A feeding device for craft pull tabs

A feeding device and process technology, applied in the directions of packaging, transportation and packaging, closing, etc., can solve the problems of limited use, poor versatility, and low accuracy of process pull tab flipping, and achieve strong versatility and guaranteed effectiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

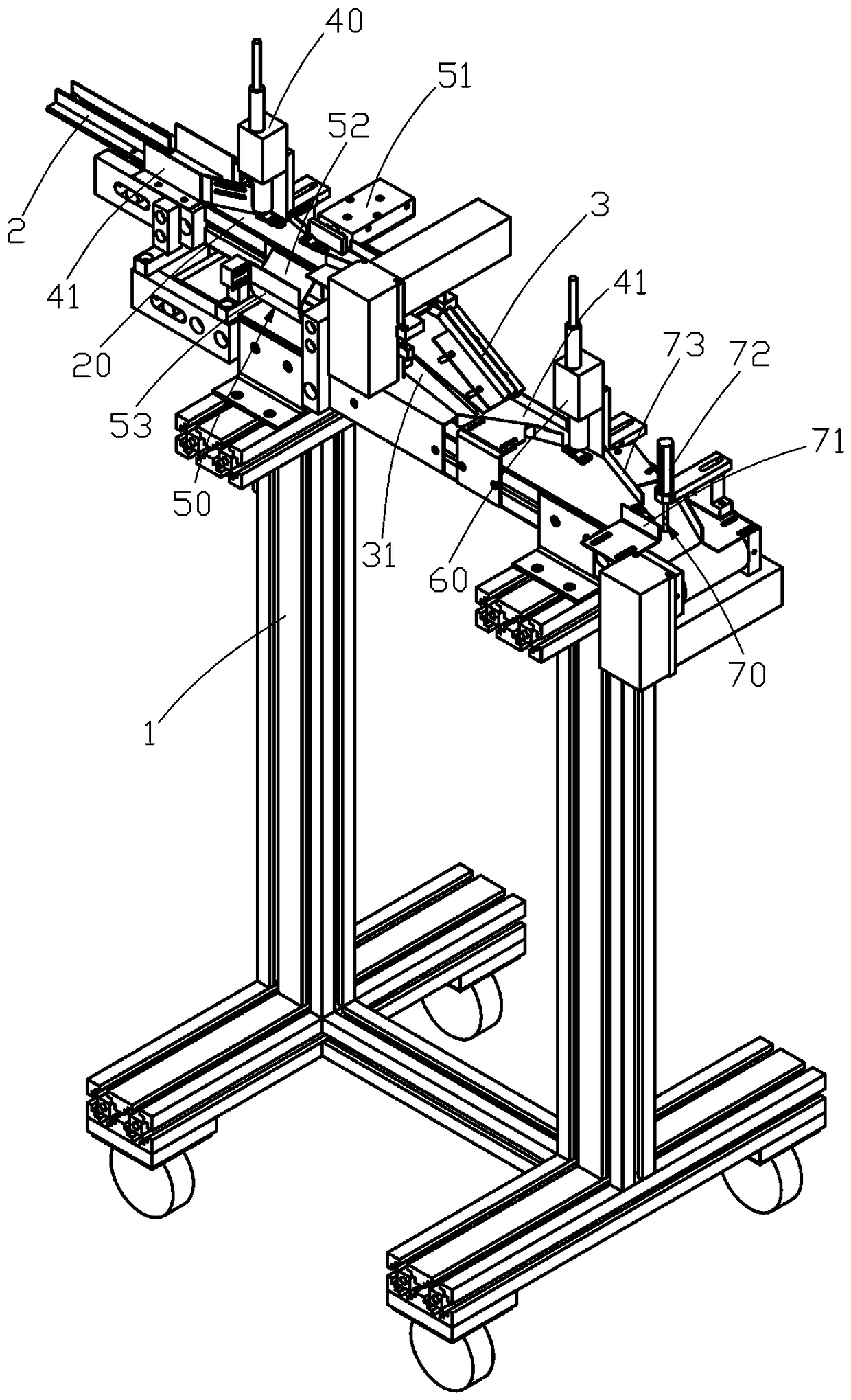

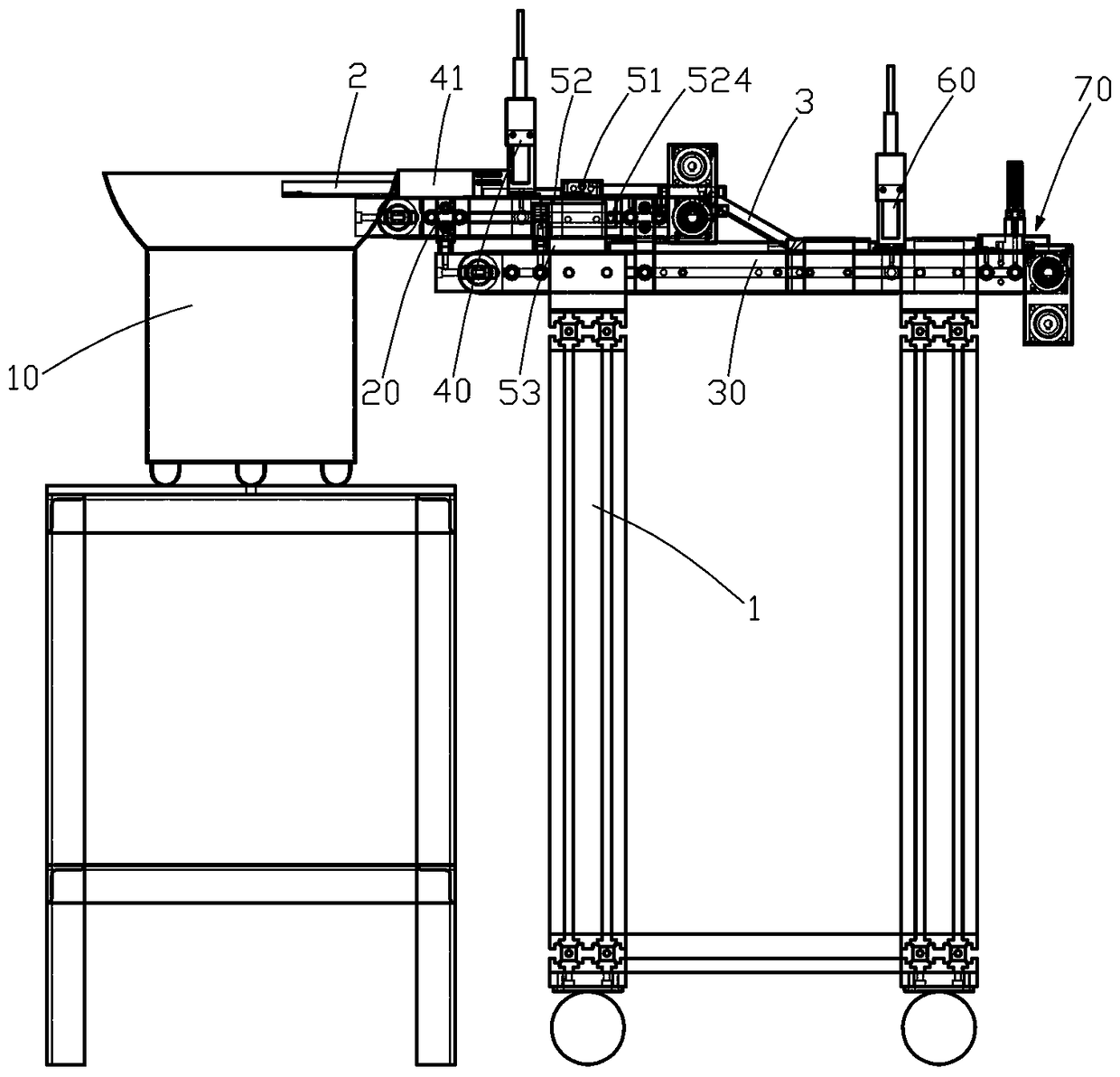

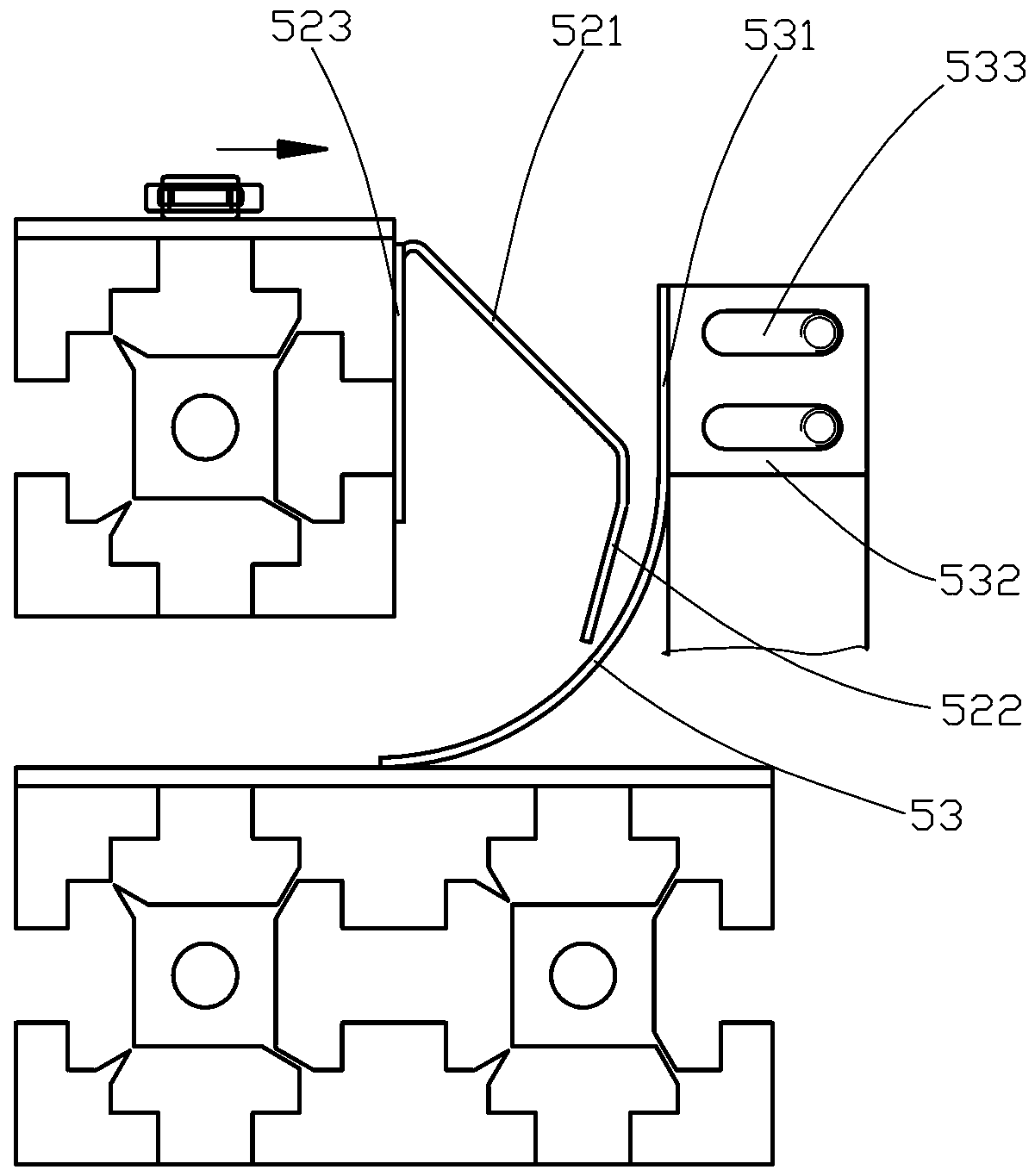

[0027] A feeding device for a craft pull tab, refer to figure 1 and figure 2 , comprising a vibration plate 10, a support frame 1, an upper conveyor 20 and a lower conveyor 30 arranged on the support frame 1, the front end of the upper conveyor 20 receives the vibration plate 10 through a transition channel 2, and the upper conveyor 20 conveys along it In the direction, the first CCD detection component 40 and the pull-tab turning mechanism 50 are arranged sequentially. The end of the upper conveyor 20 is docked with the lower conveyor 30 through an inclined channel 3, and the front end of the lower conveyor 30 is provided with a pull-tab turning mechanism. The surface turning mechanism 50 has a second CCD detection component 60 and a pulling piece turning mechanism 70 on the inclined channel 3 and the lower conveyor 30 at the end of the turning mechanism 50 . Both the front of the first CCD detection component 40 and the second CCD detection component 60 are provided with p...

Embodiment 2

[0033] refer to Figure 4 and Figure 5 , the present embodiment is different from the first embodiment except that the pull-tab U-turn mechanism is the same as the first embodiment. The pull tab turning mechanism 70 of this embodiment includes a fixed base 71, a lifting cylinder 72, a rotating cylinder 73 and a rotating box 74, the fixing base 71 is fixed on the frame of the lower conveyor 30, and the lifting cylinder 72 is fixed on the fixing base 71 side, the movable end of the lift cylinder 72 is connected to the rotary cylinder 73 through a connecting plate 721, and the movable end of the rotary cylinder 73 is connected to the rotary box 74, and between the rotary box 74 and the second CCD detection assembly 60 A pull tab material guide plate 75 is provided.

[0034] refer to Figure 5 and Figure 6 The above-mentioned rotary box 74 includes a U-shaped groove body 741 in cross section and an L-shaped cover body 742 cooperatingly arranged on the groove body 741. A hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com