Bulletproof helmet body and preparation method thereof

A bulletproof helmet and helmet body technology, which is applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of fiber strength loss, large helmet body mass, and affecting soldiers' tactical actions, so as to improve impact resistance and production The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The method for preparing the body of a bulletproof helmet provided by the invention specifically comprises the following steps:

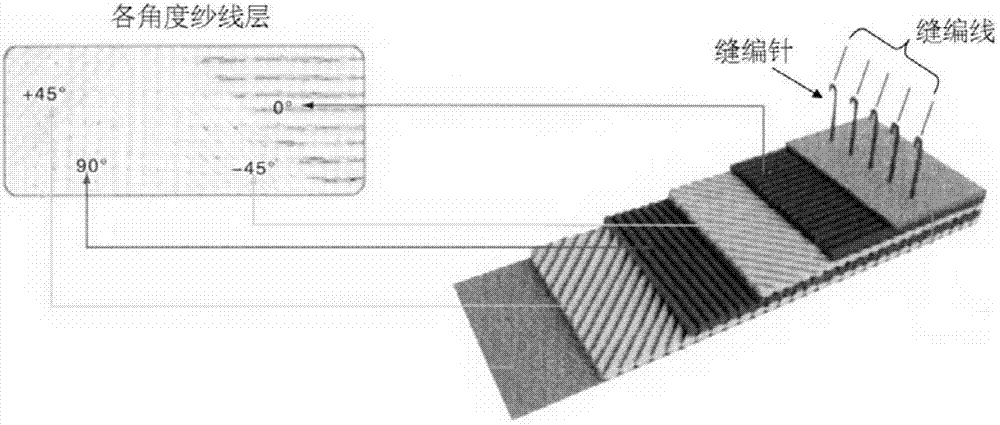

[0034] (1) Weaving of multi-axial warp knitted fabric covered with film

[0035] The para-aramid yarn and the nylon stitching thread are respectively braided according to the preset braiding angle, weaving sequence, stitching thread spacing and braiding chain length to obtain a sheet-shaped multi-axial warp knitted fabric. Then the warp knitted fabric and the release paper covered with phenolic resin-acrylic resin film pass through the hot pressing roller, and the adhesive film is transferred to the surface of the single-layer fabric by the hot pressing roller to obtain a multiaxial Para-aramid tricot.

[0036] (2) Helmet body molding method

[0037] The woven lamellar para-aramid fabric is placed between the concave and convex molds of the mold after being cut and stacked according to the size of the helmet mold. Start the four-column hyd...

Embodiment 1

[0039] (1) Weaving of multiaxial warp knitted fabrics

[0040] (1) Machine parameters

[0041] Equipment: multi-axial warp knitting machine; width: 1.27m; with weft yarn insertion system and reinforcing fiber insertion device

[0042] (2) Raw material (basic fabric)

[0043] Diagonal interlining +45°: 1000D para-aramid (also known as polyparaphenylene terephthalamide fiber) fabric

[0044] Inserted weft yarn 90°: 1000D para-aramid (also known as polyparaphenylene terephthalamide fiber) fabric

[0045] Diagonal Lining Yarn-45°: 1000D para-aramid (also known as polyparaphenylene terephthalamide fiber) fabric

[0046] Sewing Thread: 40D Nylon

[0047] (3) Organization

[0048] Ground organization: braided chain

[0049] Weaving sequence: reinforced fiber / +45° / 90° / -45° / /

[0050] (4) Fabric parameters

[0051] The distance between the stitching lines: 3mm, the length of the braided chain: 2mm; the surface density of each layer of lamellar warp knitted fabric is 250g / m 2 ;To...

Embodiment 2

[0060] (1) Weaving of multiaxial warp knitted fabrics

[0061] (1) Machine parameters

[0062] Equipment: multi-axial warp knitting machine; width: 1.27m; with weft yarn insertion system and reinforcing fiber insertion device

[0063] (2) Raw material (basic fabric)

[0064] Bias lining +45°: 600D para-aramid fabric

[0065] Bias lining -45°: 1000D ultra-high molecular weight polyethylene fiber fabric

[0066] Sewing thread: 80D ultra-high molecular weight polyethylene fiber

[0067] (3) Organization

[0068] Ground organization: braided chain

[0069] Weaving sequence: reinforced fiber / +45° / -45° / /

[0070] (4) Fabric parameters

[0071] The distance between the stitching lines: 7mm, the length of the braided chain: 5mm; the surface density of each layer of lamellar warp knitted fabric is 200g / m 2 ;Total surface density of lamellar fabric: 500g / m 2 ;

[0072] The para-aramid yarn and the nylon stitching thread are respectively braided according to the preset braiding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com