Front baffle assembly for a lawn mower

A front baffle, lawn mower technology, applied in the directions of harvesters, applications, cutters, etc., can solve the problems of difficult cleaning of lawn mowers, increased risk of water penetration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments herein are exemplified in the following non-limiting description of embodiments.

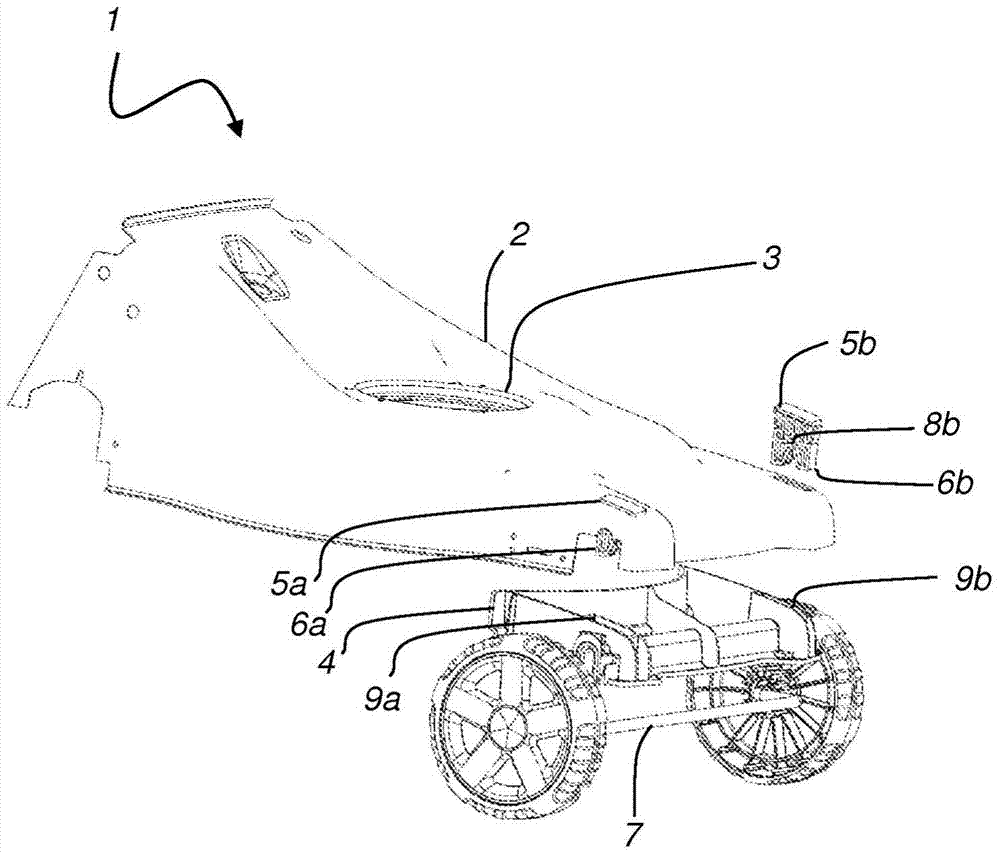

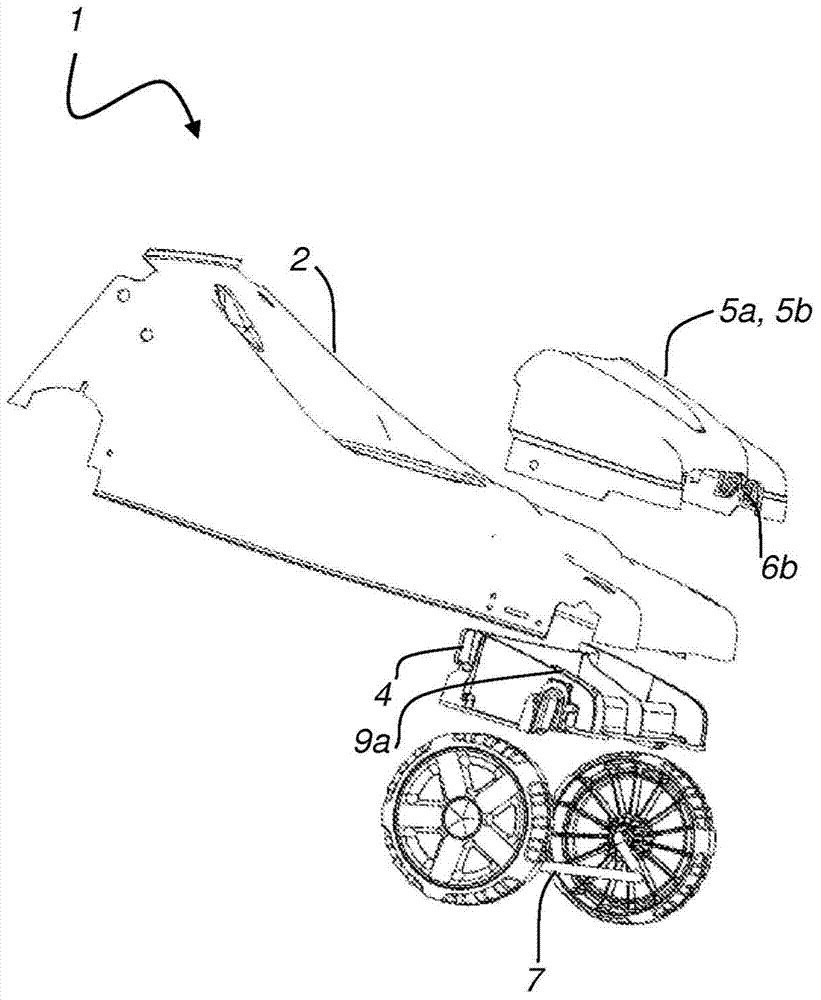

[0033] figure 1 The front fender assembly 1 is shown schematically in an exploded view. It should be understood that this exploded view has been chosen merely as a means of disclosing the components of the front fender assembly in a clear manner.

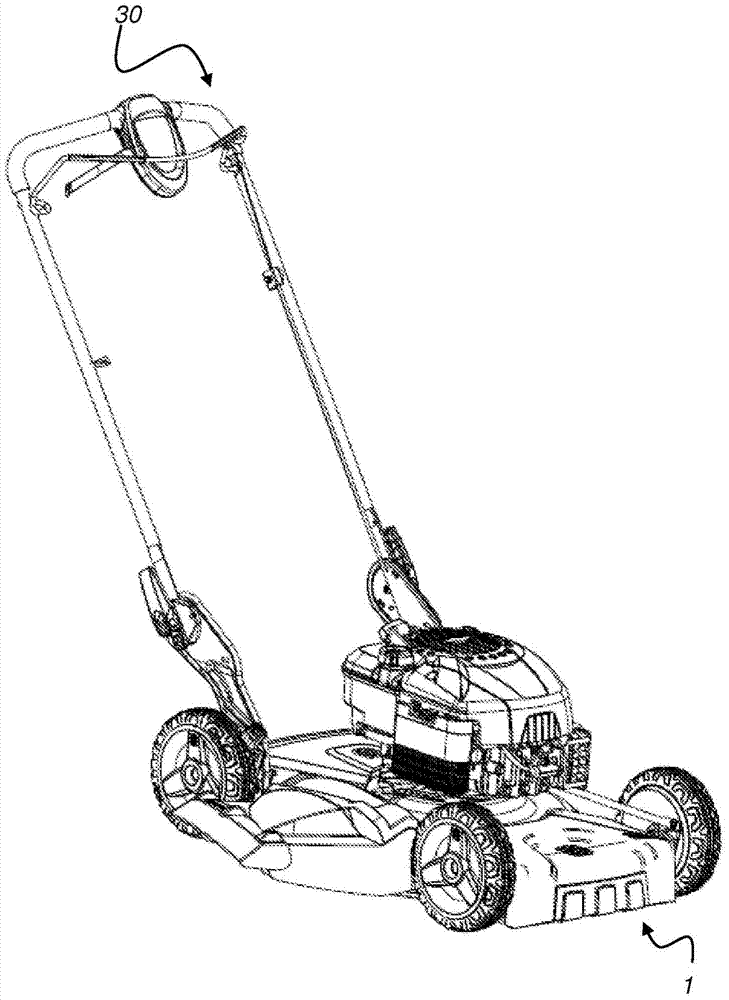

[0034] The front fender assembly 1 is configured for attachment to a lawn mower chassis 2 . The mower chassis 2 is the structural frame of the mower to which other components of the mower such as handles and axles are attached. In the illustrated embodiment, the cutting deck 3 forms an integral part of the lawnmower chassis 2 . In another embodiment, the cutting plate 3 can be a separate component.

[0035] The front fender assembly 1 includes a front fender 4 . The front fender 4 is arranged under the front of the chassis 2 and is configured to abut against the underside of the chassis 2 .

[0036] The front fender assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com