A material storage and conveying device for curved surface printing substrates

A technology of curved surface printing and conveying device, which is applied to conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of chaotic arrangement of tube tails, large resistance, and difficulty in high-speed and smooth transmission, to prevent head and tail confusion and product hygiene. Reliable, reduced human contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

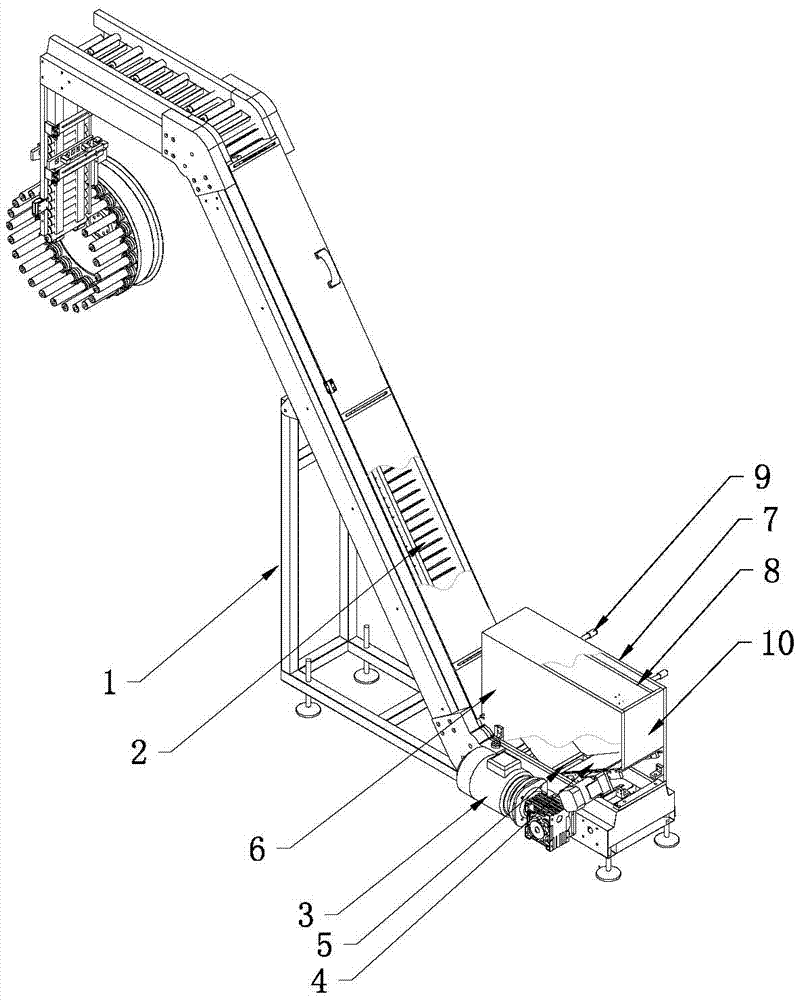

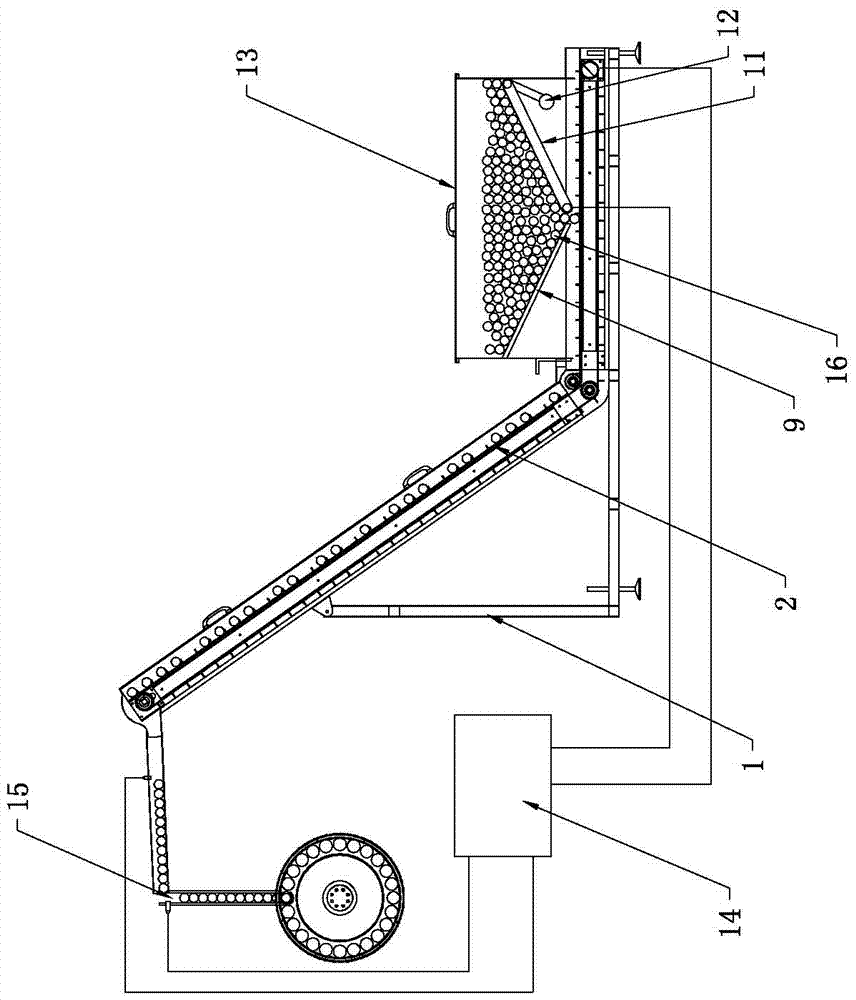

[0035] Such as Figure 1 to Figure 3 As shown, a material storage conveying device for a curved surface printing substrate 16 in this embodiment includes a lifting conveying support frame 1, a lifting conveying belt 2, a conveying belt driving device 3 and a storage bin, and the lifting conveying belt 2 is installed on the lifting conveying support Frame 1, conveyor belt driving device 3 drives the lifting conveyor belt 2 to move, and the bottom of the storage bin is provided with two inclined plates 4, and the two inclined plates 4 are arranged in an inverted figure of eight, and the gap between the two inclined plates 4 is the discharge port 5 , the width of the discharge port 5 is adjustable, and the lower part of the lifting conveyor belt 2 is located below the discharge port 5 of the storage bin.

[0036] The storage bin includes a box body and two inclined plates 4, and the two inclined plates 4 are located at the lower part of the box body. The box body includes four s...

Embodiment 2

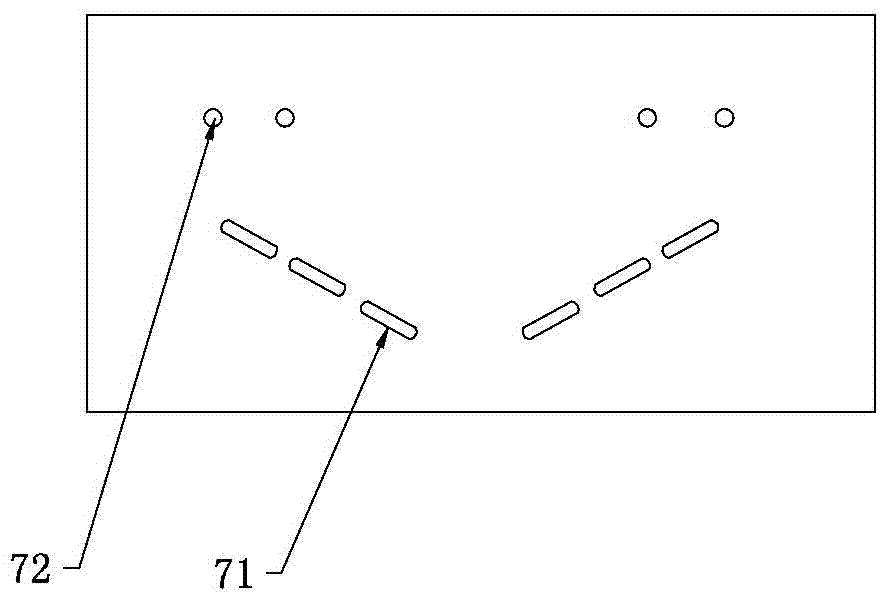

[0043] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, each side wall panel is provided with two rows of adjusting long holes, the two rows of adjusting long holes are arranged in an inverted splayed shape, and the number of adjusting long holes in each row is more than two.

Embodiment 3

[0045] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. The storage bin is provided with a sensor for sensing materials, and the sensor is electrically connected to the controller 14. When the number of substrates 16 in the storage bin is less than a certain amount and the sensor cannot sense the substrate 16, the signal is transmitted to the controller 14 , the controller 14 sends a signal for replenishing materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com