Press mounting base of motor rotor and press mounting method of press mounting base

A motor rotor, press-fit technology, applied in the manufacture of stator/rotor body, hand-held tools, manufacturing tools, etc., can solve the problems of inability to stack, press-fit, lack of benchmarks, etc., to reduce consumption and manufacturing processes, The effect of improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

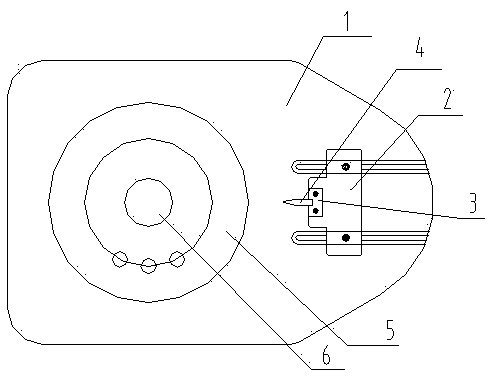

[0025] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0026] Such as figure 1 As shown, a press-fitting base of a motor rotor includes a work surface 1, a dummy shaft 6 for covering the rotor core 5, a base 2, a fixing plate 3, and a first slot marked for positioning the rotor core 5 The guide rib 4; the false shaft 6 is vertically arranged on the work surface 1, and is biased to one side of the longitudinal direction of the work surface 1, the base 2 is movably connected to the other side of the longitudinal direction of the work surface 1, and the base 2 faces the side of the false shaft 6 The guide rib 4 is fixed by the fixing plate 3, the guide rib 4 points to the dummy shaft 6, and the distance between the guide rib ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com