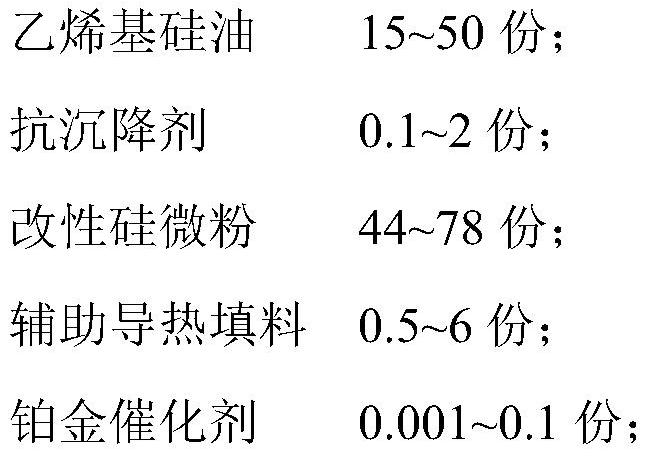

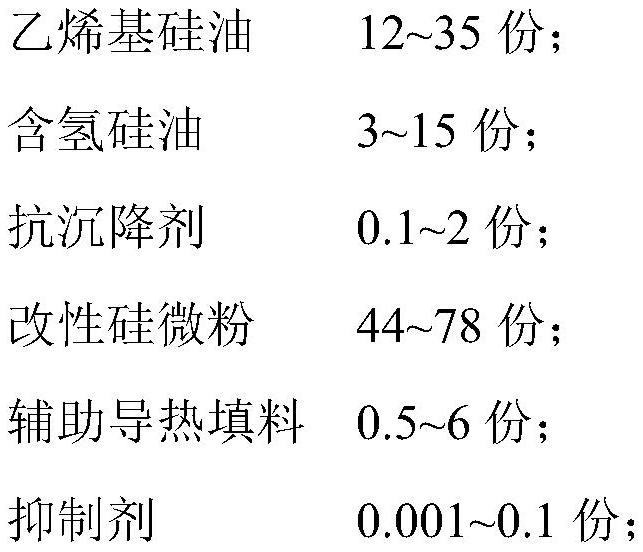

A two-component addition type organic silicon heat-conducting adhesive and preparation method thereof

A silicone, addition type technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve problems such as poor improvement effect, and achieve the effect of improving system stability, reducing density, and close and effective stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in conjunction with embodiment, but following embodiment, only preferred embodiment of the present invention, so can not limit the scope of the present invention implementation accordingly, promptly according to the equivalence change that the patent scope of the present invention and description content are done All modifications and modifications should still fall within the scope of the present invention.

[0052] Unless otherwise specified, in the present invention, "%" means percentage by weight, and "part" means parts by weight.

[0053] The preparation method of structural modification regulator:

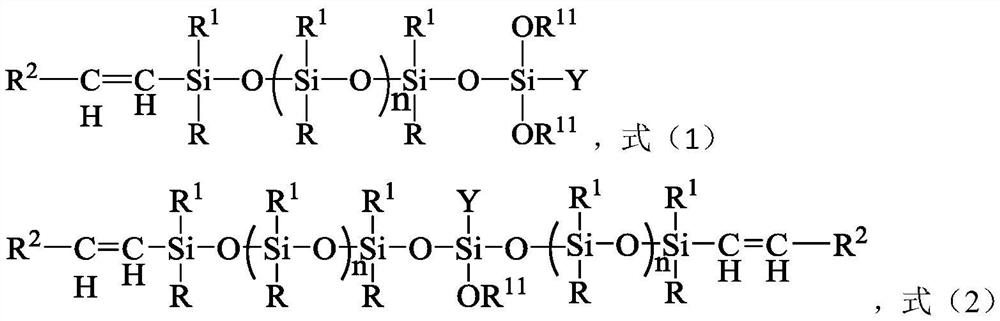

[0054] Add organosilane coupling agent A (structural formula shown in formula (1)) containing inactive organic groups to hydroxyvinyl silicone oil B (structural formula shown in formula (2)), and stir evenly at a stirring speed of 2000~ 3000rpm, stirring for 60-120min, heating to 80-100°C, distilling off the generated al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com