Efficient discharging device in production process of bamboo-wood composite floors and using method thereof

A bamboo-wood composite and production process technology, applied in the direction of cleaning methods, separation methods, chemical instruments and methods using tools, etc., can solve the problems of inability to efficiently stack and place bamboo-wood composite floors, easy adhesion of impurity materials to bamboo-wood composite floors, The lack of feeding and conveying devices and other problems achieves the effect of simple structure, wide application range and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the examples.

[0039] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

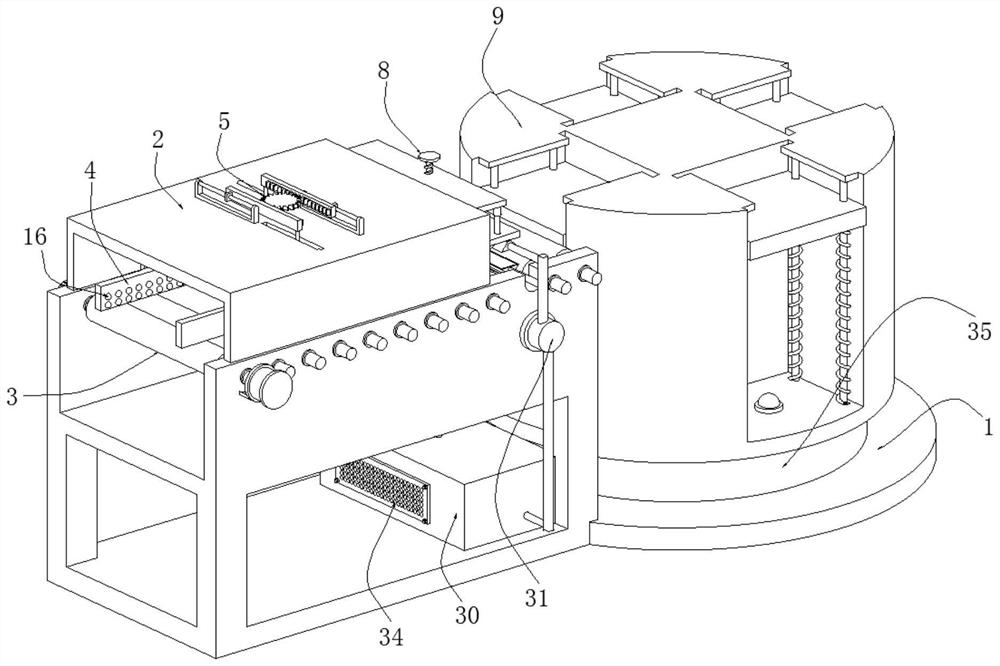

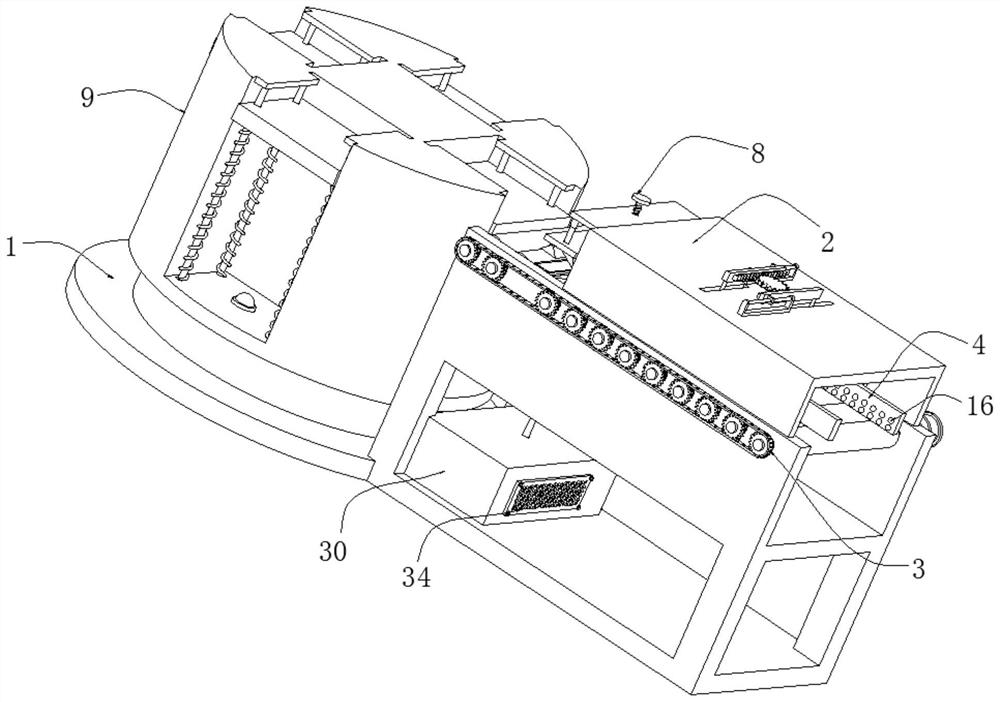

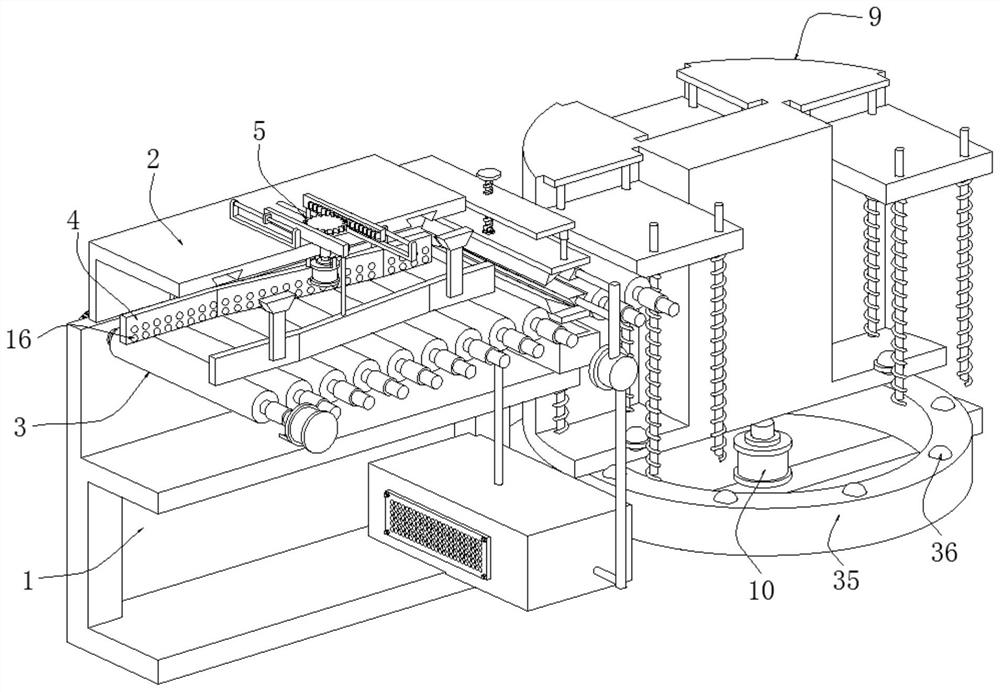

[0040] see Figure 1-7 , the present invention provides a high-efficiency unloading device in the production process of bamboo-wood composite flooring, which includes a frame 1 and a mounting frame 2 installed on the frame 1 .

[0041] The conveyor 3 is arranged on the frame 1 and is used for unloading and conveying the bamboo-wood composite floor produced from the bamboo-wood composite floor production equipment. The conveyor 3 includes several rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com