Paperboard counting and binding turnover device

A flipping device and counting technology, which is applied to the parts, packaging, and packaging protection of the strapping machine, can solve the problems of reducing the strength of the cardboard, reducing the use effect, and large number of orders, so as to facilitate adjustment and transportation, improve the use effect, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

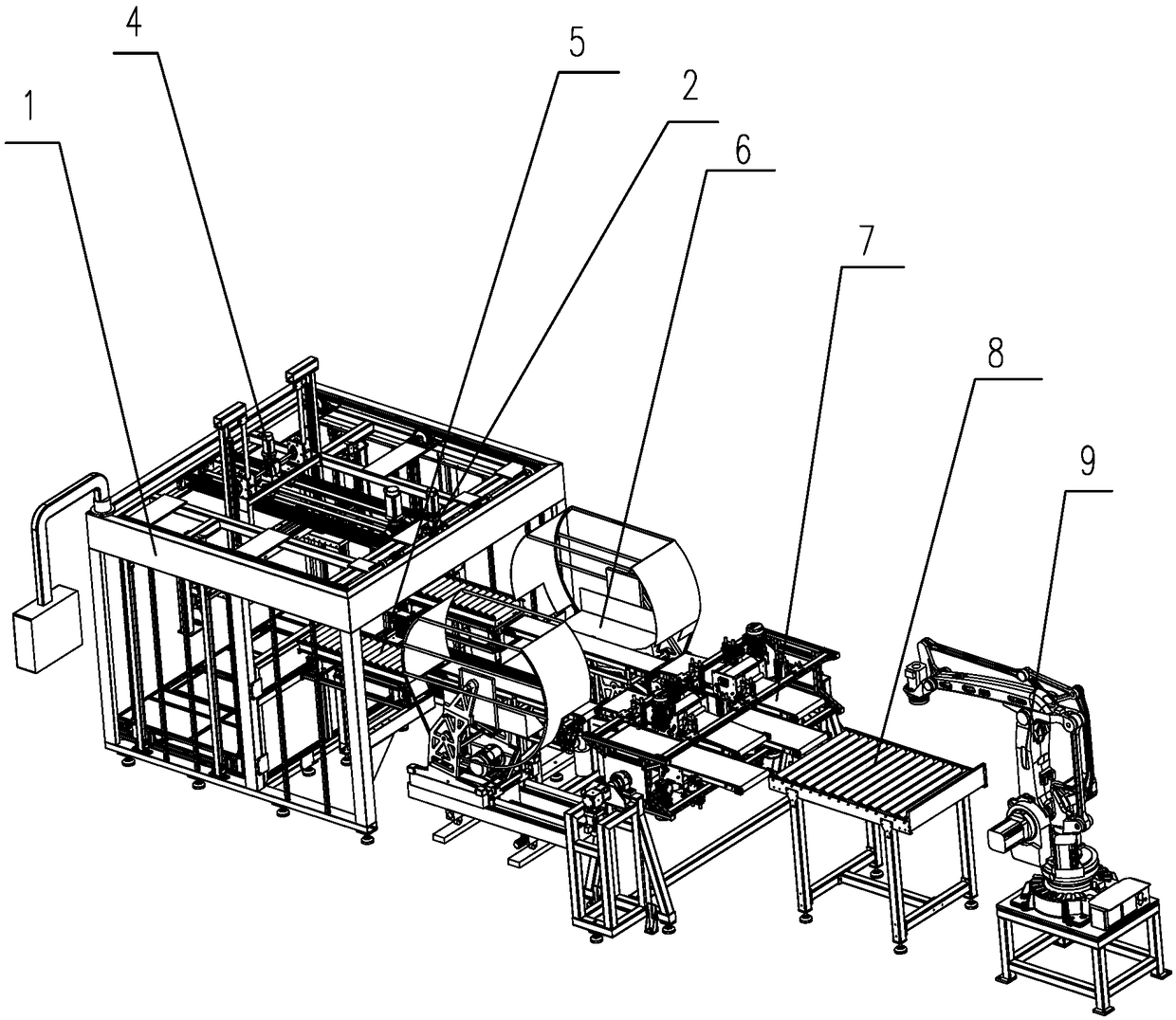

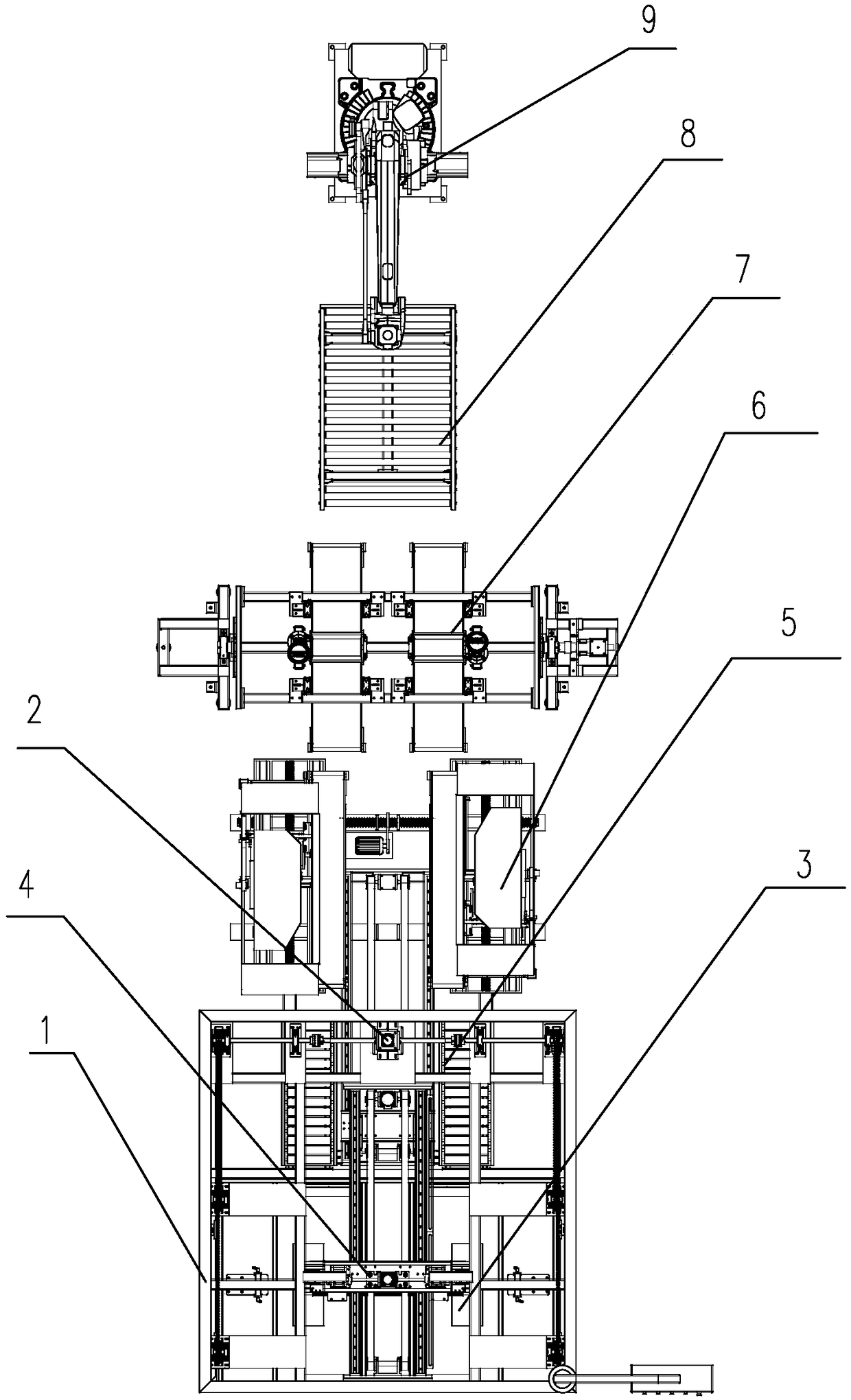

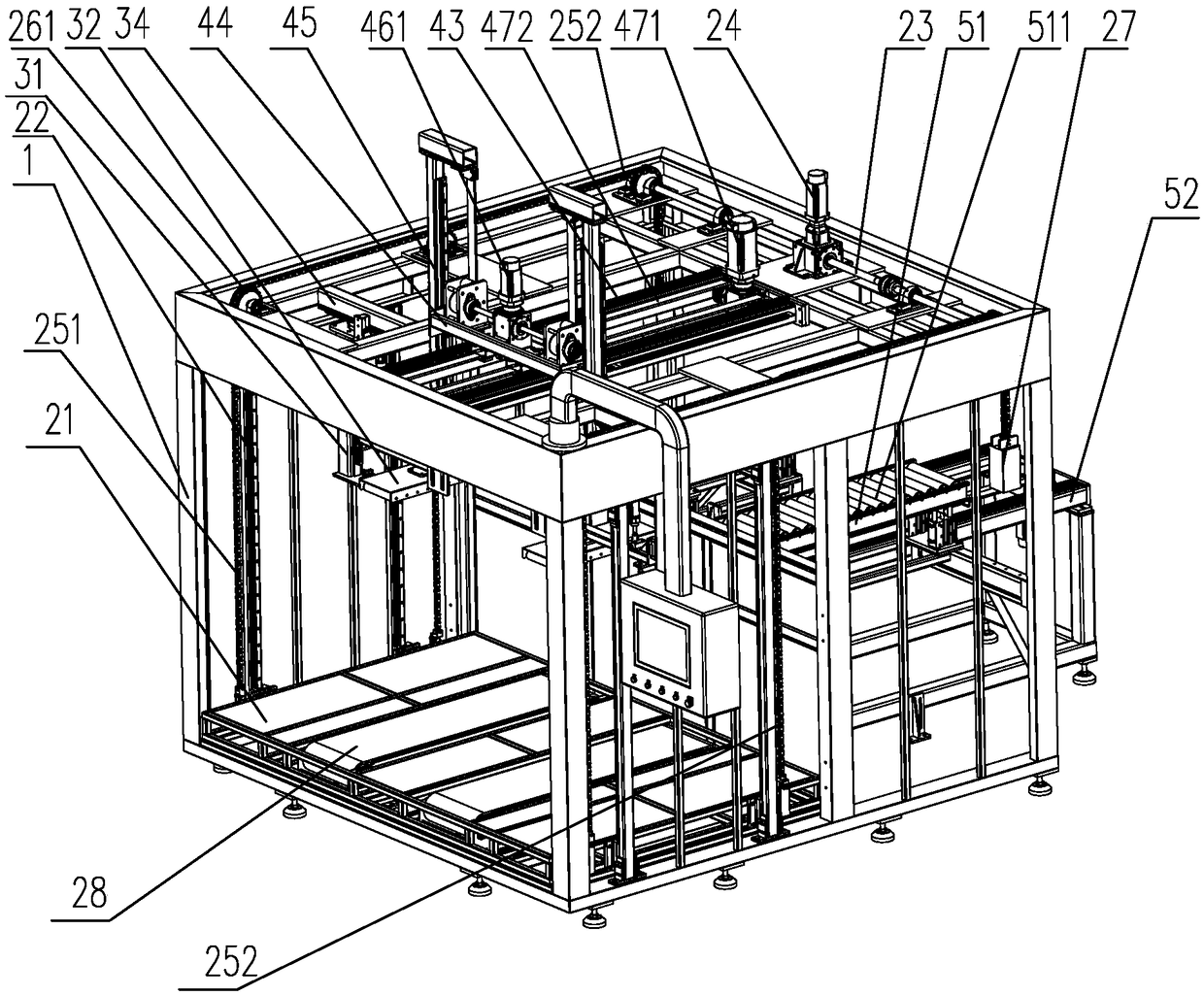

[0038] Depend on Figure 1 to Figure 14It can be seen that the present invention discloses a cardboard scoring and binding turning device. The lifting mechanism 2 for lifting the stack of cardboards, the lifting mechanism 2 includes a bottom plate 21 and a first driving member 24 for lifting the bottom plate 21, the bottom plate 21 is slidably arranged on the support 1 along the height direction of the support 1, so The propulsion mechanism 5 includes a discharge frame 51, the discharge frame 51 is arranged close to the bottom plate 21 to transport the material, the discharge frame 51 is provided with a roller 511 for conveying the material, and the discharge frame is arranged on a binding Between the mechanism 6 and the counting mechanism 3, the binding mechanism 6 includes a material receiving frame 62 and the first binding adjustment assembly for adjusting the position of the material receiving frame 62, and the material receiving frame 62 is provided with a material receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com