Method and apparatus for controlling simple controllable sequential pulse type igniting circuit

A pulse ignition and control device technology, applied in the direction of lighting devices, gas discharge lamps, electric light sources, etc., to achieve the effect of simple and precise ignition pulse timing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

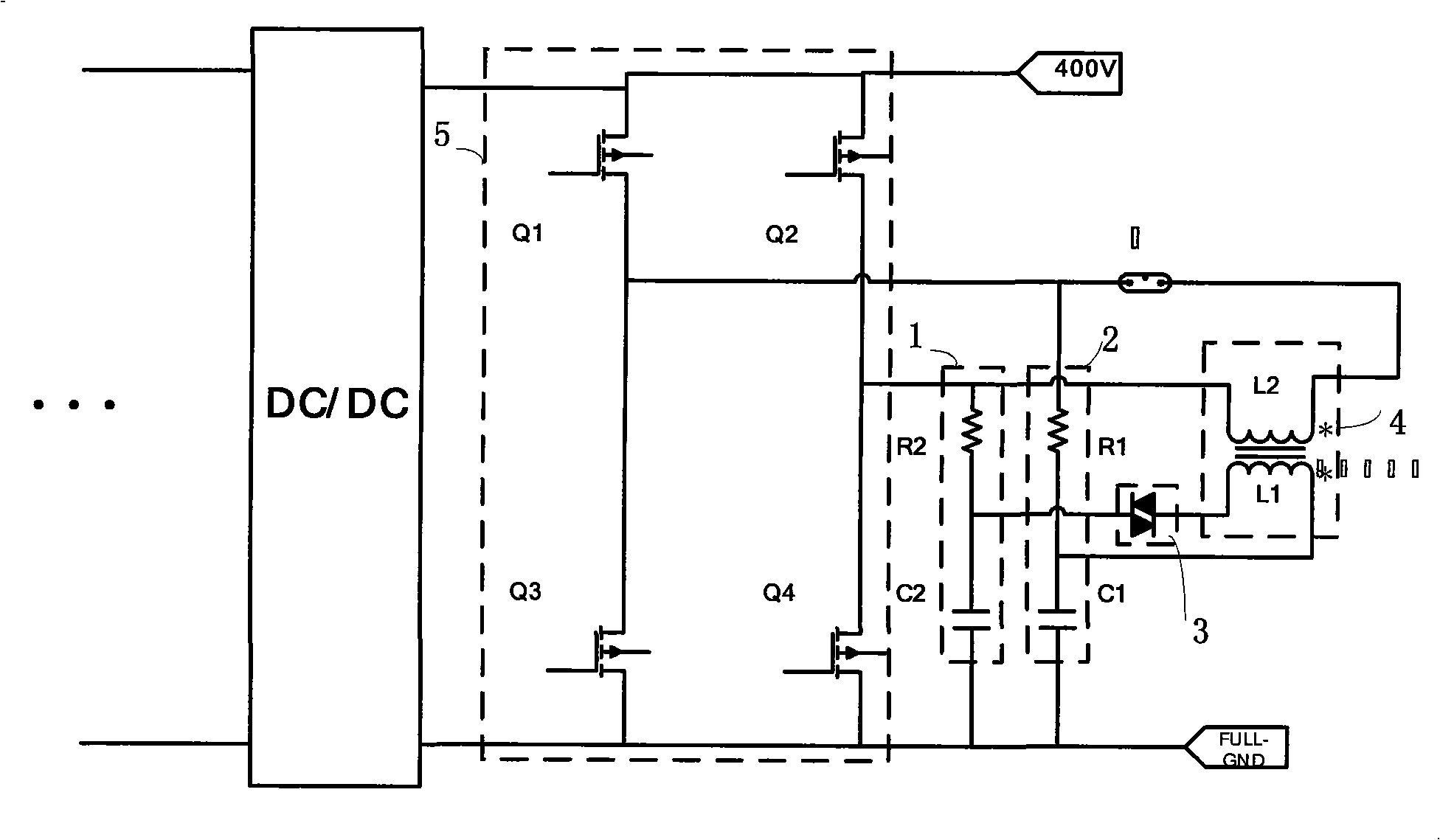

[0028] Embodiment 1, a kind of HID lamp electronic ballast ignition circuit control device (such as figure 1 shown), including Q 1 , Q 2 , Q 3 , Q 4 The composed full-bridge converter 5 includes two sets of RC charge-discharge circuits respectively connected between the midpoints of the two bridge arms of the full-bridge converter 5 and the ground, that is, the RC charge-discharge circuit I1 and the RC charge-discharge circuit II2 ; Also included with the capacitor C 1 , capacitance C 2 The gas discharge tube 3 and the ignition transformer 4 that make up the discharge circuit.

[0029] The RC charging and discharging circuit I1 consists of a series charging resistor R 1 and capacitance C 1 Composition, RC charging and discharging circuit II2 is composed of a series charging resistor R 2 and capacitance C 2 Composition; gas discharge tube 3 and primary side of ignition transformer 4 and capacitor C 1 and capacitance C 2 A series circuit is formed, and the secondary s...

Embodiment 2

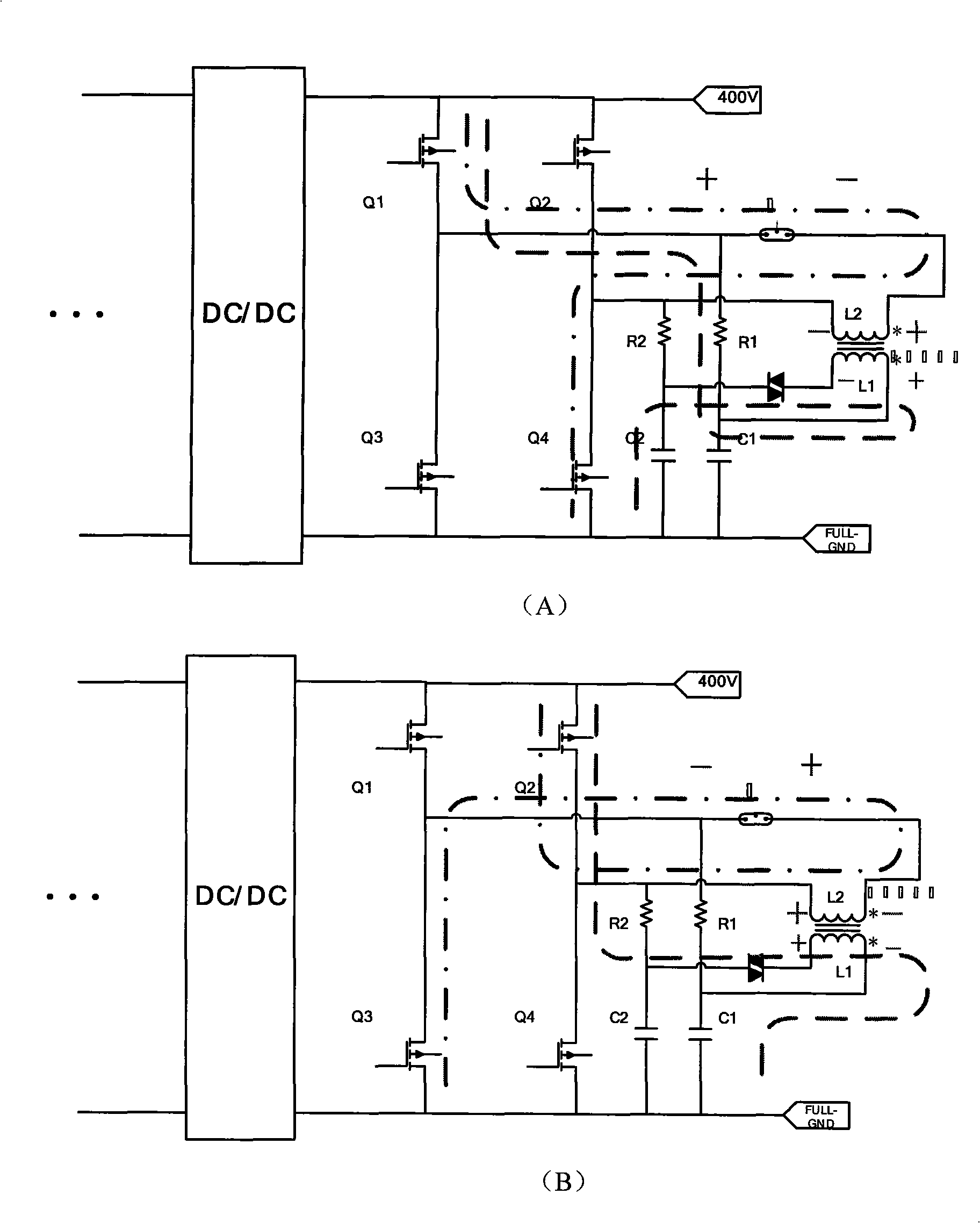

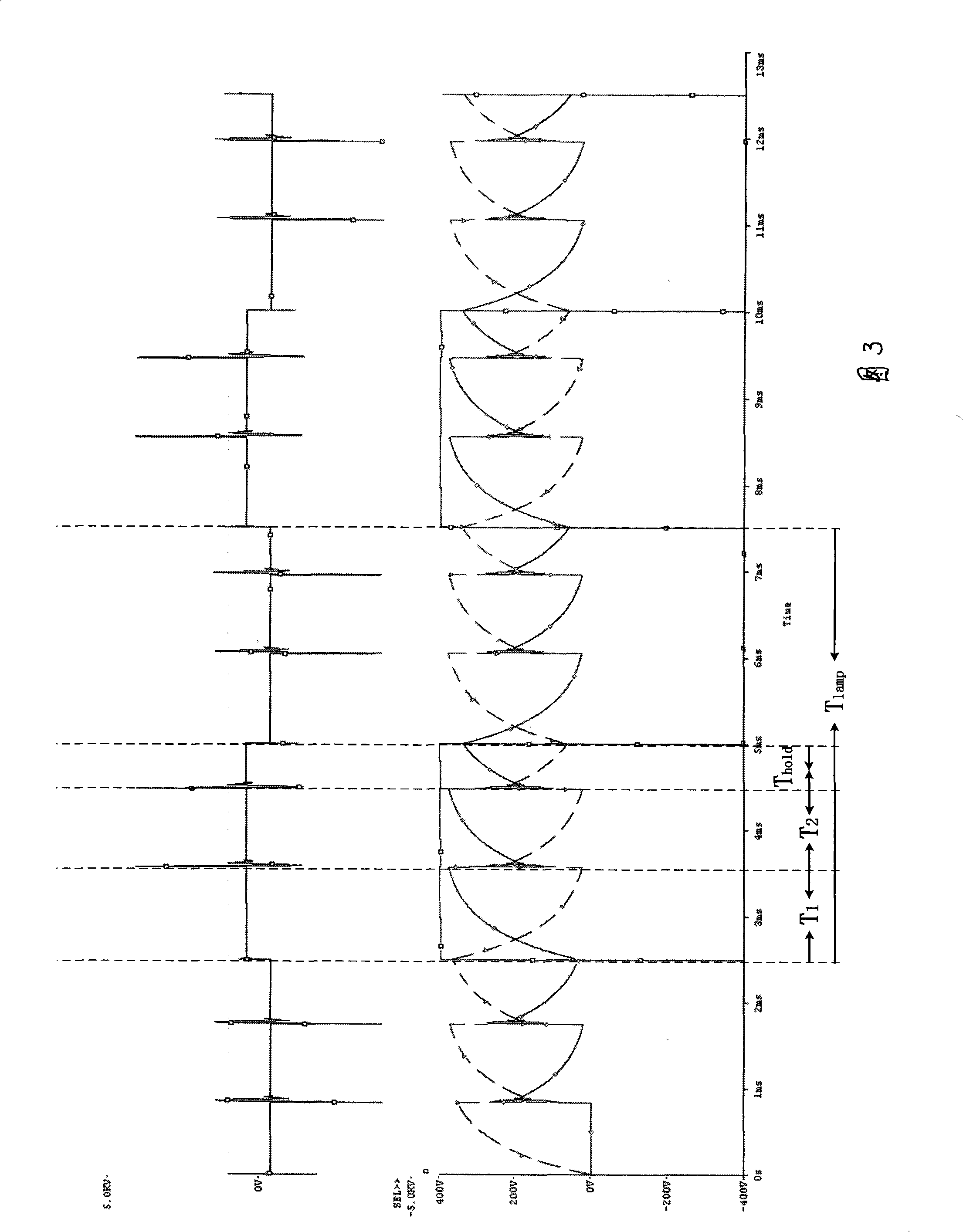

[0048] Embodiment 2, ignition pulse V pulse The phase of figure 2 The connection method shown in the figure strictly follows the output voltage of the inverter stage V dc The phase of , which ensures that the absolute value of each effective ignition pulse is V dc +V pulse . The dotted line in the figure represents the phase of the output voltage Vdc of the inverter stage, and the dotted line represents the high-voltage ignition pulse V pulse phase, it can be seen that when Q 1 , Q 4 When turned on, the bus voltage superimposed on both ends of the lamp tube is left + right -, at this time C 1 charging 2 Discharge, when the gas discharge tube 3 breaks down, the high-voltage pulse superimposed on both ends of the lamp tube is also left+right-, and the effective ignition voltage is V dc +V pulse .

[0049] On the contrary, when Q 2 , Q 3 When it is turned on, the bus voltage superimposed on both ends of the lamp is right+left-, at this time the capacitor C 2 Chargin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com