Self-adaptive trolley loading and unloading system

A loading and unloading system, self-adaptive technology, applied in the direction of loading/unloading, motor vehicles, transportation and packaging, etc., can solve the problems of low degree of automation, reduce personnel input, improve operation efficiency, and save freight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

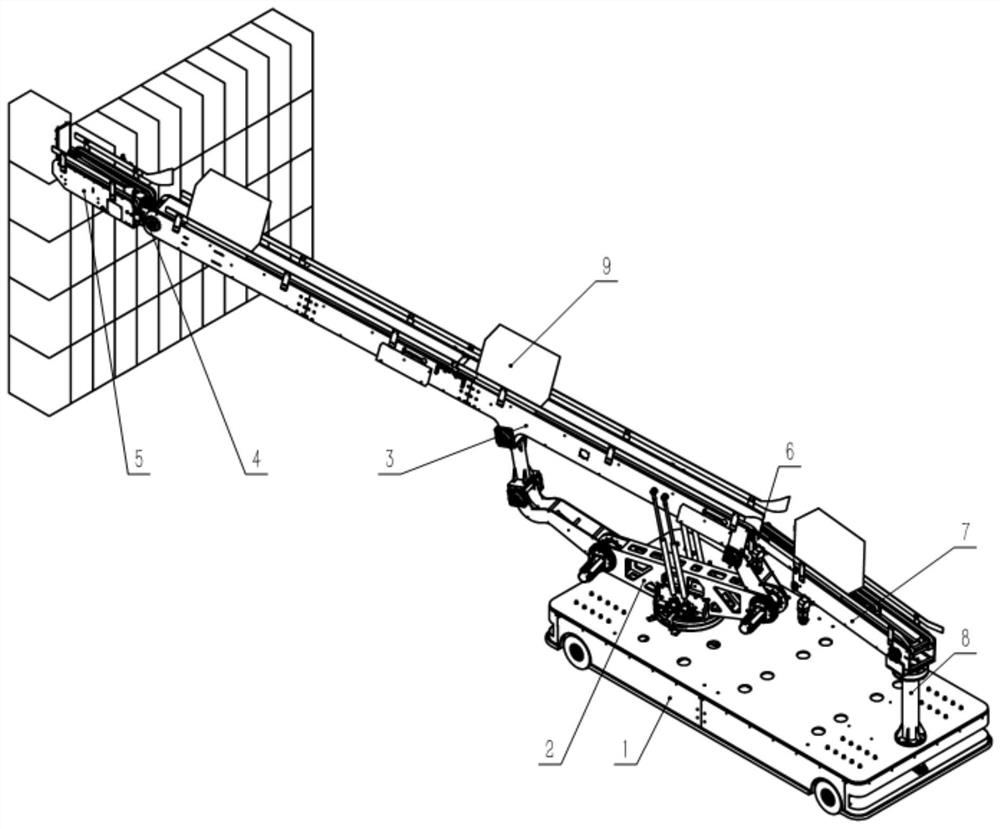

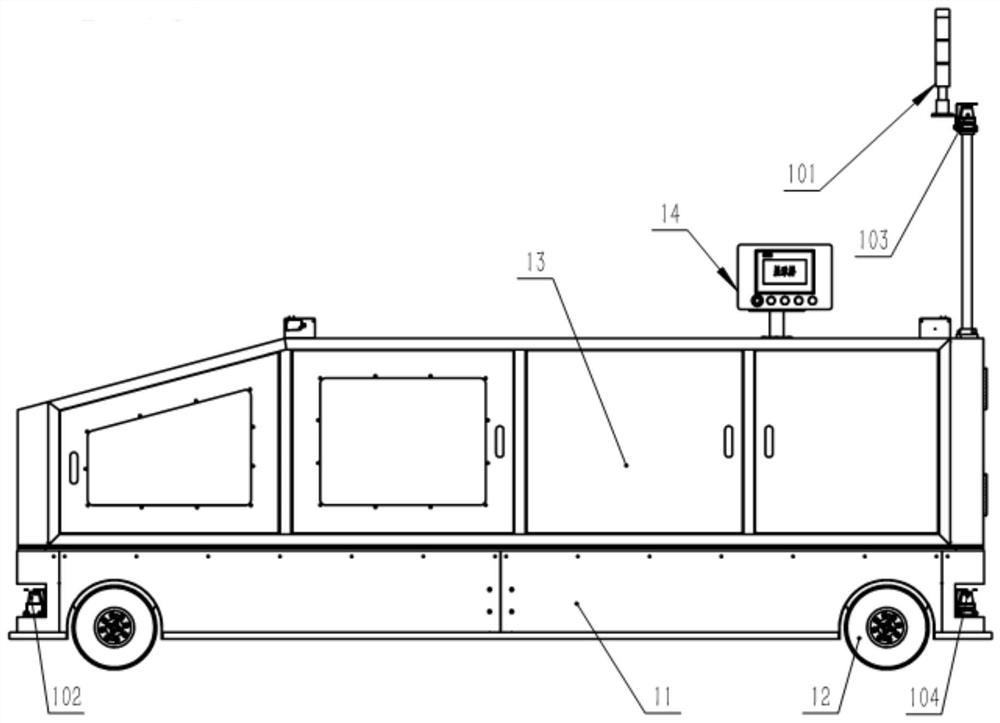

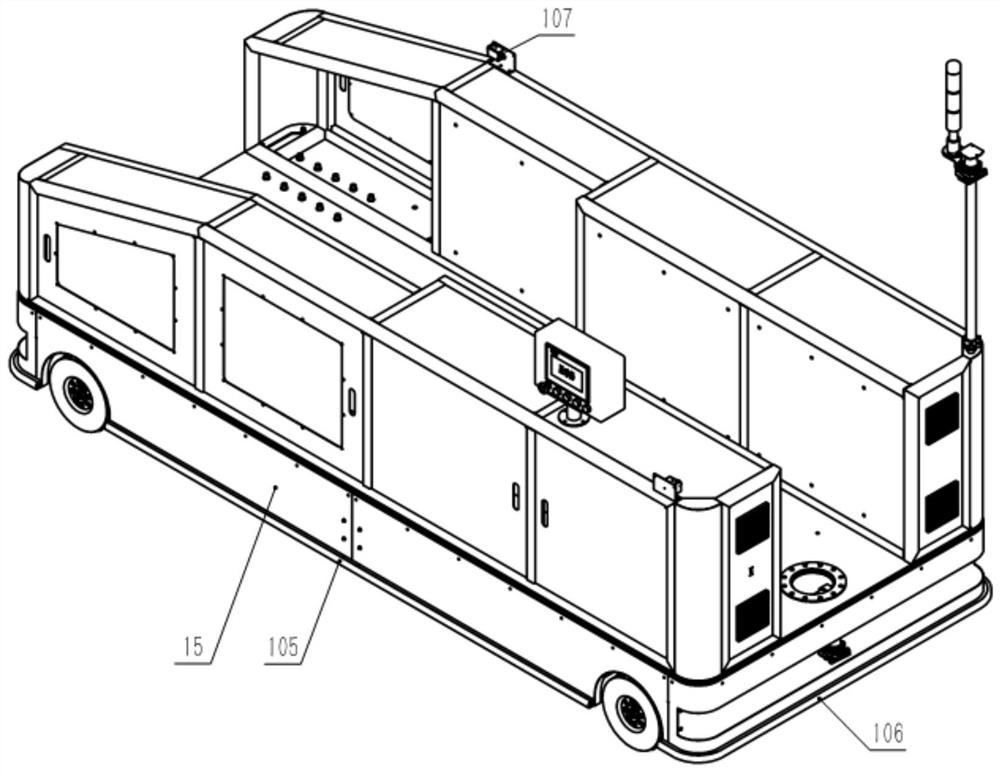

[0038] see Figure 1 to Figure 18, the present invention provides a technical solution: an adaptive trolley loading and unloading system, including a mecanum wheel trolley assembly 1, a slewing support joint assembly 2, an intermediate conveying belt conveyor assembly 3, a cross-hinged swivel joint assembly 4, and front-end unloading and stacking Component 5, criss-cross articulated rotary follow-up joint component 6, entrance telescopic belt conveyor component 7, entrance belt conveyor pillar component 8 and box material 9, mecanum wheel trolley component 1 includes front laser scanning radar 102, rear laser Positioning radar 103, rear anti-collision radar 104, AGV anti-collision strips 105 on both sides, front and rear AGV anti-collision strips 106, point laser ranging sensor 107, trolley frame assembly 11, mecanum wheel assembly 12 and trolley chassis protection assembly 15 The slewing support joint assembly 2 includes the first joint slewing mounting flange 201, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com