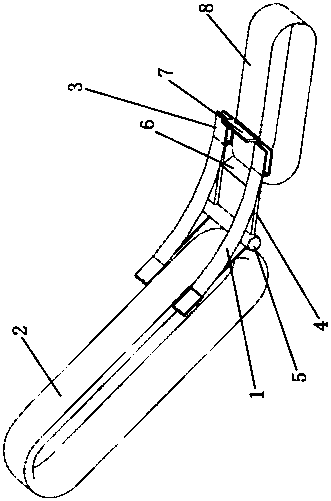

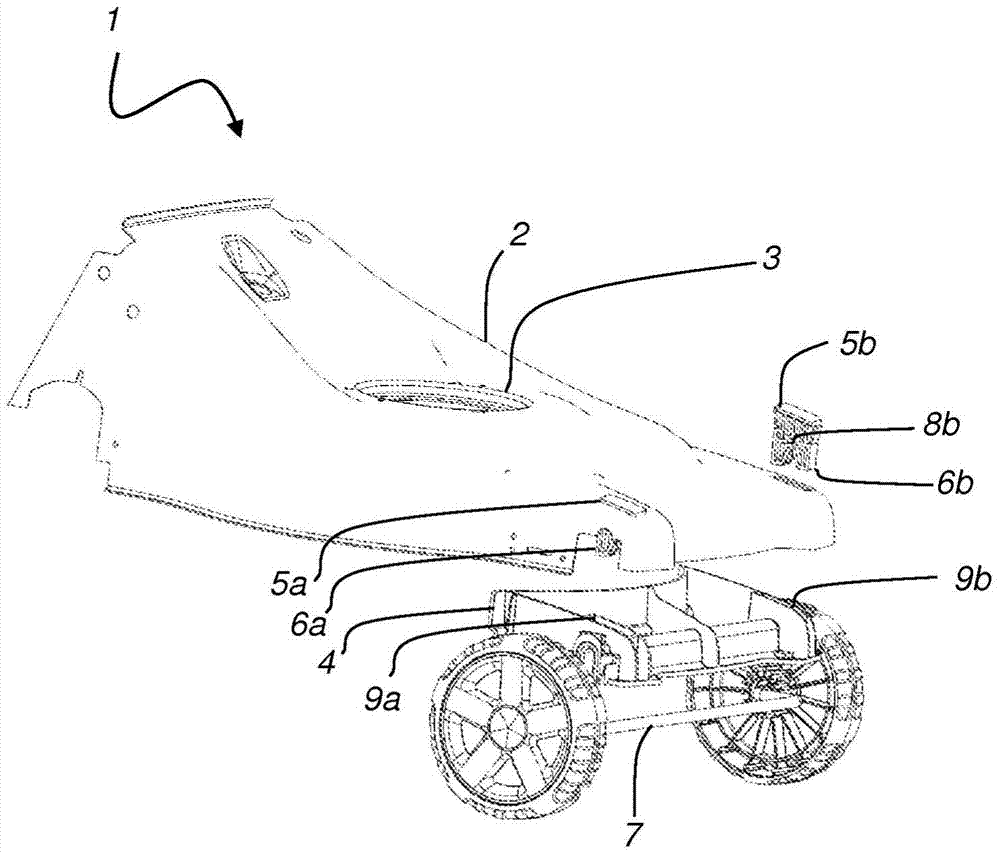

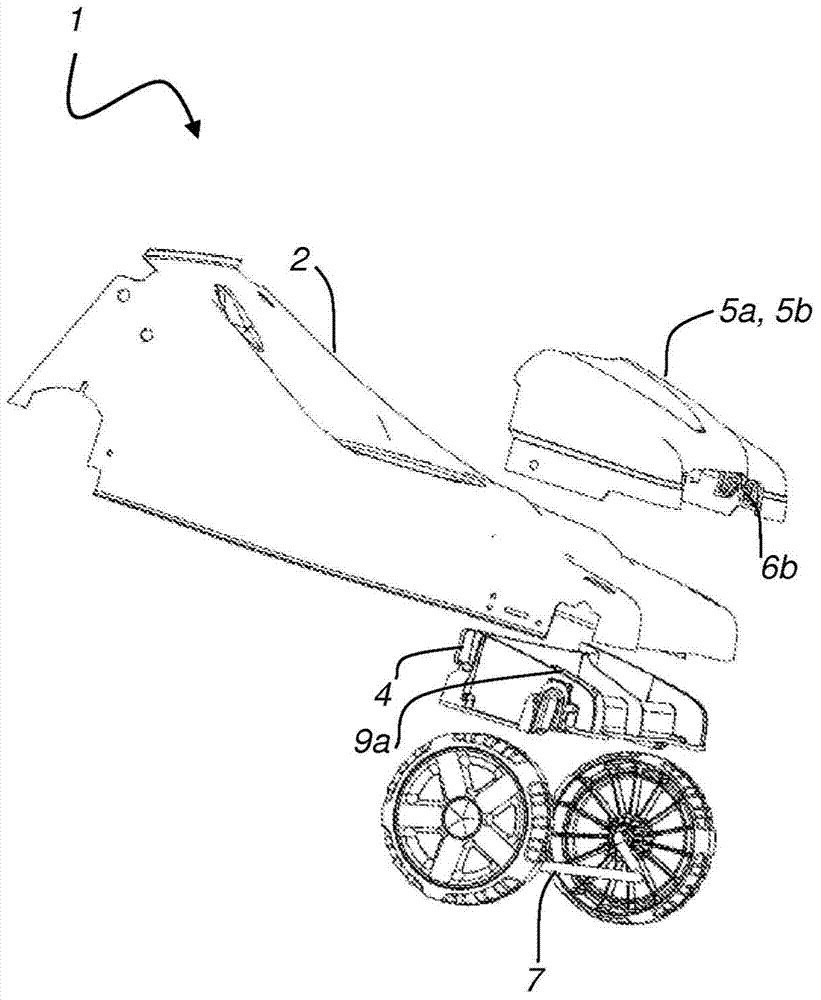

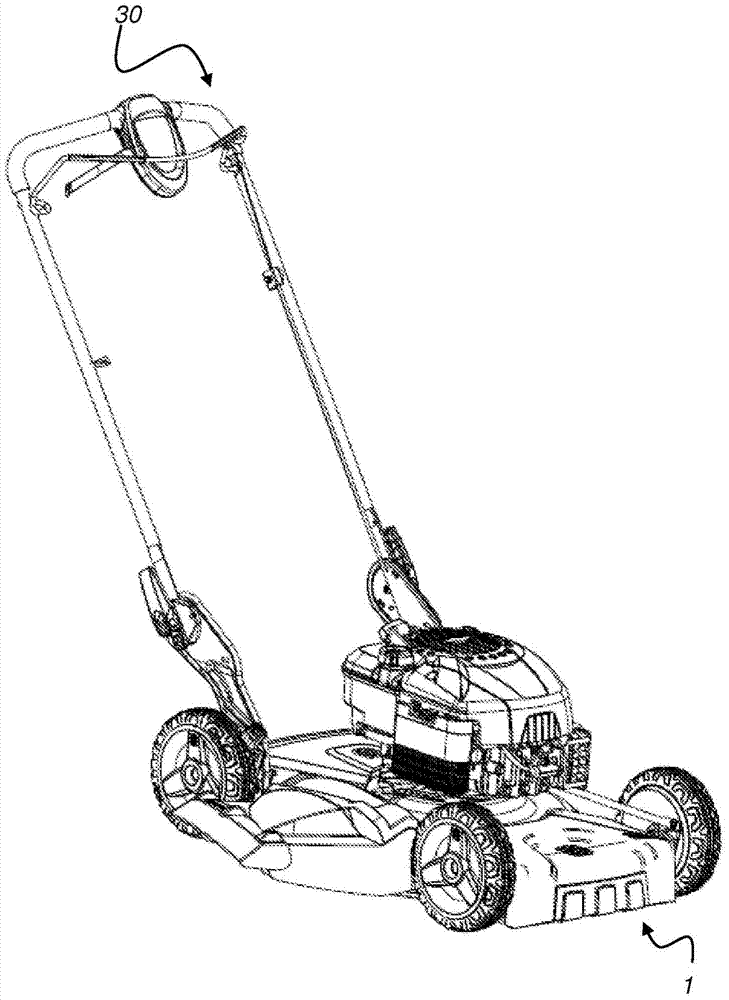

Front baffle assembly for a lawn mower

A front baffle assembly (1) for a lawn mower (30) is provided. The front baffle assembly (1) is adapted for attachment to a lawn mower chassis (2), and comprises a stopper (5a, 5b) configured to abut against an upper side of the chassis (2) and a front baffle (4) configured to abut against a lower side of the chassis (2). The front baffle assembly (1) comprises a catch element (6a, 6b) which protrudes downwardly from the stopper (5a, 5b) and is arranged to extend through the chassis (2) and beyond a lower side of the front baffle (4). The front baffle assembly (1) comprises a front axle (7) arranged to be received between the catch element (6a, 6b) and the lower side of the front baffle (4) to clamp the chassis (2) between the stopper (5a, 5b) and the front baffle (4).

Owner:HUSQVARNA AB

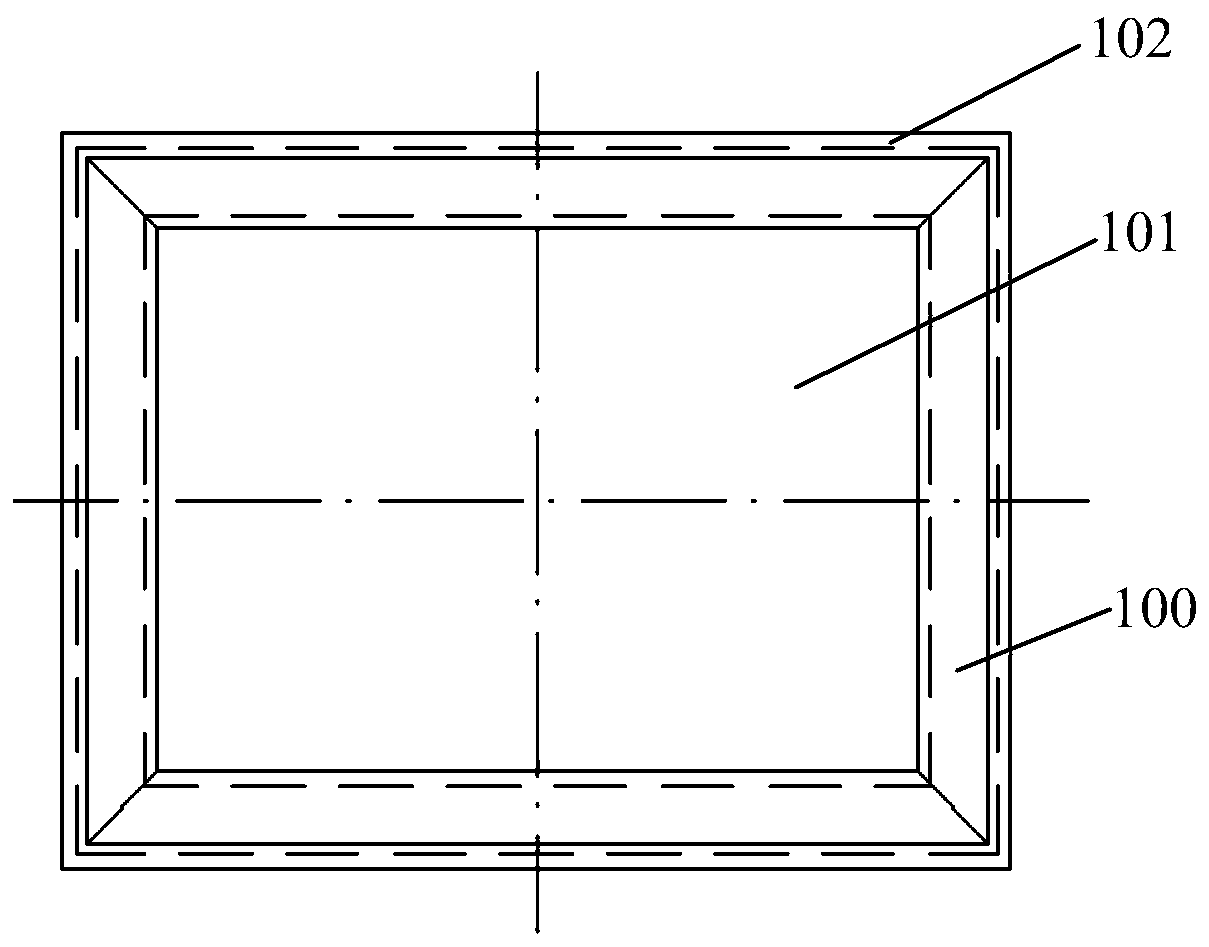

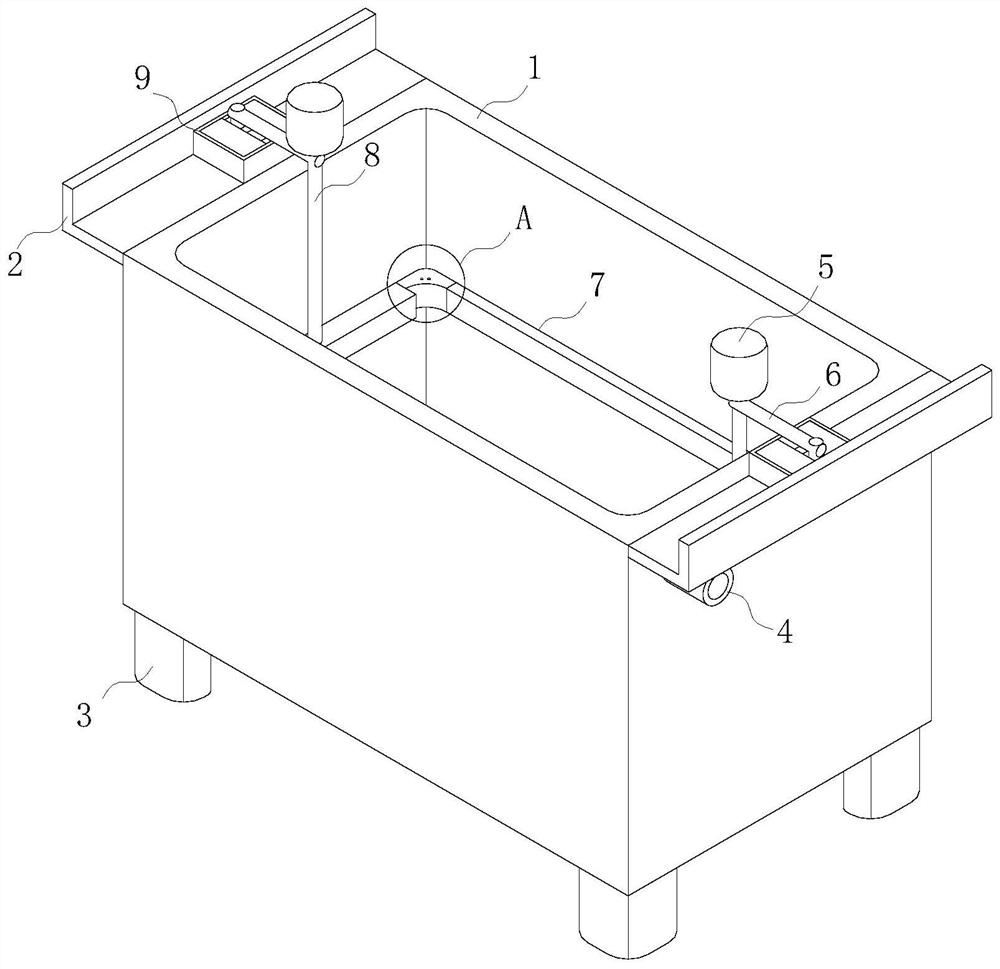

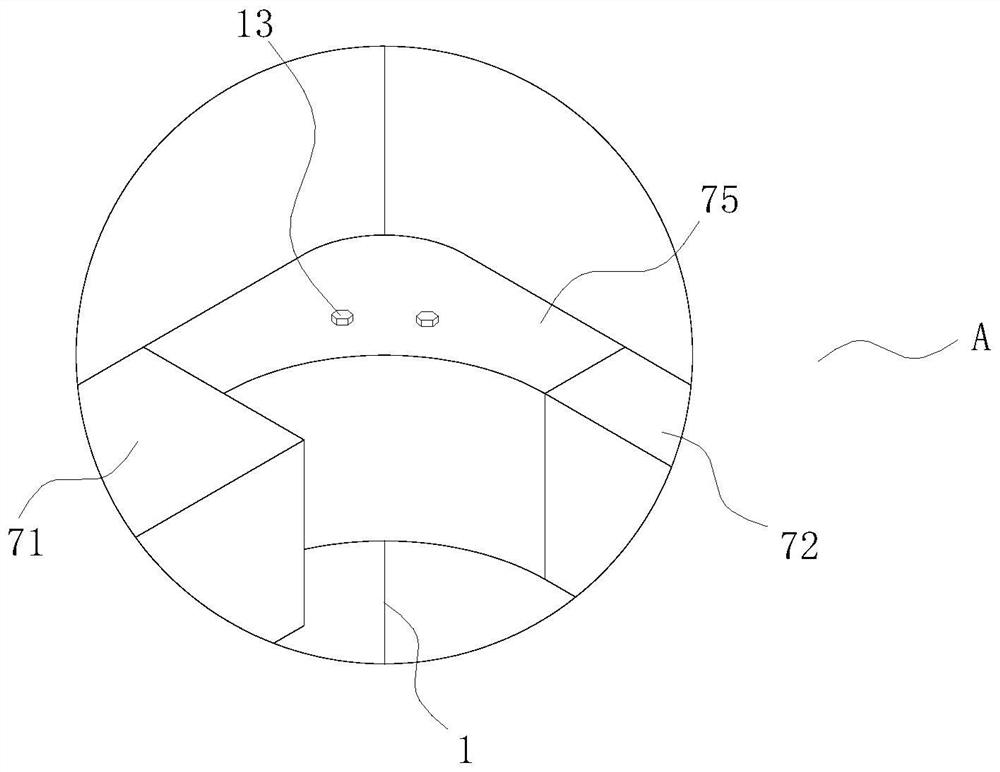

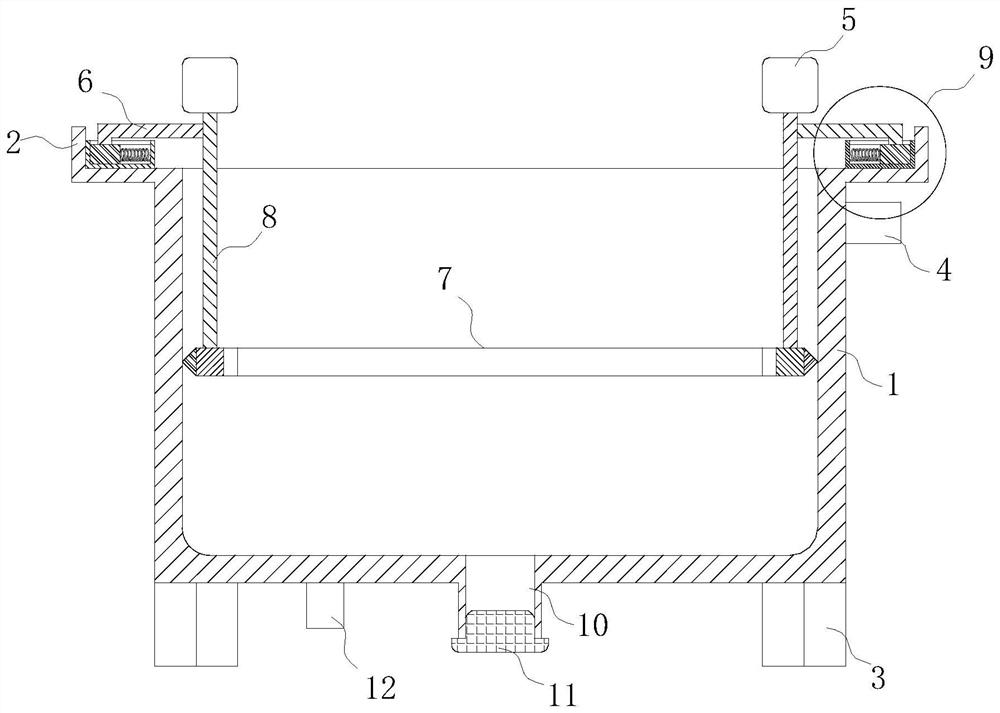

Electrolytic bath for electroplating

The invention discloses an electrolytic bath for electroplating. The electrolytic bath for electroplating comprises a bath body, foot supports are fixedly connected to the positions, close to the edges of the four corners, of the outer surface of the lower end of the bath body, fixing plates are symmetrically and fixedly connected to the positions, close to the edges of the upper end, of the outer surfaces of the left side and the right side of the bath body, protection mechanisms are fixedly connected to the middle positions of the upper surfaces of the two fixing plates, supporting rods are fixedly connected to the middle positions of the upper ends of the protection mechanisms, telescopic rods are fixedly connected to one ends of the supporting rods, a hydraulic pump is fixedly installed at the upper ends of the telescopic rods, and an inner surface cleaning mechanism is fixedly connected to the lower end of the telescopic rod. According to the electrolytic bath, impurities attached to the side faces of all the inner surfaces of the electrolytic bath can be cleared by arranging the inner surface cleaning mechanism, and thus the situation that the impurities are continuously accumulated on other side faces to affect the electroplating effect is avoided; and the impurities at the corners are cleared by arranging a corner cleaning mechanism, and thus the impurities at the corners can be effectively cleared through the corner cleaning mechanism.

Owner:仇泽金

Efficient discharging device in production process of bamboo-wood composite floors and using method thereof

PendingCN113734688AEffective stackingImprove cutting efficiencyConveyorsDispersed particle filtrationPulp and paper industryChain link

The invention discloses an efficient discharging device in the production process of bamboo-wood composite floors, and belongs to the technical field of bamboo-wood composite floor production. The efficient discharging device comprises a rack, a mounting frame, a conveyor and two material blocking plates; the mounting frame is mounted on the rack, and the conveyor is arranged on the rack and used for discharging and conveying the bamboo-wood composite floors produced by bamboo-wood composite floor production equipment; and the two material blocking plates are mounted in the mounting frame through first adjusters arranged on the mounting frame and used for limiting and blocking the bamboo-wood composite floors conveyed by the conveyor, and deviation in the conveying process is prevented. The conveyor is arranged to be matched with a material receiver for use, conveying rollers, rotating shafts, chain wheels and chains are matched to achieve conveying of the bamboo-wood composite floors, material receiving plates, springs and sliding rods are matched with the gravity of the bamboo-wood composite floors to achieve movement of the material receiving plates, then effective stacking use of the bamboo-wood composite floors is achieved, the structure is simple, use is convenient, and the discharging efficiency of the bamboo-wood composite floors is effectively improved.

Owner:ANHUI ZHI CHANG BAMBOO TECH CO LTD

Paperboard counting and binding turnover device

PendingCN109094899AGuaranteed stabilityGood synchronizationPackaging automatic controlStacking articlesPaperboardPointing device

The invention discloses a paperboard counting and binding turnover device. The device comprises a support, a counting mechanism, a propelling mechanism, a binding mechanism, a turnover mechanism and alifting mechanism, the lifting mechanism comprises a bottom plate and a first driving part, the bottom plate is arranged on a bracket in a sliding manner, the propelling mechanism comprises a discharging frame, the binding mechanism comprises a material receiving frame, a material receiving platform is arranged on the material receiving frame, the material receiving platform is flush with the discharging frame, the turnover mechanism comprises a turnover rack and a turnover seat, the turnover seat is rotationally arranged on the turnover rack, wherein the turnover seat is further provided with an auxiliary clamping assembly; the bottom plate, the discharging frame, the material receiving frame and the turnover seat are arranged in sequence, the counting mechanism comprises a compressing assembly and a transferring assembly, and the compressing assembly comprises a pressing plate, a mounting base and a second driving piece, the mounting base is arranged on the bracket, the pressing plate is arranged on the mounting base in a sliding mode, a positioning table is formed on the mounting base, the positioning table is arranged below the pressing plate, and a point device is arranged onthe positioning table. According to the paperboard counting and binding turnover device, accurate counting of the paper boards is achieved, binding is completed, and finally the paper boards are overturned and stacked.

Owner:ZHEJIANG DONGJIN TECH CO LTD

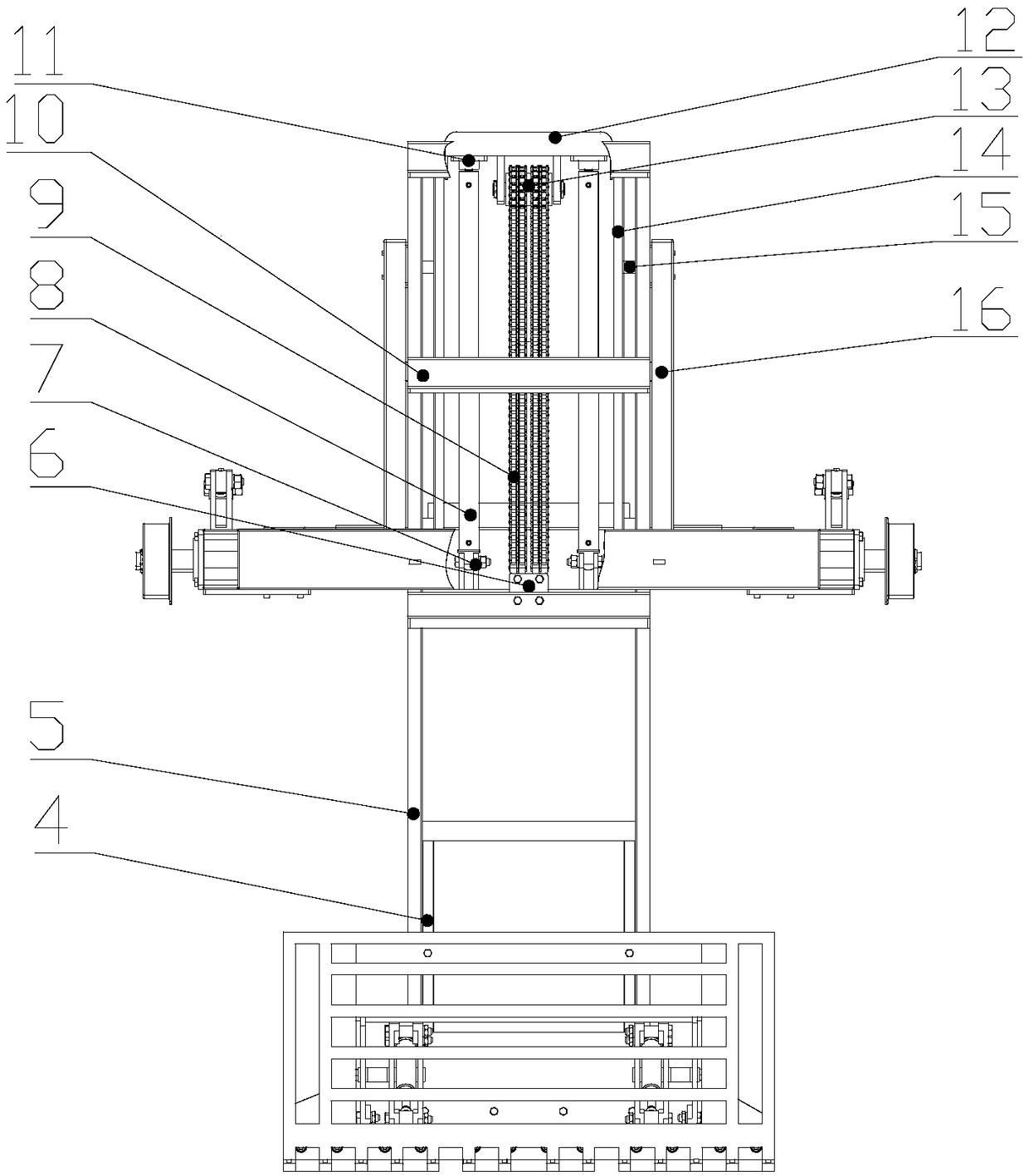

Intelligent adjusting device of stacker crane

InactiveCN107840155AIngenious structural designEffective stackingStacking articlesDe-stacking articlesMarine engineeringPalletizer

Disclosed is an intelligent adjusting device of a stacker crane. The intelligent adjusting device comprises a machine body (1). A setting module (2), a friction induction module (3), an adjusting module (4), a transmission module (5) and a management module (6) are arranged on the machine body (1). During running, the setting module (2) sets taking-up and storing places of goods, the friction induction module (3) induces whether friction generates between a gripper and the goods or not, the adjusting module (4) adjusts the shape and size of the gripper according to the different goods, and themanagement module (6) comprehensively processes various induced information; by arranging a rotating speed control module (7), speed adjusting can be conducted on operation of the stacker crane; by arranging a removing module (9), dirt generated due to operation can be instantly removed; and by arranging a hinting module (8), a hint is sent when gripper friction anomaly is detected or operation is completed.

Owner:XINCHANG YULIN STREET DAKANG MACHINERY FACTORY

Paper board binding and overturning device

PendingCN108820291AAutomate operationImprove adaptabilityStacking articlesDe-stacking articlesCardboardEngineering

The invention discloses a paper board binding and overturning device. The paper board binding and overturning device comprises a binding mechanism and an overturning mechanism; the binding mechanism comprises a material receiving rack and a first binding adjusting component which is used for adjusting the position of the material receiving rack in the width direction; a material receiving platformwhich is used for conveying a material from the binding mechanism to the overturning mechanism is arranged on the material receiving rack; a binder and a second binding adjusting mechanism which is used for adjusting the position of the binder in the length direction are arranged on the material receiving rack; the overturning mechanism comprises an overturning rack and an overturning base; the overturning base is rotatably arranged on the overturning rack; a first overturning driving component which is used for driving the overturning base to rotate is arranged on the overturning rack; an auxiliary clamping component which is used for clamping a paper board pile is further arranged on the overturning base; and the material receiving rack clings to the overturning base. The paper board binding and overturning device is simple in structure and favorable for realization; and besides, binding and overturning operations can be finished.

Owner:ZHEJIANG DONGJIN TECH CO LTD

A kind of beef fast cutting device

ActiveCN109676657BEasy to processImprove cleanupMetal working apparatusMeat shaping/cuttingEngineeringKnife blades

The invention discloses a rapid beef slitting device, and relates to the technical field of food processing. The device comprises a supporting mechanism and a conveying mechanism, a driving mechanismis arranged in the middle end of the top of the supporting mechanism, the conveying mechanism is arranged at the bottom of the supporting mechanism, the supporting mechanism is fixedly connected withthe driving mechanism through a screw, and the front face of the driving mechanism is provided with a hydraulic air cylinder. The device has the beneficial effects that according to the rapid beef slitting device, through slitting blades and a mounting sliding block, a worker refers to numerical value on a graduation ruler in advance and marks the needed slitting interval numerical value on the front face of the slitting mechanism through a corresponding marking tool, through the manual control sliding method, each slitting blade is sequentially drawn to be adjusted to the corresponding slitting interval segment point through the mounting sliding block, and through changing of the interval numerical value of each slitting blade in the sliding adjusting process, the device can convenientlyachieve cutting machining of beef needing different slitting intervals.

Owner:济南高投能源发展有限公司

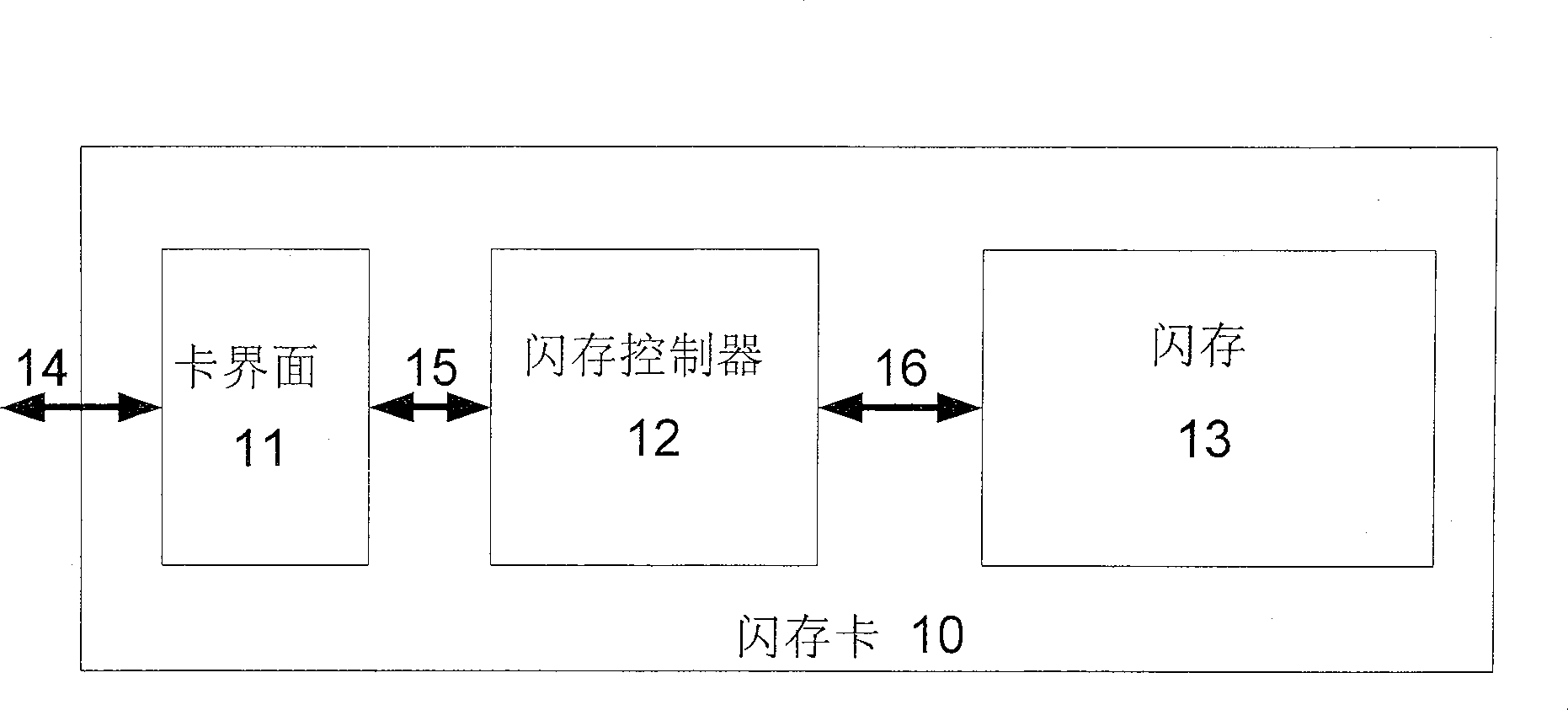

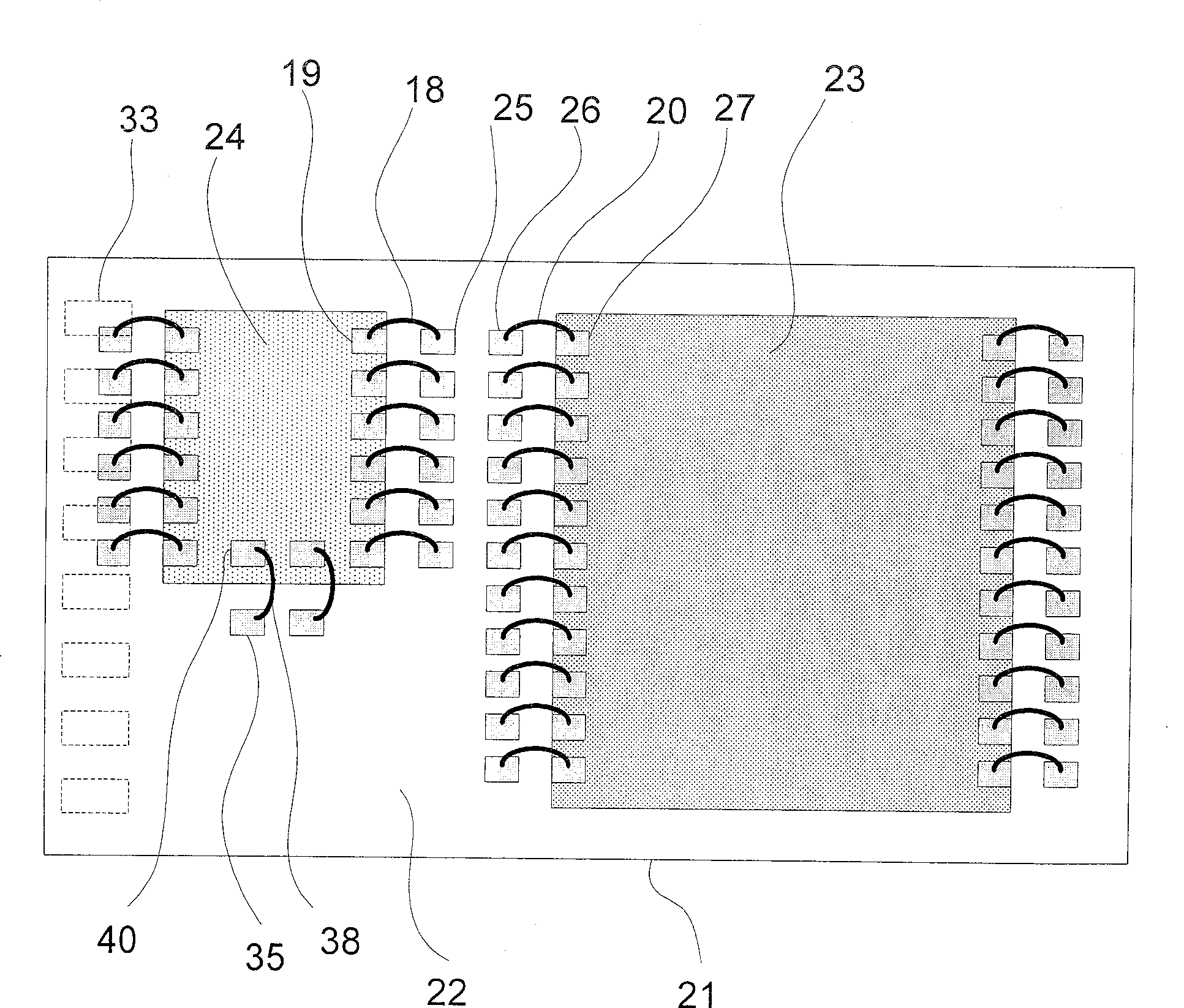

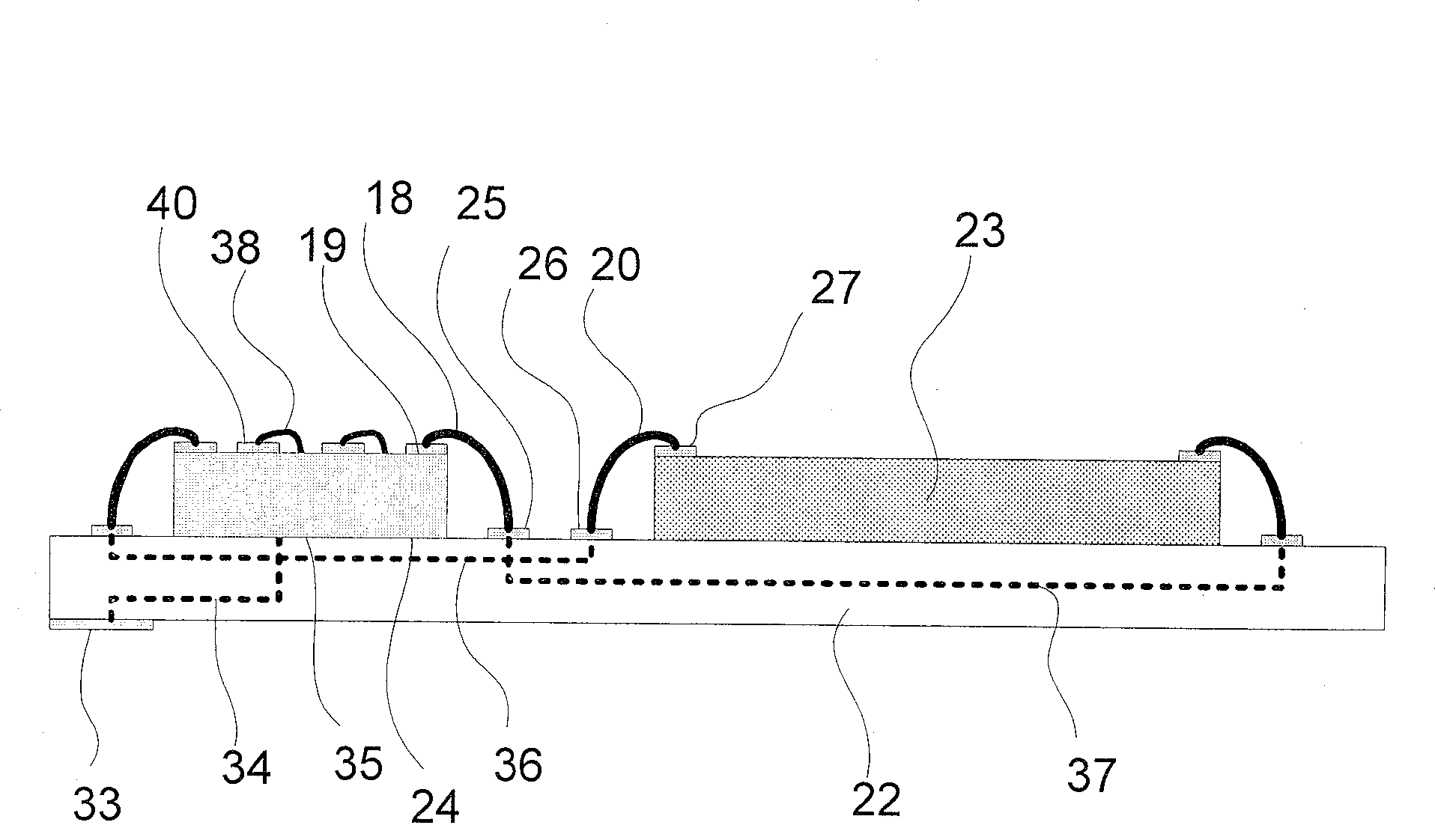

Flash memory card

ActiveCN100492406CHigh densityReduce the numberSemiconductor/solid-state device detailsSolid-state devicesEngineeringMemory cards

A memory card comprising a substrate, a memory die on top of the memory die, a controller die on top of the memory die; and a interposer surrounding the controller die and on top of the memory die wherein the interposer allows for wire bonding to the substrate to be minimized. A system and method in accordance with the present invention achieves the following objectives: (1) increase the density of the Flash card by reducing the number of wire bond pads on the substrate and enabling insertion of the largest die possible that can fit inside a given card interior boundary; (2) more efficiently stacks Flash memory dies when stacking is necessary, to increase density of the Flash card; (3) has only a few necessary signal I / O bonding wires to the substrate to improve production yield.

Owner:KINGSTON DIGITAL CO LTD

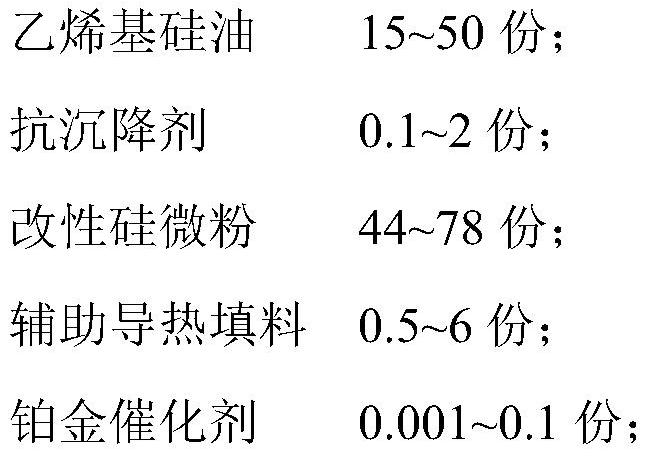

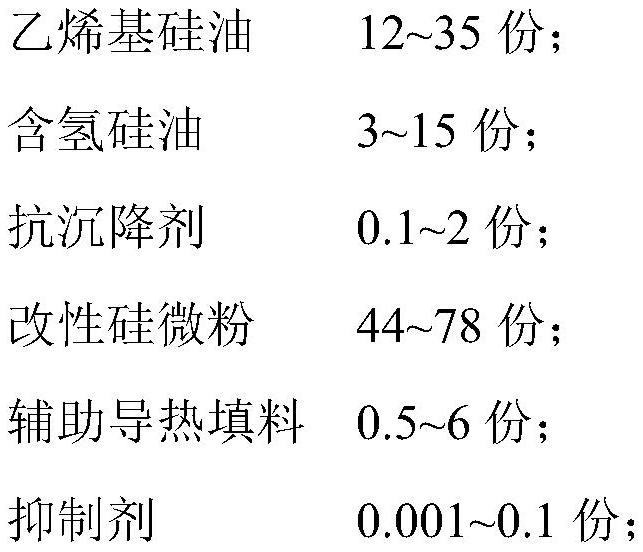

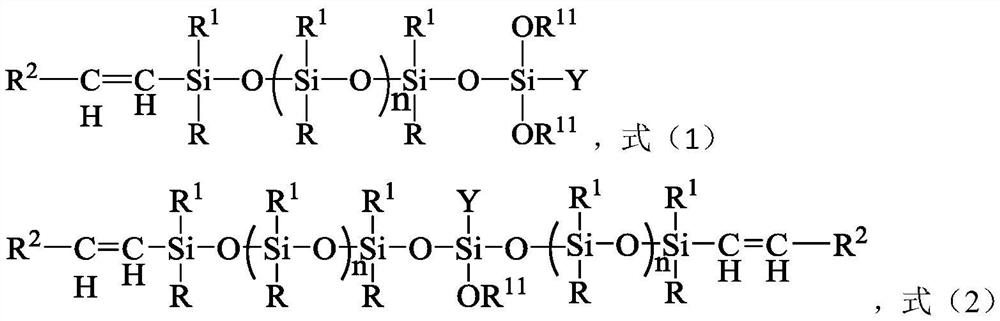

A two-component addition type organic silicon heat-conducting adhesive and preparation method thereof

ActiveCN110951448BLow densityMeet lightweight requirementsNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilicone GelsPolymer science

The invention provides a two-component addition type silicone heat-conducting adhesive and a preparation method thereof. The addition-type silicone heat-conducting adhesive includes component A and component B, and component A includes the following parts by weight: 15-50 parts of vinyl silicone oil, 0.1-2 parts of anti-settling agent, 44-78 parts of modified silica powder 0.5-6 parts of auxiliary thermal conductive filler, 0.001-0.1 parts of platinum catalyst, component B includes the following parts by weight: vinyl silicone oil 12-35 parts, hydrogen-containing silicone oil 3-15 parts, anti-settling agent 0.1-2 parts , 44-78 parts of modified silica powder, 0.5-6 parts of auxiliary heat-conducting filler, and 0.001-0.1 part of inhibitor. The present invention adopts organosilane coupling agent containing non-reactive organic functional groups and hydroxyvinyl silicone oil to prepare structural modification regulator, and the silicon micropowder is modified by the prepared structural modification regulator, which improves the phase between silicon micropowder and organosilica gel. Capacitance, which solves the dispersion and stability of silicon micropowder in organic silica gel. While improving the thermal conductivity of organic silica gel, it reduces the density of thermal conductive adhesive, and prepares silicone thermal conductivity with high thermal conductivity, low density and good stability. glue.

Owner:新纶光电材料(深圳)有限公司

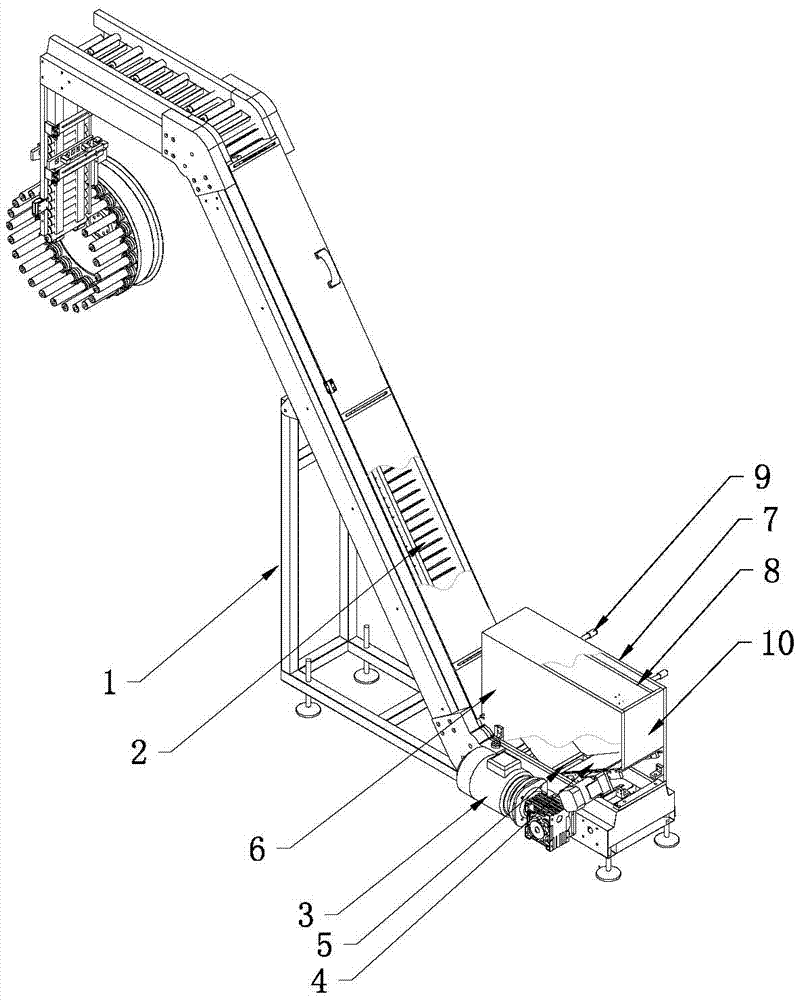

A material storage and conveying device for curved surface printing substrates

ActiveCN104310025BPrevent confusionReduce contact with human bodyConveyorsControl devices for conveyorsMaterial storageSupport plane

A material storing and conveying device of curved surface printing members comprises a lifting and conveying support, a lifting and conveying belt, a conveying belt drive device and a material storing chamber. The lifting and conveying belt is installed on the lifting and conveying support, the conveying belt drive device drives the lifting and conveying belt to move, the bottom of the storing chamber is provided with two inclined plates, the inclined plates are arranged in an inverted V shape with an opened tip, the clearance between the inclined plates serves as a discharging port with the adjustable width, and the lower portion of the conveying belt is located below the discharging port of the material storing chamber. The printing members can be stacked in the material storing chamber effectively, the width of the discharging port can be adjusted according to the diameter of actual printing members, the printing members can be discharged and fall one by one, mixture of heads of tails of the printing members can be prevented effectively, and high-speed operation of the conveying belt and printing quality are prevented from being affected.

Owner:GUANGDONG LONGXING PACKAGING IND

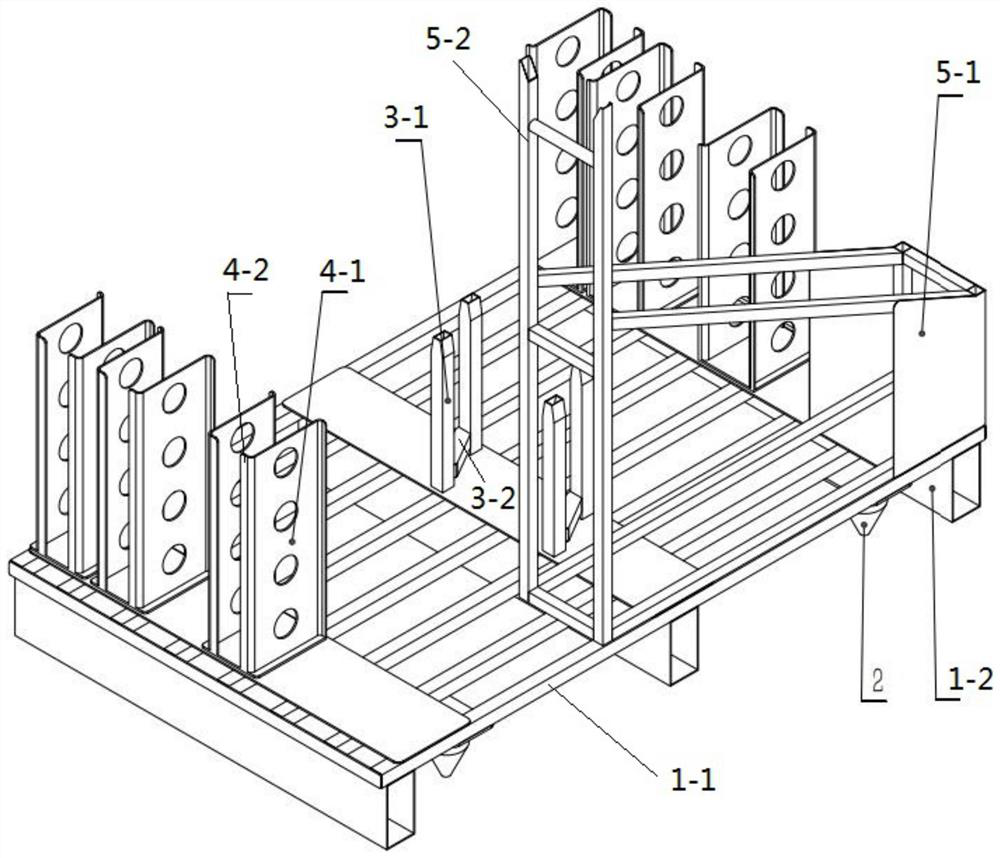

Automatic collecting and stacking device for wood-plastic composite profiles

PendingCN111646217AEffective stackingEasy transferConveyorsStacking articlesElectric machineEngineering

The invention provides an automatic collecting and stacking device for wood-plastic composite profiles. The automatic collecting and stacking device comprises a conveying device, a storage device andtwo pairs of working supports arranged in parallel at intervals. The conveying device comprises a plurality of conveying rollers, a conveying belt and a power motor. The multiple conveying rollers arearranged between the two pairs of working supports in parallel at intervals and rotationally connected to the two pairs of working supports correspondingly. According to the automatic collecting andstacking device, the wood-plastic composite profiles conveyed by the conveying belt are effectively stacked, a detachable front baffle is arranged, the profiles can be conveniently transferred in a unified manner, labor and material resources are saved, the work efficiency is improved, the orderly stacked profiles can be conveniently pushed out of the storage device, and therefore the profiles canbe conveniently transferred.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE

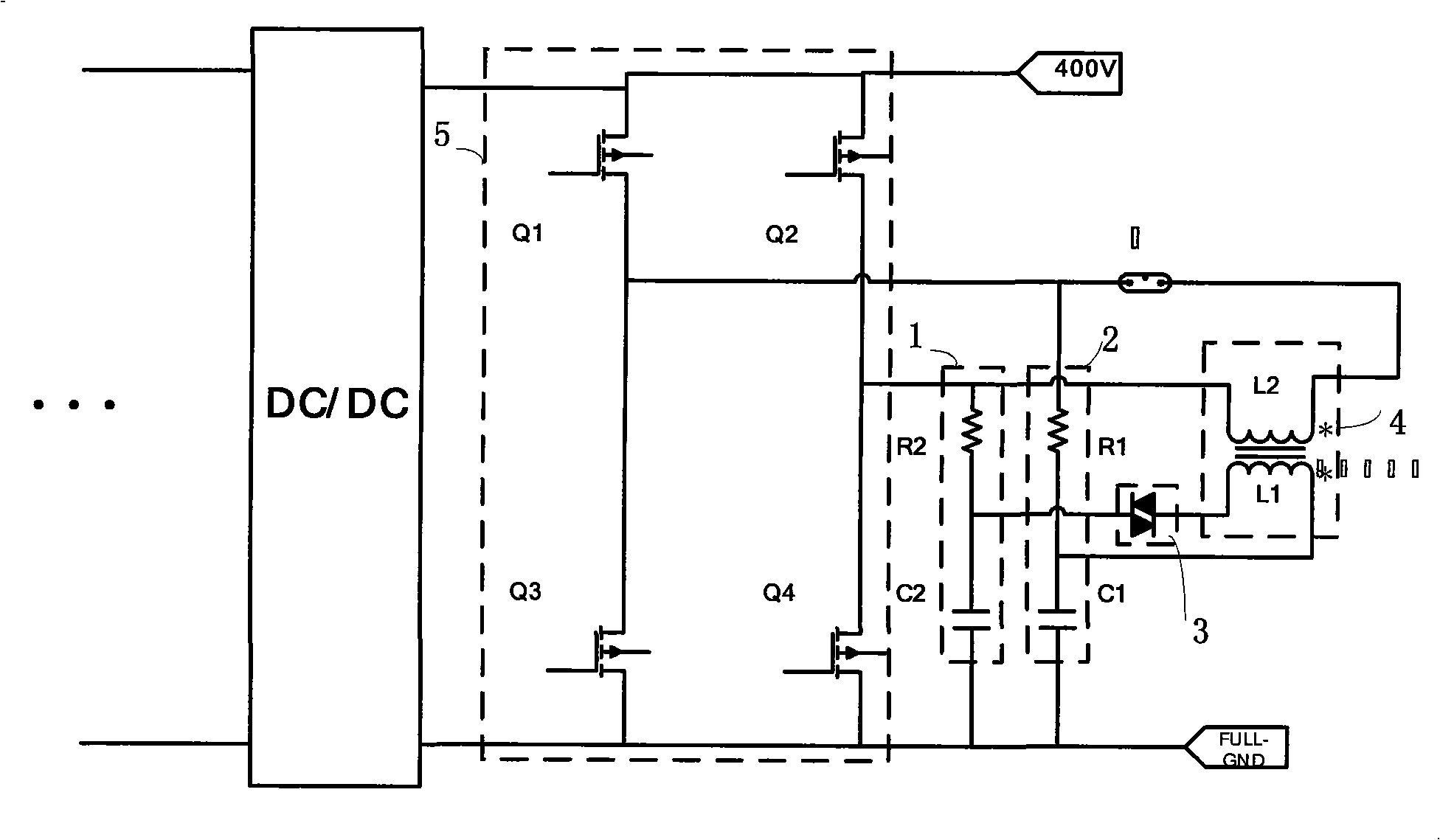

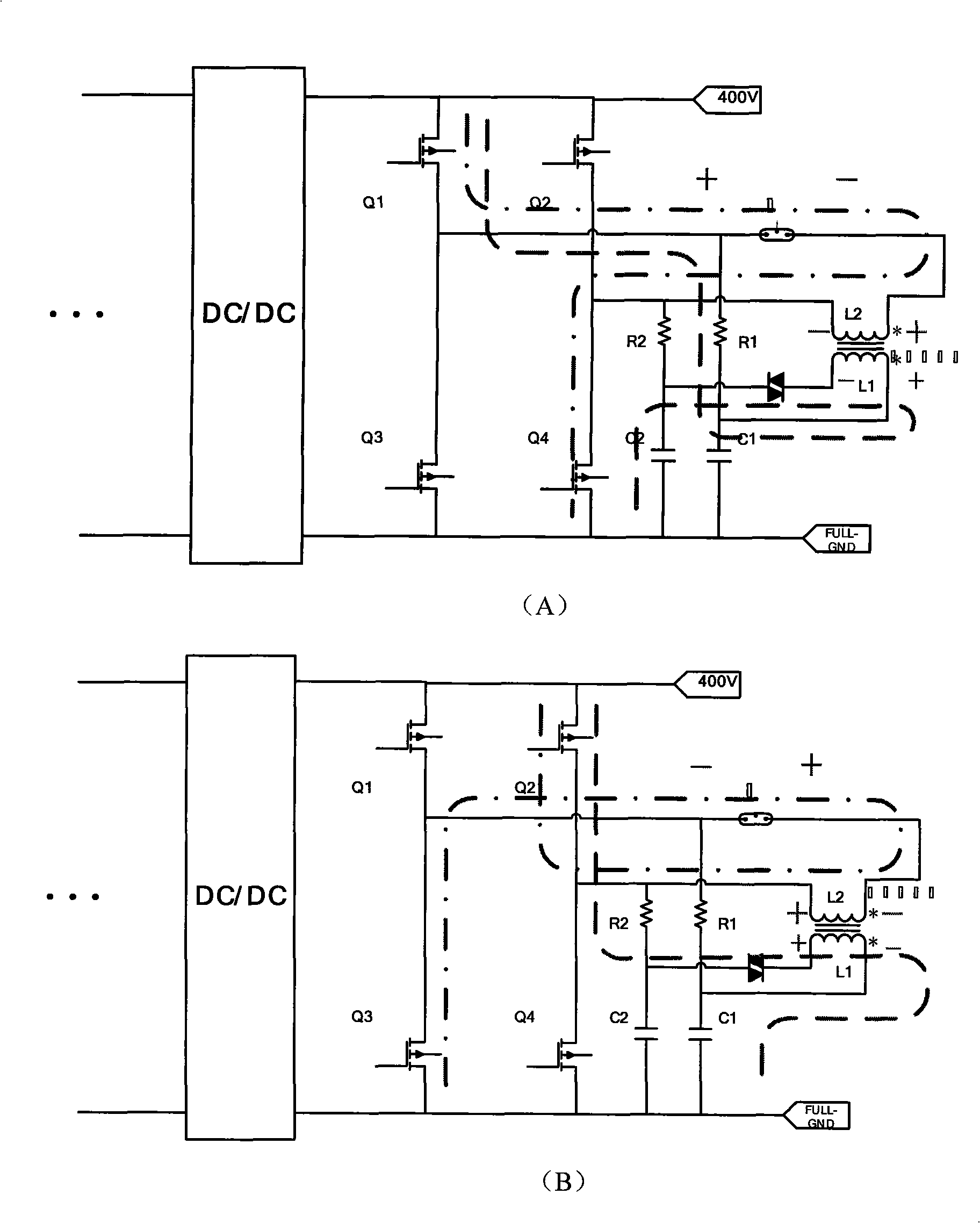

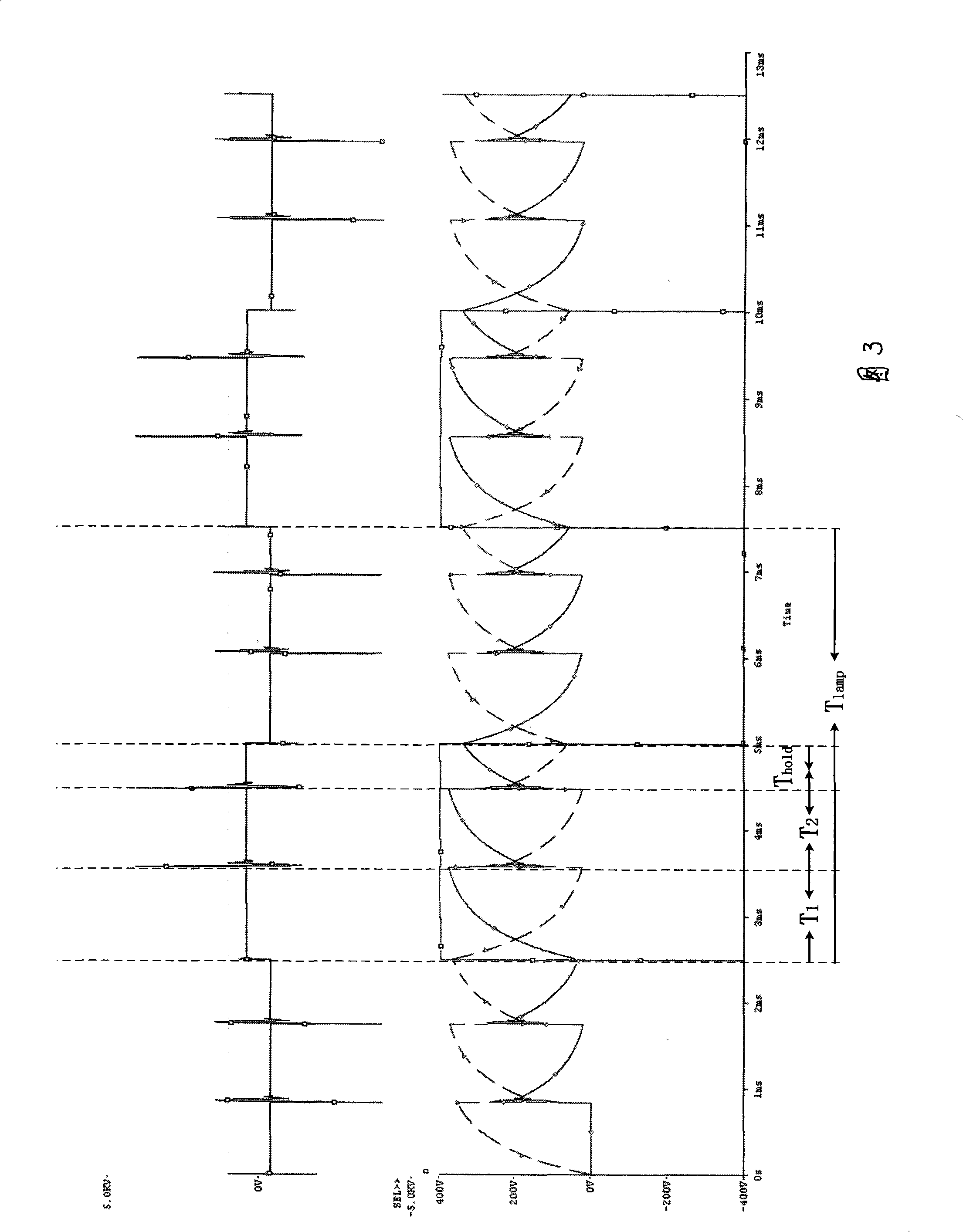

Method and apparatus for controlling simple controllable sequential pulse type igniting circuit

ActiveCN101553068BEffective stackingSimple and precise ignition pulse timing controlElectrical apparatusElectric lighting sourcesCapacitanceFull bridge

The invention discloses a pulse formula igniting controlling apparatus, which comprises groups of charging-discharge loops respectively connected between the two bridge arm middle points of a full bridge current transformer (5) and the earth: RC charging-discharge loop I (1) and RC charging-discharge loop II (2); also comprises a gas-discharge tube (3) and a igniting transformer (4) with accessory edge in serial connection with a HID lamp in the main circuit; the RC charging-discharge loop I (1) is composed of a charging resistor R1 and a capacitor C1 in serial connection, the RC charging-discharge loop II (2) is composed of a charging resistor R2 and a capacitor C2 in serial connection; the gas-discharge tube (3), primary side of the igniting transformer (4), the capacitor C1 and the capacitor C2 compose a serial connection loop. The invention further discloses a method for simple controllable sequential pulse type igniting control method using the above apparatus, and a igniting voltage superposing validity control method. The invention can solve the problems of ignition pulse sequential control and valid igniting voltage superposing at the same time.

Owner:ZHEJIANG UNIV

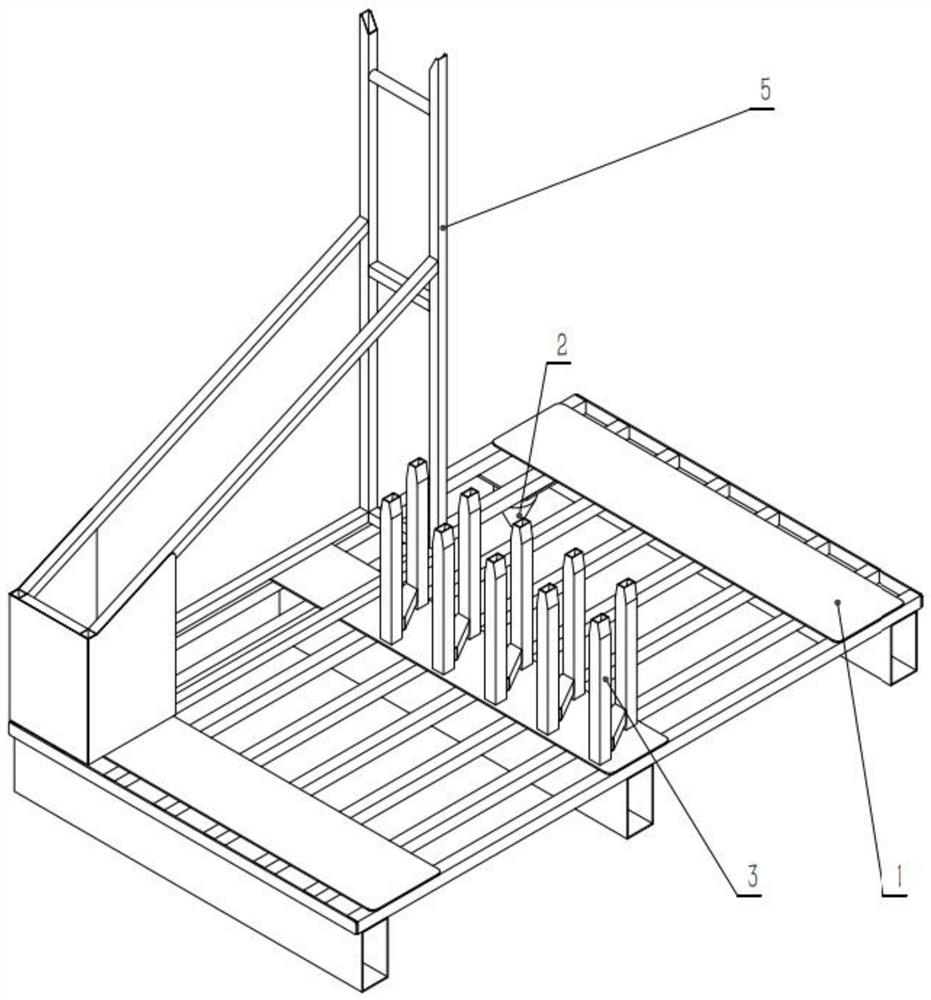

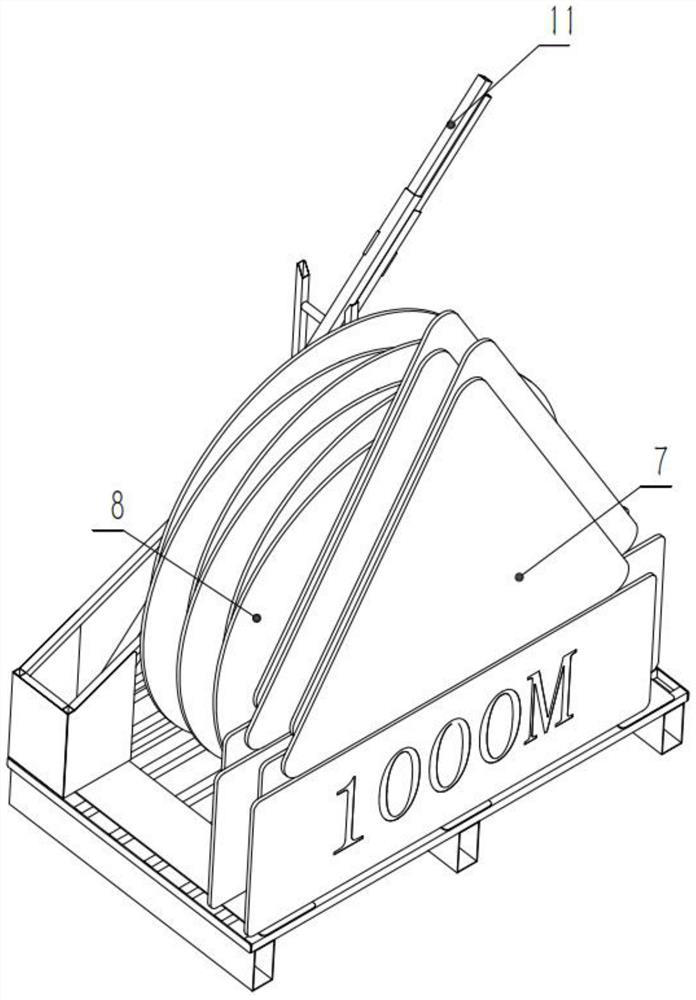

Tool tray for highway to pass through signboard by means of opposite lane

PendingCN113060387ASave storage spaceEasy accessRigid containersAgricultural engineeringStorage garage

The invention relates to the technical field of traffic engineering, in particular to a tool tray for a highway to pass through a signboard by means of an opposite lane. The tool tray comprises a signboard tray; the signboard tray is provided with at least one of a signboard positioning column, induction road bar bases, a stand column frame and a cone barrel positioning cone; the signboard positioning column comprises two vertical rods, and the two vertical rods form an inclined coplanar surface; at least two induction road bar bases are arranged, and every two induction road bar bases are symmetrically arranged at the two ends of the upper surface of the signboard tray; the stand column frame is arranged on one side of the upper surface of the signboard tray; and the large end of the cone barrel positioning cone is fixedly connected to the upper surface of the signboard tray and between the signboard positioning column and the induction road bar bases. The limited space of a warehouse can be reasonably utilized, and the borrowed opposite passing signboards are classified according to properties and stacked in order.

Owner:BEIBU GULF UNIV

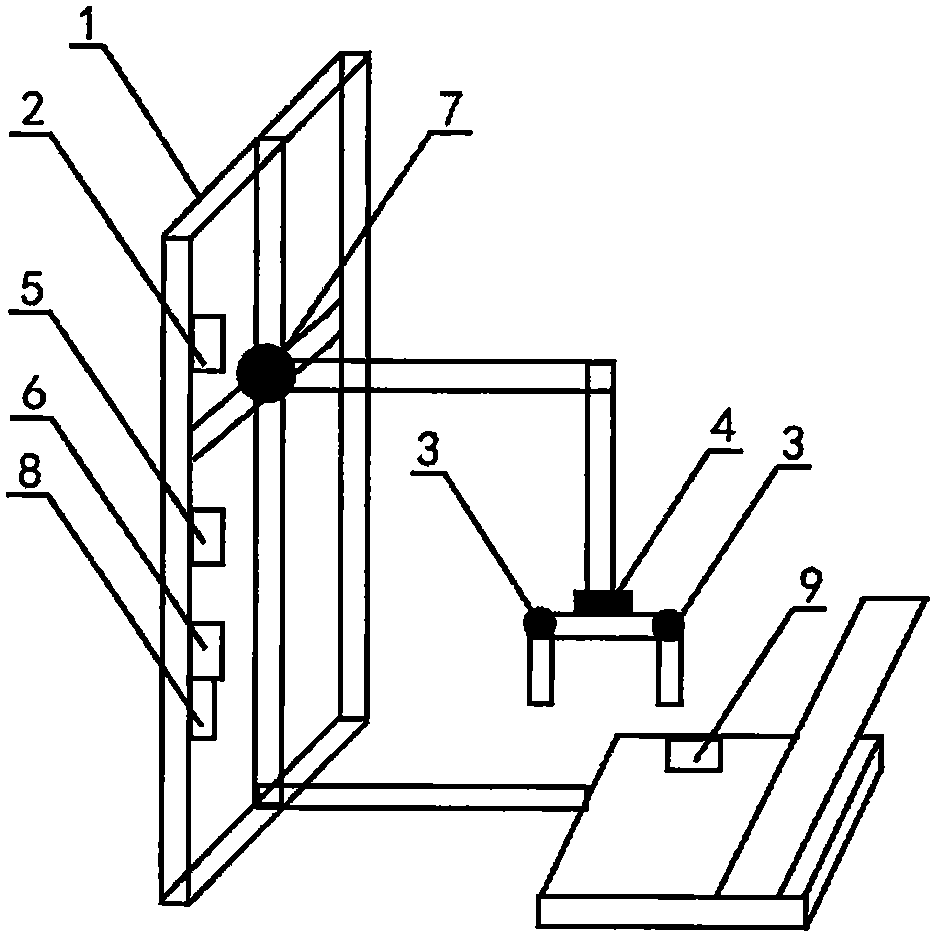

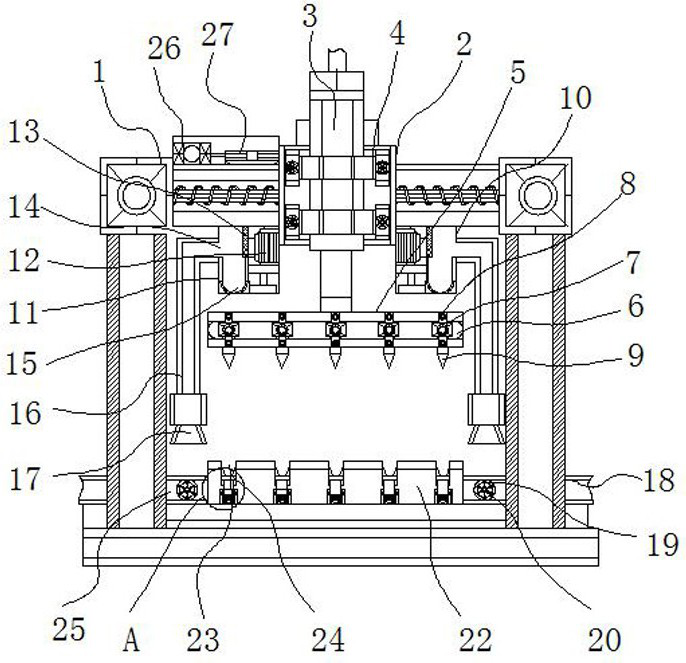

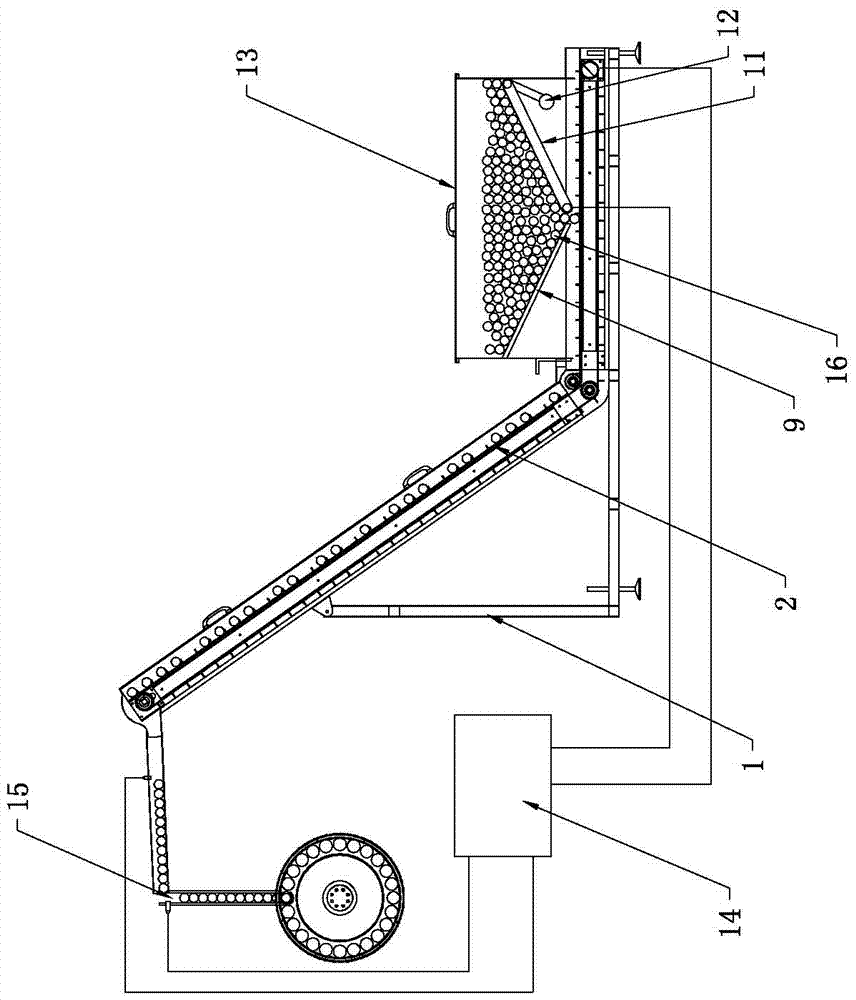

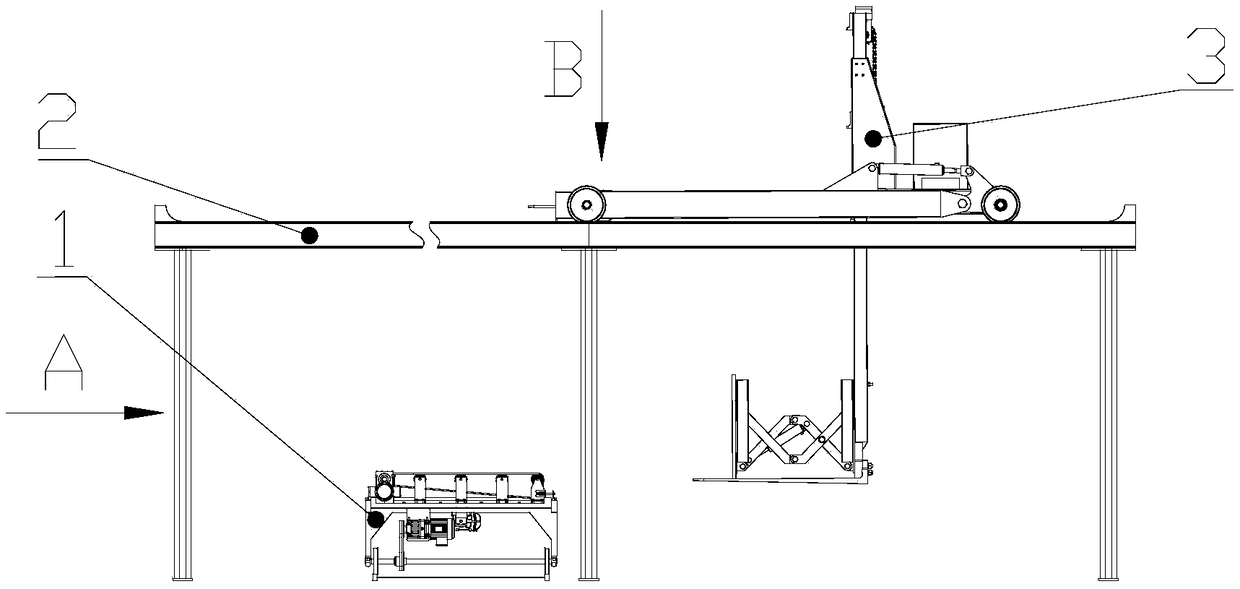

Container bag material truck-loading equipment and use method thereof

PendingCN109205341ARealize handlingRealize the integration of loading and unloadingLifting devicesLoading/unloadingHydraulic cylinderControl system

The invention relates to the field of material transferring and stacking, in particular to container bag material truck-loading equipment and a use method for the container bag material truck-loadingequipment. The container bag material truck-loading equipment comprises a container bag conveying device and a forklift stacking device, wherein the container bag conveying device conveys materials toa loading position of the forklift stacking device, the forklift stacking device conveys the materials upwards to a stacking position and performs effective stacking, container bag material carrying,loading and unloading integration is realized, and the container bag material stacking stability is greatly increased. According to the container bag material truck-loading equipment and the use method for the container bag material truck-loading equipment, all driving motors and hydraulic cylinders can be controlled by a control system, therefore, manual intervention is not needed, container bagmaterial loading and unloading automation is realized, the forklift loading and unloading scheduling capacity is greatly improved, and the efficiency and the automation degree are improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Press mounting base of motor rotor and press mounting method of press mounting base

InactiveCN105375699AEffective stackingReduce consumptionManufacturing stator/rotor bodiesMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a press mounting base of a motor rotor and a press mounting method of the press mounting base. The press mounting base comprises a working table, a false shaft, a base, a fixed plate and a guide rib, wherein the false shaft is used for sleeving a rotor iron core, the guide rib is used for positioning a marked first groove of the rotor iron core, the false shaft is vertically arranged on the working table and is partial to one side of the longitudinal direction of the working table, the base is movably connected to the other side of the longitudinal direction of the working table, the base, facing one edge of the false shaft, fixes the guide rib through the fixed plate, the guide rib points to the false shaft, and the distance between the guide rib and the false shaft is adaptive to the external diameter of the rotor iron core. Compared with the prior art, the press mounting base has the advantages that effective overlaying is carried out on a motor on the condition of benchmark shortage during the press mounting process of the rotor iron core short of a positioning groove and a mark groove, the positioning groove and the mark groove are not needed to be additionally punched during the production process of the motor rotor, the consumption and the fabrication process of a die are reduced, and the production cost is saved.

Owner:JIANGSU TONGDA POWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com