Preparing method for oriented graphene oxide fibers

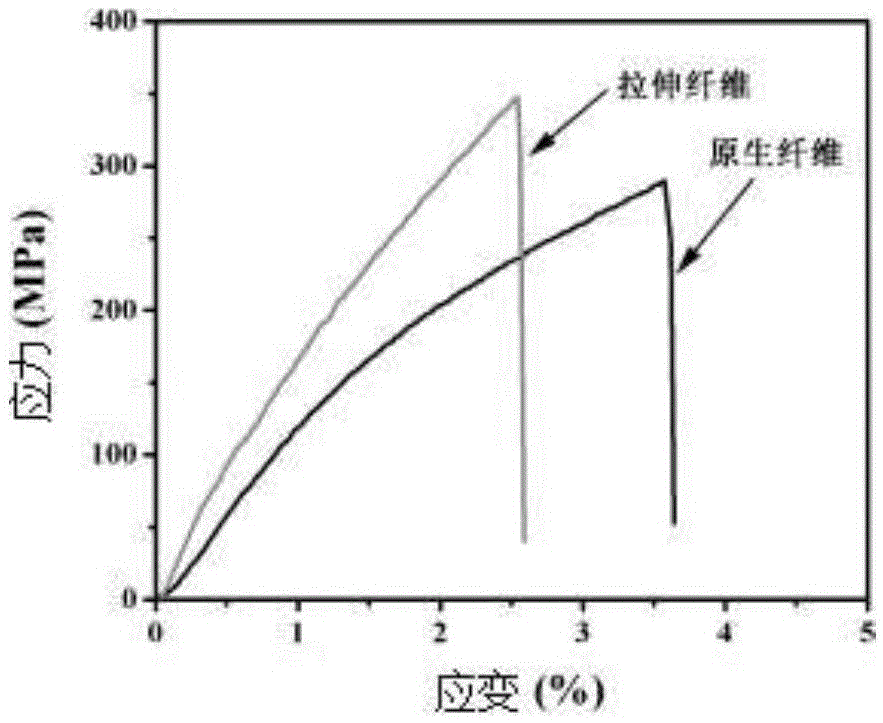

A graphene fiber, graphene technology, applied in the chemical characteristics of fibers, wet spinning, textiles and papermaking, etc., can solve the problems of limiting practical application, difficult to expand the industrial level, etc., to strengthen the role between layers, high mechanical properties , the effect of increasing the slice size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the oriented graphene oxide fiber comprises the following steps: preparing graphene oxide with flake graphite as a raw material, and configuring the graphene oxide spinning liquid; flowing the graphene oxide spinning liquid into the coagulation liquid through the wet spinning method, and preparing The raw gel graphene oxide fiber is produced; at a certain temperature, the graphene oxide fiber is radially stretched and dried to obtain the product.

[0027] Preparation of graphene oxide: Weigh 5g of 300μm expandable natural flake graphite, add 200mL of concentrated sulfuric acid and 50mL of fuming nitric acid, stir at room temperature for 24h, then slowly pour the mixture into 2L of deionized water, use a diameter of 90mm, the aperture Suction filter through a 0.2um cellulose membrane, wash twice with deionized water, and dry at 60°C for 24h after washing. The dried graphite was expanded at a high temperature of 1000° C. for 30 seconds to obtain ...

Embodiment 2

[0035] The difference between the preparation method of the oriented graphene oxide fiber of this embodiment and Example 1 is: (1) the graphene oxide preparation step also includes the graphene oxide solution prepared by freeze-drying for 5 days to prepare Solid graphene oxide. (2) Preparation of spinning solution: disperse solid graphene oxide in DMF solution as a solvent, and ultrasonicate for 15 minutes to obtain a 10 mg / ml graphene oxide solution, that is, obtain a uniformly dispersed graphene oxide spinning solution. The rest are the same as the preparation method of Example 1, and will not be repeated here.

Embodiment 3

[0037] Preparation of graphene oxide: The difference from Example 1 is that expandable natural flake graphite with a sheet size of 500 μm is selected as a raw material to prepare graphene oxide, and the rest is the same as the preparation of graphene oxide in Example 1.

[0038] Preparation of spinning solution: Take 200ml of the prepared graphene oxide solution, put it in an oil bath at 50°C, stir and concentrate, and obtain a graphene oxide spinning solution with a concentration of 5mg / ml.

[0039]Preparation of coagulation solution: prepare a 5% ethylenediamine aqueous solution as the coagulation solution.

[0040] Preparation of native graphene oxide fibers: use a mechanical syringe pump, select a spinning needle with an inner diameter of 0.43mm, push the syringe through the syringe pump, inject the spinning solution into the coagulation solution at a speed of 0.3ml / min, and form native graphene oxide fiber.

[0041] Preparation of oriented graphene oxide fibers: the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com