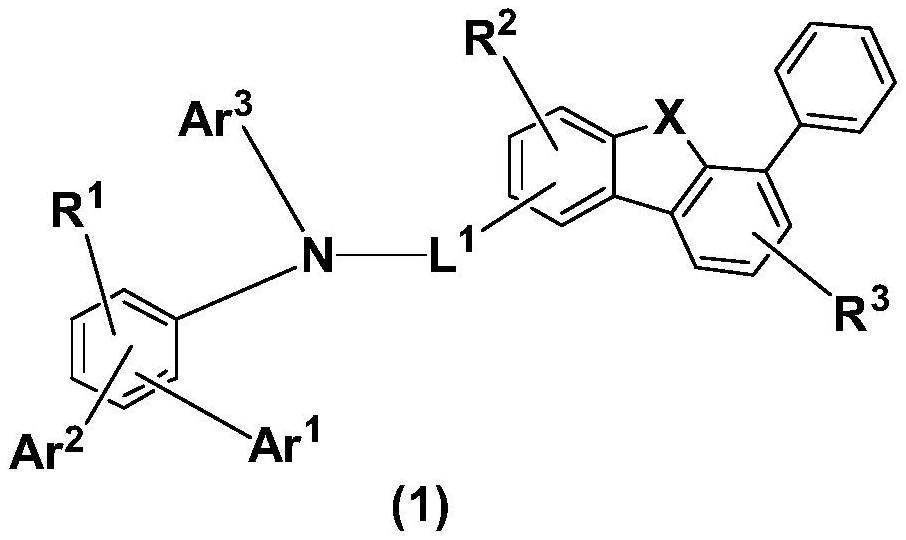

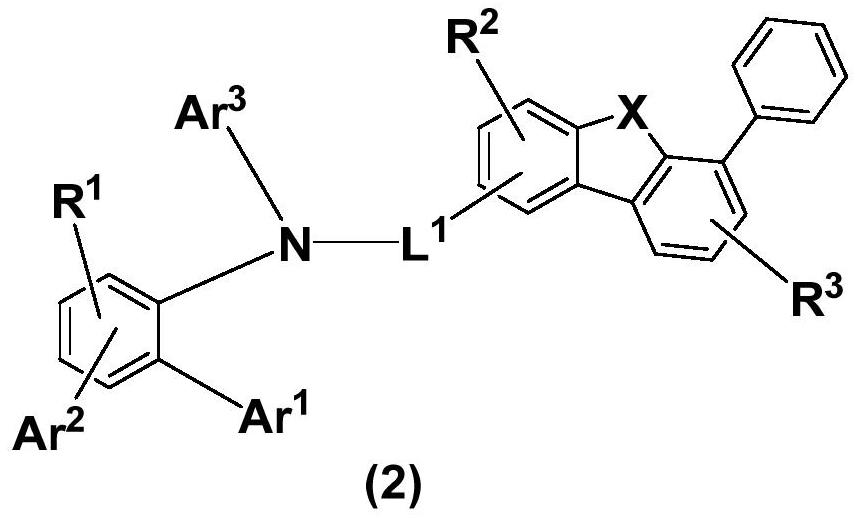

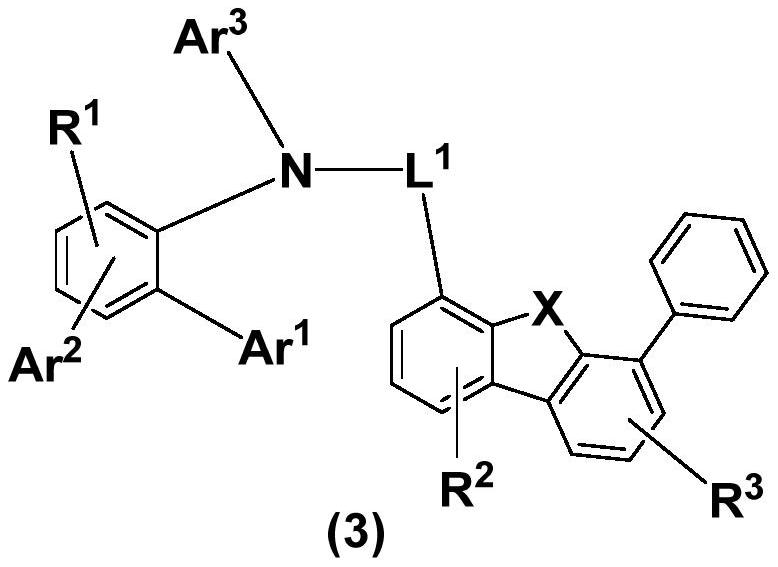

Compound, application thereof and organic light-emitting device comprising compound

A general compound, unsubstituted technology, applied in the field of organic electroluminescent devices, can solve the problems of high driving voltage, short display life, affecting technical practicality, etc. The effect of interaction forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0124] The OLED includes a first electrode and a second electrode, and a layer of organic material between the electrodes. The organic material can in turn be divided into regions. For example, the organic material layer may include a hole transport region, a light emitting layer, and an electron transport region.

[0125] In particular embodiments, a substrate may be used either below the first electrode or above the second electrode. The substrates are all glass or polymer materials with excellent mechanical strength, thermal stability, water resistance and transparency. In addition, a thin-film transistor (TFT) may be provided on a substrate for a display.

[0126] The first electrode may be formed by sputtering or depositing a material used as the first electrode on the substrate. When the first electrode is used as the anode, oxide transparent conductive materials such as indium tin oxide (ITO), indium zinc oxide (IZO), tin dioxide (SnO2), zinc oxide (ZnO) and any comb...

Embodiment 1

[0173] Prepare the organic electroluminescent device IVD-1, the specific preparation process is as follows:

[0174] The glass plate coated with the ITO transparent conductive layer is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, ultrasonically degreased in acetone: ethanol mixed solvent, baked in a clean environment until the water is completely removed, and then cleaned with ultraviolet light. Light and ozone cleaning, and bombardment of the surface with a beam of low-energy cations;

[0175] Place the above-mentioned glass substrate with anode in a vacuum chamber, and evacuate to -5 Pa, 10nm of HT-4:HI-3 (97 / 3, w / w) mixture was vacuum thermally evaporated sequentially on the above-mentioned anode layer film as the hole injection layer, and 60nm of the compound C1 of the present invention was used as the hole transport layer Floor;

[0176] On top of the hole transport layer, HT-14 was vacuum evaporated as the electron blocking layer of ...

Embodiment 2-7

[0180] Organic electroluminescence devices IVD-2 to IVD-7 were prepared by the same method as IVD-1, replacing C1 in the hole transport layer with the corresponding material as described in the hole transport layer in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com